High-strength refractory anti-seismic steel bar and low-cost preparation cost thereof

An anti-seismic steel bar and high-strength technology, applied in the field of high-strength refractory anti-seismic steel bar and its low-cost preparation, can solve the problems of cumbersome preparation process and high cost of high-strength refractory steel bar, achieve stable strength and performance, low cost, and save concentrate resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

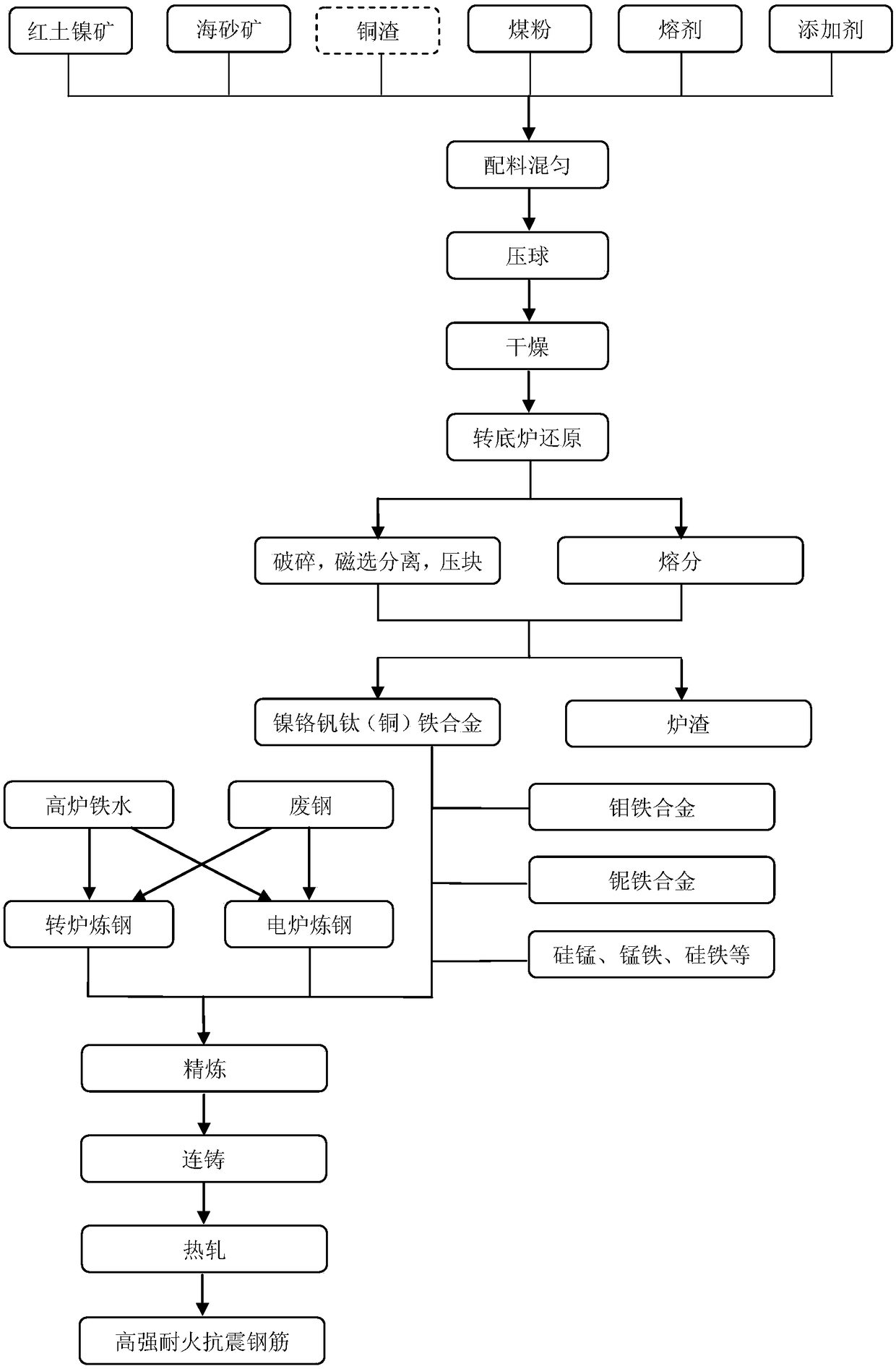

[0053] The preparation of the high-strength refractory steel bars described in the present invention belongs to the field of steel smelting and manufacturing. Iron and steel enterprises purchase very cheap sea sand ore and laterite nickel ore from the Southeast Asian market, and through direct reduction, obtain nickel-chromium-vanadium-titanium alloys. The cost of raw materials and The production process has low energy consumption, replacing the existing technology to purchase very expensive nickel-iron alloys, ferrochrome alloys, ferro-vanadium alloys or vanadium-nitrogen alloys, supplemented with ferro-niobium or ferro-molybdenum alloys and then added to molten steel for alloying, so the production cost of high-strength refractory steel bars by this method Inexpensive and highly competitive in the market.

[0054] Obviously, the preparation of traditional nickel-iron alloy, ferrochrome alloy, vanadium-iron alloy or vanadium-nitrogen alloy and the preparation of high-strength ...

Embodiment 1

[0136] The main components of the low-nickel and high-iron laterite nickel ore in this example are shown in Table 3, and the ingredients of sea placer, coal powder and slaked lime are shown in Table 4, Table 5 and Table 6, respectively.

[0137] Table 3 The main components (wt%) of low-nickel high-iron lateritic nickel ore 1#

[0138]

[0139] The main component (wt%) of table 4 sea placer

[0140] Element

TF

FeO

Fe 2 o 3

TiO 2

V 2 o 5

Al 2 o 3

CaO

MgO

SiO 2

other

content%

56.13

27

49.84

7.61

0.53

3.66

1.64

3.52

4.9

0.99

[0141] The main component (wt%) of table 5 pulverized coal

[0142]

[0143] The main component (wt%) of table 6 slaked lime

[0144]

[0145] In the present embodiment, the reduction-magnetic separation process route is adopted, and the operation steps of producing nickel-chromium-vanadium-titanium-iron alloy using the above-mentioned lateri...

Embodiment 2

[0151] See Table 8 for the main components of the high-nickel and low-iron laterite nickel ore used in this example, and see Table 4, Table 5 and Table 6 in Example 1 for the main components of sea placer, coal powder and slaked lime.

[0152] The main component (wt%) of table 8 high nickel low iron laterite nickel ore 2#

[0153]

[0154] In this embodiment, the reduction-magnetic separation process route is adopted:

[0155] The ratio of high nickel and low iron laterite nickel ore, sea sand ore, coal powder, slaked lime, and syrup is 363.54:100:60.22:88.39:36.73; the amount of coal powder is converted and weighed according to the C / O of 1.2, and the flux Slaked lime is weighed according to the basicity of 0.6 (CaO / SiO 2 =0.6), the additive syrup is weighed by 6% of the total weight, and the water is weighed by 5% to 6% of the total weight. The rest is the same as in Example 1, reduction-crushing-magnetic separation and briquetting to obtain nickel-chromium-vanadium-tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com