Continuous efficient seed priming device

A seed and high-efficiency technology, which is applied in the field of continuous seed high-efficiency actuation device, can solve the problems of poor infiltration effect of the initiator, slow actuation speed, discontinuous operation, etc., to solve the problem of large consumption of the actuator, simple and reliable mechanism, and realization of constant temperature control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

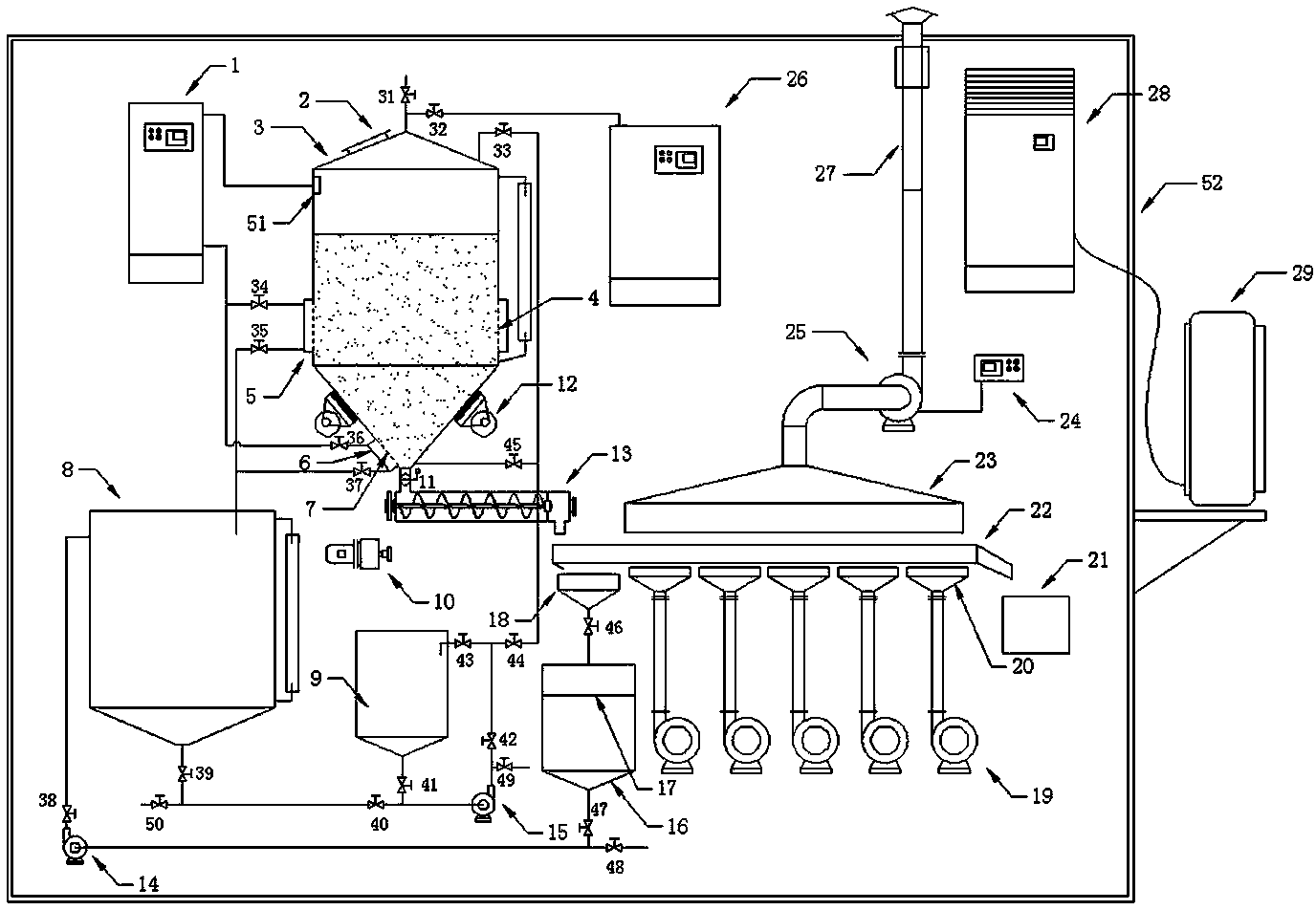

[0034] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0035] Such as figure 1 The continuous seed high-efficiency driving device shown in the figure includes an actuator dissolution output device and a tank body 3. The tank body 3 is provided with a tank cover 2. The tank body 2 is connected to the vacuum machine 26 through a valve 32 and is provided with a vacuum breaking valve 31 and a moisture discharge valve. 31; Humidity sensor 51 is provided in the tank, and humidity sensor 51 is connected to air compressor 1, and air compressor 1 is connected to chambers 5 and 6 through valves 34 and 36, and chambers 5 and 6 have filter screens 4 and 7 and tank body 3 connected; cavities 5 and 6 are connected to the initiator storage tank 8 through valves 35 and 37, and the initiator storage tank 8 is connected to the initiator dissolution output device; the initiator dissolution tank 9, the circulation output pump 15 and its pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com