Production method of HRB600E high-strength anti-seismic reinforcing steel bar

A technology of anti-seismic steel bars and production methods, which is applied to the improvement of process efficiency and the manufacture of converters, etc., can solve the problems of difficulty in adapting to the continuous casting high-speed casting process, the tempering structure of the product metallography, and the difficulty in stably controlling the alloy content, etc., to achieve Stable control of product performance, easy promotion, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

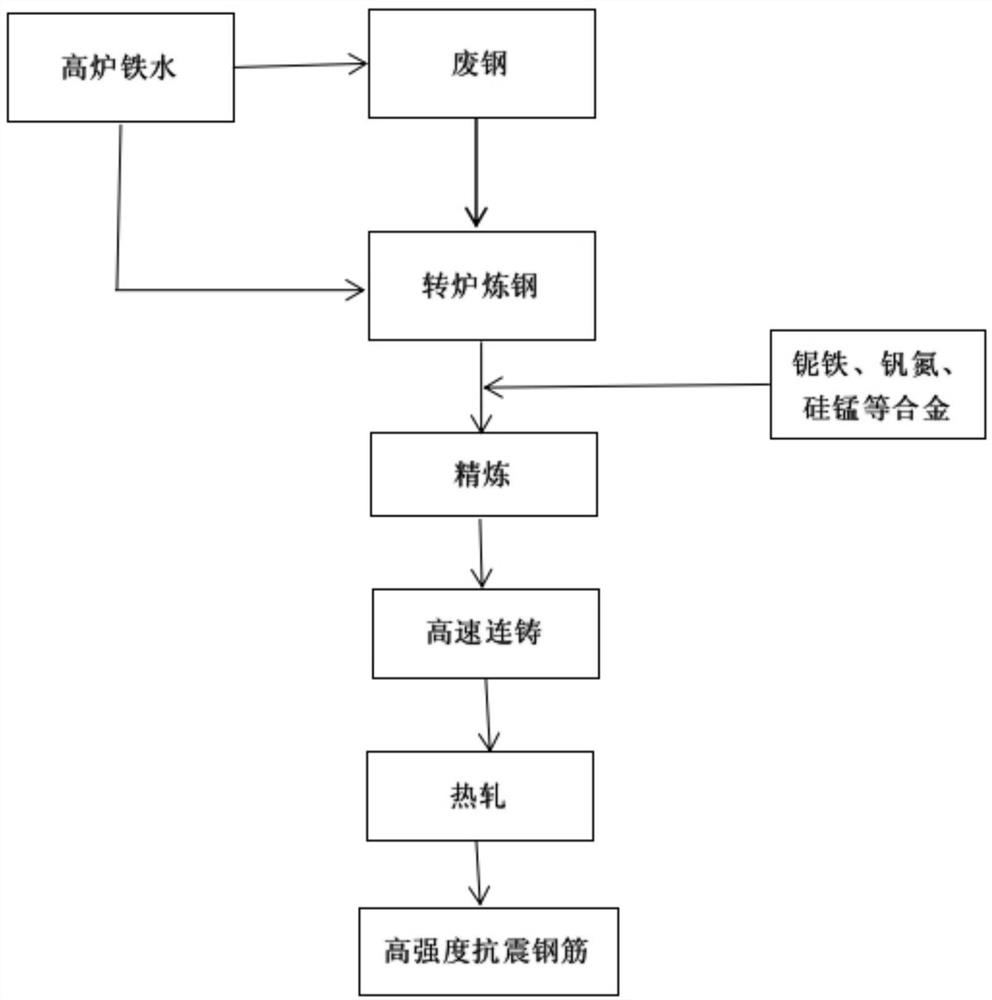

[0035] according to figure 1 As shown, the present embodiment proposes a production method of HRB600E high-strength seismic steel bar, comprising the following steps:

[0036] Step 1: Blast Furnace Smelting

[0037] Put 95t of molten iron and 35.5t of steel scrap into the converter, then add 2.29t of lime to carry out smelting to obtain the final slag. Tapping is carried out. When tapping, the slag is used to tap the steel. The slag thickness is controlled to be ≤50mm. The end point components are controlled as: C=0.073%, P=0.0106%, S=0.020%. 121.48t, when the content of C at the end point does not meet the control requirements, spot blowing treatment is performed; when the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com