Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Achieve patterning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

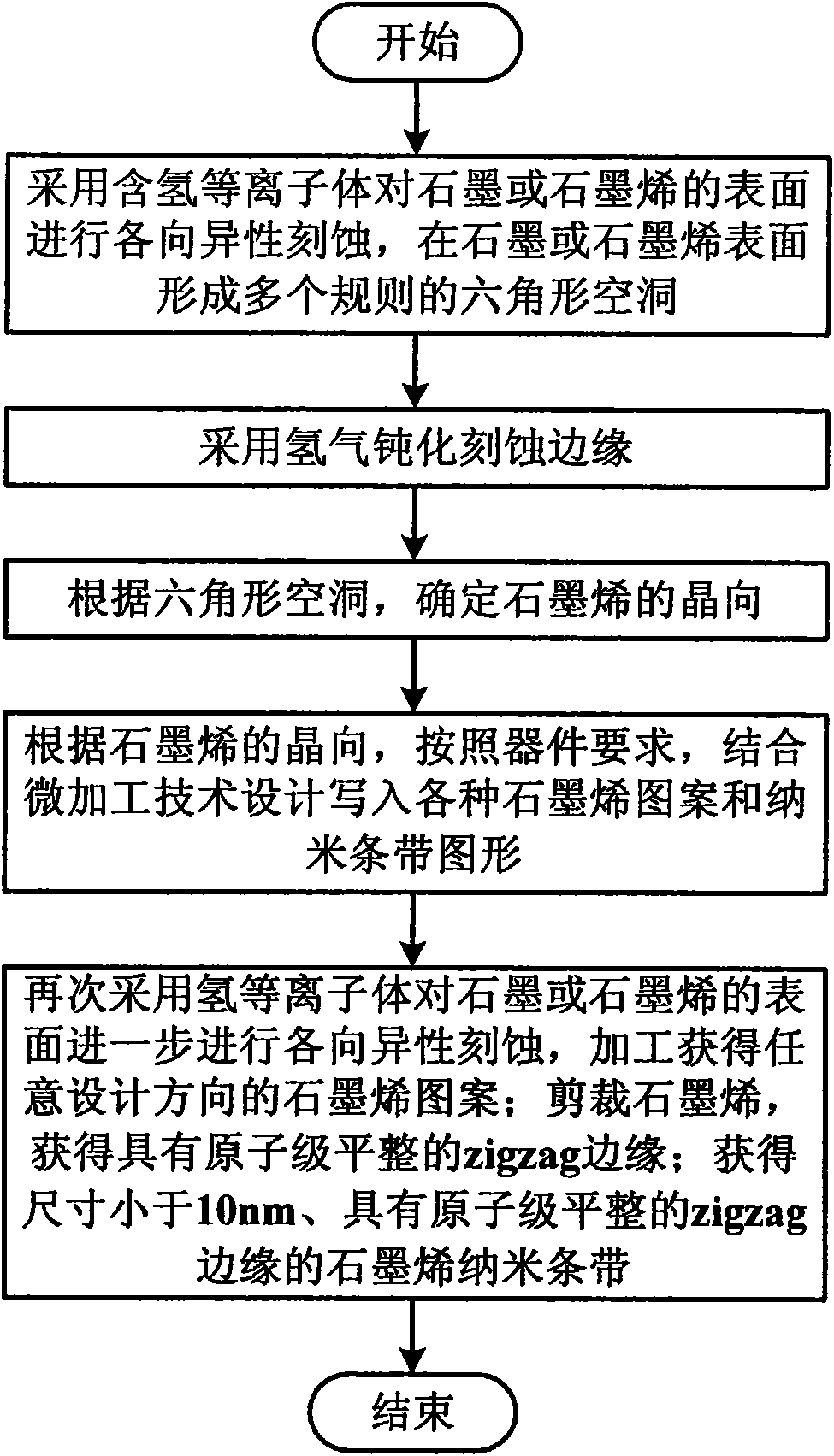

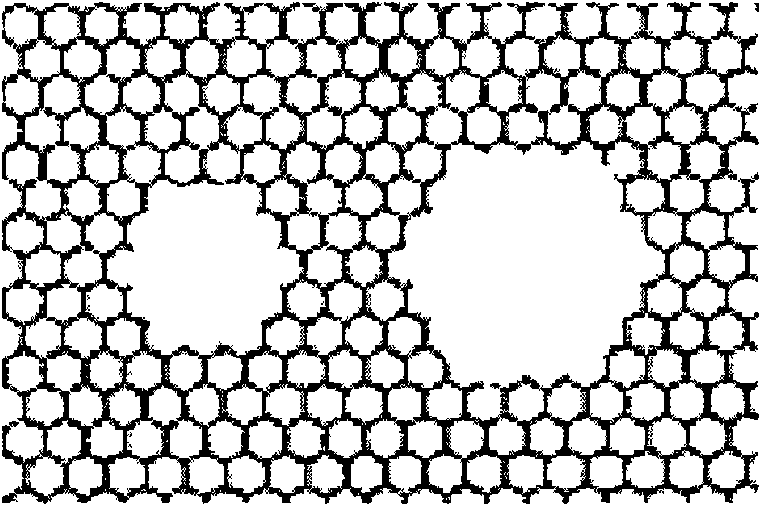

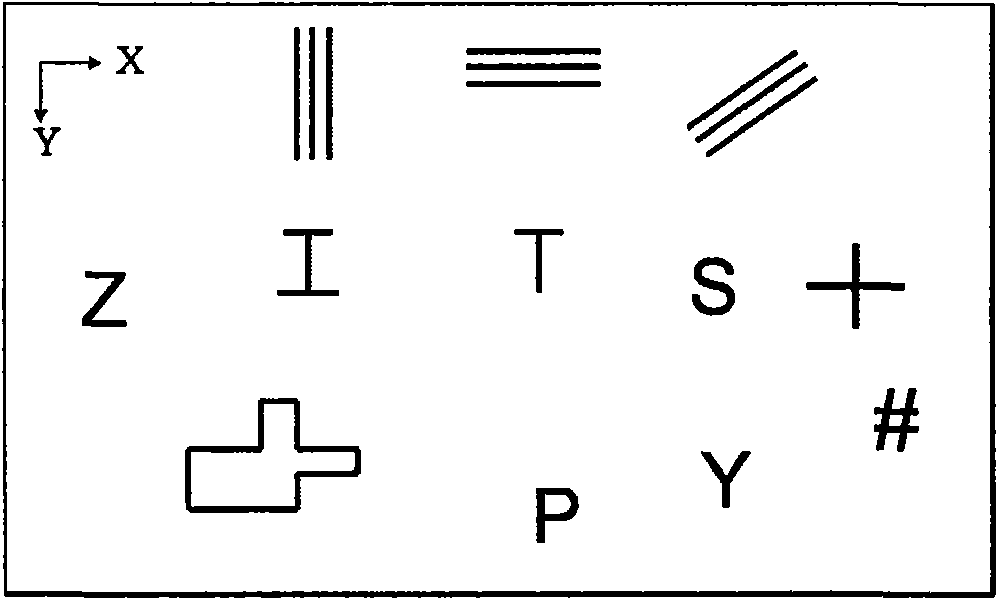

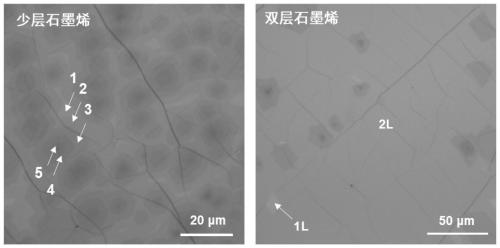

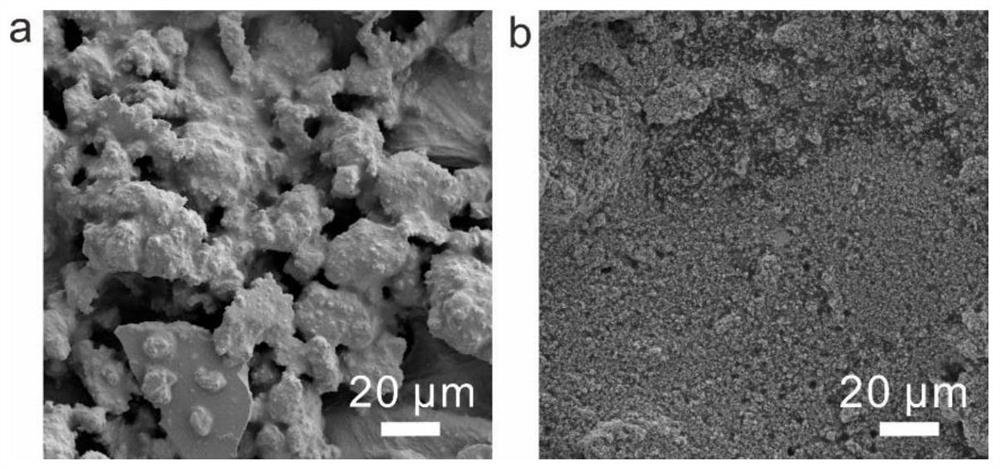

Anisotropic etching method of graphite or graphene

ActiveCN101996853AGood size controlRealize the processing effectNanostructure manufactureSemiconductor/solid-state device manufacturingHydrogenCrystal orientation

The invention discloses an anisotropic etching method of graphite or grapheme, which is used for realizing crystal orientation of graphene, graphene cutting and patterning. The method comprises the following steps of: performing anisotropic etching on the surface of graphite or grapheme by adopting hydrogen-containing plasma, and forming a plurality of regular hexagonal holes on the surface of graphite or grapheme. All the hexagonal holes have the same orientation, the orientation is matched with the crystal orientation of graphene, etched edges have atomic scale smoothness, and all the edge structures are zigzag configurations. The invention overcomes the limitations existing in the traditional etching method of graphite or grapheme and realizes cutting and patterning graphene with controllable size and atomic scale smooth edges.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Flexible stretchable conductive circuit and preparation method and use thereof

InactiveCN108668431AReduce dosageAchieve mass productionLithography/patterningConductive pattern formationWire widthImage resolution

The invention provides a flexible stretchable conductive circuit, a preparation method and use thereof. The invention also provides double-sided wiring, multilayer board, flexible display, flexible electronics, and / or sensor comprising the flexible stretchable circuit described above. The method for preparing flexible stretchable conductive circuit provided by the invention is simple and rapid, and is generally applicable to various substrate materials, the liquid metal is used in a small amount, does not require additional external force, and the pattern does not generate cracks, the wire width is controllable, has a high resolution and it's very suitable for mass production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

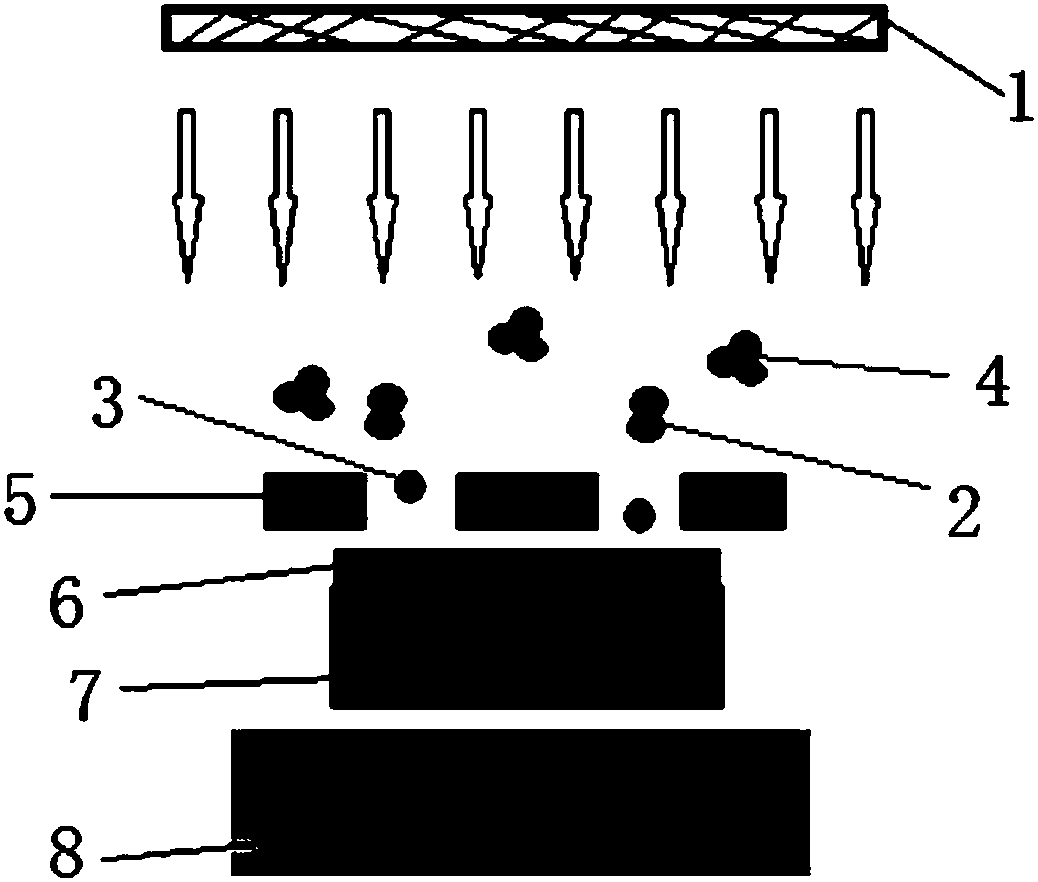

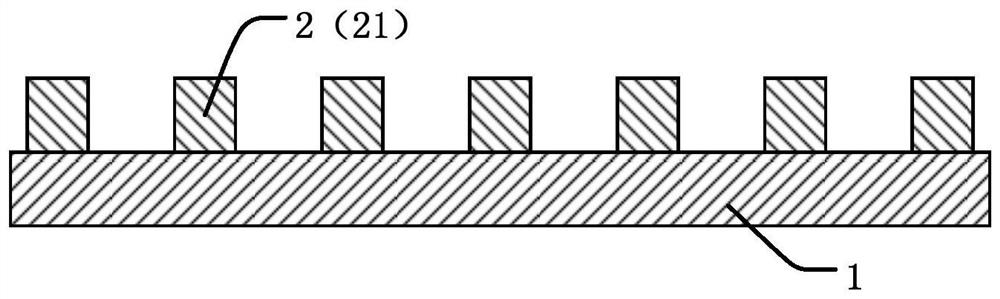

Micro-chip transfer printing device and system

ActiveCN108346606AAchieve patterningRealize simultaneous transferSemiconductor/solid-state device manufacturingConveyor partsEngineeringElectrical and Electronics engineering

The invention relates to the technical field of transfer printing, and discloses a micro-chip transfer printing device and system. The device comprises a press head substrate; a transfer printing array layer which is disposed at one side, facing a bearing substrate, of the press head substrate, is used for the transfer printing of a miniature device on the bearing substrate, and comprises a plurality of transfer printing blocks distributed on the press head substrate in an array, wherein each transfer printing block has a non-pick-up state and a pick-up state for picking up the miniature device, and the switching of each transfer printing block between the non-pick-up state and the pick-up state is independently controllable. The switching of each transfer printing block the device betweenthe non-pick-up state and the pick-up state is independently controllable. The device can achieve the patterning of the transfer printing array layer, achieves the simultaneous transfer printing of alarge number of miniature devices, also can change the patterns of the transfer printing array layer according to different transfer printing requirements, achieves the application of the transfer printing array layer under different transfer printing demands, avoids the complex replacement operation of a transfer printing head, and reduces the transfer printing cost of the miniature devices.

Owner:BOE TECH GRP CO LTD

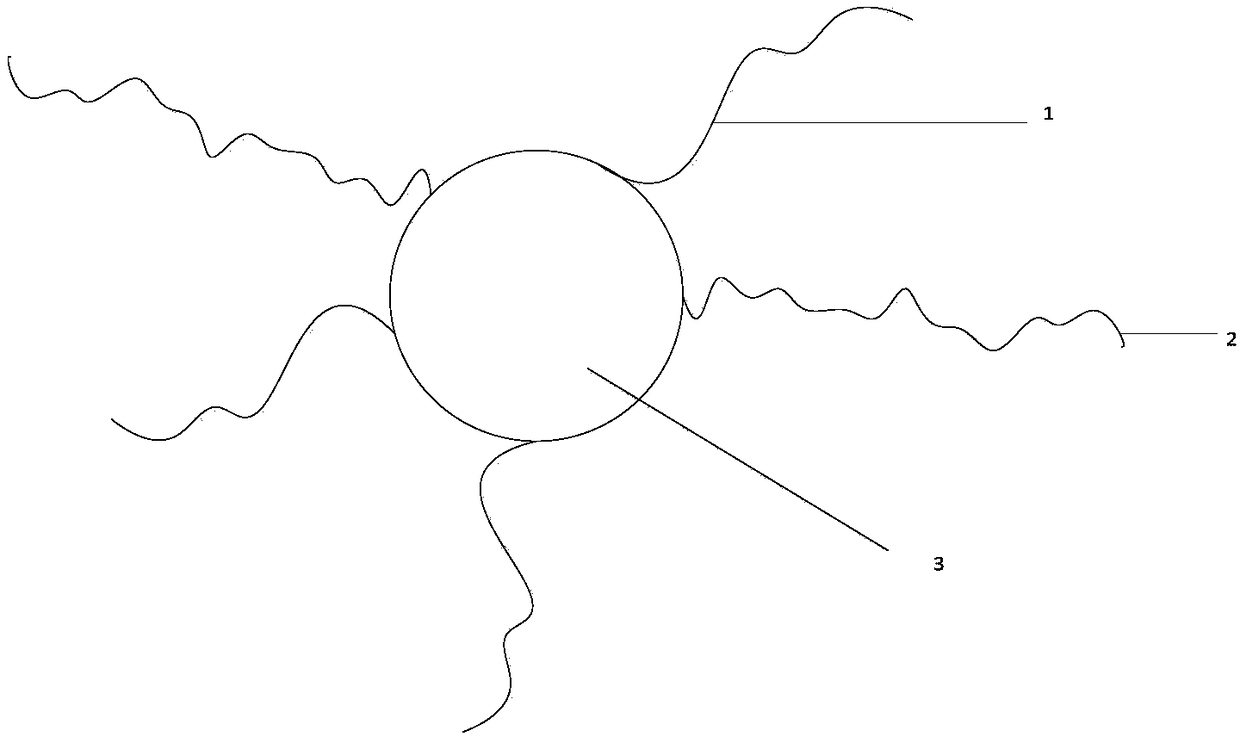

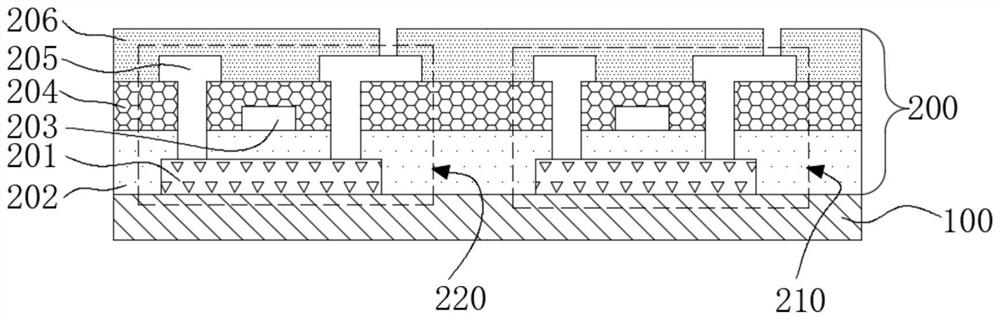

Nanoparticle, display substrate preparation method and display device

ActiveCN109378395APrevent bleachingHigh resolutionMaterial nanotechnologySolid-state devicesSolubilityNanoparticle

The present invention relates to the field of display, and in particular to a nanoparticle, a display substrate preparation method, and a display device. The nanoparticle comprise a nanoparticle body,and first ligands and a second ligands connected to a surface of the nanoparticle body, wherein the first ligands have alkaline solubility, and the second ligands are crosslinked upon exposure to heat. The display substrate preparation method includes: forming a nanoparticle layer on the substrate; coating the nanoparticle layer with the photoresist, and exposing the photoresist by using a mask after the pre-baking treatment; performing development processing, wherein the photoresist in the the nano-particle layer unretained area is completely removed, and the exposed nanoparticle layer is dissolved in a developing solution; subjecting the second ligands of the nanoparticle covered by the photoresist retention region to a crosslinking reaction after the post-baking treatment, and fixing the nanoparticle layer on the substrate; stripping the photoresist to complete patterning of the nanoparticle layer. The nanoparticle can be combined with a photolithography process to achieve high resolution of nanoparticle patterning.

Owner:BOE TECH GRP CO LTD +1

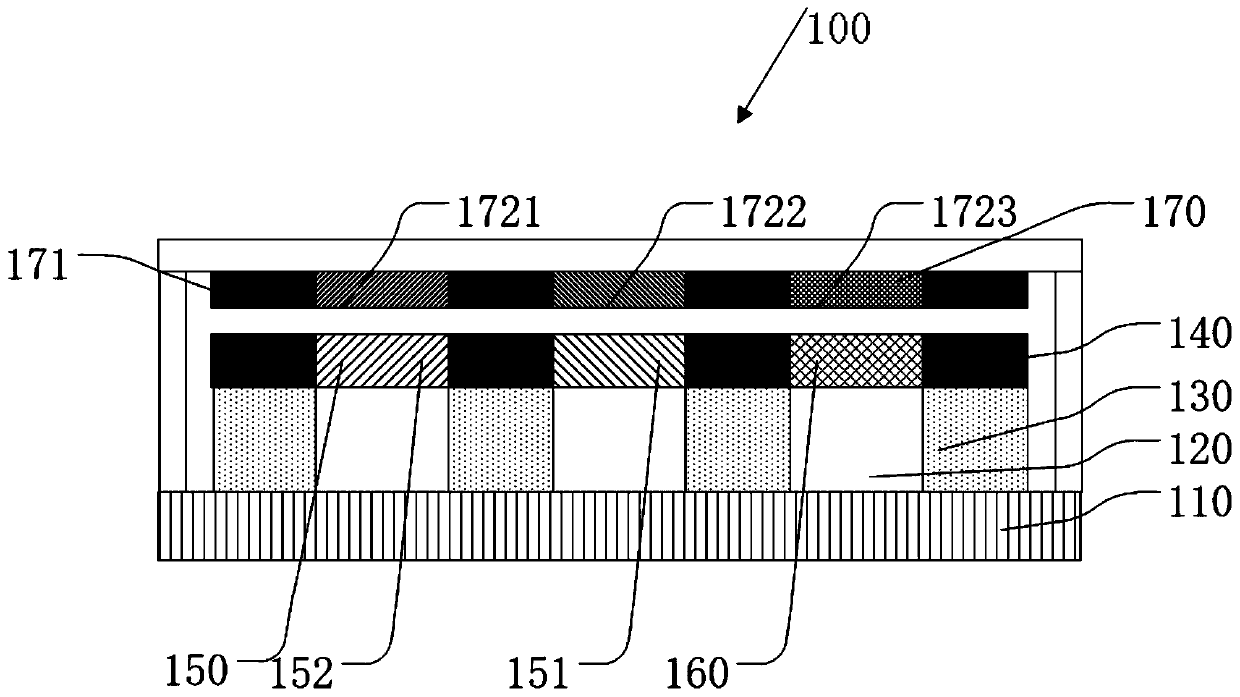

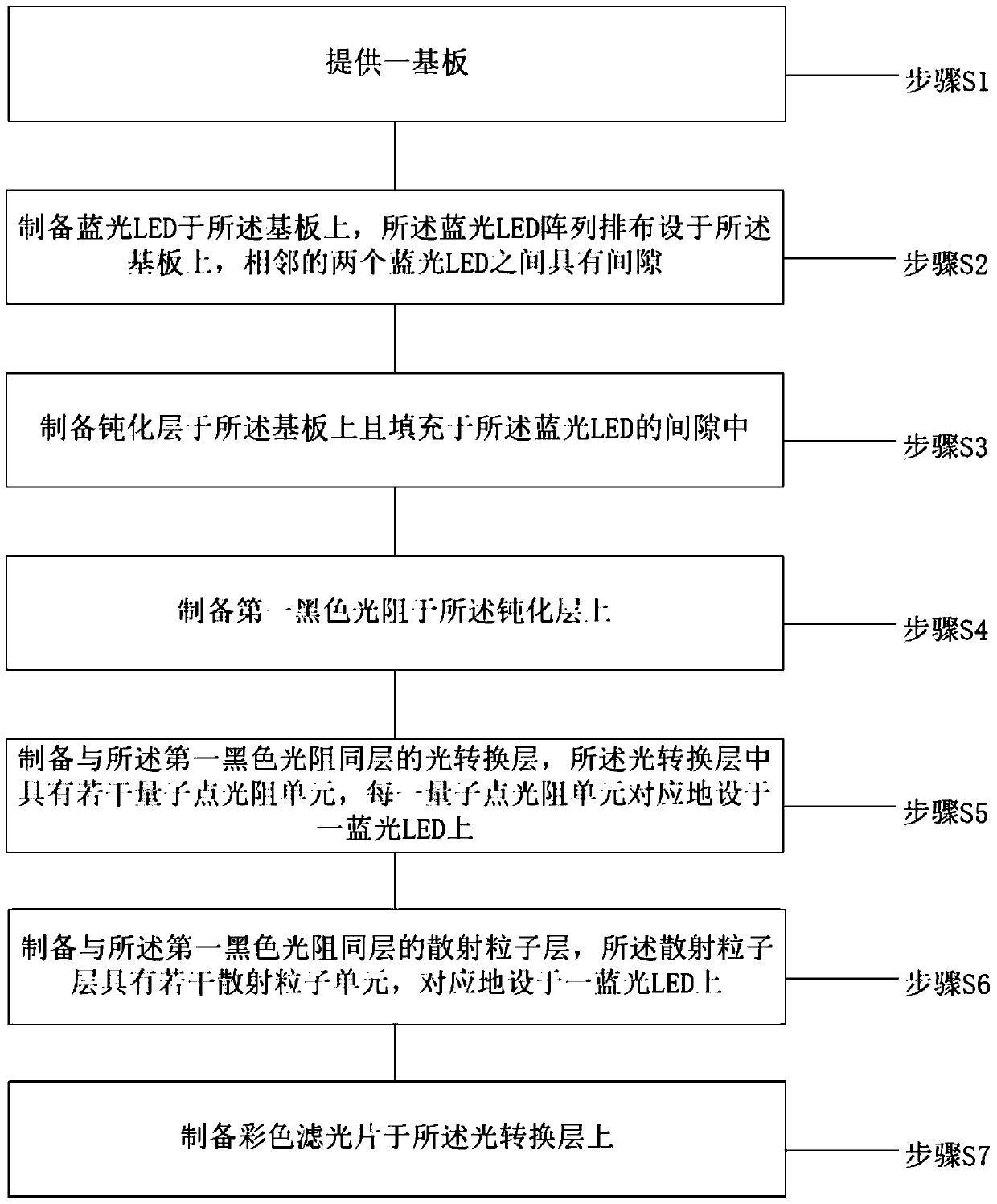

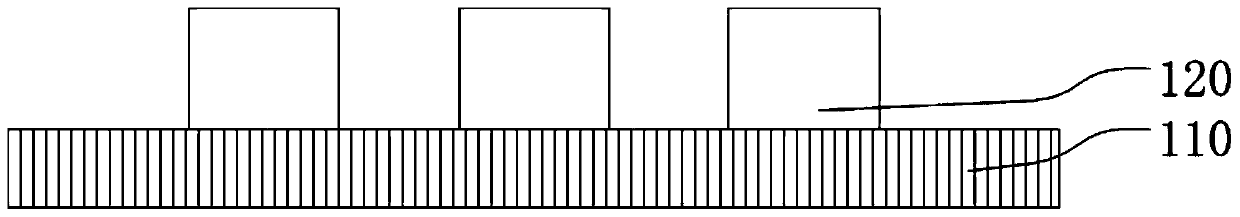

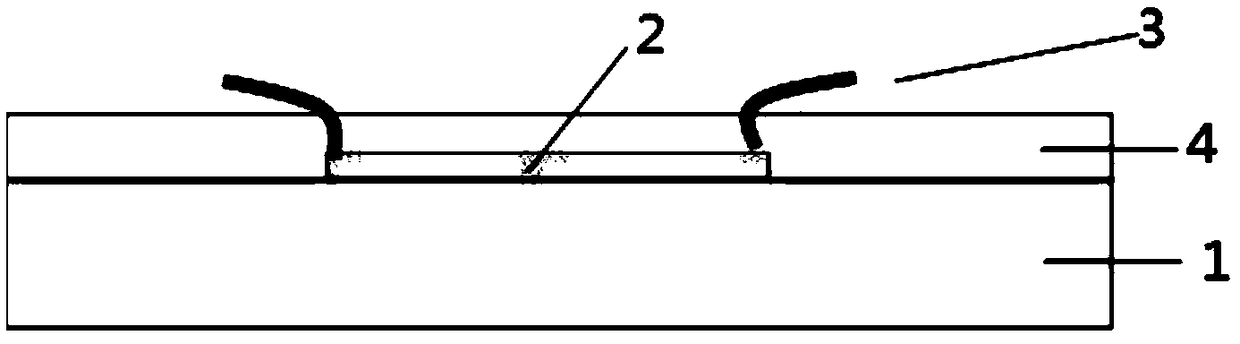

Display panel and preparation method thereof

InactiveCN111028704AAchieve patterningRealize full color displaySolid-state devicesIdentification meansQuantum dotEngineering

The invention discloses a display panel and a preparation method thereof. The display panel includes: a substrate; blue light LEDs that are arranged on the substrate in an array manner, and a gap is formed between every two adjacent blue light LEDs; a passivation layer that is arranged on the substrate and is filled in the gap of the blue light LED; a first black light resistor that is arranged onthe passivation layer; a light conversion layer that is arranged on the same layer with the first black light resistor; a plurality of quantum dot photoresist units that are arranged in the light conversion layer, and each quantum dot photoresist unit is correspondingly arranged on one blue light LED; and a scattering particle layer that is arranged on the same layer with the light conversion layer, and the scattering particle layer is provided with a plurality of scattering particle units which are correspondingly arranged on a blue light LED.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

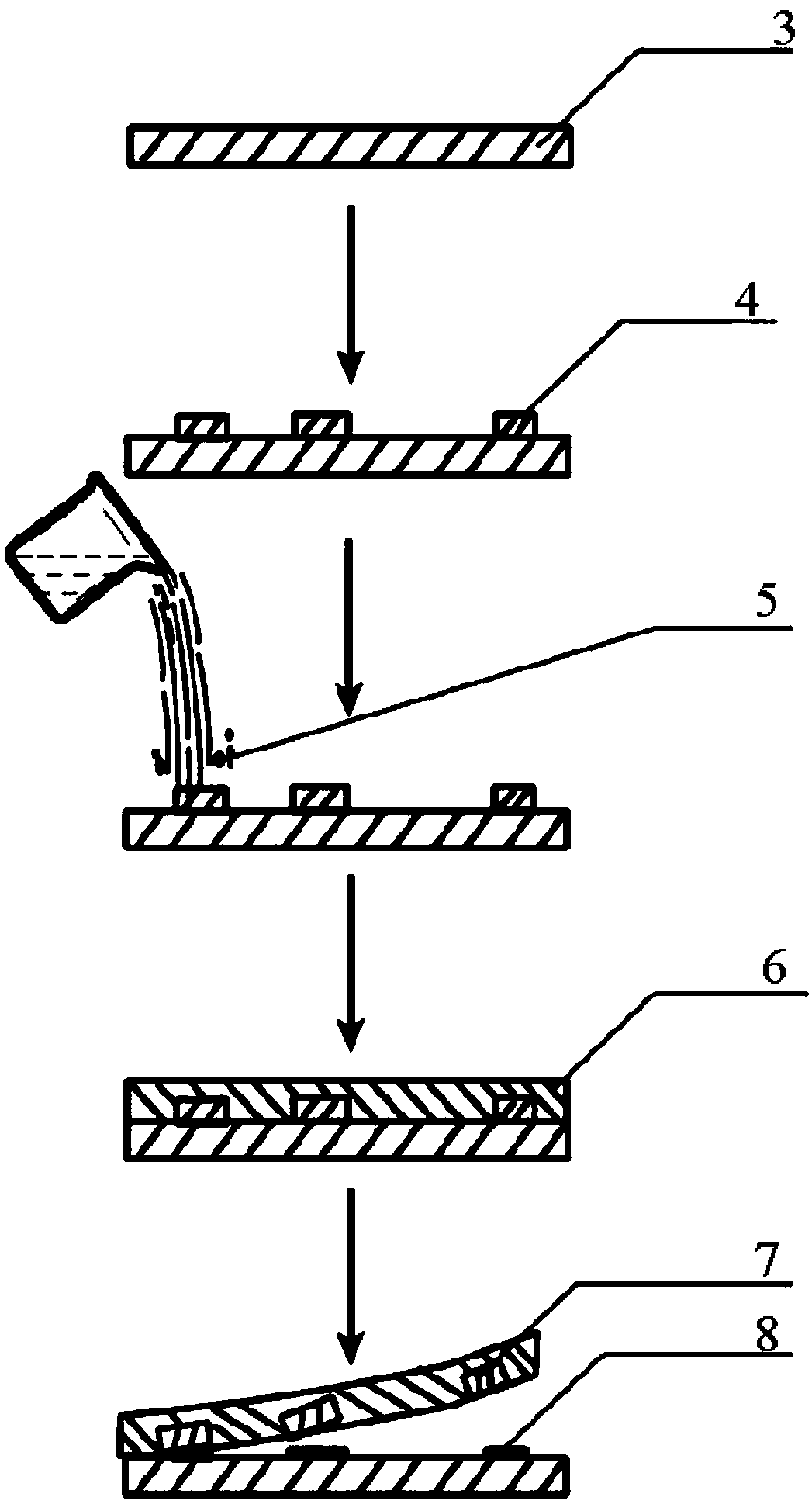

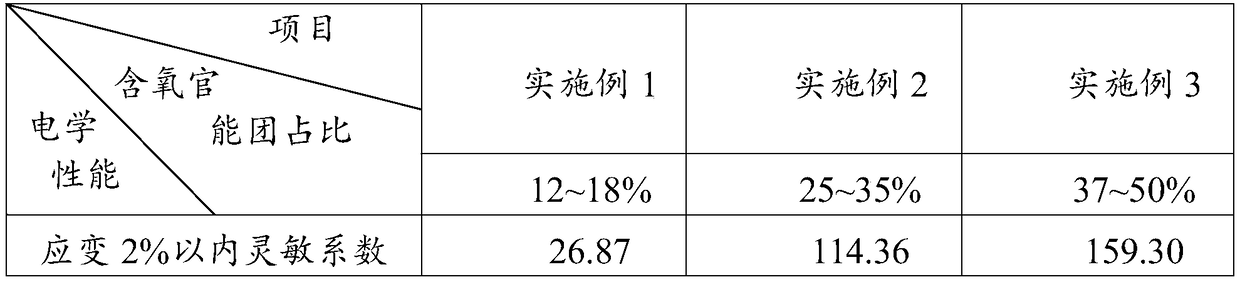

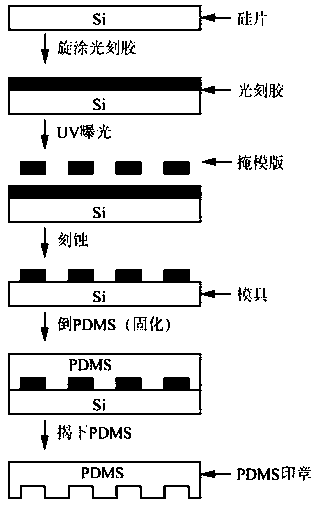

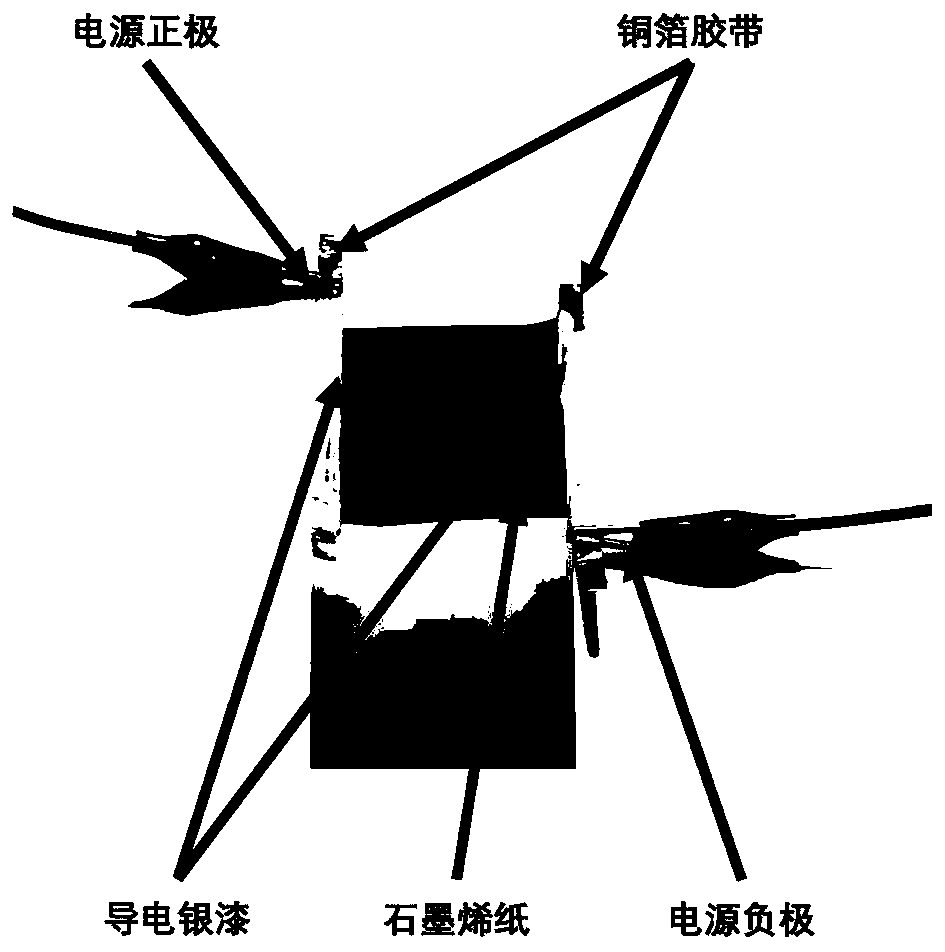

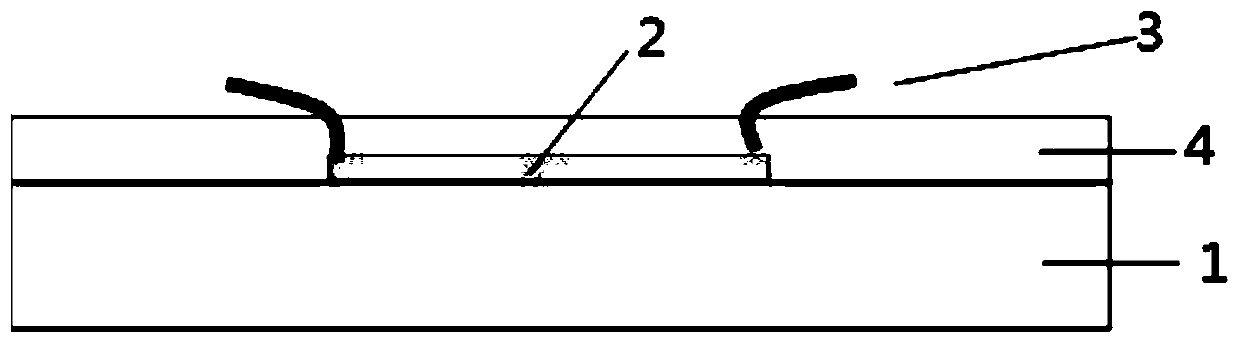

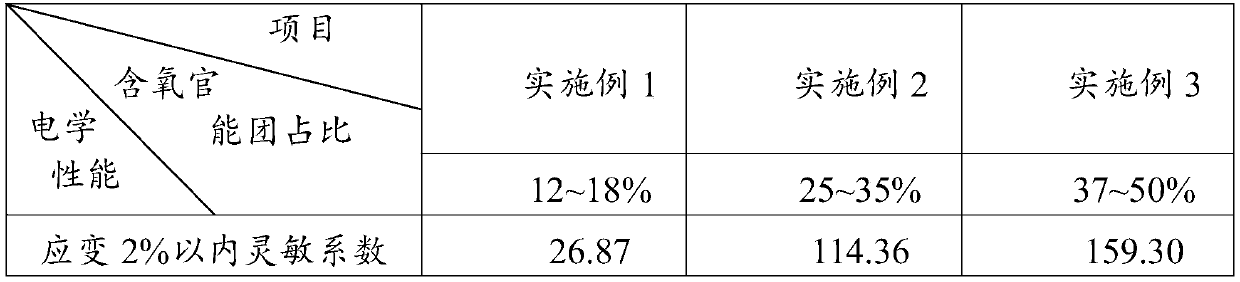

Preparation method of patterned graphene flexible strain sensor

InactiveCN109163653AEasy to manufactureAchieve patterningElectrical/magnetic solid deformation measurementElastomerSilver paste

The invention provides a preparation method of a patterned graphene flexible strain sensor. The method comprises the following steps: firstly, preparing a predetermined pattern on the surface of a hard substrate material by using photoetching to obtain a patterned mold, and then pouring mixed slurry of polymer material elastomer and a curing agent onto the surface of the patterned mold for curingto obtain a micro-channel mold; and then covering the surface of a flexible substrate with the micro-channel mold, performing patterned modification on the flexible substrate by using dopamine, preparing a graphene sensitive layer on the surface of the modified substrate, and finally coating conductive silver paste and bonding a conducting wire to obtain the patterned graphene flexible strain sensor. According to the preparation method provided by the invention, no photoetching needs to be performed on the flexible substrate, so that the main body structure of the flexible substrate is not damaged, the preparation method is suitable for complex curved surfaces, large-area manufacturing and fine pattern processing, and the requirements for the own material, the shape and the surface structure of the flexible substrate are reduced.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

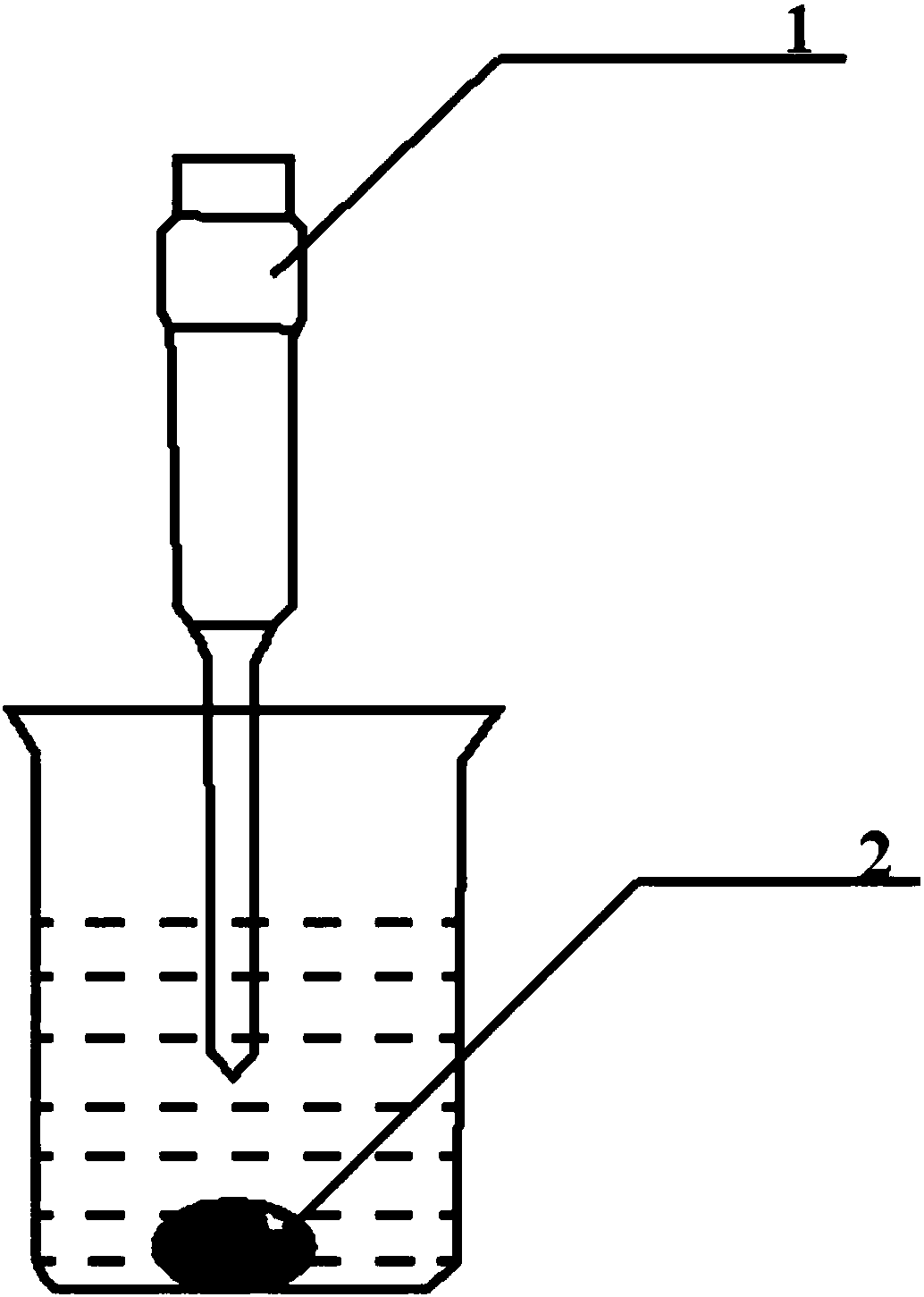

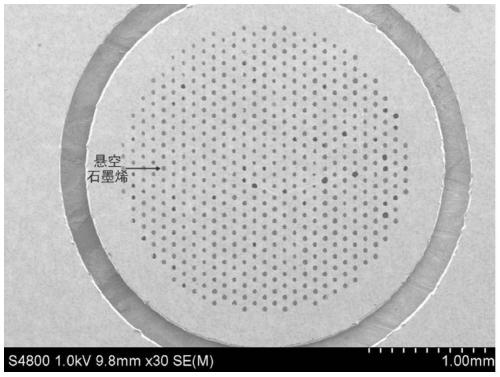

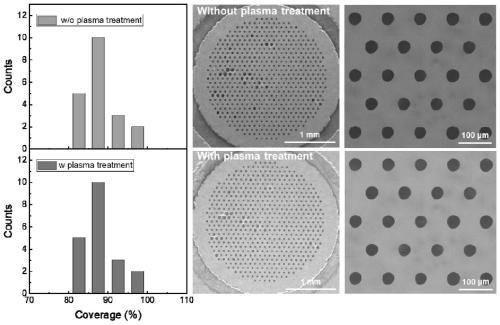

Method for preparing suspended graphene support film of Janus structure

ActiveCN109824046ASimple processAchieve patterningMaterial analysis using wave/particle radiationGrapheneHigh resolution imagingNanoparticle

The invention discloses a method for preparing a suspended graphene support film of a Janus structure. The method comprises the steps that a graphene thin film is grown on the metal substrate surfacethrough a chemical vapor deposition method, then a suspended graphene thin film is prepared, finally obtained suspended graphene is placed in a plasma cleaner, and the graphene surface is functionalized to obtain the Janus graphene support film which is controllable in hydrophilicity and hydrophobicity and high in integrity (more than 80%). The preparation method is simple in process, and the hydrophilicity and hydrophobicity of the graphene can be regulated through one-step plasma treatment; the patterned Janus suspended graphene support film can be prepared by additionally arranging a mask plate. The contact angle range of the obtained graphene support film is wide (50-90 degrees), the contact angle range (60-80 degrees) of a commercial amorphous carbon electron microscopy supporting membrane is covered, and effective loading and high resolution imaging of water-soluble samples such as biological protein and nano-particles are facilitated.

Owner:PEKING UNIV

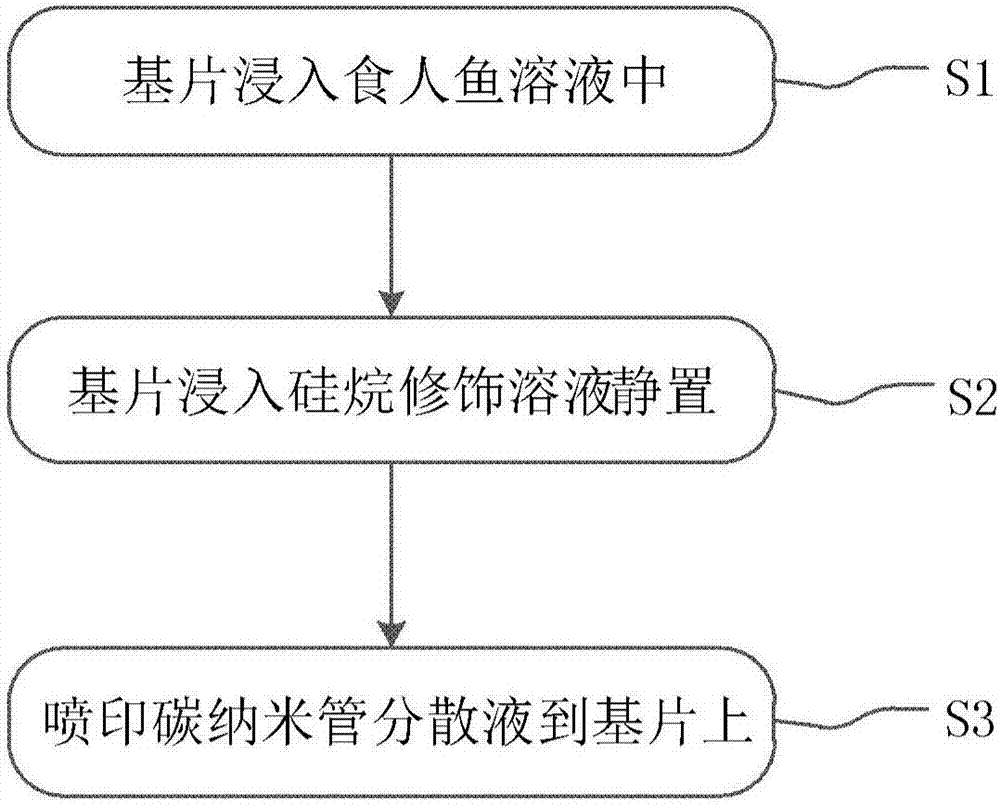

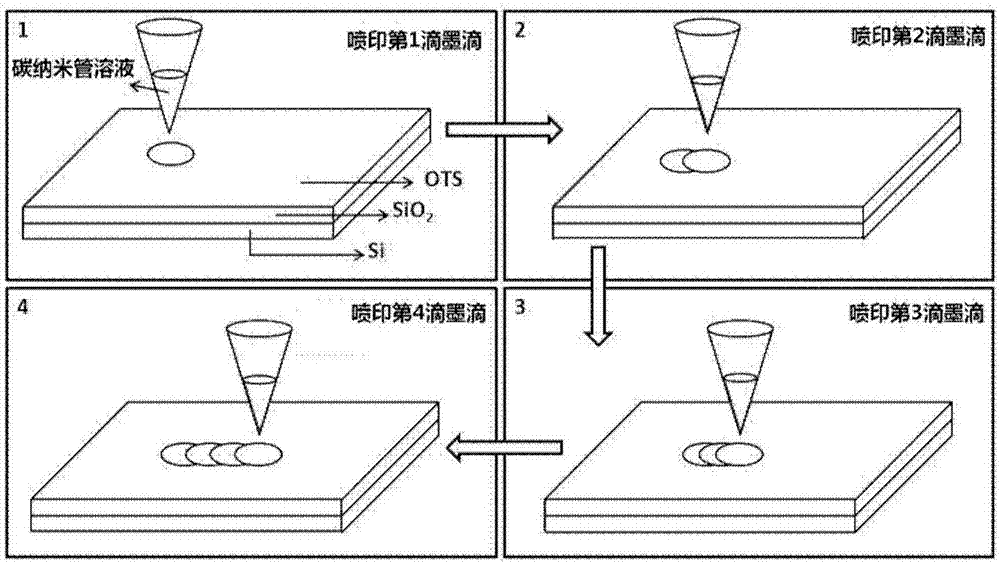

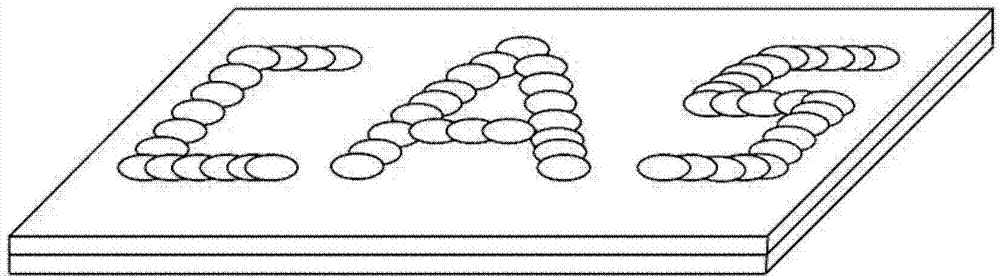

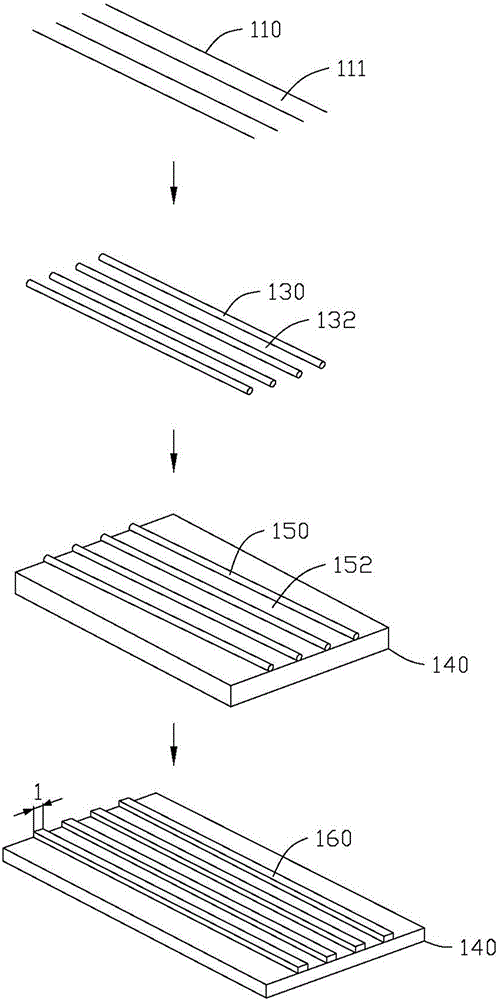

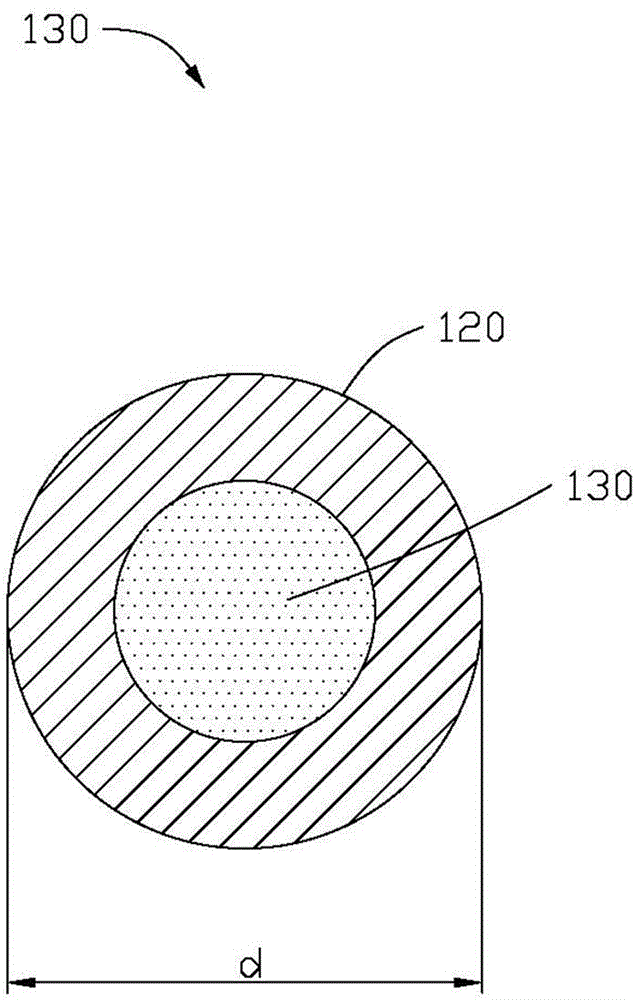

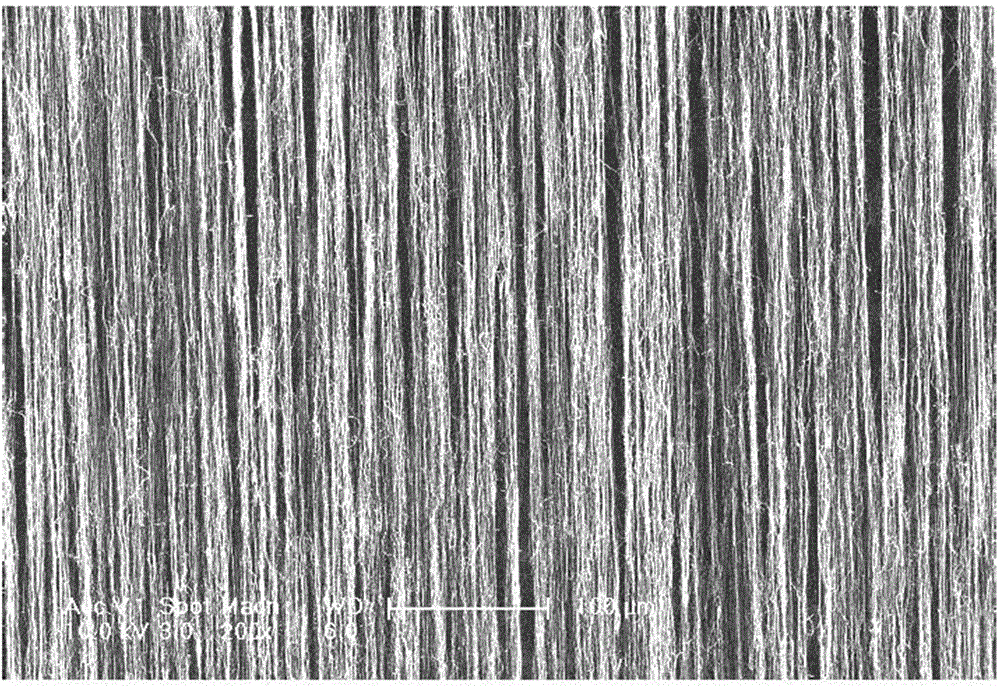

Single aligned carbon nano tube jet-printing arrangement method

ActiveCN107963610ASimple processAchieve patterningMaterial nanotechnologyNanostructure manipulationOctadecyltrichlorosilaneNano-device

The invention provides a single aligned carbon nano tube jet-printing arrangement method. The method comprises the steps that a substrate is modified with octadecyltrichlorosilane (OTS), so that the surface of the substrate has a hydrophobic property; precise control over the thin film position, the aligned density and patterning of aligned carbon nano tubes is achieved on the functional hydrophobic substrate through ink-jet printing, and a carbon nano tube thin film which is uniform in density and consistent in orientation and has different patterns is arranged. By means of the method, the carbon nano tube arrangement area of the size from several micrometers to the wafer level can be effectively controlled; the problems can be solved that in all existing arrangement methods, the arrangement position, the arrangement orientation, the arrangement density and the thin film array patterning of one-dimensional nano materials on the substrate cannot be efficiently and precisely controlled;the method can be widely used for preparing various high-performance photoelectric devices, logic circuits and functional thin films based on the carbon nano tubes, and the method also has a wide application prospect in the field of flexible wearable nano devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method utilizing ultraviolet oxidation in implementing and regulating graphene film patterning

ActiveCN107611020AQuality improvementHigh graphic precisionSemiconductor/solid-state device manufacturingNanotechnologyCvd grapheneMicrometer

Provided in the invention is a method for utilizing ultraviolet oxidation in implementing and regulating graphene film patterning, comprising: a step 1: utilizing a xenon lamp excimer ultraviolet oxidation method and a hard mask in implementing graphene film microstructure graphic patterning; a step 2: by applying a nonuniform magnetic field in the perpendicular direction to the surface of a graphene film, controlling oxygen excitons to move in the direction of the magnetic field towards the graphene film, thus enhancing the directionality of etching the graphene film in the perpendicular direction, and increasing the quality of graphene film microstructure patterning; and a step 3: by adjusting the strength and direction of the magnetic field (such as in the horizontal direction), controlling the directionality of the movement of the oxygen excitons, and regulating the shape being etched on the graphene film graphic structure, thus achieving the goal of regulating graphene film patterning. The method of the invention implements and regulates a micrometer graphic structure array, is suitable for large-area graphene film patterning, free of photoresist contamination, and inexpensive, and provides a patterned graphene film of high quality.

Owner:SHANGHAI JIAO TONG UNIV

Large-area disulfide hafnium thin film preparation method based on atomic layer deposition process

InactiveCN110616413ASelf-limitingPrecise and controllable atomic thicknessChemical vapor deposition coatingSelf limitingChemical reaction

The invention discloses a large-area disulfide hafnium thin film preparation method based on an atomic layer deposition process. The method mainly comprises the following steps that (1), a substrate is put into an atomic layer deposition system reaction cavity; (2), vacuumizing is performed on the atomic layer deposition system reaction cavity; and (3), a precursor is introduced into the atomic layer deposition system reaction cavity alternately and is made to generate self-limiting chemical reaction on the substrate surface and grow a large-area disulfide hafnium thin film. By means of the large-area disulfide hafnium thin film preparation method based on the atomic layer deposition process referred by the invention, the fact that the prepared two-dimensional disulfide hafnium thin film has the advantages of precisely controllable atomic-scale thickness, large area, uniformity and the like can be realized, and the reaction temperature is low, flexible substrates can be compatible, andpatterning of the prepared thin film can be realized in combination with subsequent photoetching and other semiconductor processes.

Owner:ANYANG NORMAL UNIV

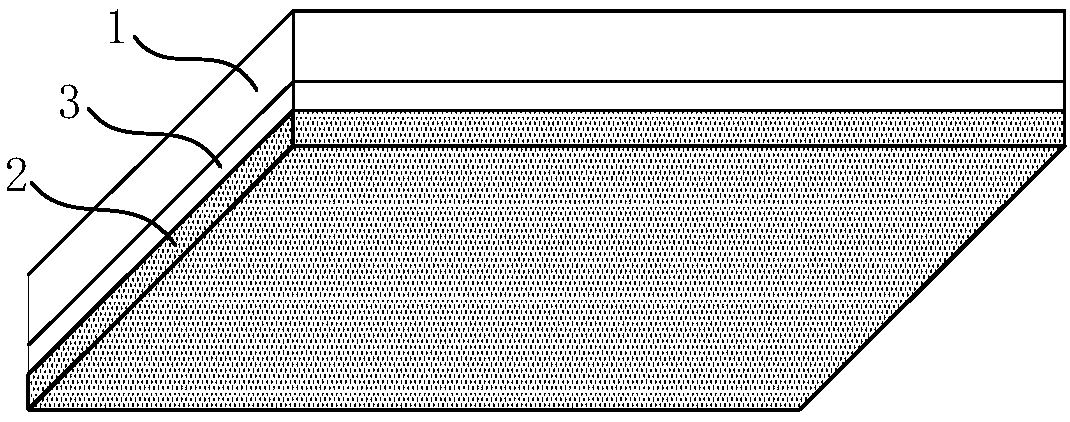

Transparent conductive substrate, preparation method thereof and application thereof

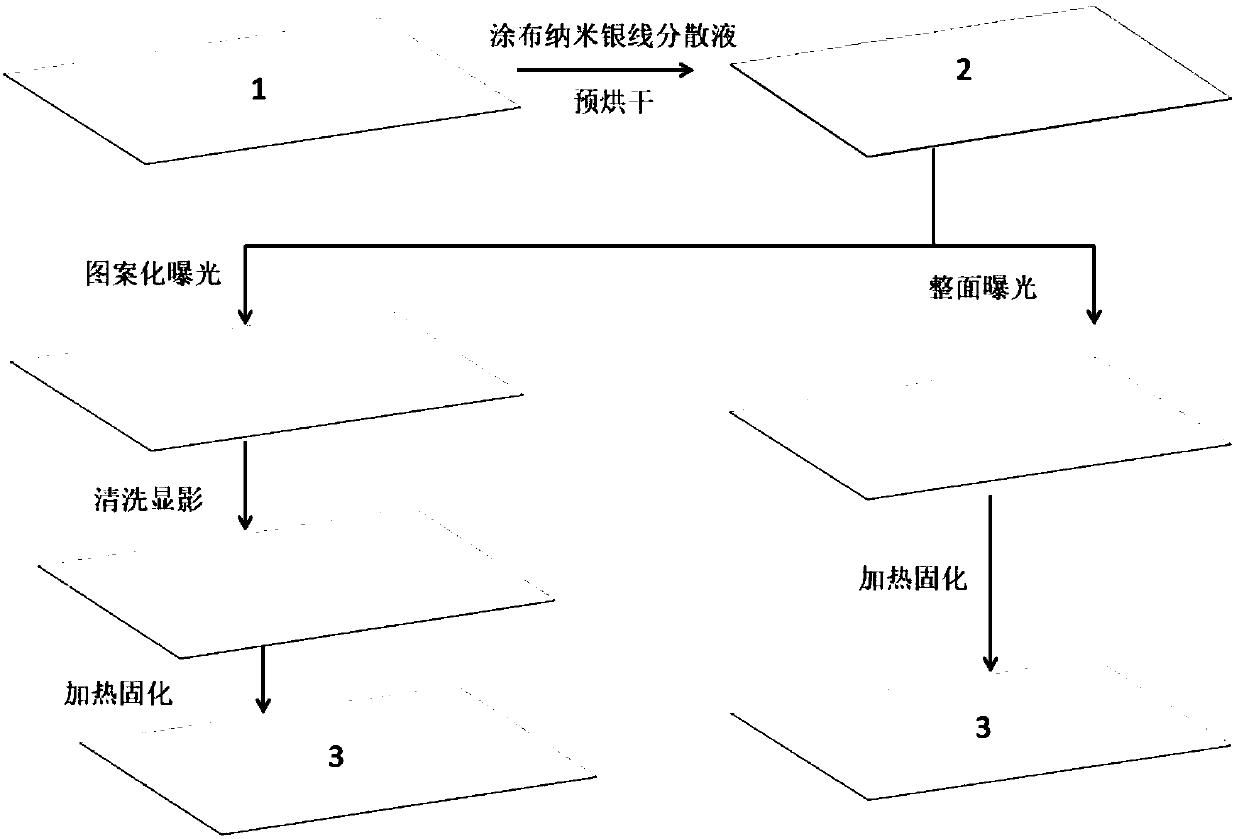

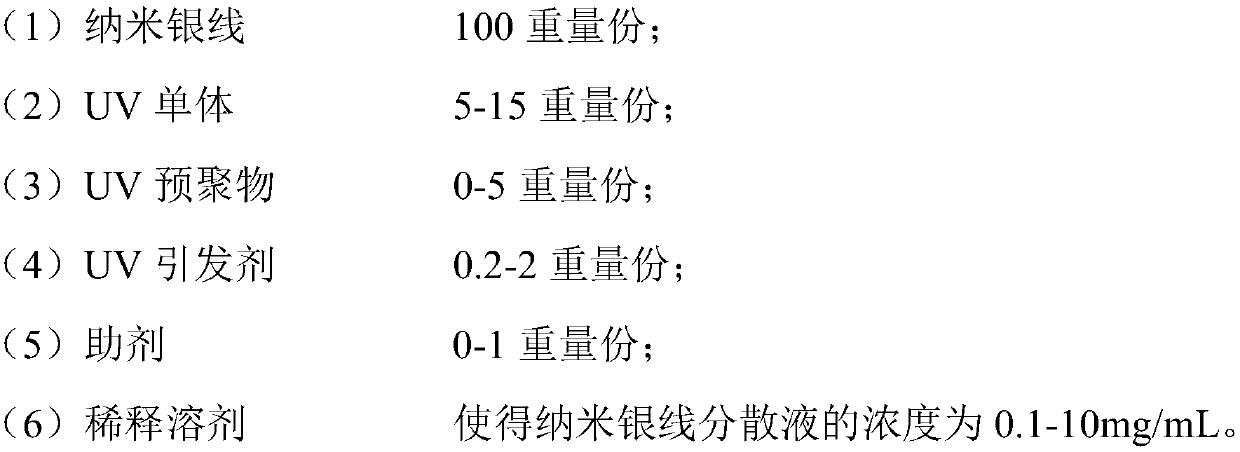

ActiveCN109524151AThickness is easy to controlFast preparationMaterial nanotechnologyConductive layers on insulating-supportsTransmittanceConductive materials

The invention relates to the field of conductive materials and discloses a transparent conductive substrate, a preparation method and an application thereof. The method comprises the steps of (a) uniformly coating the surface of a transparent substrate with a nano silver wire dispersion liquid and performing pre-baking to obtain a substrate coated with a nano silver wire coating, (b1) performing pattern exposure treatment on the substrate coated with the nano silver wire coating and performing cleaning development and heat curing to obtain the transparent conductive substrate, or (b2) performing whole surface exposure treatment on the substrate coated with the nano silver wire coating and performing heat curing to obtain the transparent conductive substrate. The prepared transparent conductive substrate has good conductivity and light transmittance, a large-area transparent conductive substrate can be prepared by the method, the patterning can be directly realized, and the applicationof multiple scenes and complicated scenes is satisfied.

Owner:INST OF CHEM CHINESE ACAD OF SCI

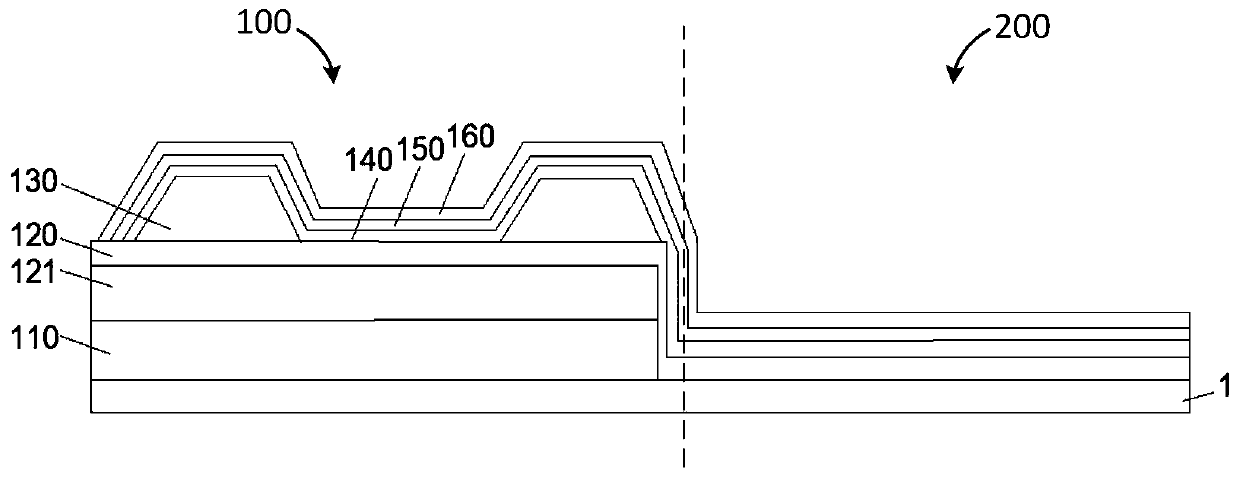

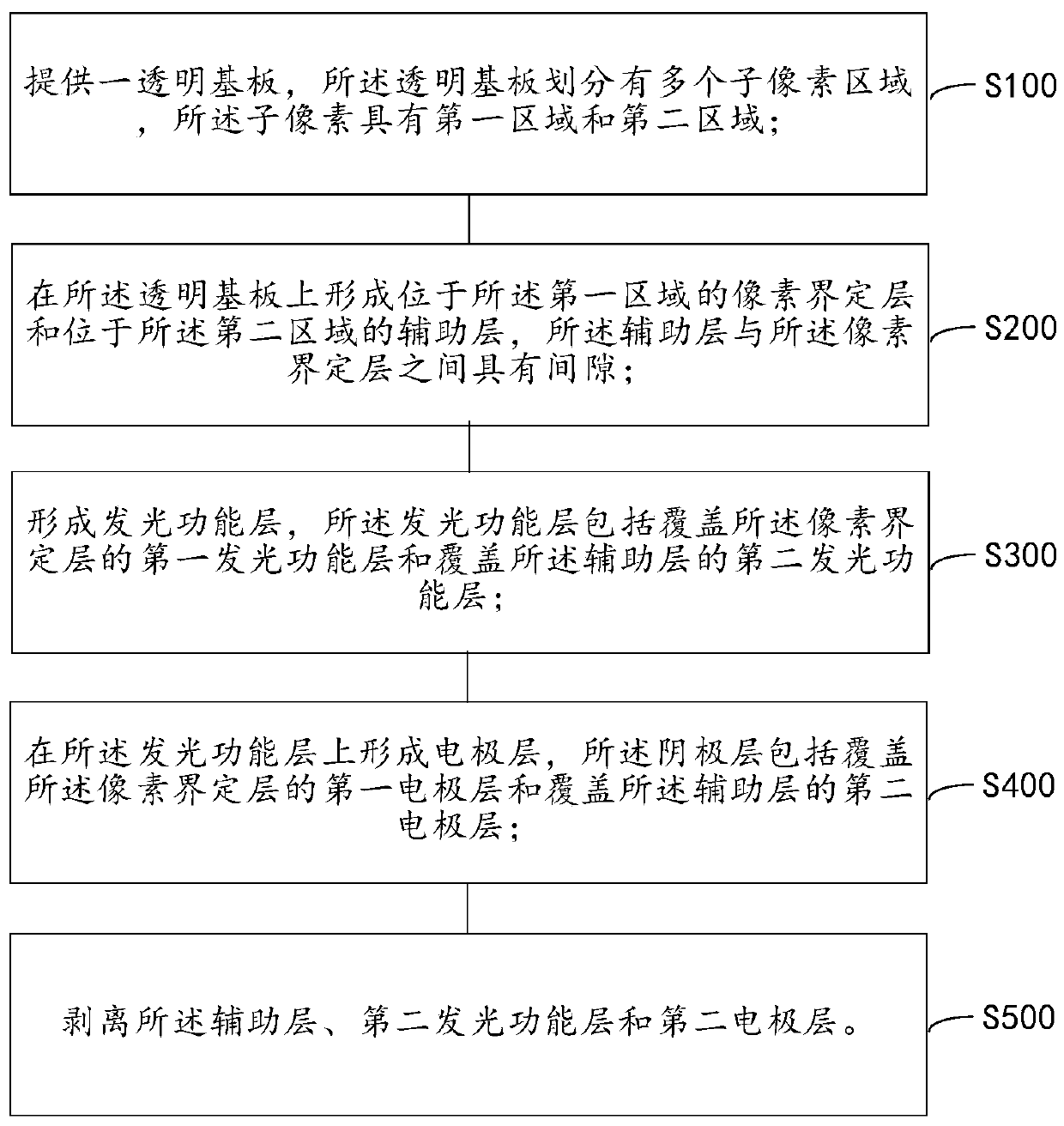

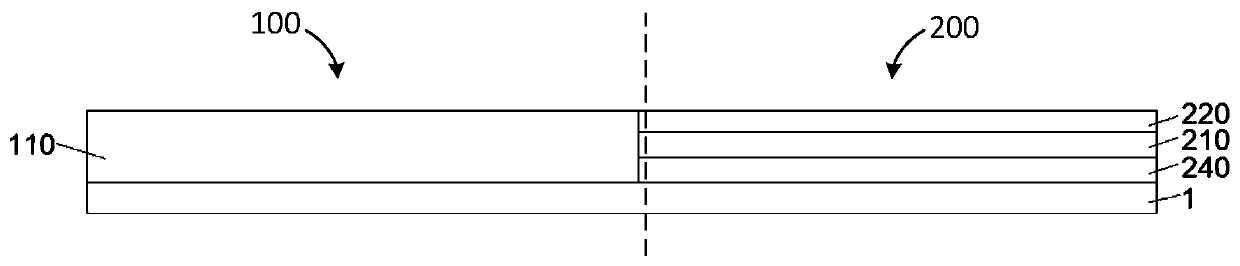

Display panel, manufacturing method thereof and display device

ActiveCN110767846AReduce in quantityImprove transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTransmittance

The invention provides a display panel, a manufacturing method thereof and a display device. The manufacturing method of the display panel comprises the steps: after a pixel defining layer is prepared, an auxiliary layer with a certain gap with the pixel defining layer is prepared in a transparent area; then a light-emitting function layer and a cathode layer are formed on the pixel defining layerand the auxiliary layer; and finally, the auxiliary layer is stripped, and the light-emitting function layer and the cathode layer in the transparent area can be stripped at the same time. Accordingto the method, the light-emitting function layers and the cathode layers in the transparent area are reduced, the number of the film layers is reduced, particularly, the cathode layers which greatly influence the light transmittance are removed, the light transmittance of the transparent area is greatly improved, and the transparent display effect is improved.

Owner:BOE TECH GRP CO LTD

Large-scale preparation and patterning method of two-dimensional material semiconductor film and two-dimensional material semiconductor film

ActiveCN111863624AEasy to prepareThickness is easy to controlTransistorSemiconductor/solid-state device manufacturingPoly(diallyldimethylammonium chloride)Thin membrane

The invention belongs to the technical field of two-dimensional semiconductor film preparation, and particularly relates to a large-scale preparation and patterning method of a two-dimensional material semiconductor film. The method comprises the following steps of pre-treating a substrate; photoetching a target pattern on the pretreated substrate by using negative photoresist; preparing a two-dimensional semiconductor film on the substrate with a photoresist pattern by using a solution self-assembly technology, wherein the substrate is firstly soaked in a poly(diallyldimethylammonium chloride) aqueous solution and then soaked in a MoS2 aqueous solution, and the process can be repeated for many times; and soaking the film obtained on the substrate in acetone to remove the photoresist, andfinally, obtaining the target MoS2 pattern. The method has the advantages that the preparation method is simple and can be operated on any substrate; the thickness of the film is controllable, and thepatterning can be realized; reaction conditions are mild, and the method has wide application space in the field of high-performance two-dimensional semiconductor film electronic devices.

Owner:NANKAI UNIV

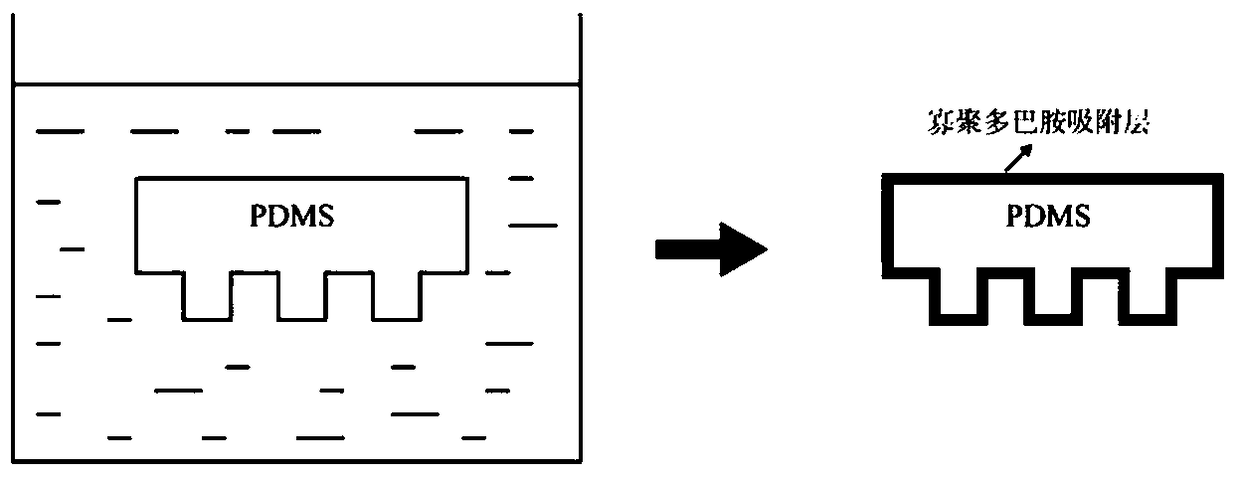

Novel microcontact printing system for cell patterning

ActiveCN108641892AThe operation process is simple and convenientAchieve patterningBioreactor/fermenter combinationsBiological substance pretreatmentsMicrocontact printingDopamine

The invention provides a novel microcontact printing system for cell patterning. The system comprises oligomeric dopamine formed by dopamine monomers through polymerization. The molecular weight of the oligomeric dopamine is between 1000 and 10000 D; and a structural formula is shown in the description. A substrate is firstly subjected to chemical modification treatment to obtain a bioadhesion-resistant inert substrate; then, a water solution of the oligomeric dopamine is prepared; a stamp is prepared; next, the stamp is soaked into the water solution of the oligomeric dopamine; and next, thestamp adsorbing the oligomeric dopamine is stamped onto the inert substrate, so that a pattern on the stamp is obtained from the surface of the substrate. The patterning substrate can also be used forcell patterning growth. The realization of the system is simple. The existing technology for cell patterning is simplified.

Owner:广州波奇亚标准及检测技术有限公司 +1

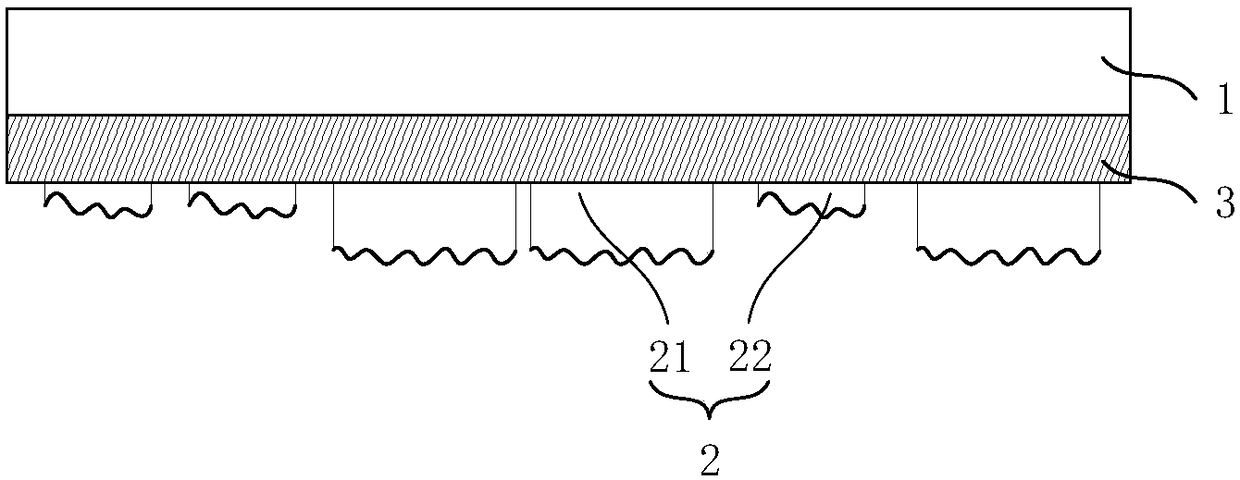

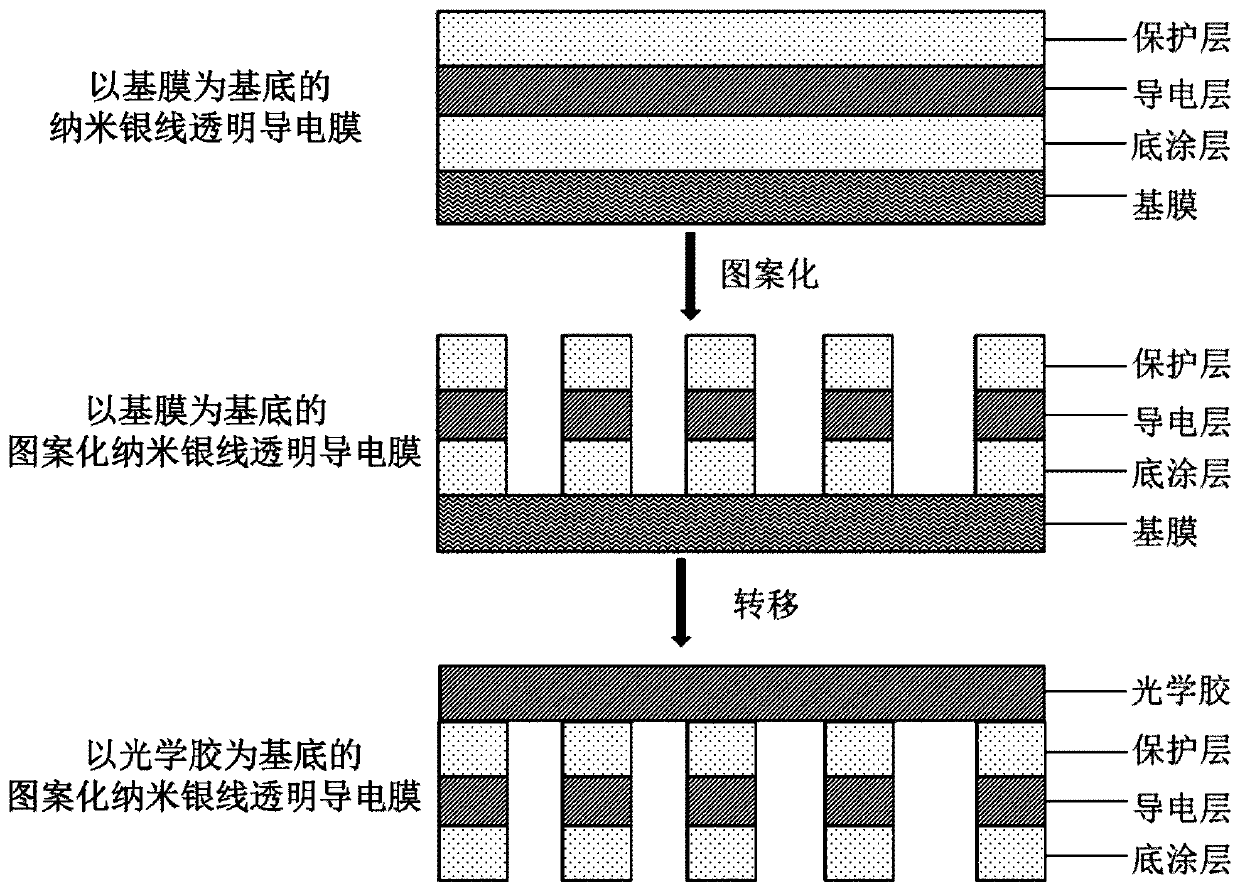

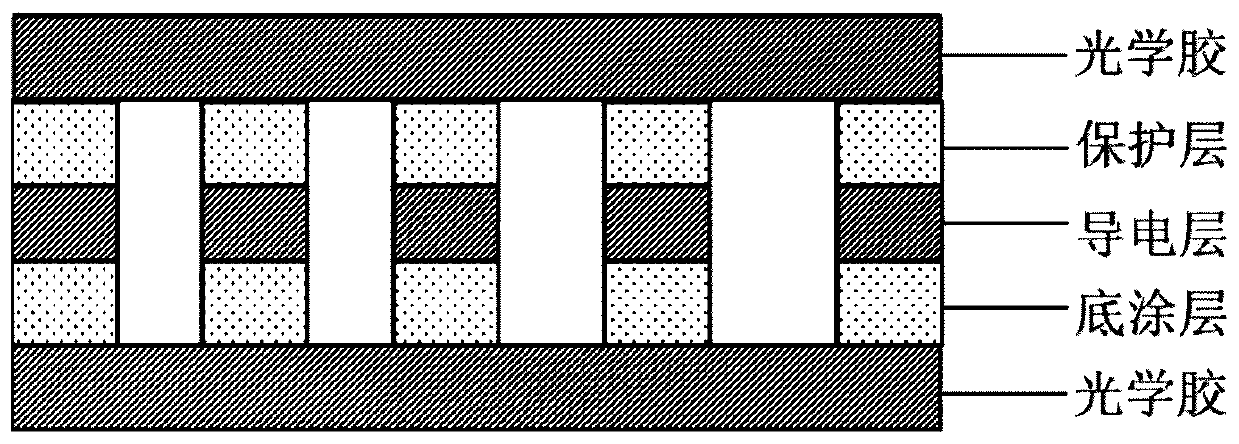

Manufacturing method of nano silver wire transparent conductive film with customizable patterns

ActiveCN110970173AAchieve patterningSimple processApparatus for manufacturing conducting/semi-conducting layersNanowireAdhesive

The invention discloses a manufacturing method of a nano silver wire transparent conductive film with customizable patterns. Patterning of a nano silver nanowire transparent conductive film is realized by utilizing the change of stripping force between coating liquid with a UV irradiation viscosity reduction function and a base film before and after UV irradiation and combining an adhesive suitable for the nano silver nanowire conductive film and a flexible transparent optical adhesive, and the patterned nano silver nanowire transparent conductive film taking the flexible transparent optical adhesive as a substrate is obtained. The process is simple, the product yield is higher, and the obtained conductive film has better optical performance and flexibility.

Owner:合肥微晶材料科技有限公司

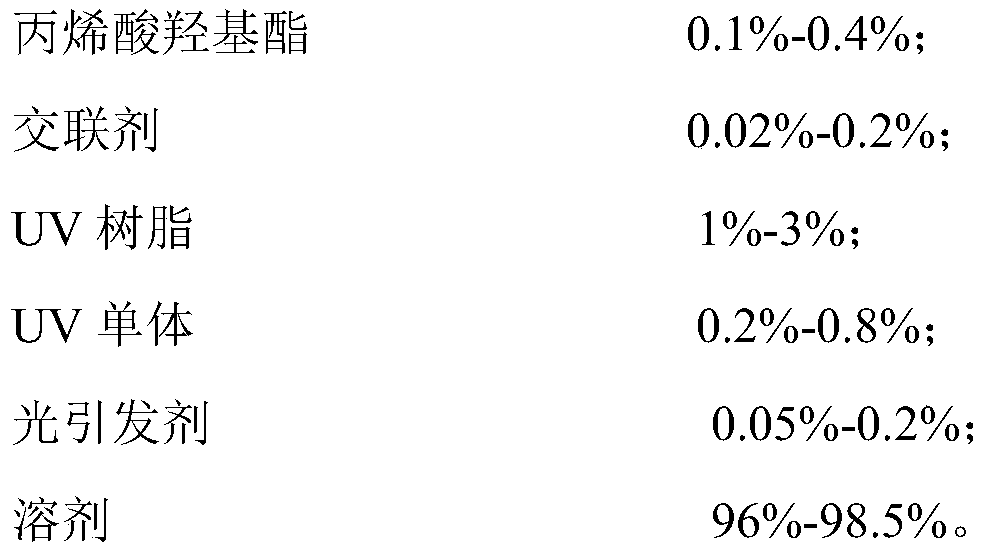

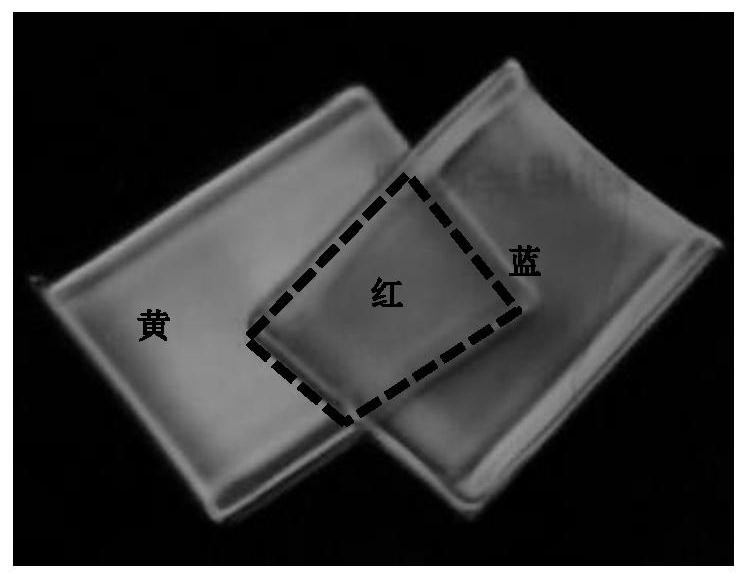

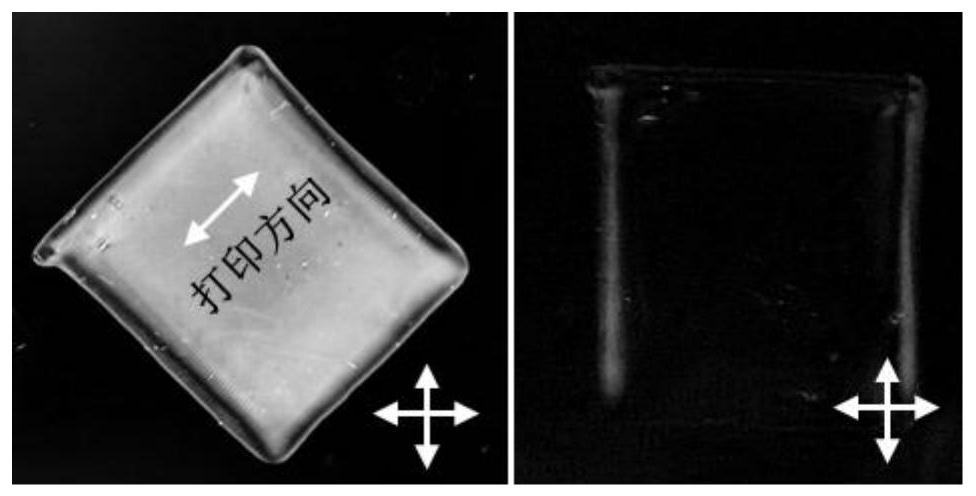

Preparation method and application of nanocellulose polymer optical composite hydrogel

The invention discloses a preparation method and application of nanocellulose polymer optical composite hydrogel. Nanocellulose is arranged in a parallel orientation mode, the ordered arrangement structure of the nanocellulose is fixed by initiating macromolecule cross-linking, and the optical composite hydrogel which shows uniform interference color under an orthogonal polaroid is successfully prepared and the color of the optical composite hydrogel is fixed. The brightness difference or color difference is changed by changing the orientation direction of the nanocellulose, the concentration of the nanocellulose, the material thickness and other factors to form optical materials with different patterns, and the optical materials have the stimulation responsiveness of soft materials at the same time and have wide application prospects in the aspects of anti-counterfeiting, information storage, sensing and the like.

Owner:广东省科学院生物与医学工程研究所

Semiconductor device, manufacturing method thereof and electronic device

ActiveCN105084300ARealize functionImprove yieldTelevision system detailsImpedence networksConductive materialsInterconnection

The invention relates to a semiconductor device, a manufacturing method thereof and an electronic device. The method comprises the following steps: S1, providing a substrate, wherein a component, a metal interconnection structure and a dielectric layer are formed in sequence on the substrate; S2, patterning the dielectric layer in order to form an opening for exposing the metal interconnection structure; S3, depositing a metal bonding layer in order to partially fill the opening while covering the dielectric layer; S4, forming an etching stop layer on the metal bonding layer in order to cover the metal bonding layer; S5, depositing a conductive material layer in order to fill the opening and cover the etching stop layer; S6, etching the conductive material layer back onto the etching stop layer in order to form a contact plug; and S7, patterning the etching stop layer and the metal bonding layer in order to form a second opening for exposing the dielectric layer. Through adoption of the semiconductor device, the manufacturing method thereof and the electronic device, damage to the metal bonding layer is avoided, and patterning can be realized smoothly in a subsequent process.

Owner:SEMICON MFG INT (SHANGHAI) CORP

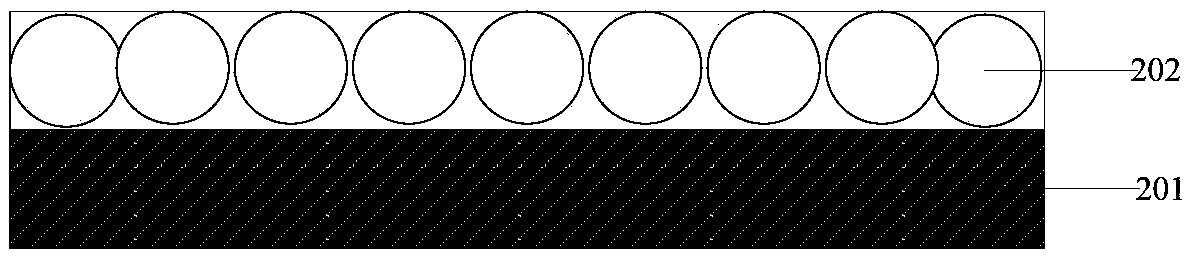

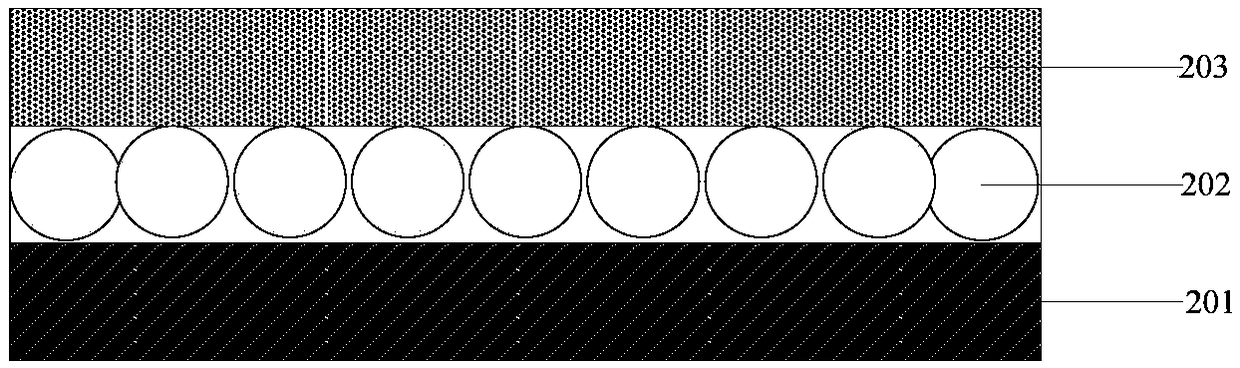

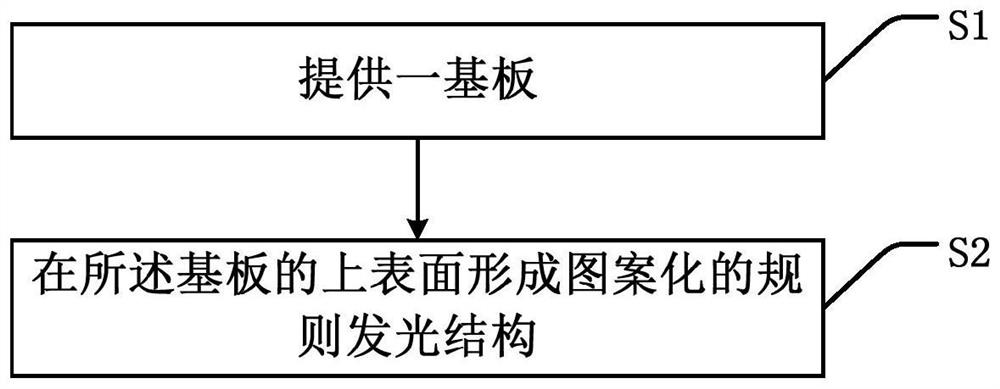

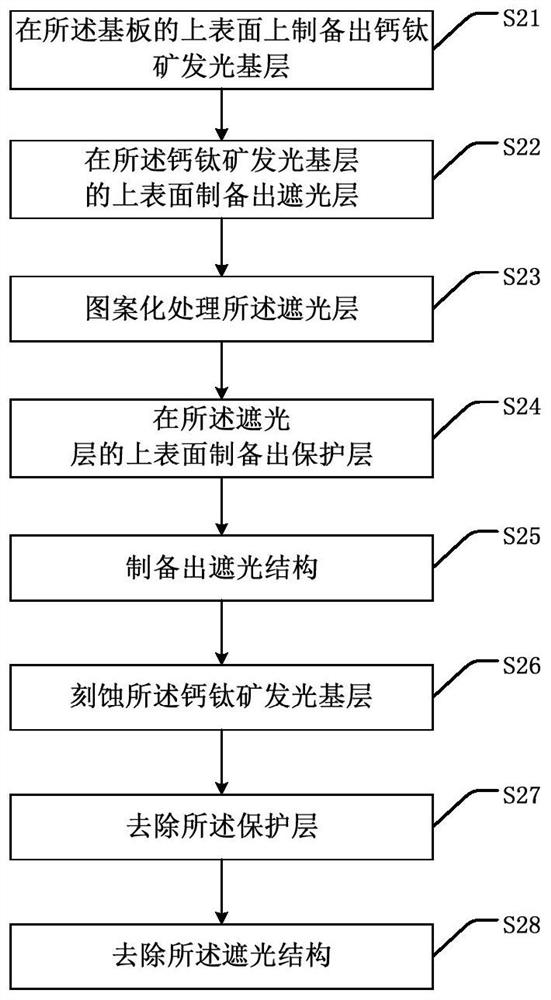

Perovskite light-emitting film layer, preparation method thereof and display panel

ActiveCN112002816APrecise patterningAchieving spontaneous patterningSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsPerovskite (structure)

The invention discloses a perovskite light-emitting film layer, a preparation method thereof and a display panel. The perovskite light-emitting film layer comprises a substrate and a perovskite film layer. The preparation method of the perovskite light-emitting film layer comprises the steps of providing the substrate and forming a patterned regular light-emitting structure on the upper surface ofthe substrate. The method has the technical effects that the spontaneous patterning of the block copolymer film layer is realized through the induction treatment of the block copolymer; and on the basis, the patterning of the perovskite film layer is realized, and the precise patterning of the perovskite film layer is realized.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

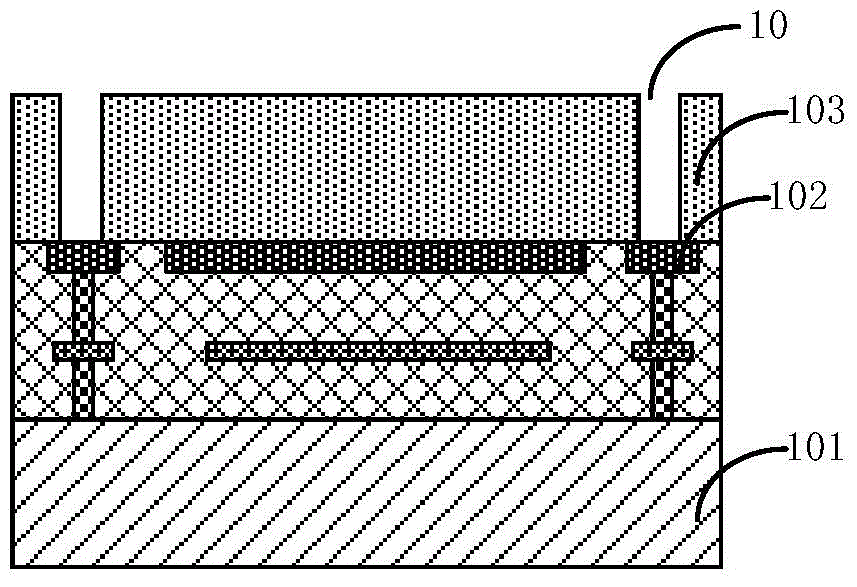

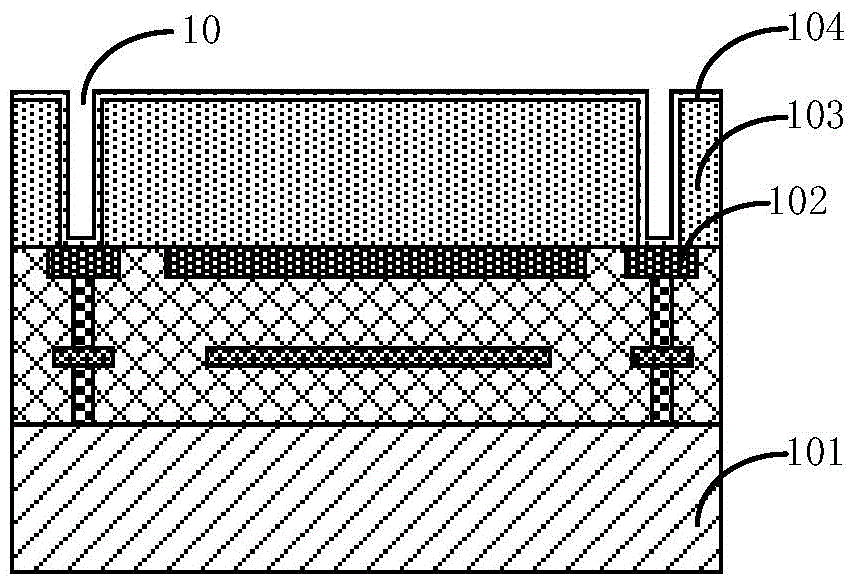

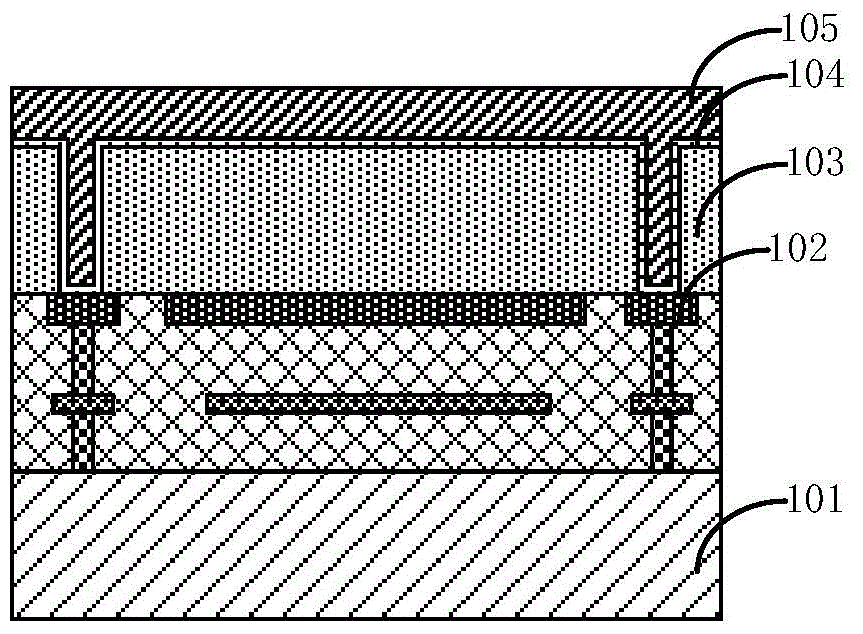

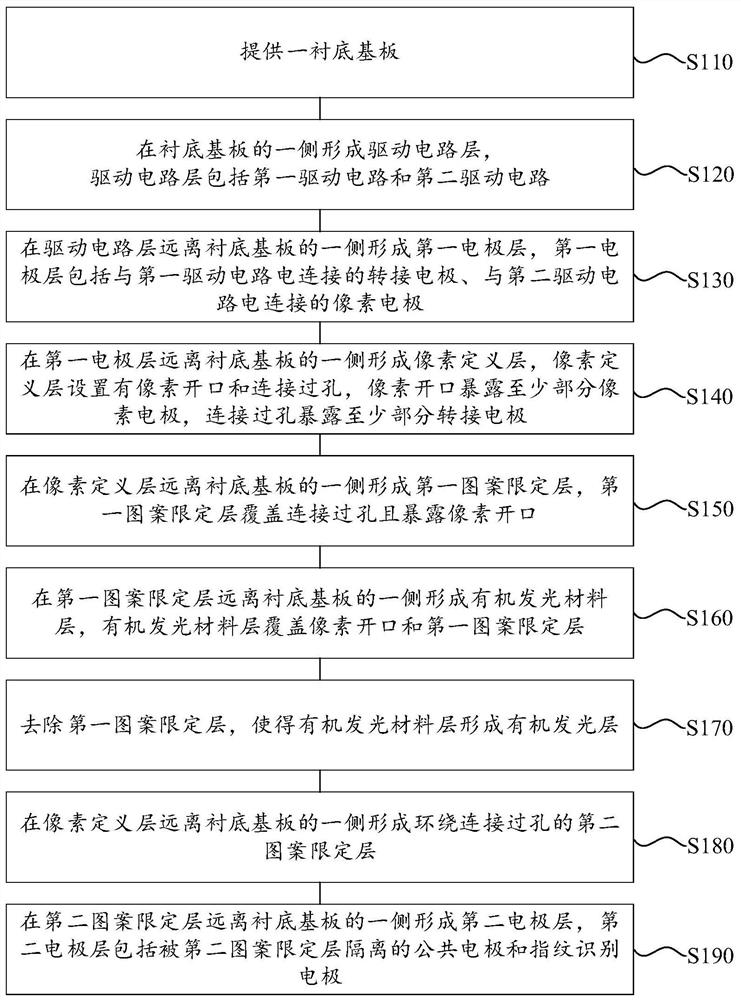

Array substrate and preparation method thereof

ActiveCN111640773AAchieve patterningOvercome the defect that self-capacitive fingerprint recognition cannot be realizedSolid-state devicesSemiconductor/solid-state device manufacturingHemt circuitsLuminescent material

The invention provides an array substrate and a preparation method thereof, and belongs to the technical field of display. The preparation method of the array substrate comprises the steps of: forminga driving circuit layer, a first electrode layer, a pixel defining layer, a first pattern definition layer and an organic light-emitting material layer sequentially on one side of a substrate, wherein the driving circuit layer comprises a first driving circuit and a second driving circuit, the first electrode layer comprises an adapter electrode electrically connected to the first driving circuitand a pixel electrode electrically connected to the second driving circuit, the pixel defining layer is provided with a connecting via hole, the connecting via hole exposes at least part of the adapter electrode, and the first pattern definition layer covers the connecting via hole; removing the first pattern definition layer to form a second pattern definition layer and a second electrode layersequentially, and making the second pattern definition layer surround the connecting via hole, wherein the second electrode layer comprises a common electrode and a fingerprint recognition electrode which are isolated. According to the preparation method of the array substrate, a self-capacitive fingerprint sensor is embedded into an OLED display panel.

Owner:BOE TECH GRP CO LTD

Preparation method of nanoscale micro structure

ActiveCN105336566AEasy to prepareImprove efficiencyNanoinformaticsVacuum evaporation coatingComposite structureMask layer

The invention relates to a preparation method of a nanoscale micro structure. The preparation method comprises includes the following steps that: a carbon nanotube structure is provided, wherein the carbon nanotube structure includes a plurality of orderly-arranged carbon nanotubes; the carbon nanotube structure is suspended, and a prefabricated layer is arranged on the surface of the carbon nanotube structure, and the thickness of the prefabricated layer on the surface of each carbon nanotube ranges from 3 nanometers to 50 nanometers, and therefore, a carbon nanotube composite structure can be formed; the carbon nanotube composite structure is arranged on the surface of a substrate so as to form a mask layer, and a plurality of micropores are formed in the mask layer, and a part of the surface of the substrate is exposed; and the substrate is subjected to dry etching, so that a micro structure can be formed on the surface of the substrate.

Owner:TSINGHUA UNIV +1

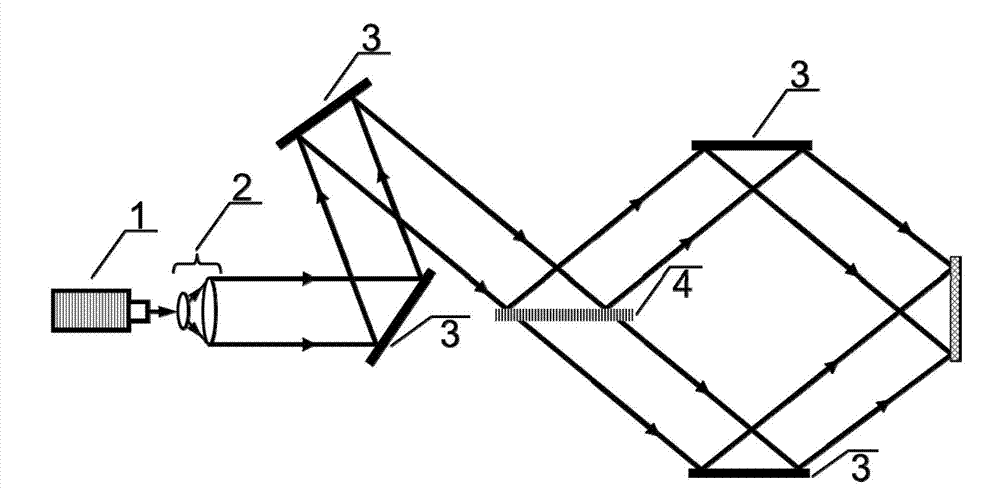

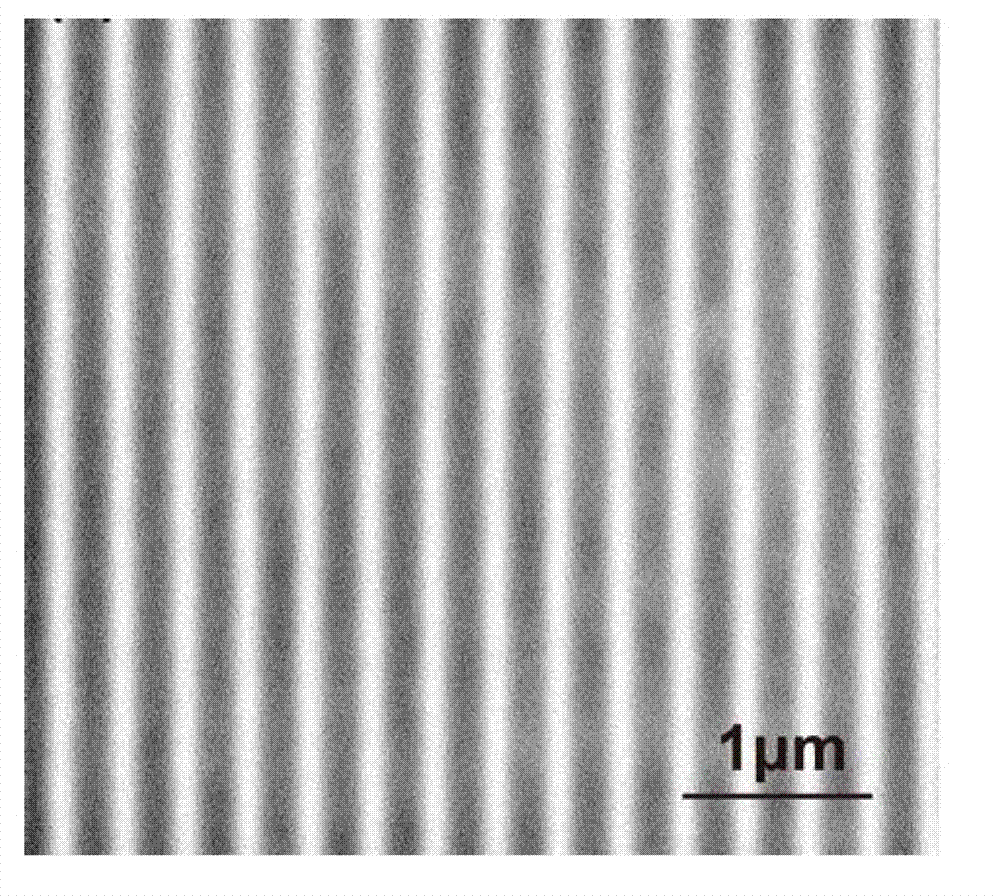

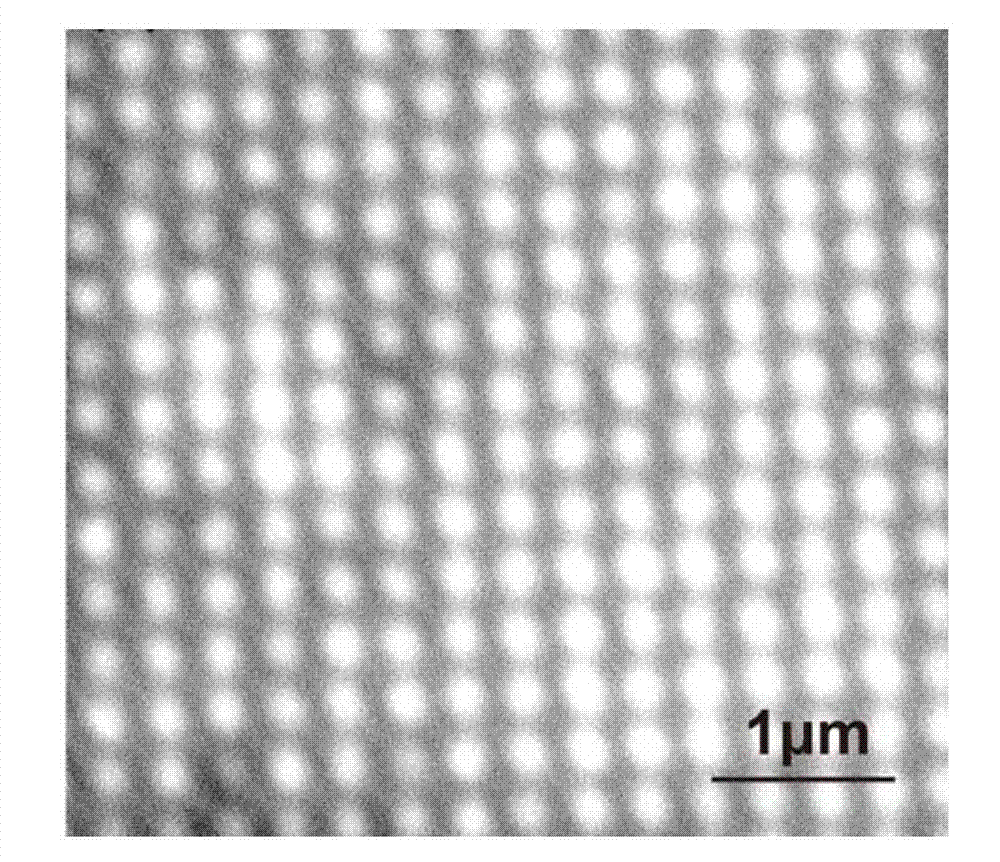

Production method of metal micro-nano structure based on laser interference induced cross-linking reaction

ActiveCN103204460ALow costGood repeatabilityDecorative surface effectsChemical vapor deposition coatingSurface reliefOptoelectronic materials

The invention discloses a production method of a metal micro-nano structure based on laser interference induced cross-linking reaction and belongs to the technical field of optoelectronic materials and devices. The production technique includes: subjecting polymers to cross-linking reaction through organic semiconductor polymer material coated with a metal film by laser irradiation, forming a surface relief structure, and texturizing the attached metal film. The production method has the advantages of low cost, high efficiency, capability of producing large-area metal structures with plasma resonance spectral response, and the like.

Owner:BEIJING UNIV OF TECH

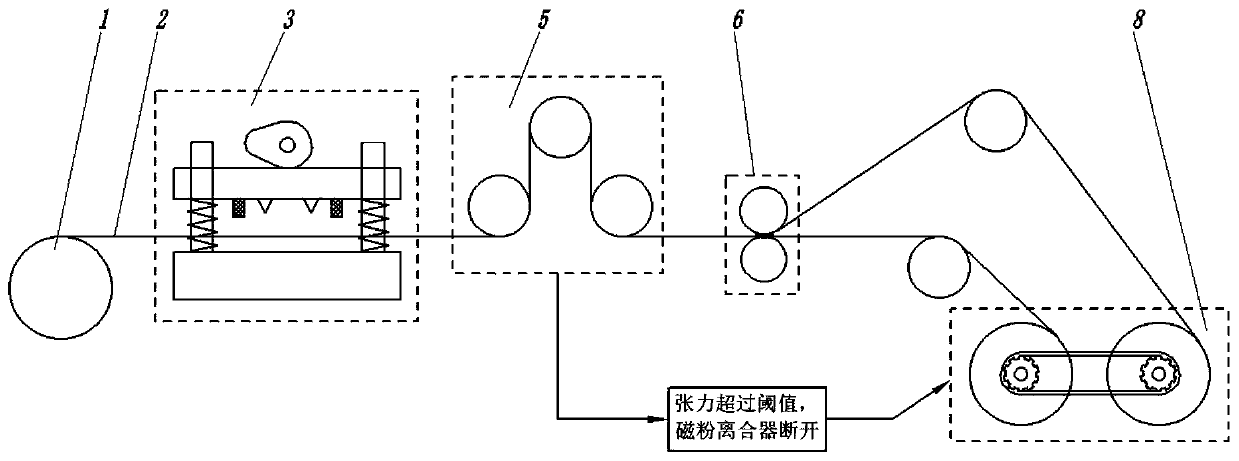

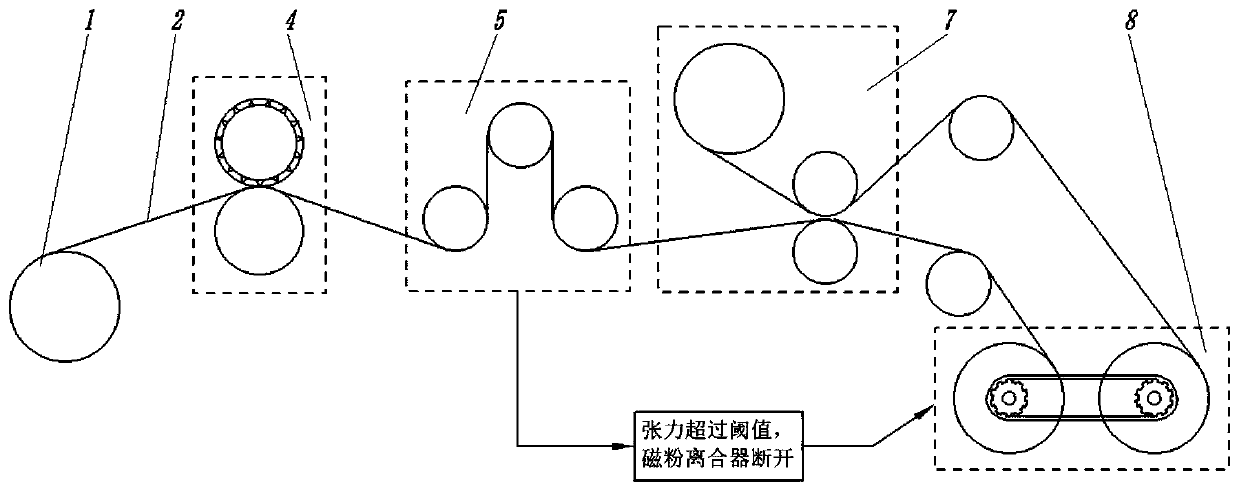

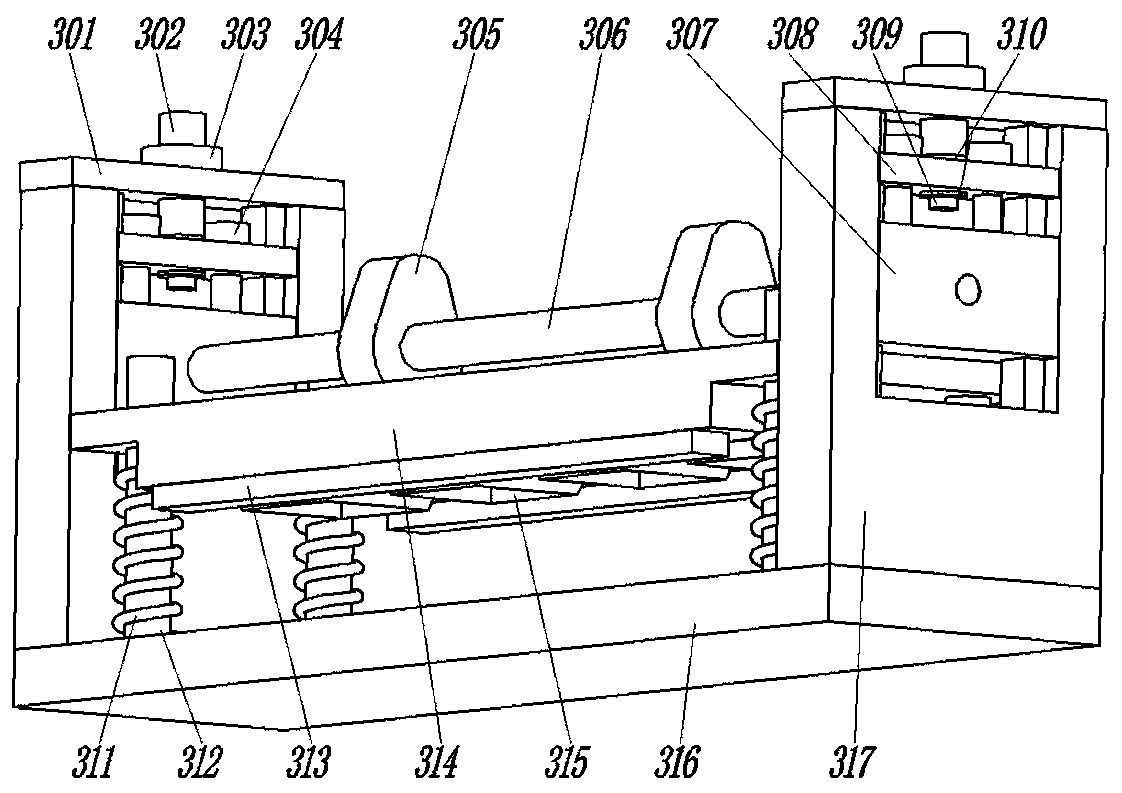

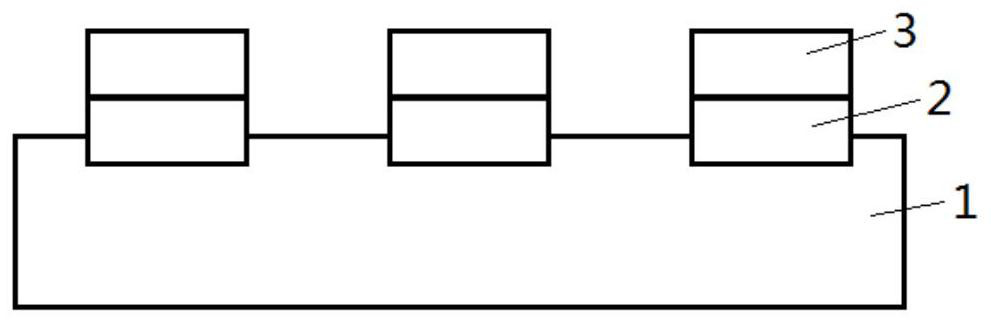

Roll-to-roll patterning equipment based on die cutting

ActiveCN111498558ALow costImprove efficiencyMetal working apparatusArticle deliveryWaste productStructural engineering

The invention belongs to the technical field related to ductile circuit manufacturing, and discloses roll-to-roll patterning equipment based on die cutting. The equipment comprises an unwinding roller, a flexible belt, a die cutting mechanism, a tension detection mechanism, a stripping mechanism and a winding mechanism, wherein the unwinding roller, the die cutting mechanism, the tension detectionmechanism, the stripping mechanism and the winding mechanism are sequentially arranged at intervals; one end of the flexible belt is accommodated in the unwinding roller, and the other end of the flexible belt sequentially penetrates through the die cutting mechanism, the tension detection mechanism and the stripping mechanism to be connected to the winding mechanism; the die cutting machine is used for patterning the flexible belt; the tension detection mechanism is used for carrying out tension detection on the flexible belt and feeding back the detection results to the winding mechanism; the stripping mechanism is used for stripping the patterned flexible belt; and the winding mechanism is used for collecting a stripped finished product roll and a stripped waste product roll and adjusting the flexible belt according to the detection results, so that the tension of the flexible belt is made to be within a preset range. According to the roll-to-roll patterning equipment based on thedie cutting, the production efficiency is improved, and the cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

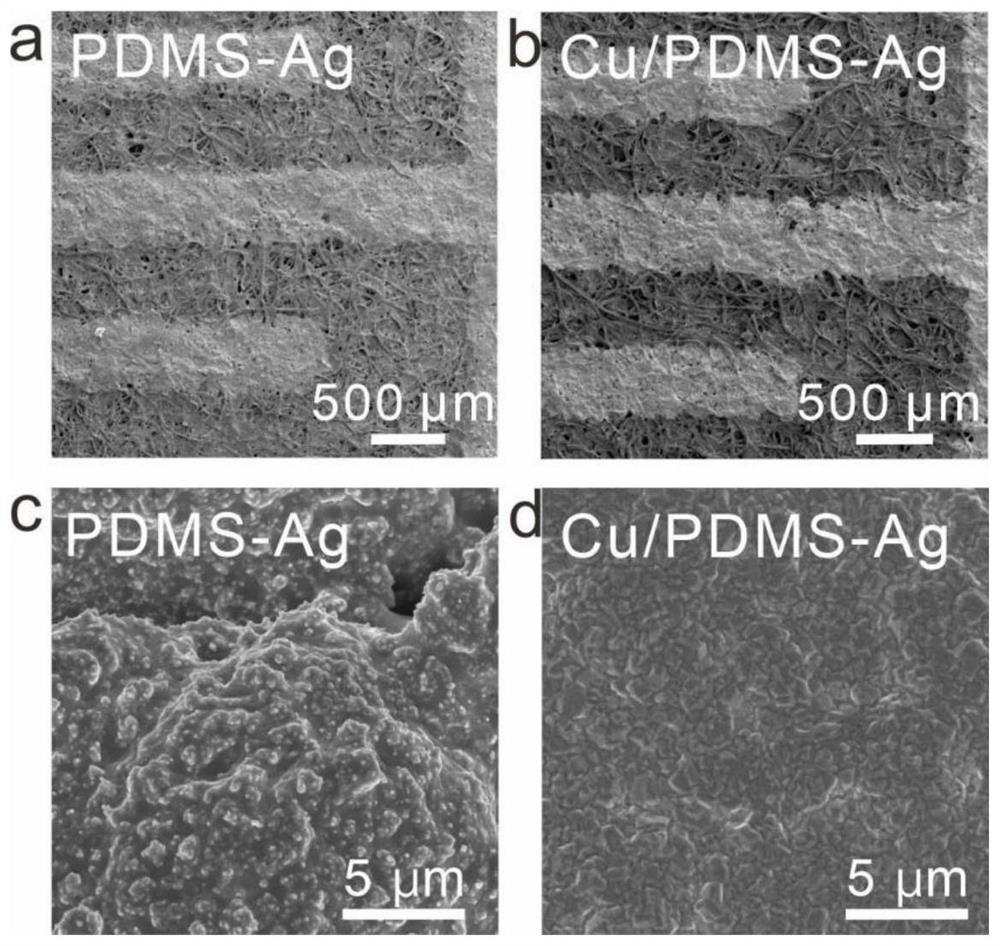

Flexible conductive metal pattern, preparation method and application of flexible conductive metal pattern, and conductive material

ActiveCN113035448AImprove adhesionImprove conductivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersSolution treatmentChemical plating

The invention belongs to the technical field of electronic device preparation, and provides a flexible conductive metal pattern, a preparation method and application of the flexible conductive metal pattern, and a conductive material. The preparation method of the conductive metal pattern comprises the following steps: mixing metal nanopowder having been subjected to or not subjected to surface silanization treatment, a polydimethylsiloxane prepolymer and a curing agent with or not with a first solvent to obtain ink; printing the ink on a flexible substrate, and curing the flexible substrate to obtain a printed substrate; and immersing the printed substrate into a second solvent which is mutually soluble with water and can swell ink for swelling treatment, then transferring the substrate into a metal salt solution to realize metallization of the pattern via a chemical plating process, and then conducting drying to obtain the conductive metal pattern. The preparation method provided by the invention is simple in process and low in cost, a printing and solution treatment method compatible with an industrial preparation method is adopted, and the prepared flexible conductive metal pattern is high in binding force with a substrate, high in conductivity and high in printing precision.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

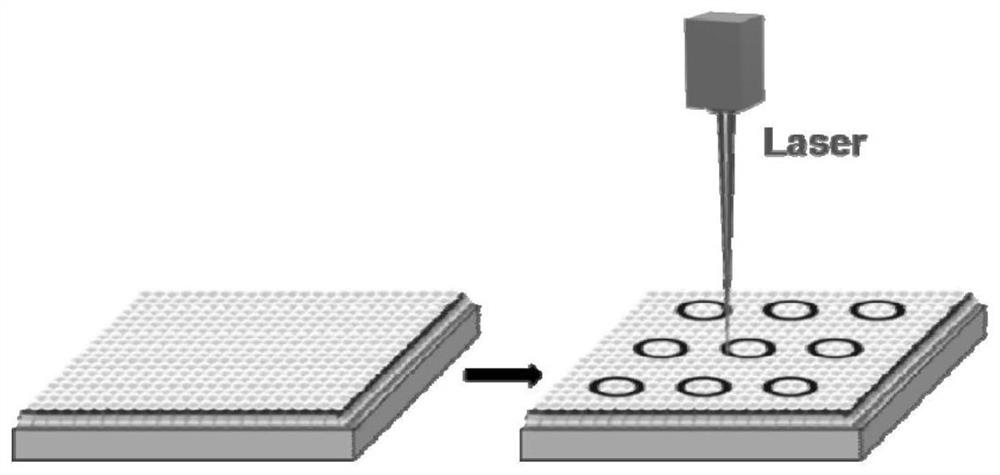

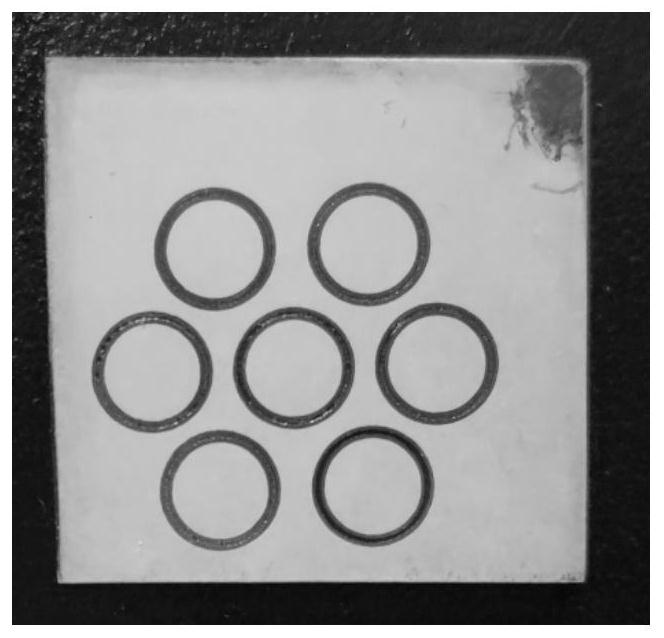

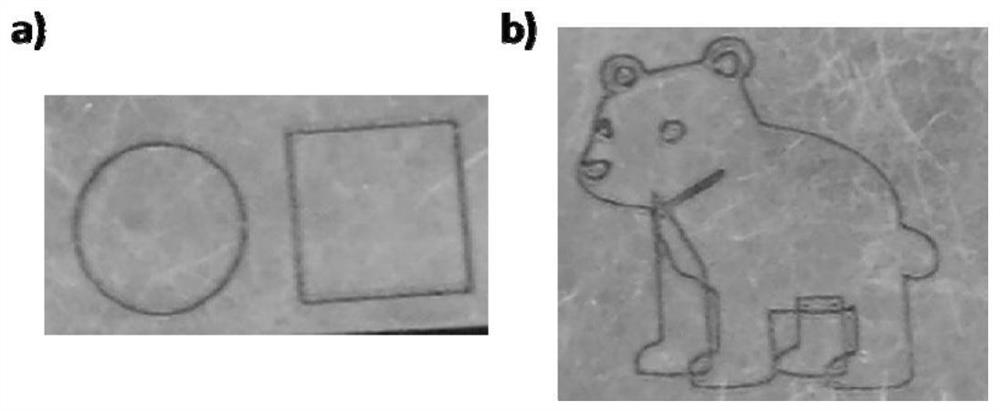

Method for rapidly preparing colloidal photonic crystal array chip by utilizing laser direct writing

InactiveCN111929991ARealize array preparationAchieve patterningPolycrystalline material growthAfter-treatment detailsPhotonic crystalPhysical chemistry

The invention belongs to the technical field of preparation and application of patterned colloidal photonic crystals, and particularly relates to a method for rapidly preparing a colloidal photonic crystal array by utilizing laser direct writing. The method comprises the steps of carrying out modification treatment on the surface of a substrate material so as to enable the surface of the substrateto have super-hydrophilicity or super-hydrophobicity; preparing a colloidal photonic crystal film on the substrate; and placing the substrate with the colloidal photonic crystal film deposited on thesurface under a laser, etching a pre-designed pattern, and cooling at the room temperature. According to the invention, the laser direct writing method is used for preparing the colloidal photonic crystal array chip for the first time, and the preparation method is easy to operate, extremely short in consumed time and wide in application range. The invention provides a feasible new method for rapid and accurate patterned surface preparation in the field of material science by combining the advantages of a rapid and efficient laser direct writing technology and the characteristic that the physical and chemical properties of a polymer photonic crystal material are changed when the polymer photonic crystal material is heated.

Owner:DALIAN UNIV OF TECH

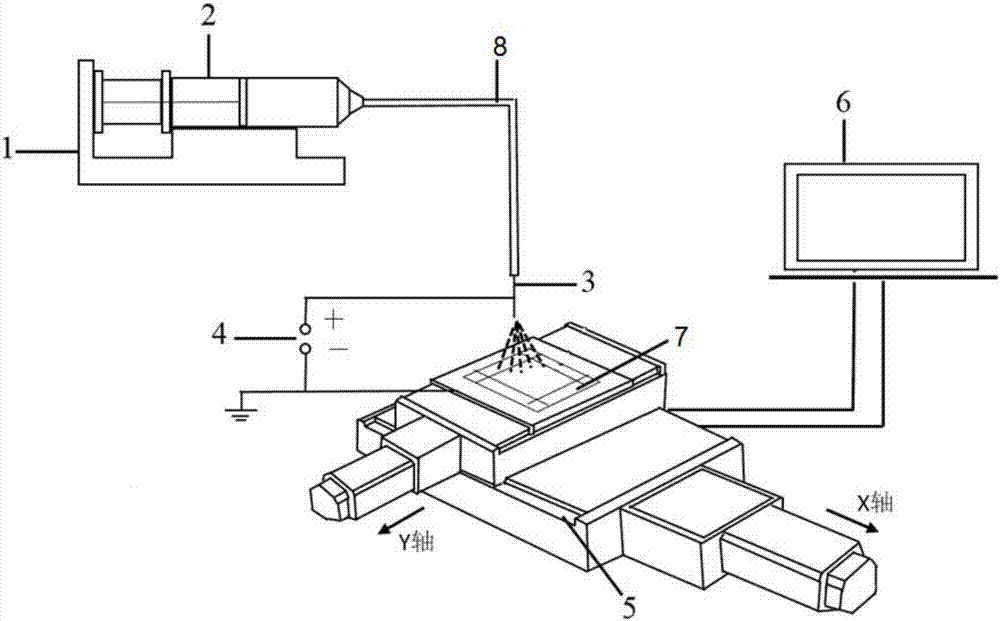

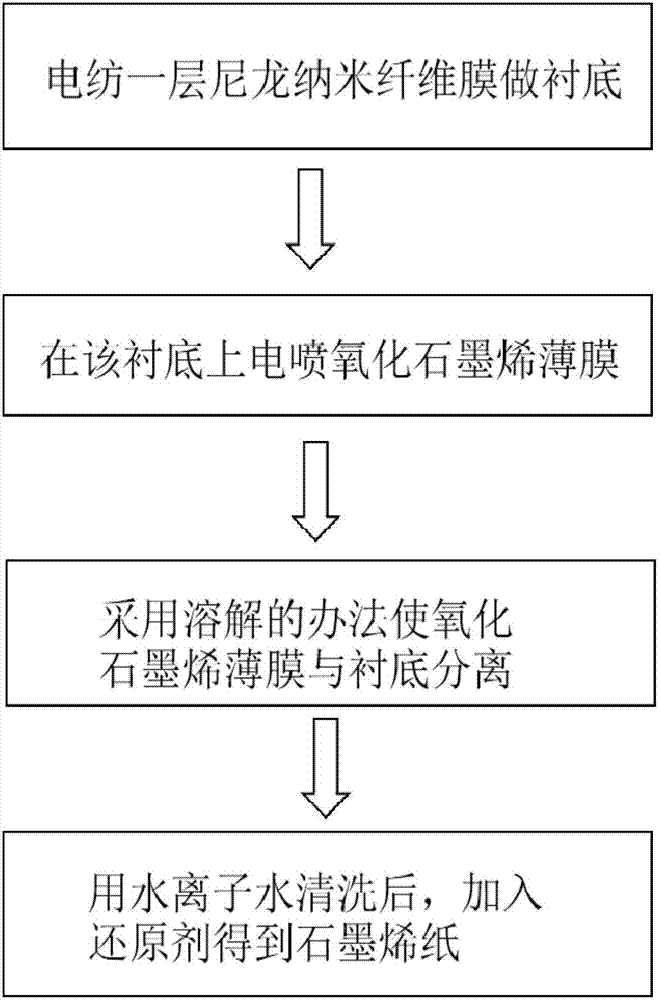

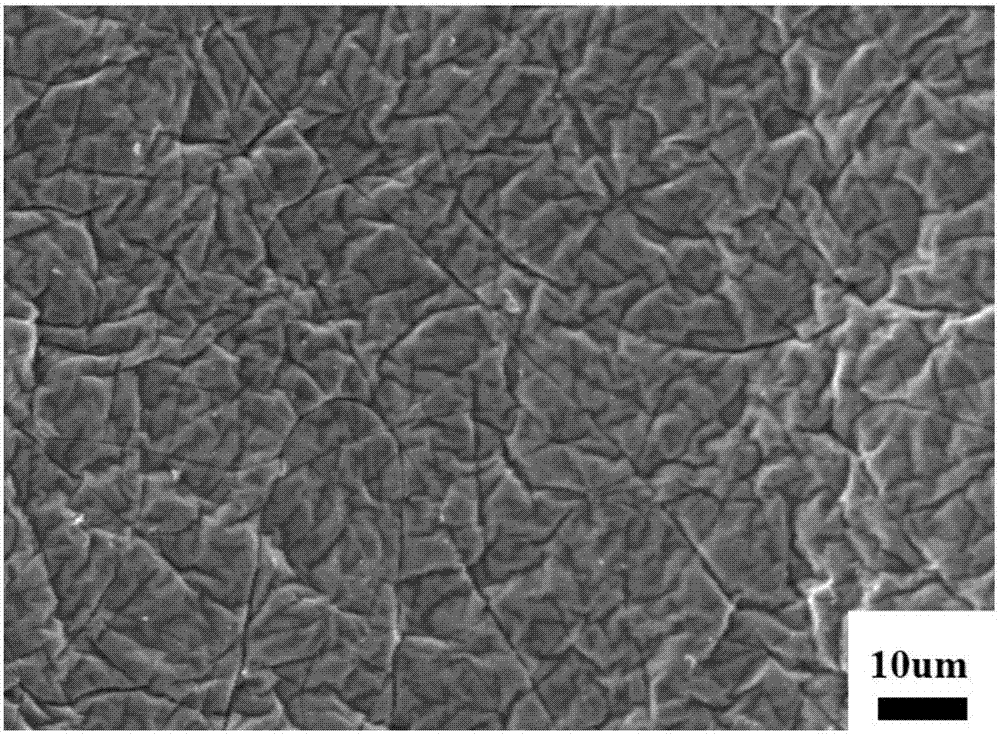

Preparation method of graphene paper

The invention discloses a preparation method of graphene paper. The preparation method includes following steps: (1), electrospinning a nanofiber membrane substrate; (2), electrospraying to a composite graphene oxide thin film; (3), removing a substrate; (4), reducing graphene oxide. Compared with existing methods, the preparation method has the advantages that the preparation method is simpler to operate and low in cost, the graphene paper prepared by the method is uniform in thickness, has good electrochemical performance and easy to separate from a substrate material, large-area graphene paper can be prepared by the method, patterning of the graphene paper can be realized directly in the process of preparation, and application field of materials is expanded.

Owner:QINGDAO UNIV

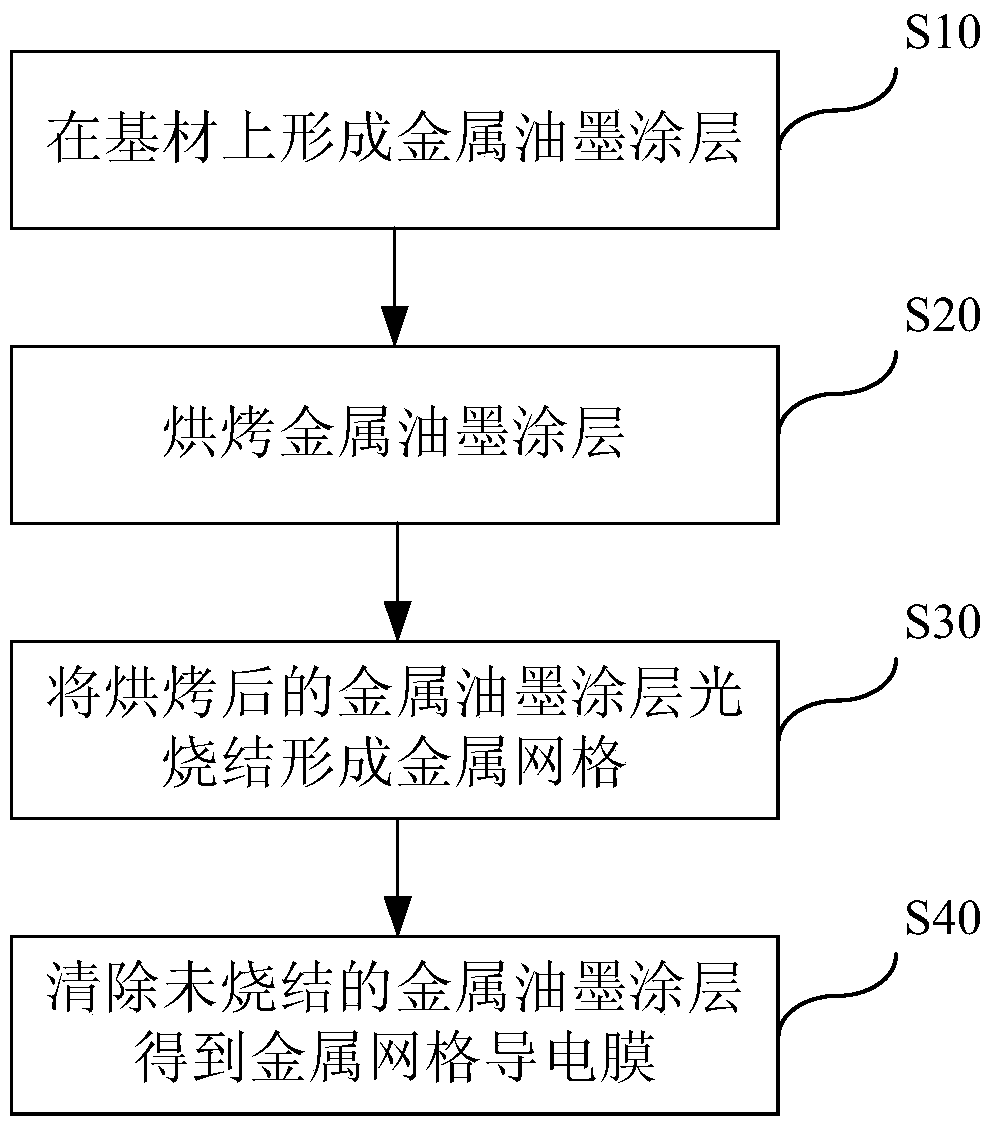

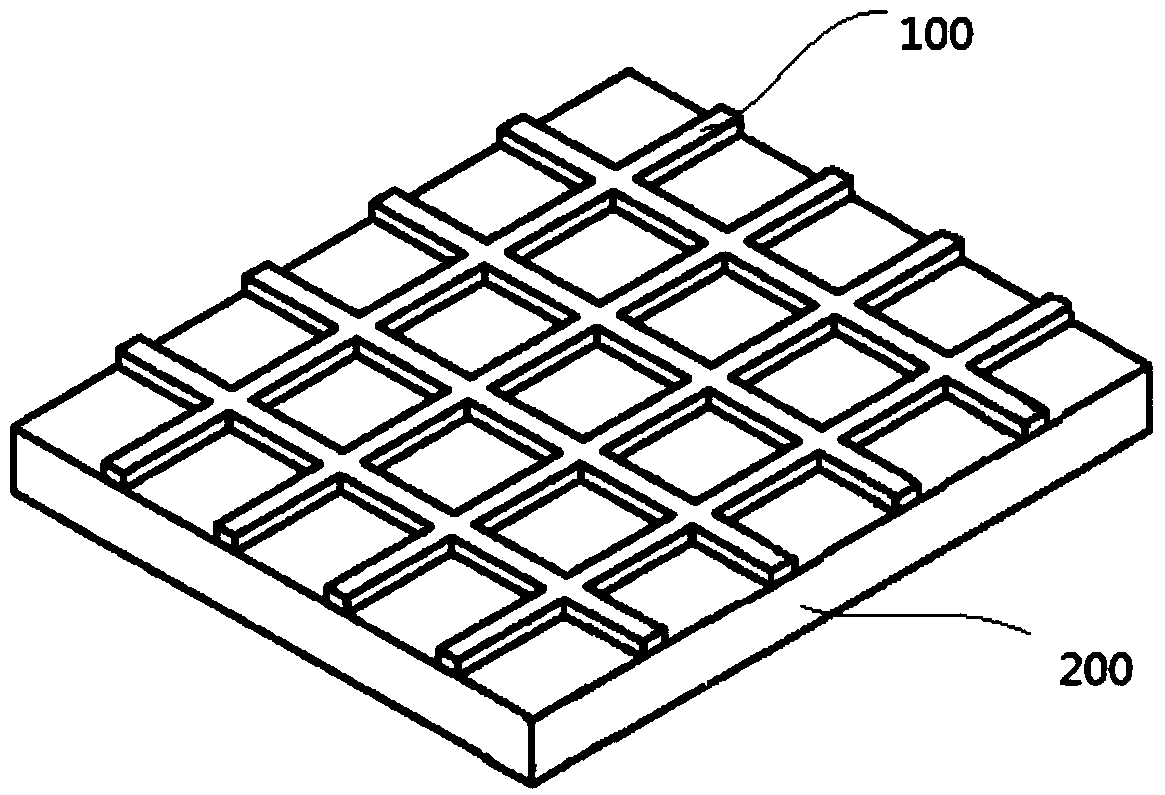

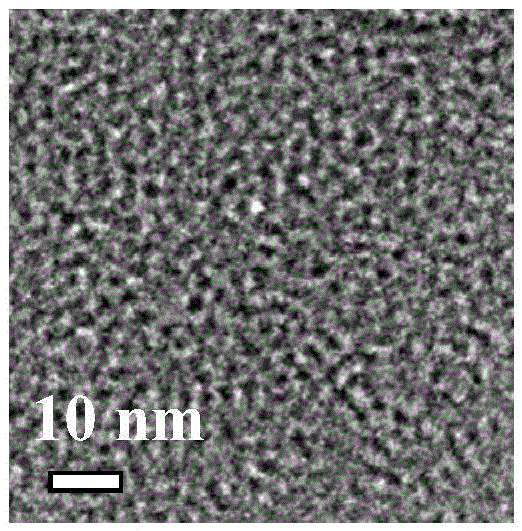

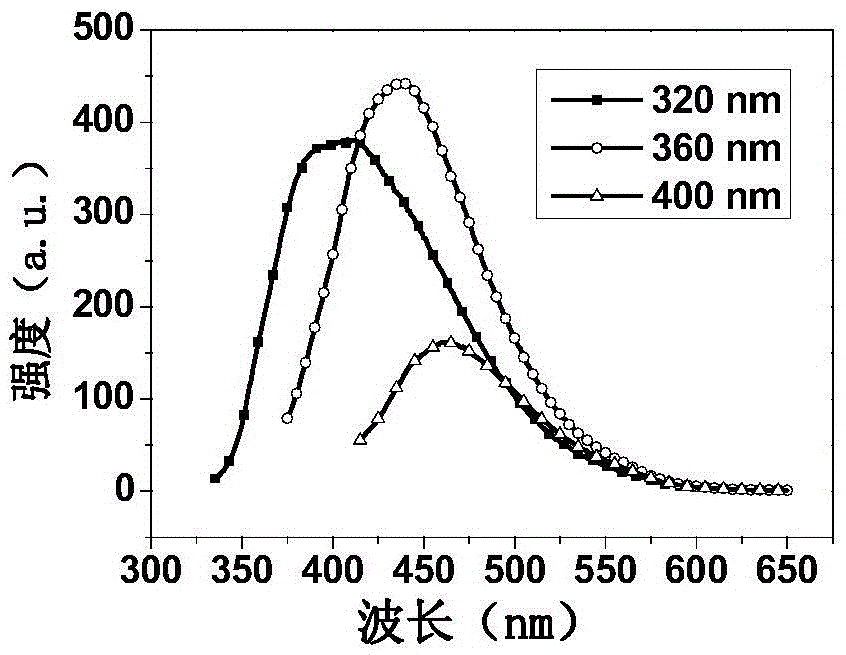

Manufacturing method of metal grid conductive film, metal grid conductive film and touch panel

ActiveCN104750311BAchieve patterningImprove adhesionInput/output processes for data processingCooking & bakingTouch panel

Owner:SHENZHEN SUCCESS ELECTRONICS LTD

A kind of preparation method of carbon dots/chitosan in situ composite material

InactiveCN104356430BWide range of follow-up applicationsEasy to manufactureElectrolytic inorganic material coatingLuminescent compositionsComposite filmFluorescent light

The invention provides a preparation method of a carbon dot / chitosan in-situ composite material. The carbon dot / chitosan in-situ composite material is prepared by an in-situ method. The method comprises the following steps: carrying out microwave treatment on a chitosan solution to obtain a carbon dot / chitosan in-situ complex, and preparing the carbon dot / chitosan in-situ complex into the carbon dot / chitosan in-situ composite material. According to the method, a carbon dot / chitosan in-situ composite film material is prepared by a casting and film-forming method, and a carbon dot / chitosan composite coating material is prepared by a controllable electro-deposition method. The preparation method of the carbon dot / chitosan in-situ composite material has the advantages of being simple, convenient to operate, mild in preparation conditions and easy to control; equipment used by the method is simple and convenient, has energy conservation and environment protection effects, and is low in cost; the carbon dot / chitosan composite film material has good application prospects in the fields of fluorescent biological film materials, optical film materials, biological detectors and fluorescent light-emitting materials. The carbon dot / chitosan composite coating material has good application prospects in the fields of surface decoration and surface patterning of metal biological materials, biological electrodes, biological chips and biological devices.

Owner:WUHAN UNIV OF TECH

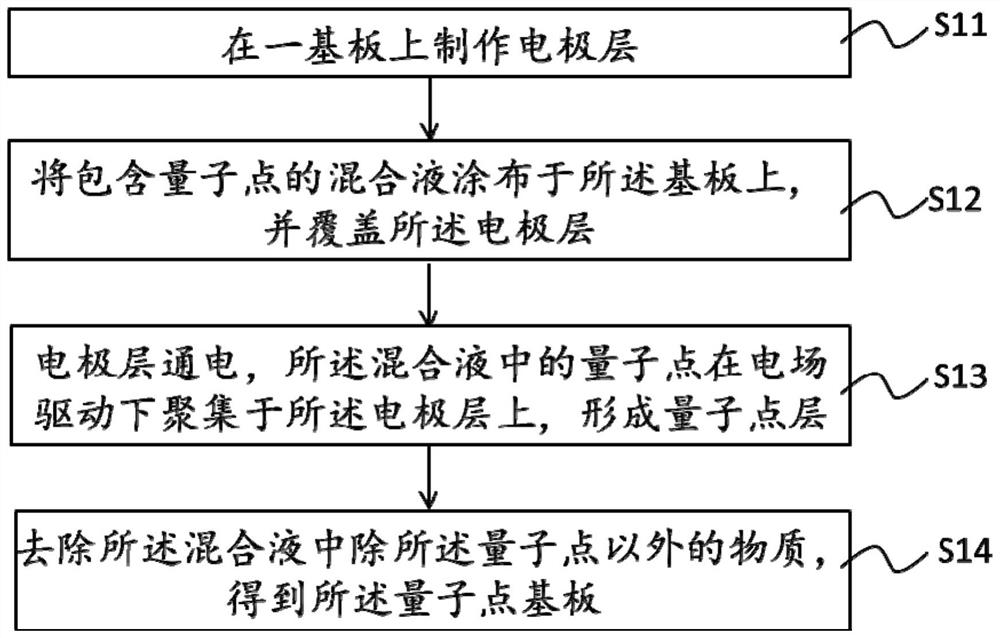

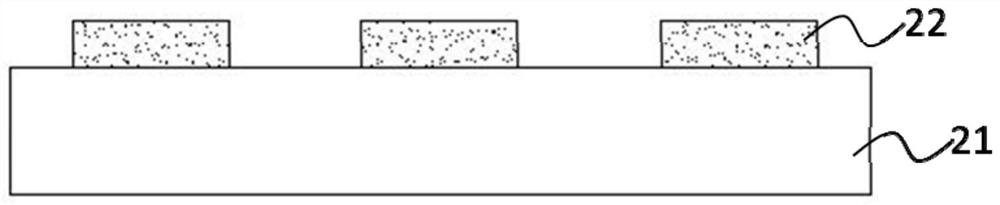

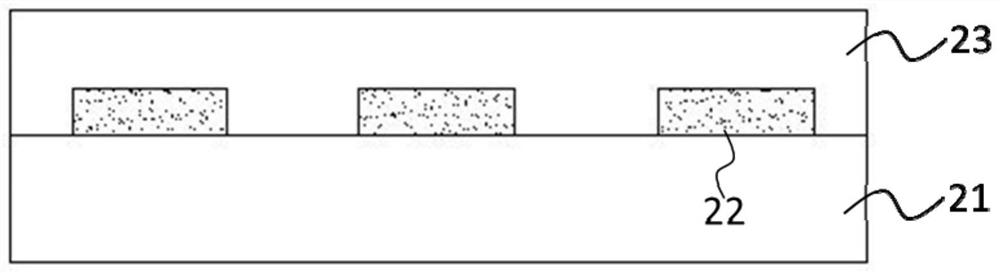

Manufacturing method of quantum dot substrate

ActiveCN112820190AAchieve patterningSimple manufacturing processFinal product manufactureIdentification meansManufacturing cost reductionQuantum dot

The invention provides a manufacturing method of a quantum dot substrate. The manufacturing method comprises the following steps: manufacturing an electrode layer on a substrate; coating the substrate with a mixed solution containing quantum dots, and covering the electrode layer; electrifying the electrode layer, wherein the quantum dots in the mixed solution are gathered on the electrode layer under the driving of an electric field, and a quantum dot layer is formed; removing substances except the quantum dots in the mixed solution, and obtaining the quantum dot substrate. The electric field generated after the electrode layer is electrified is utilized to drive the quantum dot material to directionally deposit, so that patterning of the quantum dot layer is realized, the manufacturing process of the quantum dot substrate is simplified, the utilization rate of the quantum dot material is improved, and the manufacturing cost is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

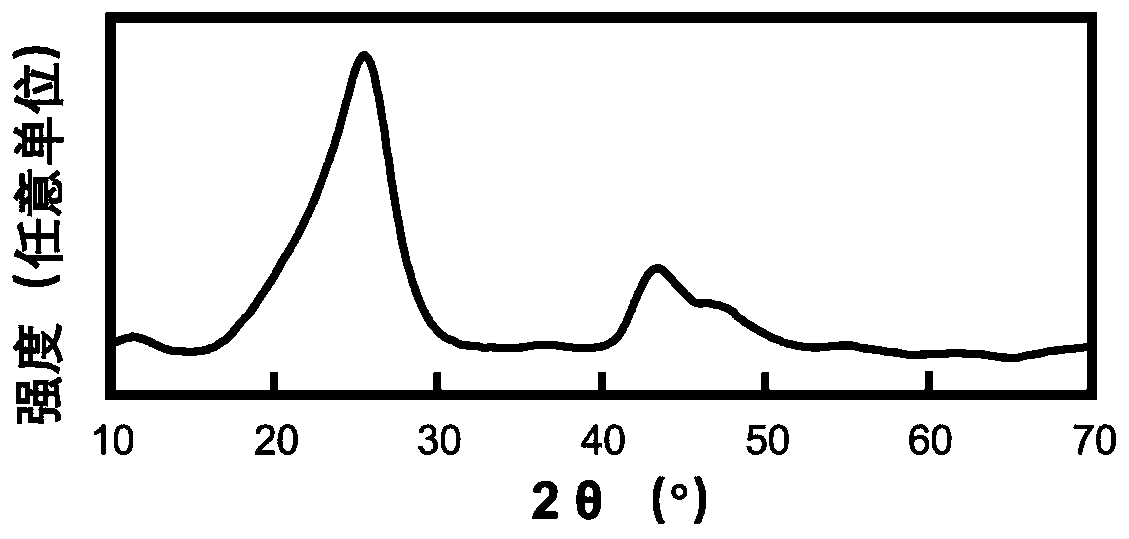

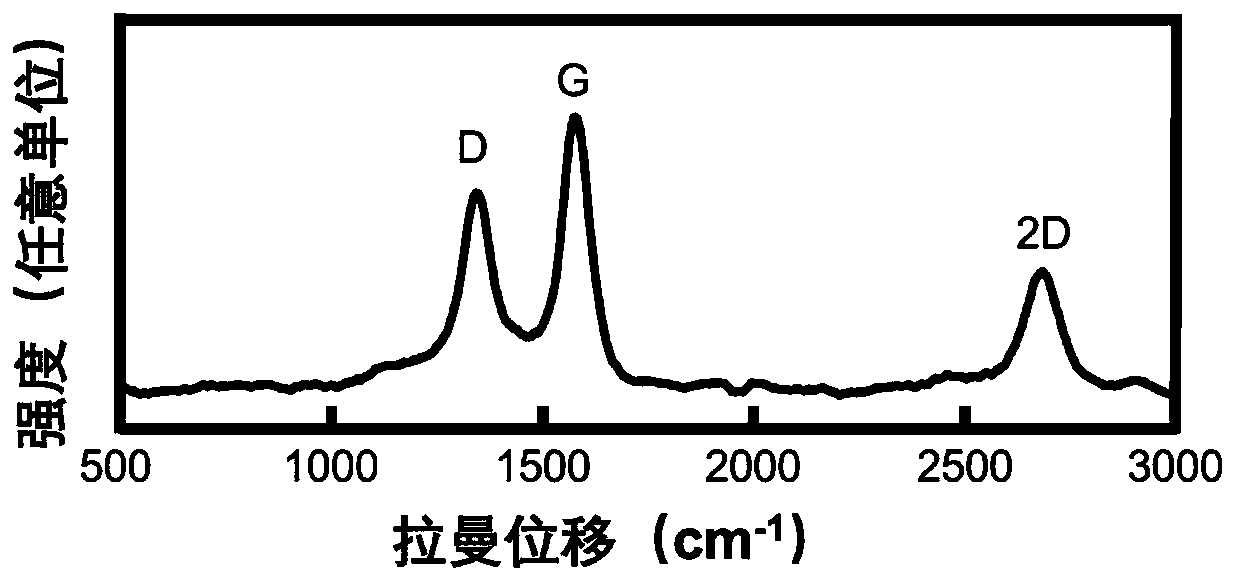

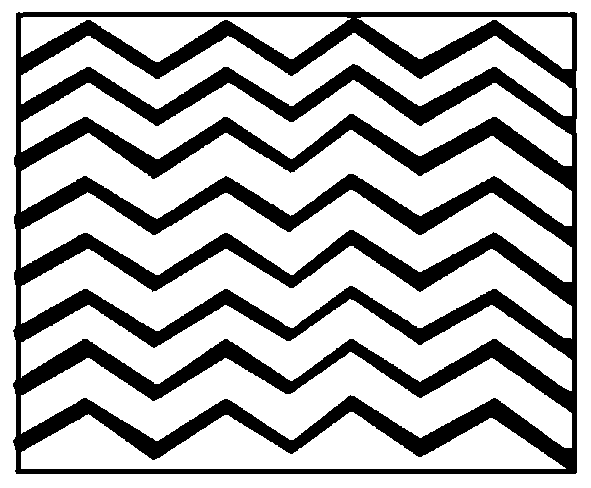

Adjustable laser-induced graphene paper heater and application thereof

ActiveCN111432507AWide heating temperature rangeImprove heating efficiencyHeating fuelLighting and heating apparatusEngineeringGraphite

The invention provides a laser-induced graphene paper heater and application thereof, and belongs to the technical field of heaters. The laser-induced graphene paper heater comprises a graphene paper,electrodes are pasted to the two ends of the graphene paper respectively, the joints of the electrodes and the graphene paper are coated with conductive silver paint, and the graphene paper is prepared by the laser-induced reduction of a polyimide paper. The graphene paper heater is larger in heating temperature range, high in heating efficiency and high in temperature rising speed. Furthermore,the patterned graphene paper is obtained by one-time processing through the laser digital customized design and manufacturing, so that the patterned graphene paper heater is convenient to further prepare; and the temperature region regulation and control can be realized by changing an equivalent circuit connection mode and a region area mode, so that the graphene paper heater can be applied to theaspects of wearable equipment, household heating, industrial heating equipment, thermosetting composite material low-energy-consumption curing molding and the like, and is wide in application prospect.

Owner:北京烯塔科技有限公司

A preparation method of patterned graphene flexible strain sensor

InactiveCN109163653BEasy to manufactureAchieve patterningElectrical/magnetic solid deformation measurementSilver pasteElastomer

The invention provides a preparation method of a patterned graphene flexible strain sensor. The method comprises the following steps: firstly, preparing a predetermined pattern on the surface of a hard substrate material by using photoetching to obtain a patterned mold, and then pouring mixed slurry of polymer material elastomer and a curing agent onto the surface of the patterned mold for curingto obtain a micro-channel mold; and then covering the surface of a flexible substrate with the micro-channel mold, performing patterned modification on the flexible substrate by using dopamine, preparing a graphene sensitive layer on the surface of the modified substrate, and finally coating conductive silver paste and bonding a conducting wire to obtain the patterned graphene flexible strain sensor. According to the preparation method provided by the invention, no photoetching needs to be performed on the flexible substrate, so that the main body structure of the flexible substrate is not damaged, the preparation method is suitable for complex curved surfaces, large-area manufacturing and fine pattern processing, and the requirements for the own material, the shape and the surface structure of the flexible substrate are reduced.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com