Method for producing ferro-nickel alloy from low-grade laterite-nickel ore in half-molten state

A technology of lateritic nickel ore and nickel-iron alloy, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high energy consumption and high cost of the treatment process, and achieve short smelting cycle, low energy consumption and low reduction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

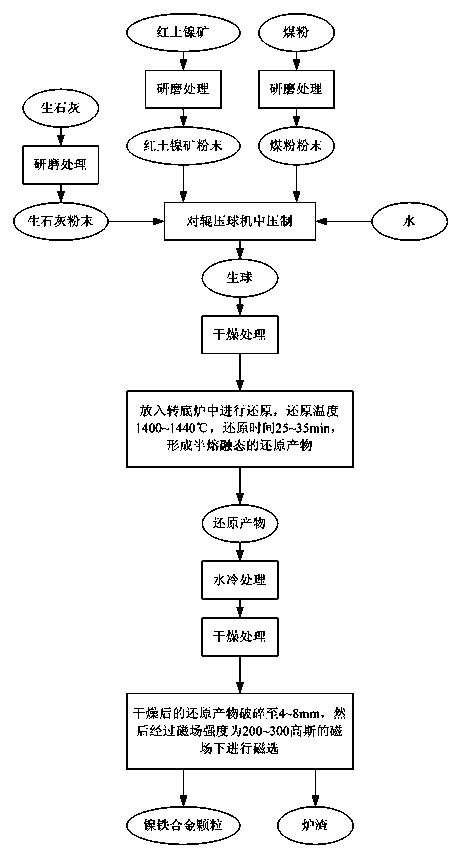

Method used

Image

Examples

Embodiment 1

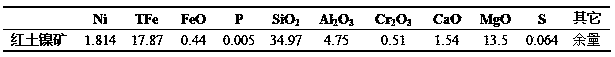

[0042] In this embodiment, the method of the present invention is used to process low-grade lateritic nickel ore in a mining area to produce nickel-iron alloy. The main components of the low-grade lateritic nickel ore are shown in Table 1, and the components of coal powder and quicklime used in the production of nickel-iron alloy are shown in Table 2 and Table 3, respectively.

[0043] Table 1 Main components of lateritic nickel ore (wt%)

[0044]

[0045] Table 2 Composition of pulverized coal (wt%)

[0046]

[0047] Table 3 Quicklime composition (wt%)

[0048]

[0049] In the present embodiment, adopt the method of the present invention, utilize above-mentioned low-grade laterite nickel ore to produce the operation steps of nickel-iron alloy as follows:

[0050] 1) Grind dry laterite nickel ore, coal powder, and quicklime to a powder with particles of -0.074mm accounting for more than 80%.

[0051] 2) Take the laterite nickel ore powder, coal powder, and quicklim...

Embodiment 2

[0067]The present embodiment still adopts the method of the present invention to process the low-grade lateritic nickel ore of embodiment one to produce ferronickel, but the control parameters are slightly different, and its operation steps are as follows:

[0068] 1) Grind dry laterite nickel ore, coal powder, and quicklime to a powder with particles of -0.074mm accounting for more than 80%;

[0069] 2) The powder mixture formed by uniformly mixing the laterite nickel ore powder, coal powder, and quicklime powder is added to a double-roller briquetting machine, and is pressed with water to form green balls with a diameter of about 30mm; wherein, the amount of water added is the total amount of the powder mixture. 8% of the quality; the mixing ratio of laterite nickel ore powder, coal powder, and quicklime powder in the powder mixture is obtained by theoretical calculation according to the proportioning conditions of the present invention (1) and (2) according to the respective...

Embodiment 3

[0078] The present embodiment still adopts the method of the present invention to process the low-grade lateritic nickel ore of embodiment one to produce ferronickel, but the control parameters are slightly different, and its operation steps are as follows:

[0079] 1) Grind dry laterite nickel ore, coal powder, and quicklime to a powder with particles of -0.074mm accounting for more than 80%.

[0080] 2) Take the laterite nickel ore powder, coal powder, and quicklime powder to form a powder mixture that is uniformly mixed and put it into a double-roller briquetting machine, and add water to press it to form a green ball with a diameter of about 35mm; wherein, the amount of water added is the total amount of the powder mixture. 10% of the quality; the mixing ratio of laterite nickel ore powder, coal powder, and quicklime powder in the powder mixture is obtained by theoretical calculation according to the proportioning conditions of the present invention (1) and (2) according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com