Baking apparatus and baking process for oolong tea

A baking device and oolong tea technology, applied in tea treatment before extraction, etc., can solve the problems of loss of tea moisture and aroma, no continuous frying of tea, low heat conversion efficiency, etc., to ensure all-round heating, improve tea baking efficiency, Reduce the effect of the heat transfer link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

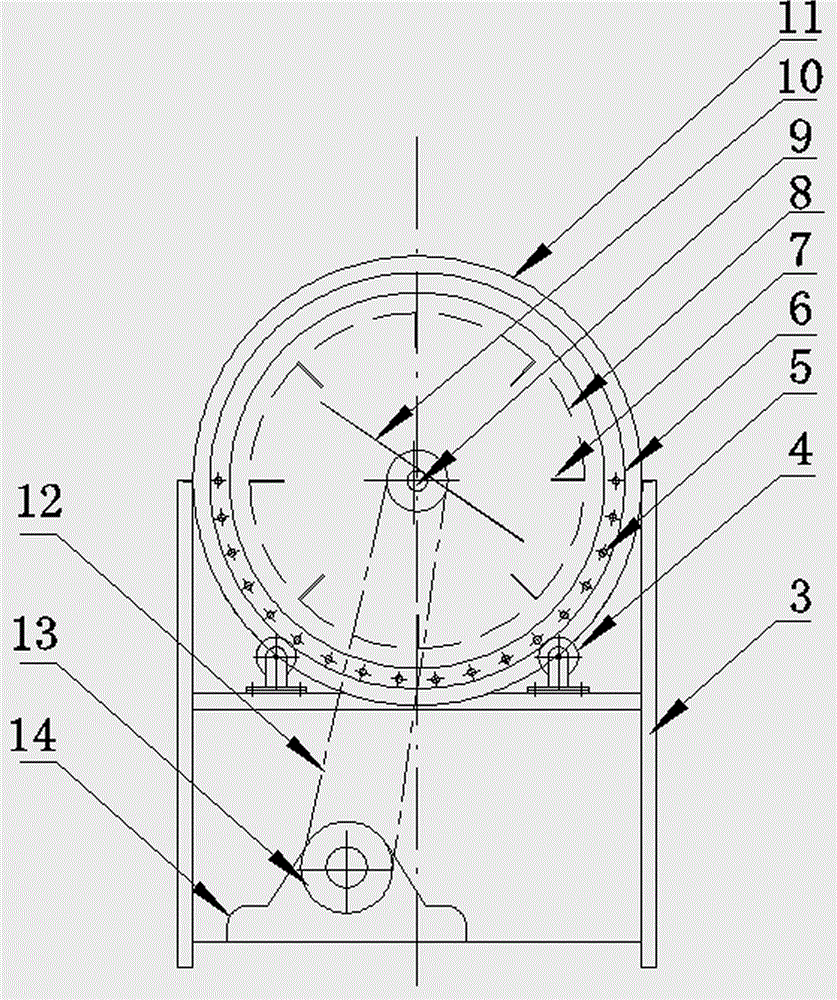

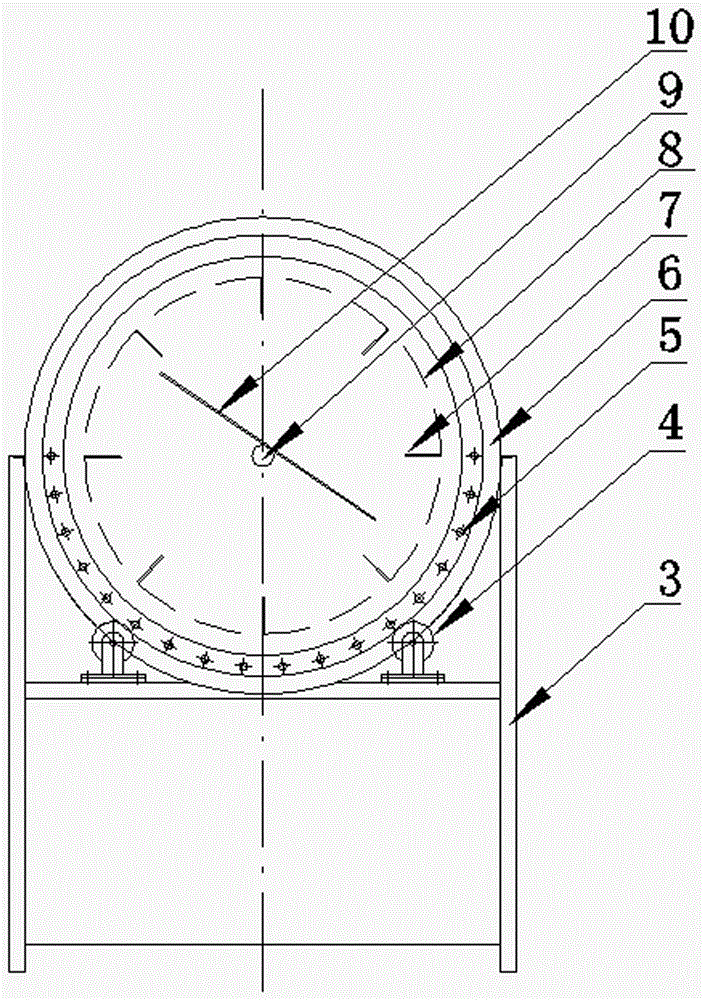

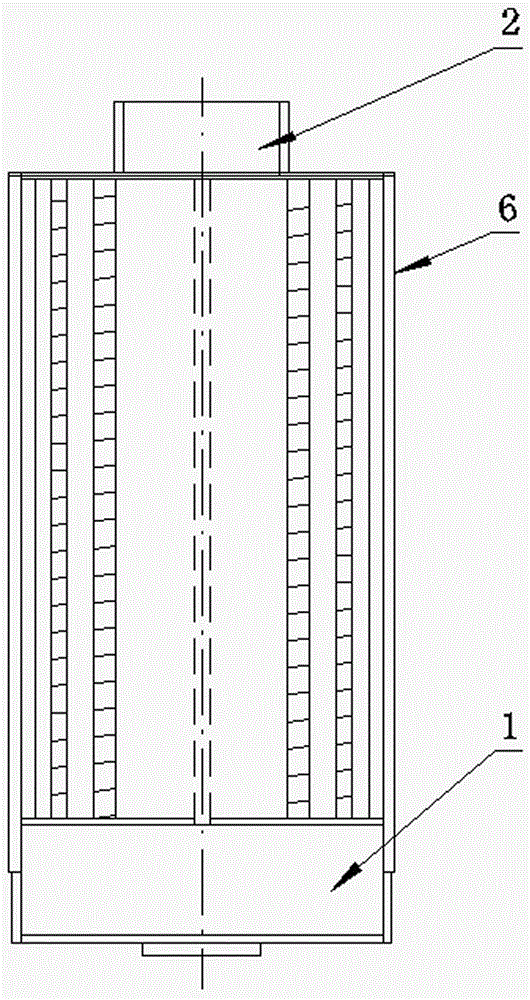

Method used

Image

Examples

example 1

[0024] The northern Fujian oolong tea uses the above-mentioned roasting process of the tea roasting spiral stir-frying device, including the following technical measures:

[0025] a. Control the roasting flow rate of oolong tea: Put 200kg of northern Fujian oolong tea to be roasted into the feeding port through the conveyor belt at a feeding speed of 120kg / h to ensure the production efficiency of oolong tea baking;

[0026] b. Control the baking temperature inside the drum: set a certain temperature according to the different processing raw materials. The temperature of the electric furnace is set at 230-240°C (the temperature of the tea surface, referred to as the leaf temperature is controlled at 110-120°C), to ensure that the oolong tea is heated quickly and fully ;

[0027] c. Control the baking time of oolong tea and the stir-frying function of stir-frying leaves and stir-frying deflector, set the drum speed to 550r / min, to ensure that the oolong tea is fully stir-fried, ...

example 2

[0029] The baking process of the southern Fujian oolong tea using the above-mentioned tea baking spiral stir-frying device includes the following technical measures:

[0030] a. Control the roasting flow rate of oolong tea: Put 300kg of southern Fujian oolong tea to be roasted into the feeding port through the conveyor belt at a feeding speed of 150kg / h to ensure the production efficiency of oolong tea baking;

[0031] b. Control the baking temperature inside the drum: set a certain temperature according to the different processing raw materials, and set the temperature of the electric furnace at 200-220°C (the temperature on the surface of the tea leaves, referred to as the leaf temperature is controlled at 95-105°C), to ensure that the oolong tea is quickly and fully heated ;

[0032] c. Control the baking time of oolong tea and the stir-frying function of stir-frying leaves and stir-frying deflector, set the drum speed to 550r / min, to ensure that the oolong tea is fully sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com