Compact production method of austenitic stainless steel

A technology of austenitic stainless steel and production method, applied in the direction of manufacturing converters, etc., can solve the problems of high energy consumption, complex production process and high cost, and achieve the effects of compact production process, avoiding process dispersion and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

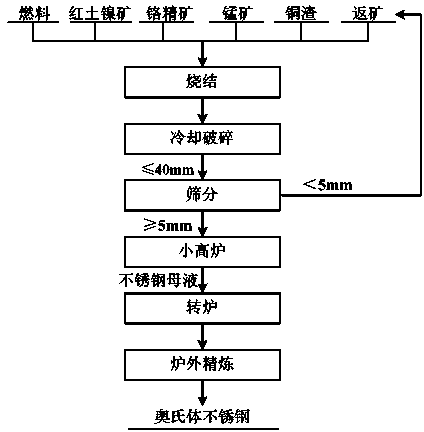

Method used

Image

Examples

Embodiment

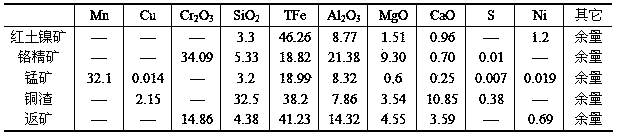

[0042] The chemical components of the raw materials used in the examples of the present invention are shown in Table 1, and the industrial analysis of the coke powder used is shown in Table 2.

[0043] Table 1 Chemical composition of raw materials (%)

[0044]

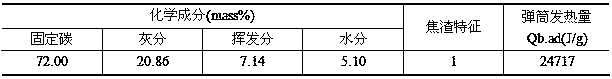

[0045] Table 2 Industrial analysis of coke powder

[0046]

Embodiment 1

[0048] Add 46 parts by weight of laterite nickel ore, 16 parts by weight of chromite concentrate, 6 parts by weight of manganese ore, 14 parts by weight of copper slag, 8 parts by weight of coke powder and 10 parts by weight of returned ore into the drum mixer, and then press 18% of the total weight of the mixture is added with water for mixing and granulation. The granulated mixture balls are evenly distributed on the base material on the trolley of the sintering machine using a distributor for sintering. The ignition temperature is 1050°C and the ignition time is 2 Minutes, the suction pressure is 8~10kPa. The obtained sintered ore is subjected to thermal crushing (≤40mm) treatment and then cooled to room temperature, and then sieved with a vibrating screen to measure the physical properties of the sintered ore. The yield, drop strength, drum strength, and anti-wear index of the sinter are 68.85%, 73.23%, 49.18%, and 20.10%, respectively. The finished sintered ore larger tha...

Embodiment 2

[0050] Add 45 parts by weight of laterite nickel ore, 15 parts by weight of chromite concentrate, 5 parts by weight of manganese ore, 10 parts by weight of copper slag, 10 parts by weight of coke powder and 15 parts by weight of returned ore into the drum mixer, and then press 18% of the total weight of the mixture is added with water for mixing and granulation. The granulated mixture balls are evenly distributed on the base material on the trolley of the sintering machine using a distributor for sintering. The ignition temperature is 1050°C and the ignition time is 2 Minutes, the suction pressure is 8~10kPa. The obtained sintered ore is subjected to thermal crushing (≤40mm) treatment and then cooled to room temperature, and then sieved with a vibrating screen to measure the physical properties of the sintered ore. The yield, drop strength, drum strength, and anti-wear index of the sinter are 72.32%, 75.86%, 51.49%, 19.21%, respectively. Put the finished sintered ore larger th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com