Mechanical transmission device

A technology of mechanical transmission and transmission shaft, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., and can solve problems such as inability to use mechanical fuel, troublesome and inconvenient installation of shaft-shaped connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

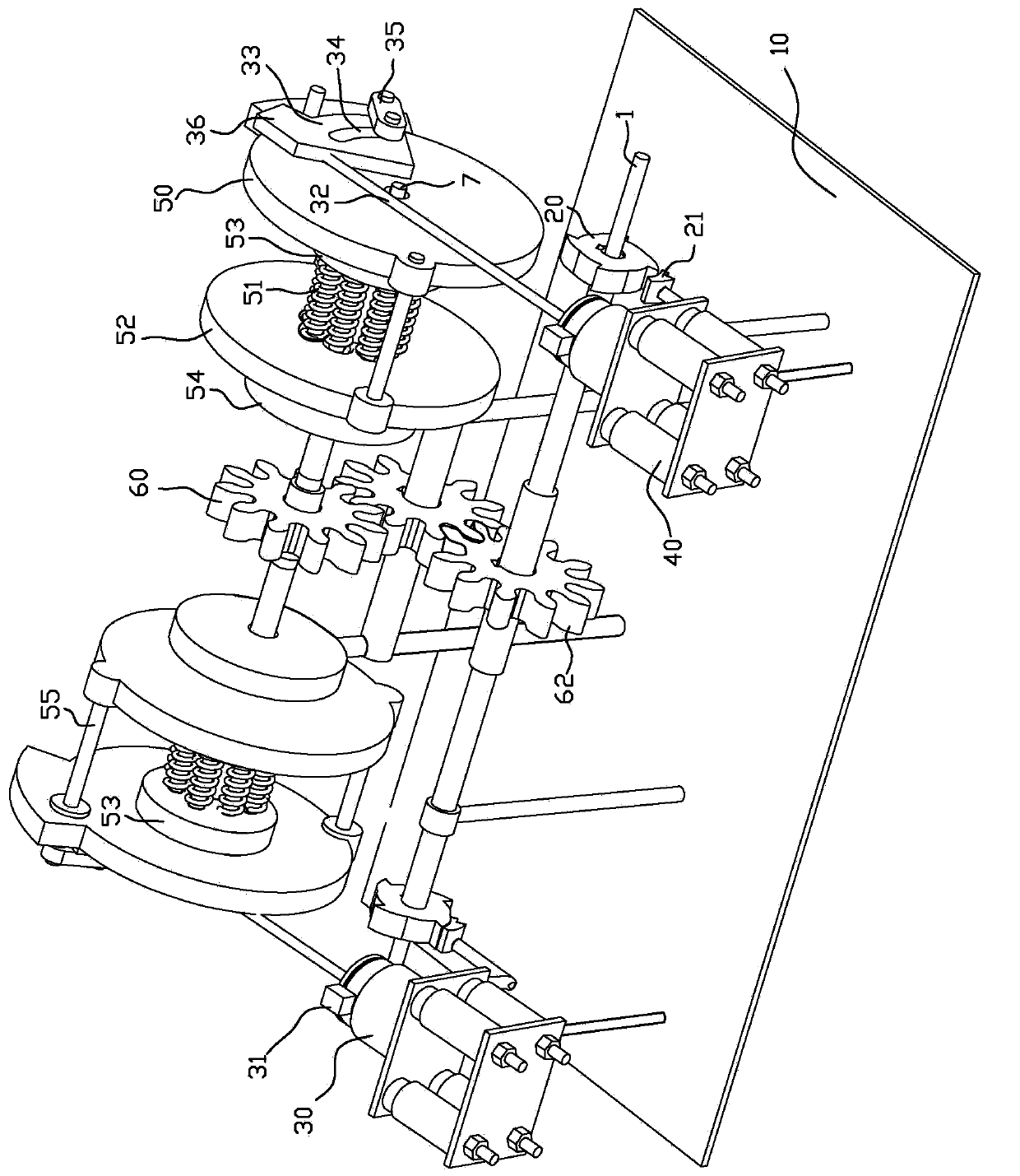

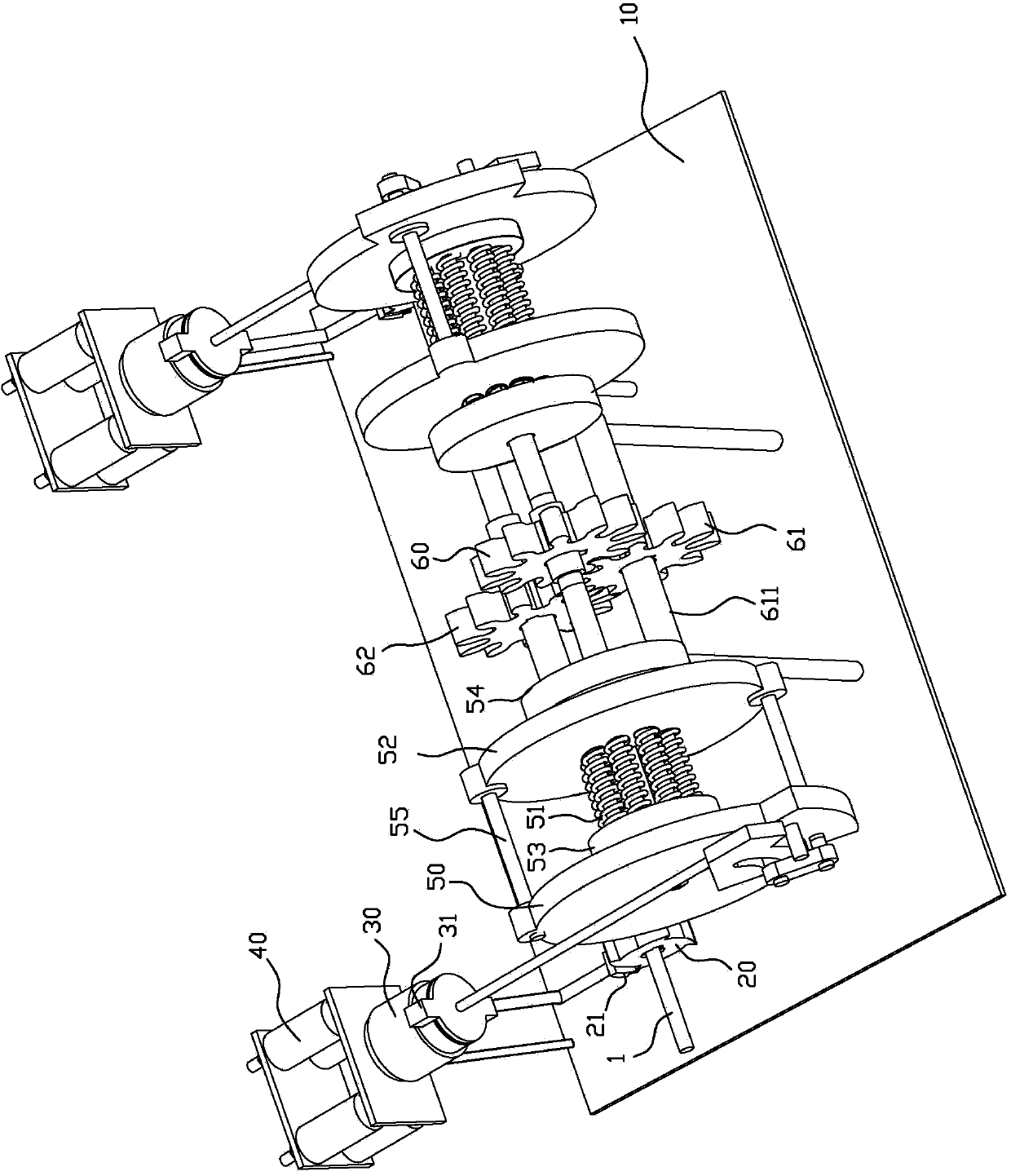

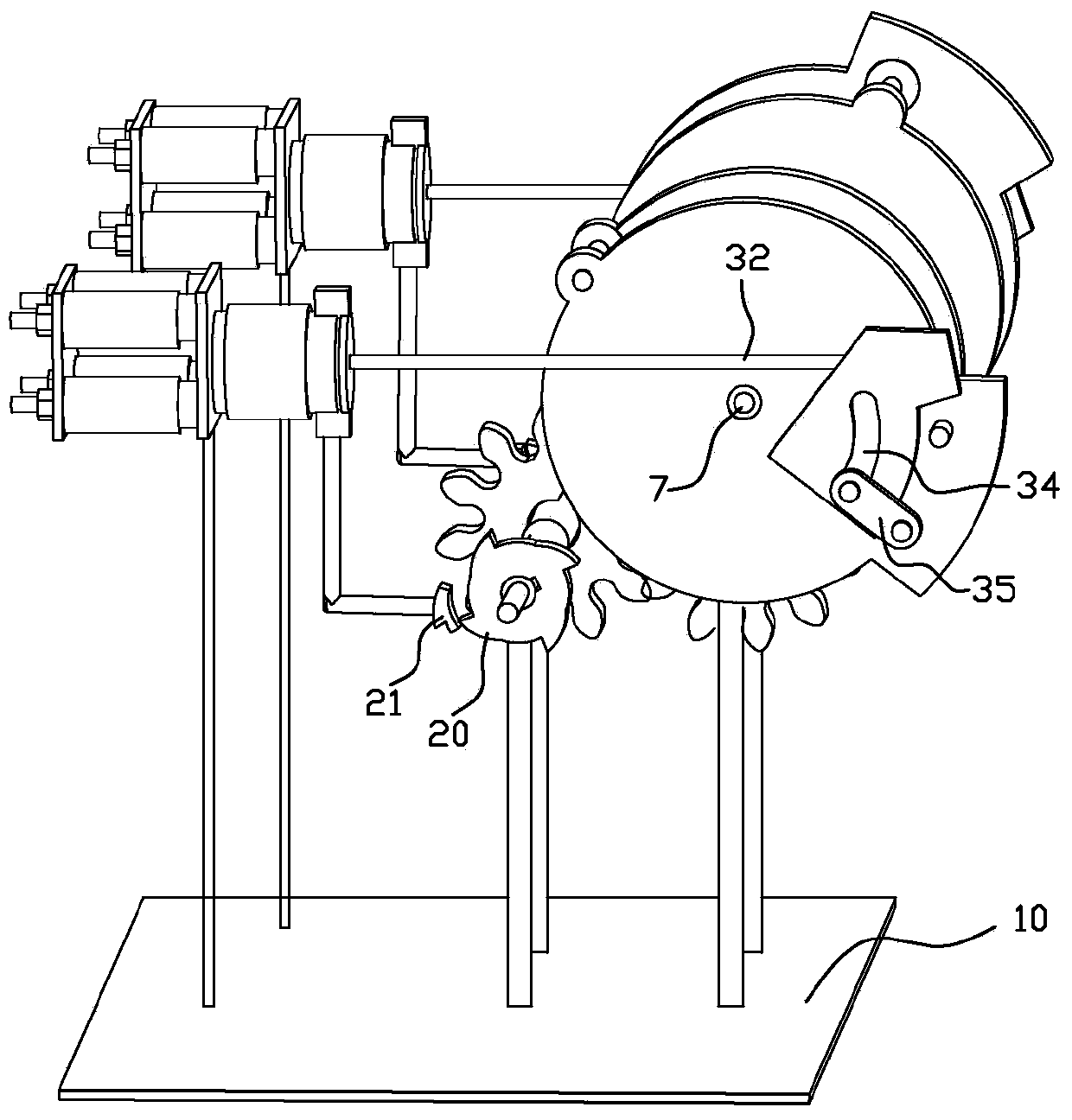

[0038] A kind of mechanical transmission device of the present invention, as Figure 1~3 As shown, the device includes a power generation mechanism, a power release mechanism, a power transition mechanism and a power return mechanism, wherein the power generation mechanism, the power release mechanism and the power transition mechanism are fixed on the base through a connecting rod component.

[0039] The power generating mechanism includes a power device and a connecting cylinder 30, one end of the connecting cylinder 30 is connected to the power device, and the other end is connected to the power release mechanism through a connecting rod assembly, and the end of the connecting cylinder 30 deviated from the power device is provided with two The fixed angles 31 , one of the fixed angles 31 is connected to the power return mechanism through the contraction plate 21 .

[0040] The power release mechanism includes a power output shaft 7, a first gear 60 fixedly sleeved at the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com