Method for preparing composite plate by recycling bag type dust remover waste filter bags

A technology for dust collectors and composite panels, which is applied in chemical instruments and methods, formwork/template components, and on-site preparation of building components, etc., can solve problems such as insufficient cleaning, difficulty in realization, and changes in fiber chemical composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

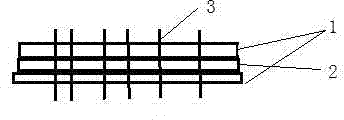

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0027] A method of recycling waste filter bags of bag type dust collectors to make composite panels, comprising the following steps:

[0028] Pulverization: The waste filter bag is pulverized by a pulverizer, and the size of the pulverized waste material is 0.5-1.5cm;

[0029] Cleaning: The pulverized material is washed 2-5 times by the cleaning machine, so that the residual amount of dust on the pulverized material is reduced to less than 8%;

[0030] Drying: send the wet material into the desiccant for full drying;

[0031] Opening: loosen the large pieces of entangled pulverized material fibers into small pieces or bundles by tearing, and at the same time, it is accompanied by mixing and impurity removal during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com