Method for preparing suspended graphene support film of Janus structure

A technology of graphene film and graphene film, which is applied in the field of materials, can solve the problems of pollutants, introduction of graphene surface, restrictions on wide application, etc., and achieve the effect of simple process, high integrity and wide range of contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1, preparation of Janus suspended graphene support film

[0074] figure 1 It is a process flow diagram of the present invention. A specific implementation process is as follows:

[0075] (1) Spot electrochemical polishing of copper foil: the electrolyte is phosphoric acid: ethylene glycol solution with a volume ratio of 3:1, the current is 0.3-1.0A, and the polishing time is 20-30min.

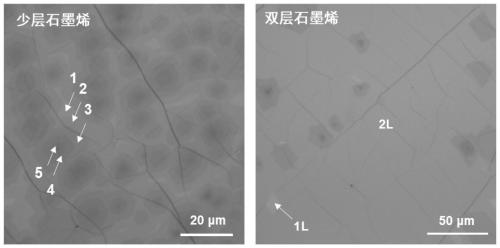

[0076] (2) Growth of graphene: heat up the copper foil substrate to 1030° C. and anneal in 100 sccm argon for 30 minutes, keep the pressure at about 100 Pa, and then reduce it with 100 sccm hydrogen for 10 minutes. Finally, the graphene is grown in an atmosphere of 500-1000 sccm hydrogen and 1 sccm methane, the pressure is 0.5-5KPa, and the growth time is 0.5-5 hours.

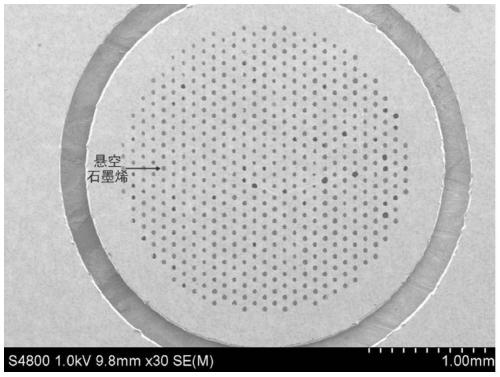

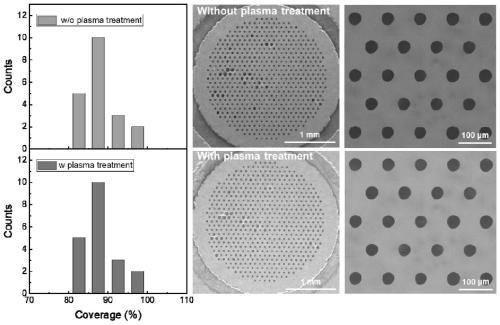

[0077] (3) prepare suspended graphene film: (1) air plasma cleaning machine (Germany Diener, Pico model) etch away the graphene film on metal substrate side, gas volume is 10sccm, and power is 200W, and process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com