Method for predicting heat protection performance of fabric

A heat protection and fabric technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high energy consumption, long test process, and environmental pollution, shorten the test process and time, and achieve accurate results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides a method for predicting fiberglass twill fabrics.

[0031] 1. Test the geometric structure parameters and physical properties of fibers, yarns and fabrics in the twill fabric to be tested.

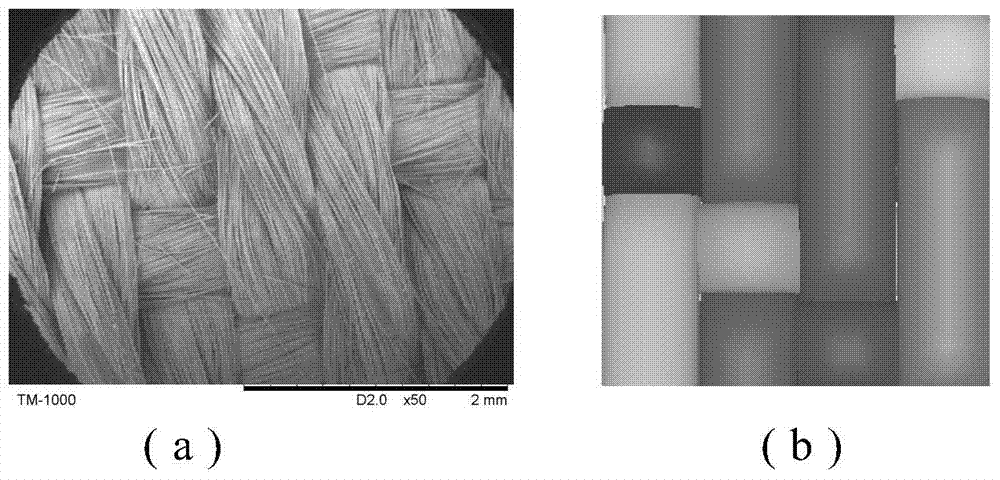

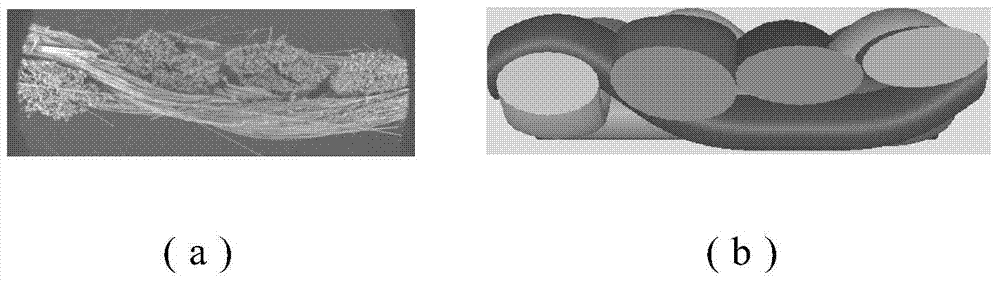

[0032] According to known national standards, the fabric fiber has a diameter of 9 μm and a density of 2.34×10 3 kg / m 3 , surface area 6.3585×10-11 m 2 Utilize the optical electron microscope test to obtain that warp yarn width 0.678mm, height 0.402mm, spacing 0.717mm and cross-section shape are ellipse, and weft yarn width 0.716mm, height 0.413mm, spacing 0.704mm and cross-section shape are oval (see figure 1 (a)), yarn linear density 2.8×10 -4 kg / m, the number of fibers contained in a single yarn is 1.8×10 3 root; according to the characteristics of the interweaving path of the yarn, the fabric weave is determined to be 3 / 1 twill, and the fabric thickness obtained by the test is 0.906mm.

[0033] 2. Use the fabric modeling software TexGen (texgen-bundle-...

Embodiment 2

[0039] This example provides a method for predicting fiberglass plain weave fabrics.

[0040] 1. Test the geometric structure parameters and physical properties of fibers, yarns and fabrics in plain weave fabrics.

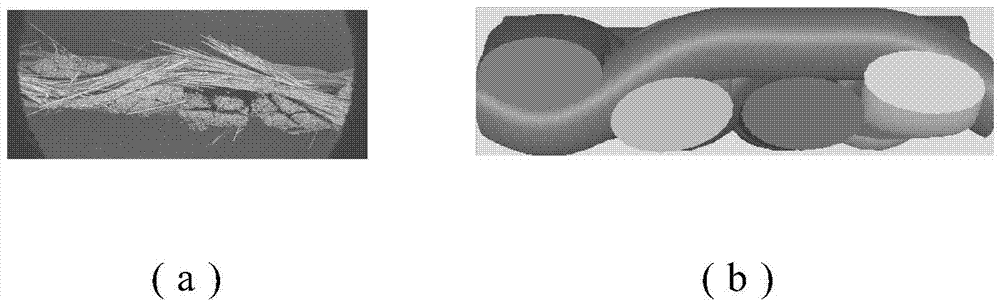

[0041] According to known national standards, the fabric fiber has a diameter of 9 μm and a density of 2.34×10 3 kg / m 3 , surface area 6.3585×10 -11 m 2 Utilize the optical electron microscope test to obtain warp yarn width 0.37mm, height 0.29mm, spacing 0.44mm and cross-sectional shape are convex lens shape, weft yarn width 0.39mm, height 0.27mm, spacing 0.52mm and cross-sectional shape are oval (see figure 1 (a)), yarn linear density 2.8×10 -4 kg / m, the number of fibers contained in a single yarn is 1.8×10 3 root; according to the characteristics of the interweaving path of the yarn, the fabric weave is determined to be plain weave, and the thickness of the tested fabric is 0.74mm.

[0042] 2. Use TexGen (texgen-bundle-64bit-3.6.0 version) software to build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com