Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about "Nanostructure manipulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

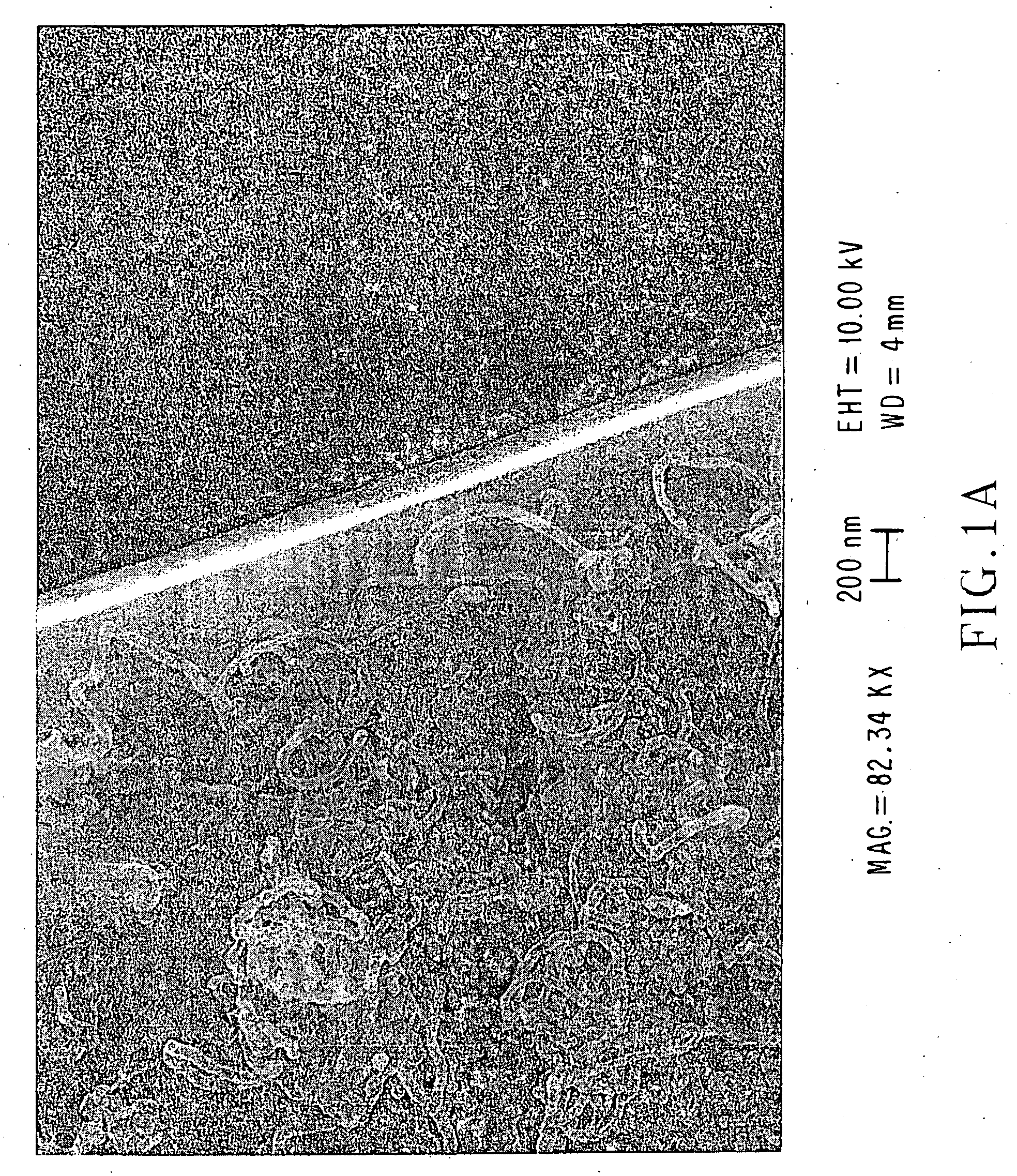

Carbon-Based Fine Structure Array, Aggregate of Carbon-Based Fine Structures, Use Thereof and Method for Preparation Thereof

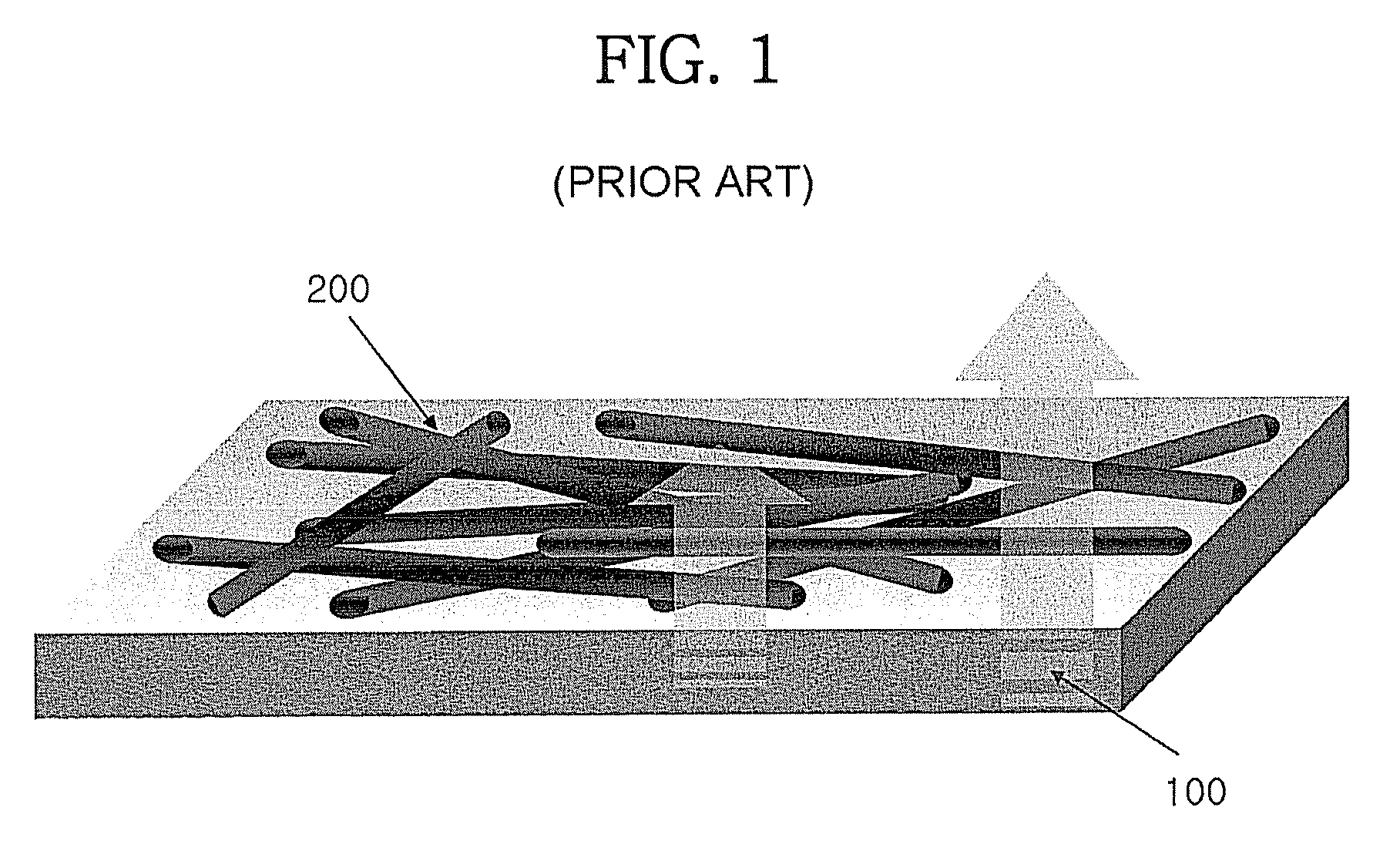

ActiveUS20080095694A1Long and strong aggregateEasy alignmentMaterial nanotechnologyLayered productsFine structureStrong interaction

An aggregate of carbon-based fine structures in which a plurality of carbon-based fine structures are collected, wherein respective carbon-based fine structures are oriented in the same direction. The above aggregate of carbon-based fine structures is an aggregate of a plurality of carbon-based fine structures in a state they are pulled by one another with strong interaction, and has such a length that allows the improvement of the handleability and workability thereof.

Owner:NIPPON SANSO CORP

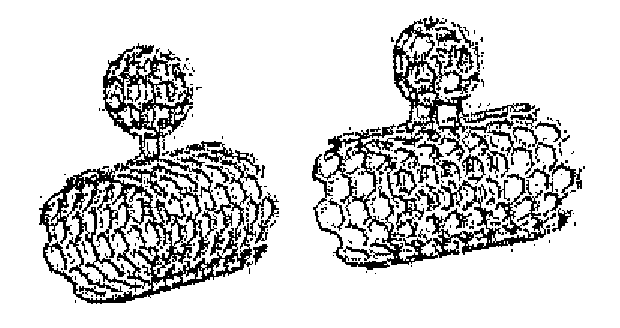

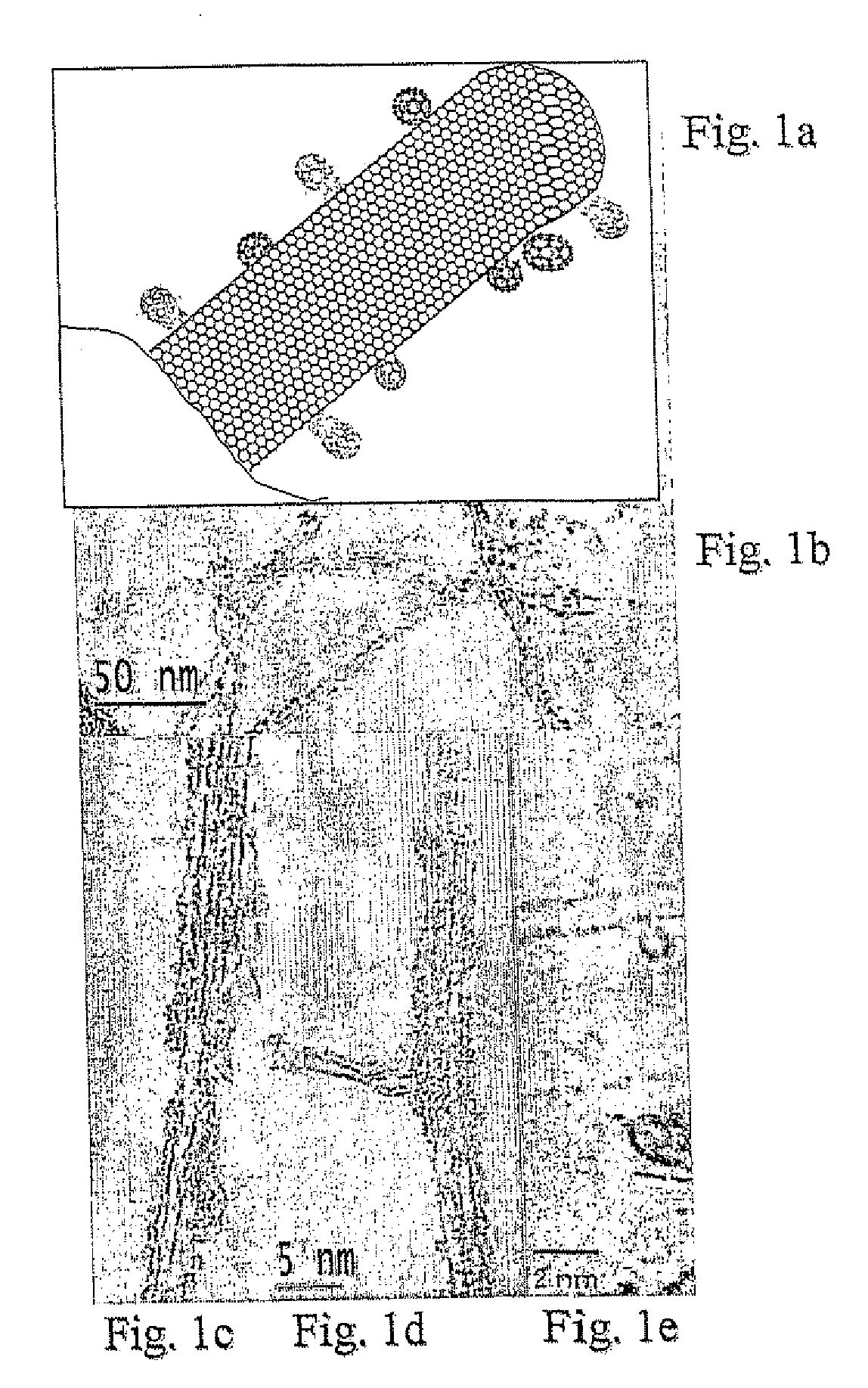

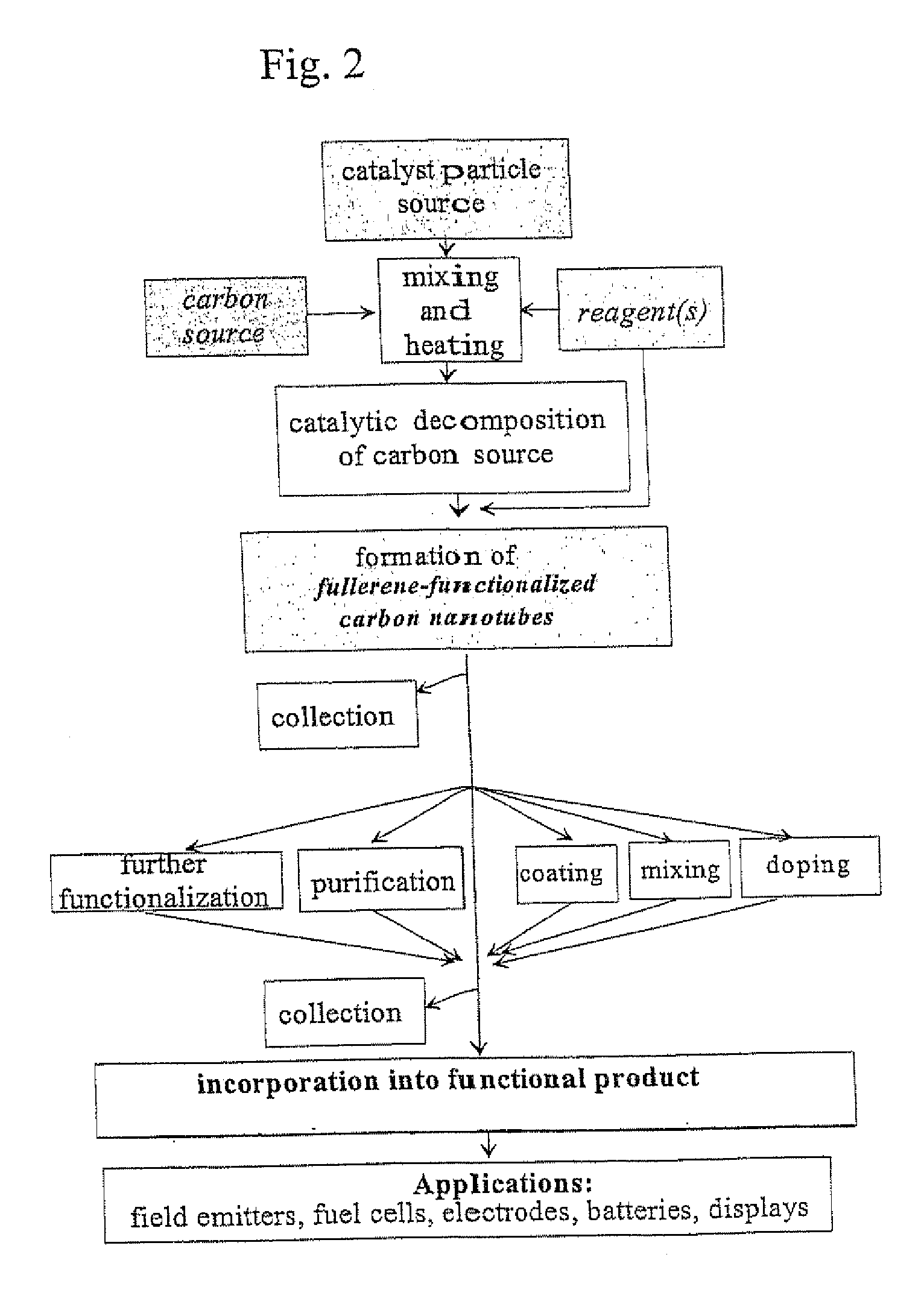

Carbon nanotubes functionalized with fullerenes

InactiveUS20090226704A1Enhancement in cold electron field emissionImprove mechanical propertiesSpecific nanostructure formationMaterial nanotechnologyC60 fullereneNanotube

The present invention relates to covalently bonded fullerene-functionalized carbon nanotubes (CBFFCNTs), a method and an apparatus for their production and to their end products. CBFFCNTs are carbon nanotubes with one or more fullerenes or fullerene based molecules covalently bonded to the nanotube surface. They are obtained by bringing one or more catalyst particles, carbon sources and reagents together in a reactor.

Owner:CANATU OY

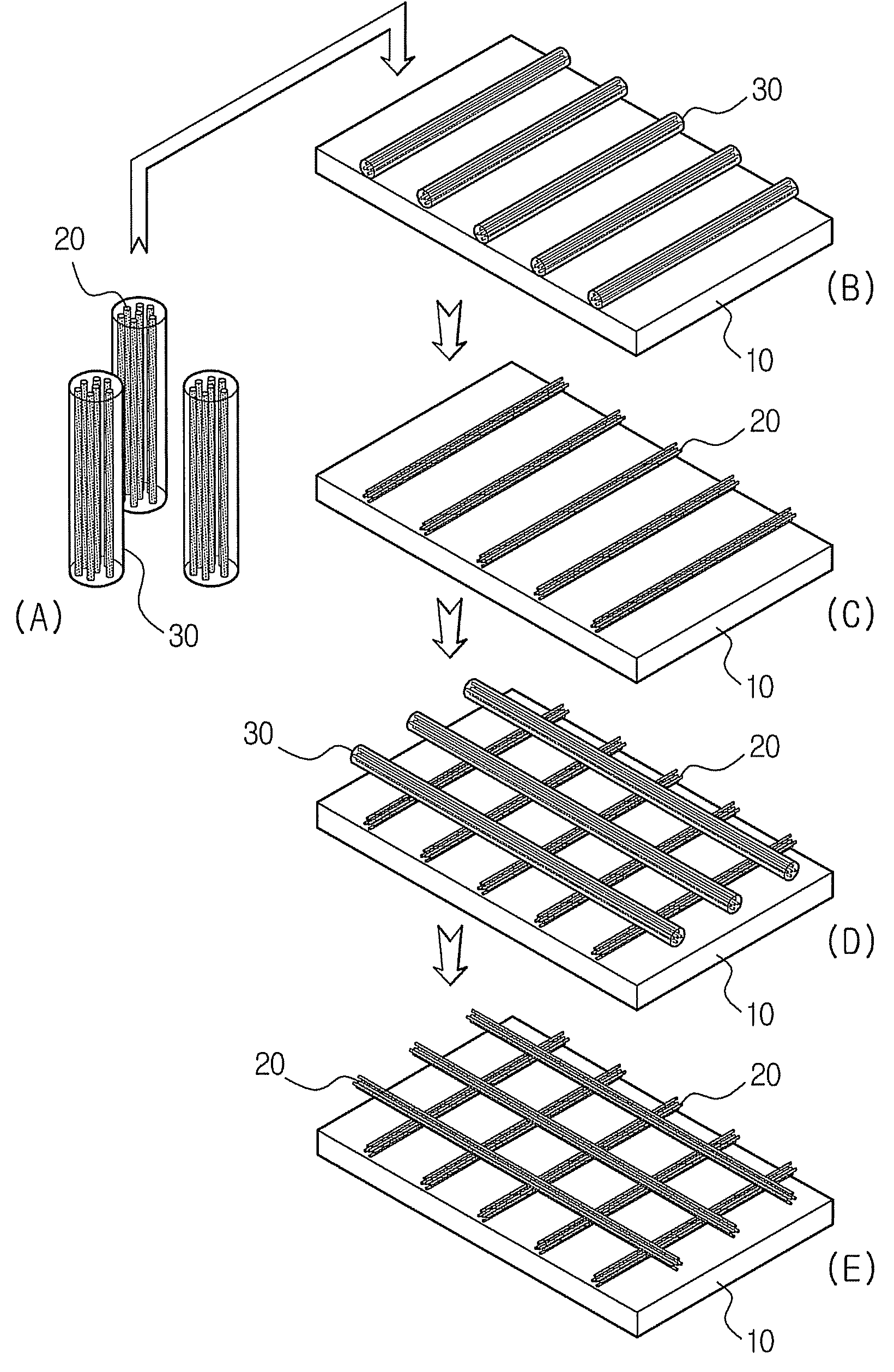

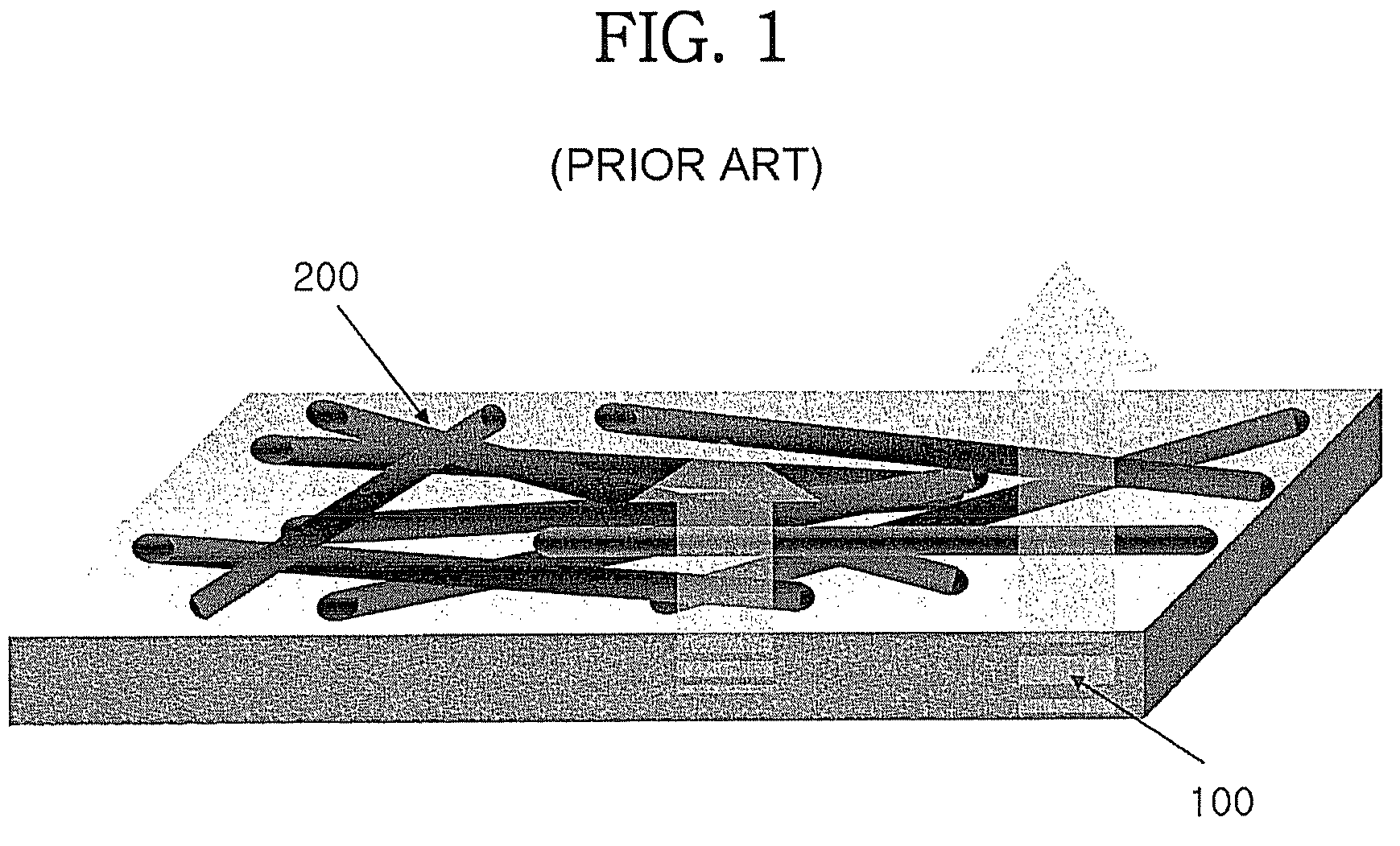

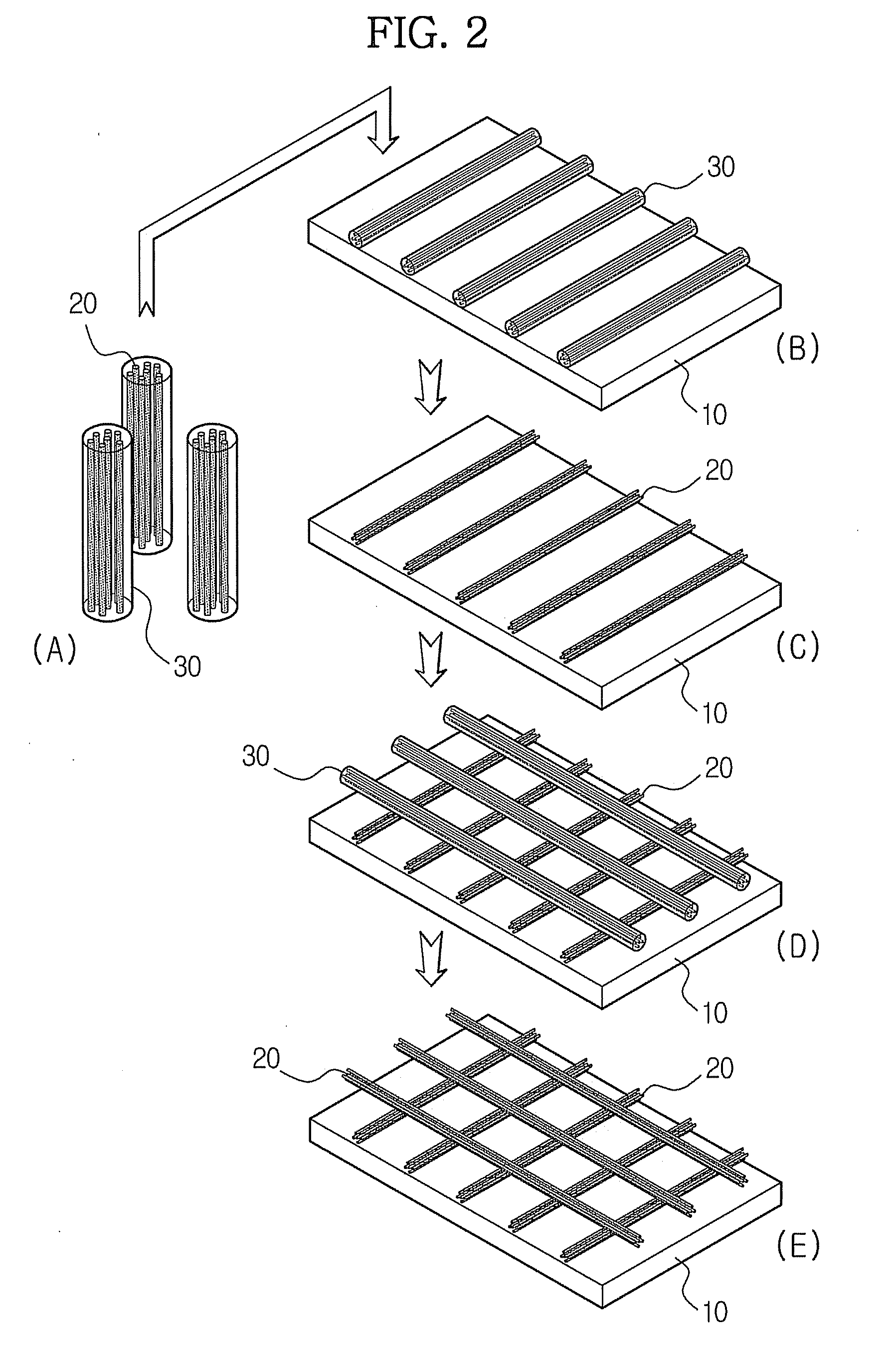

Method of preparing patterned carbon nanotube array and patterned carbon nanotube array prepared thereby

InactiveUS7662732B2Improved array uniformity and transmittanceEasy to prepareMaterial nanotechnologyCarbon compoundsNanotube array

A method of preparing a patterned carbon nanotube array a patterned carbon nanotube array prepared thereby are provided. The method includes forming carbon nanotubes in channels of porous templates, arranging the templates in a predetermined pattern on a substrate and selectively removing the templates to expose the carbon nanotubes.

Owner:SAMSUNG ELECTRONICS CO LTD

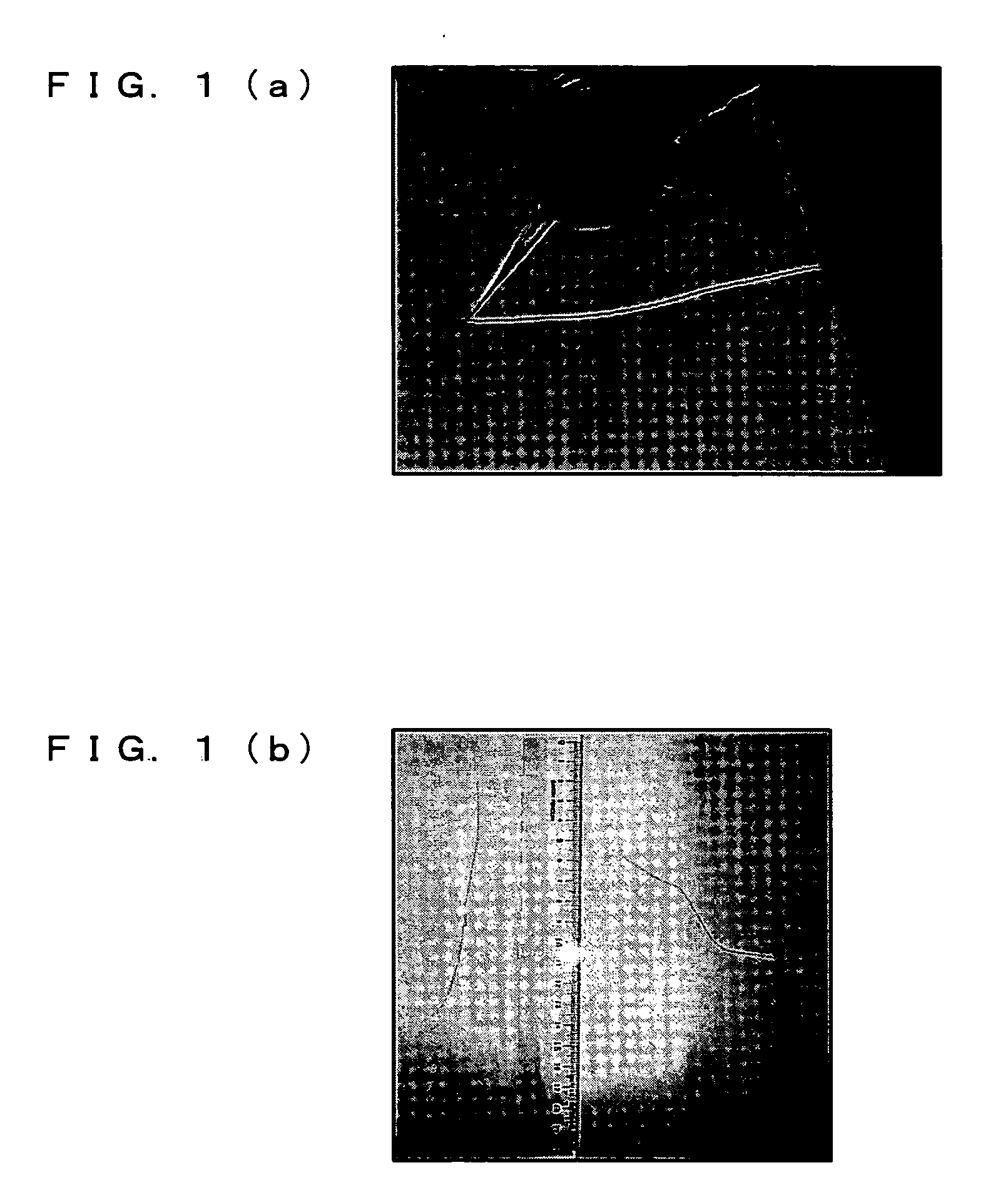

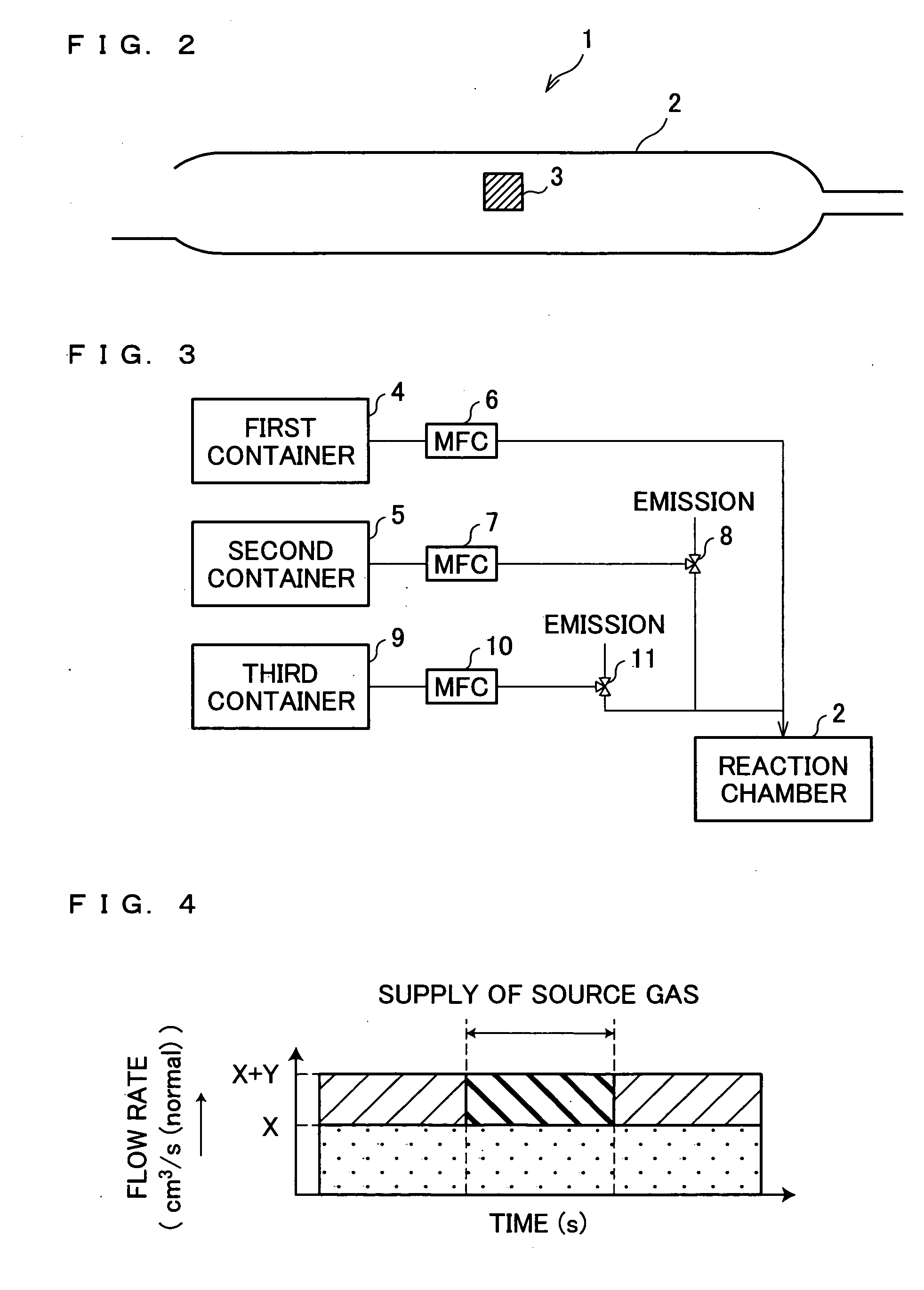

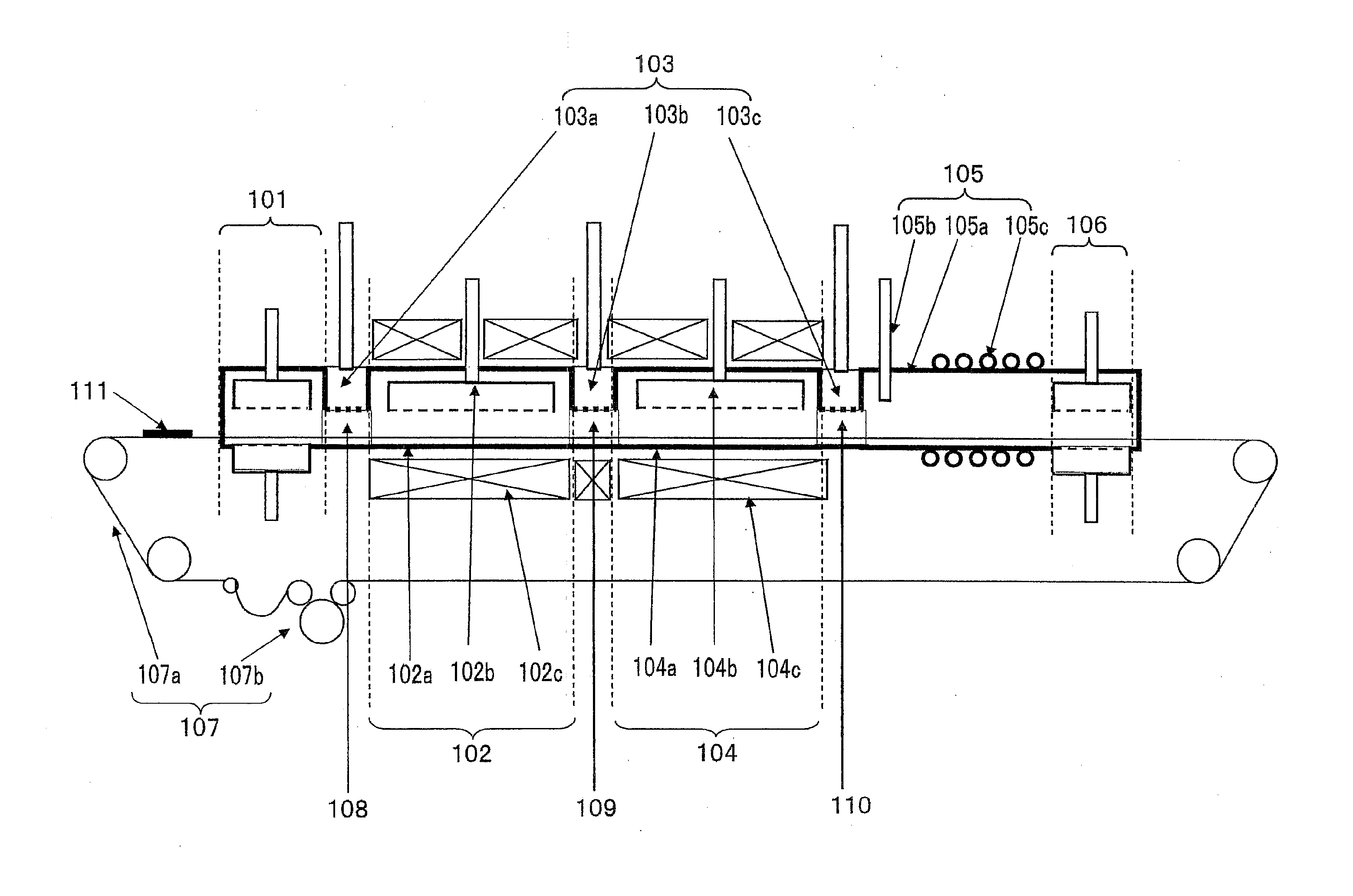

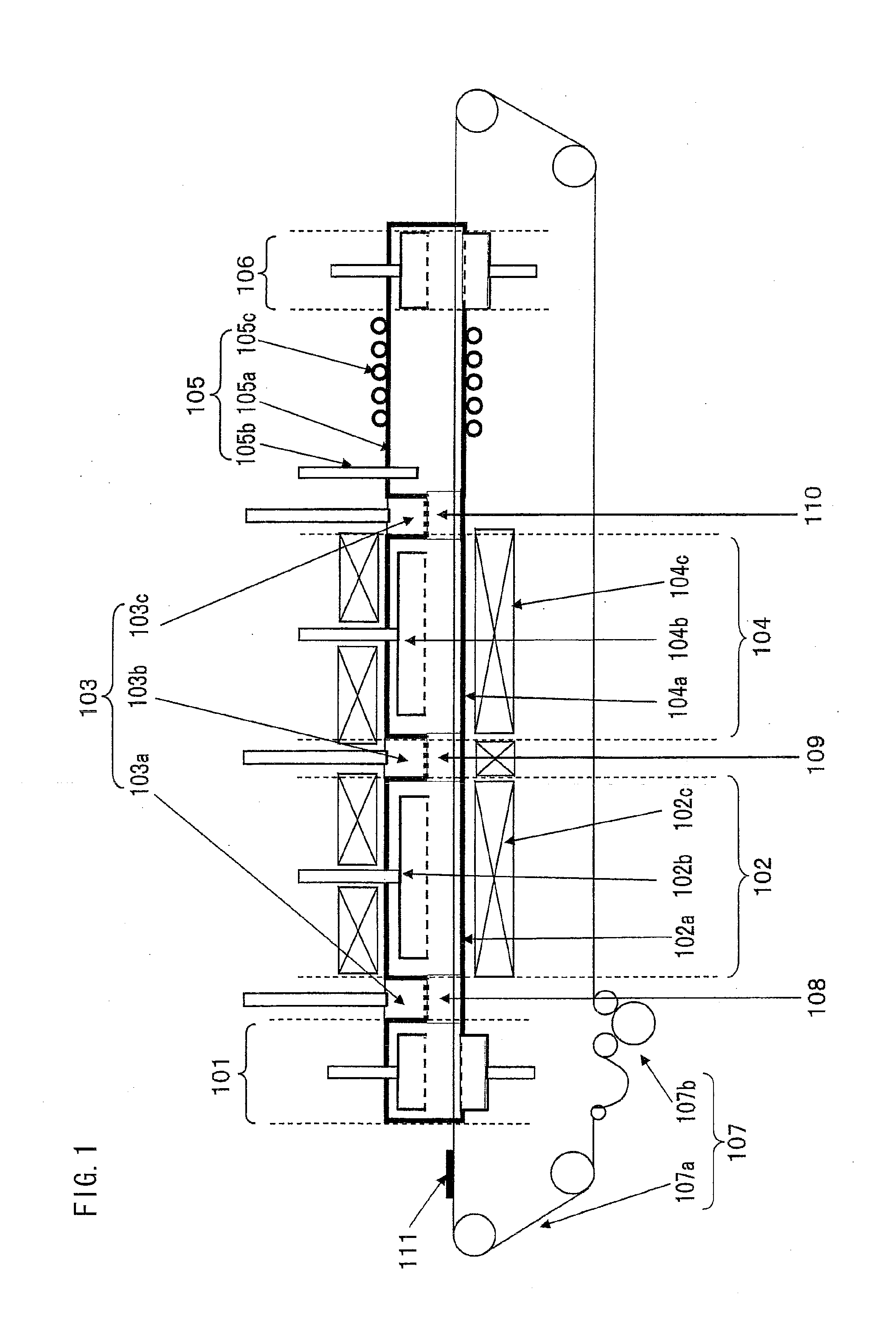

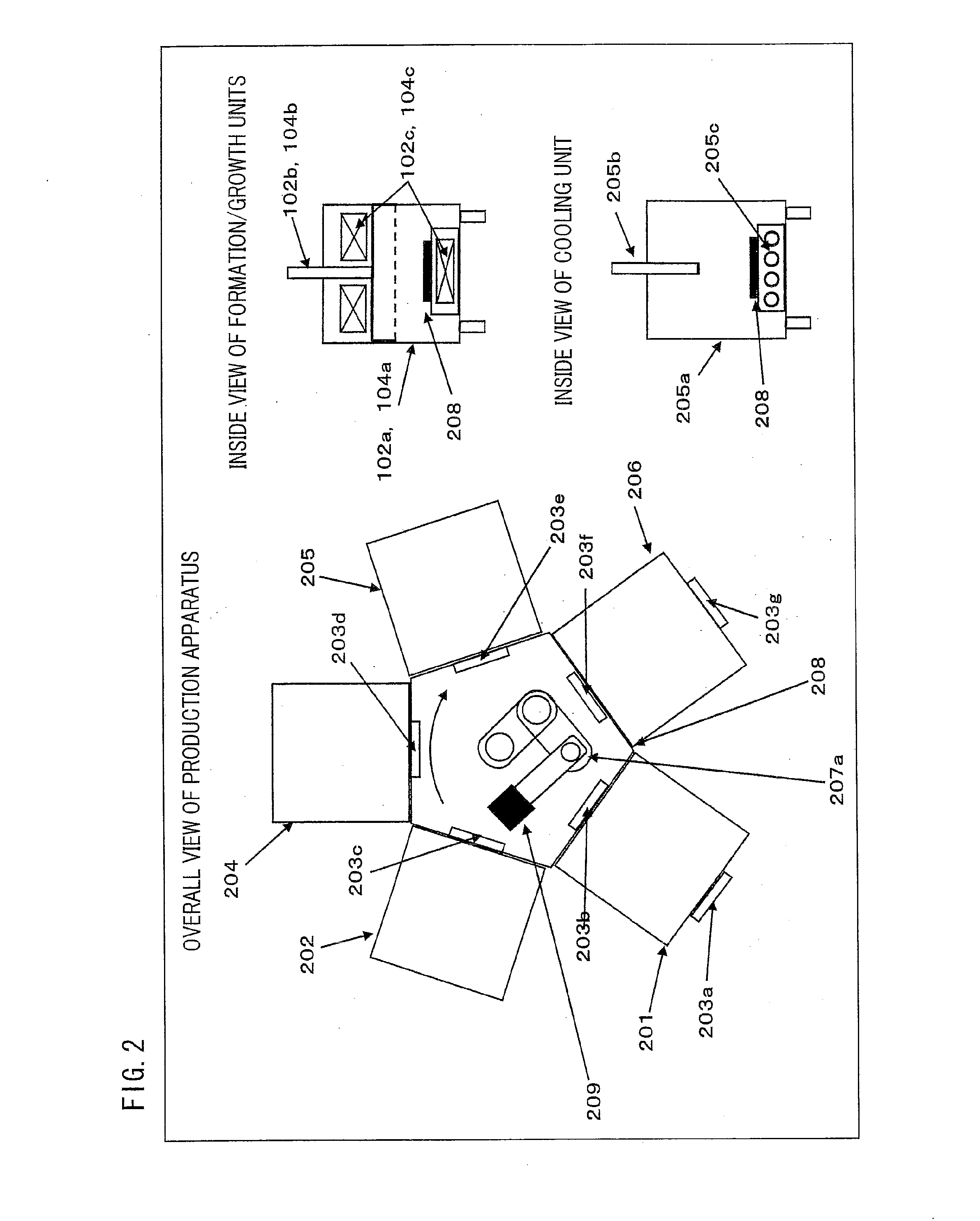

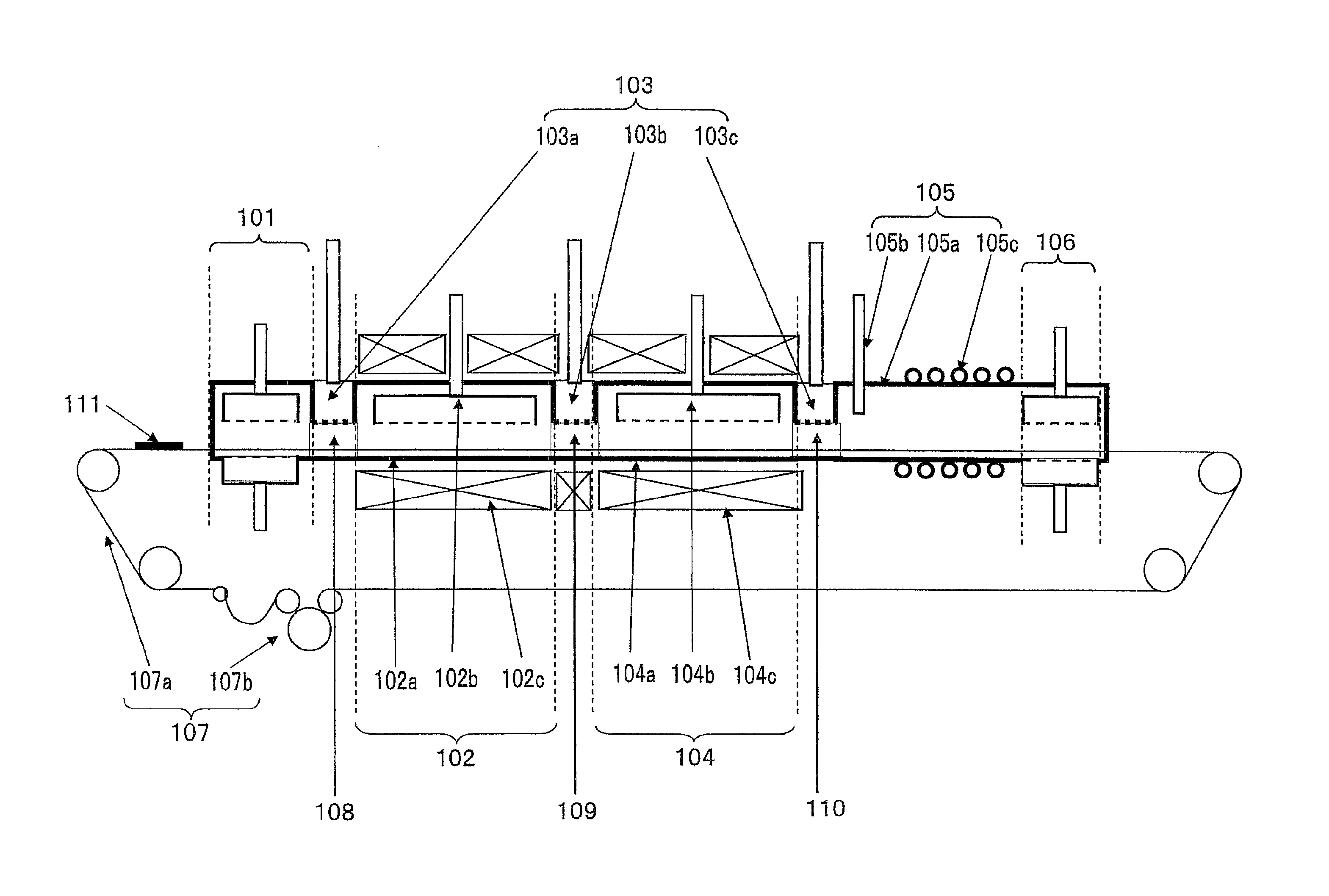

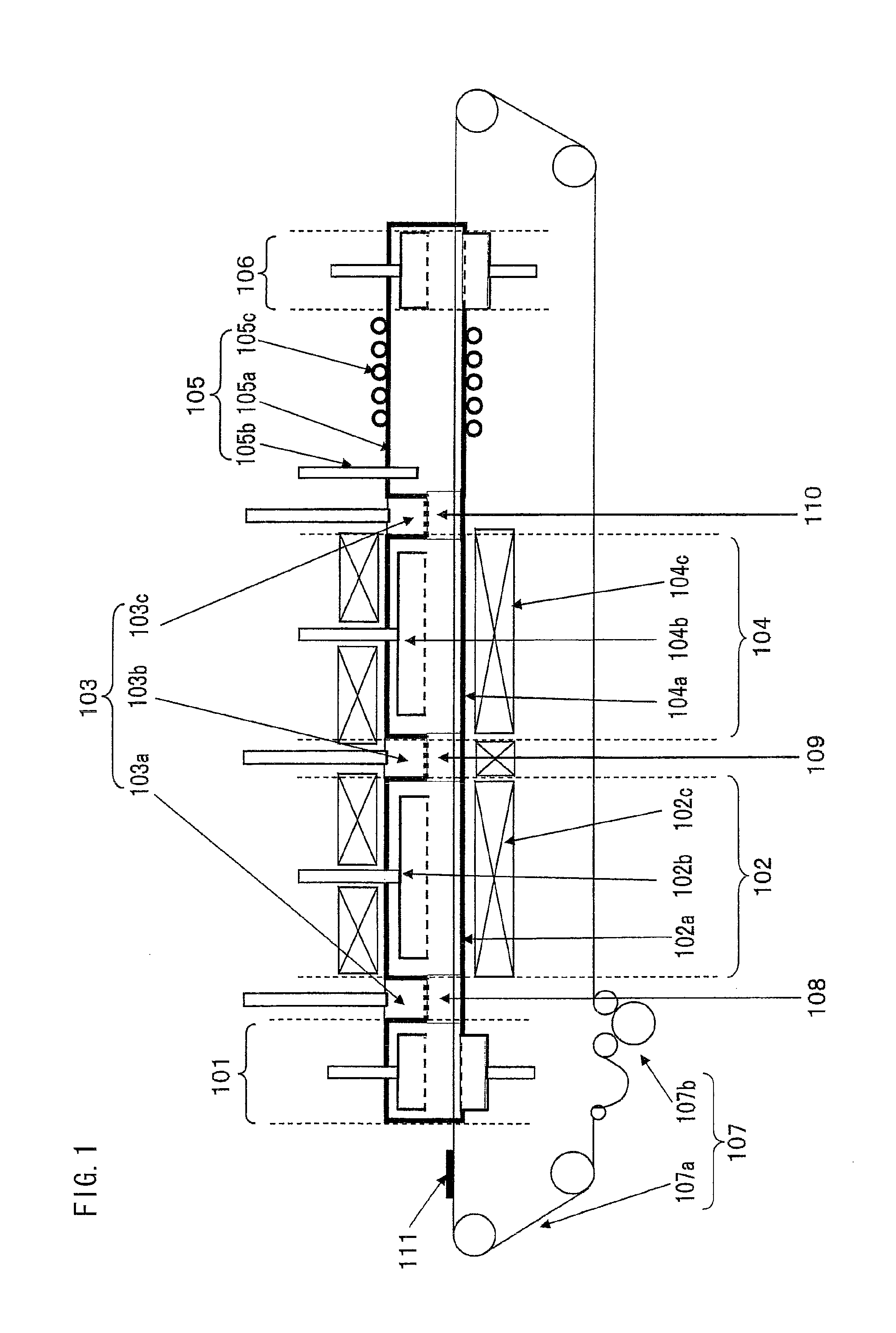

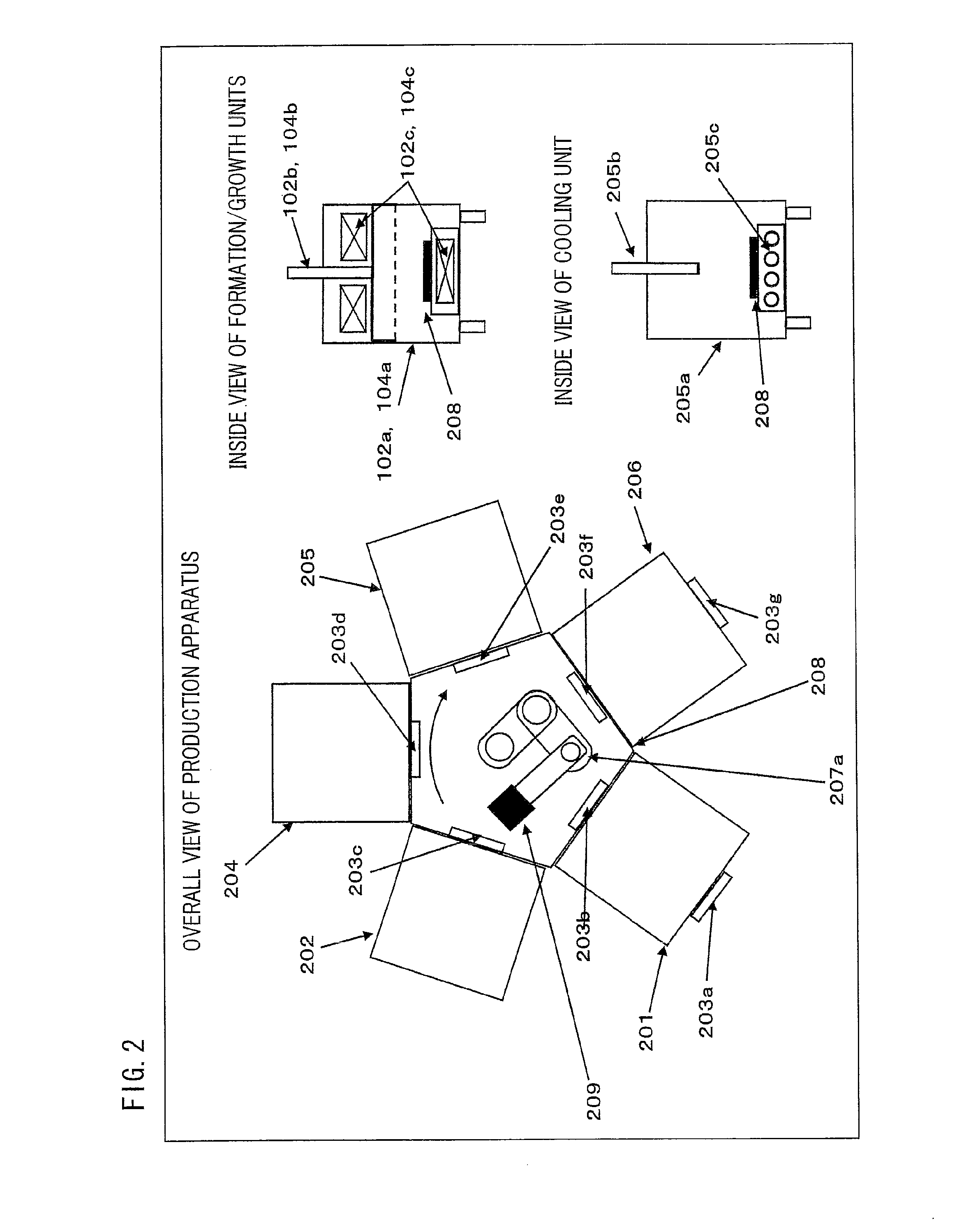

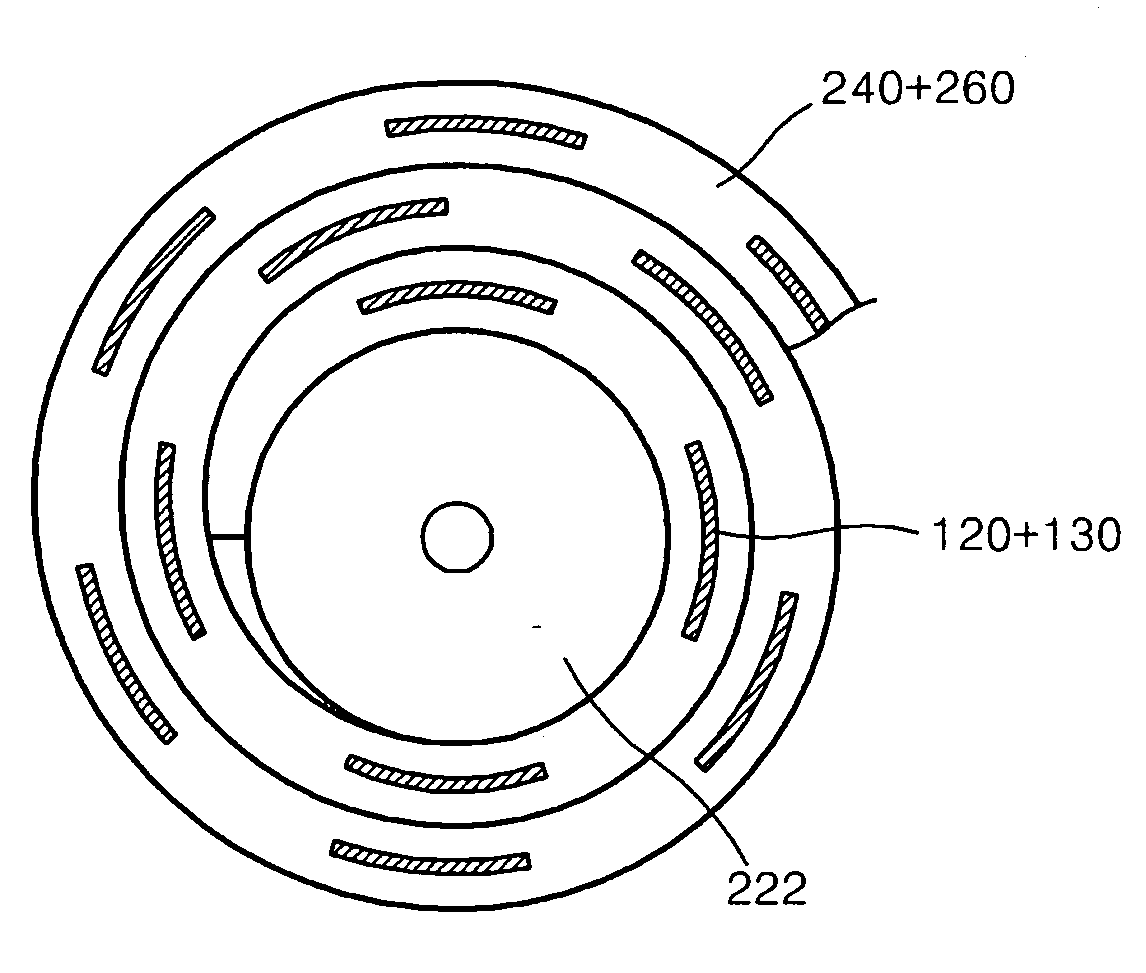

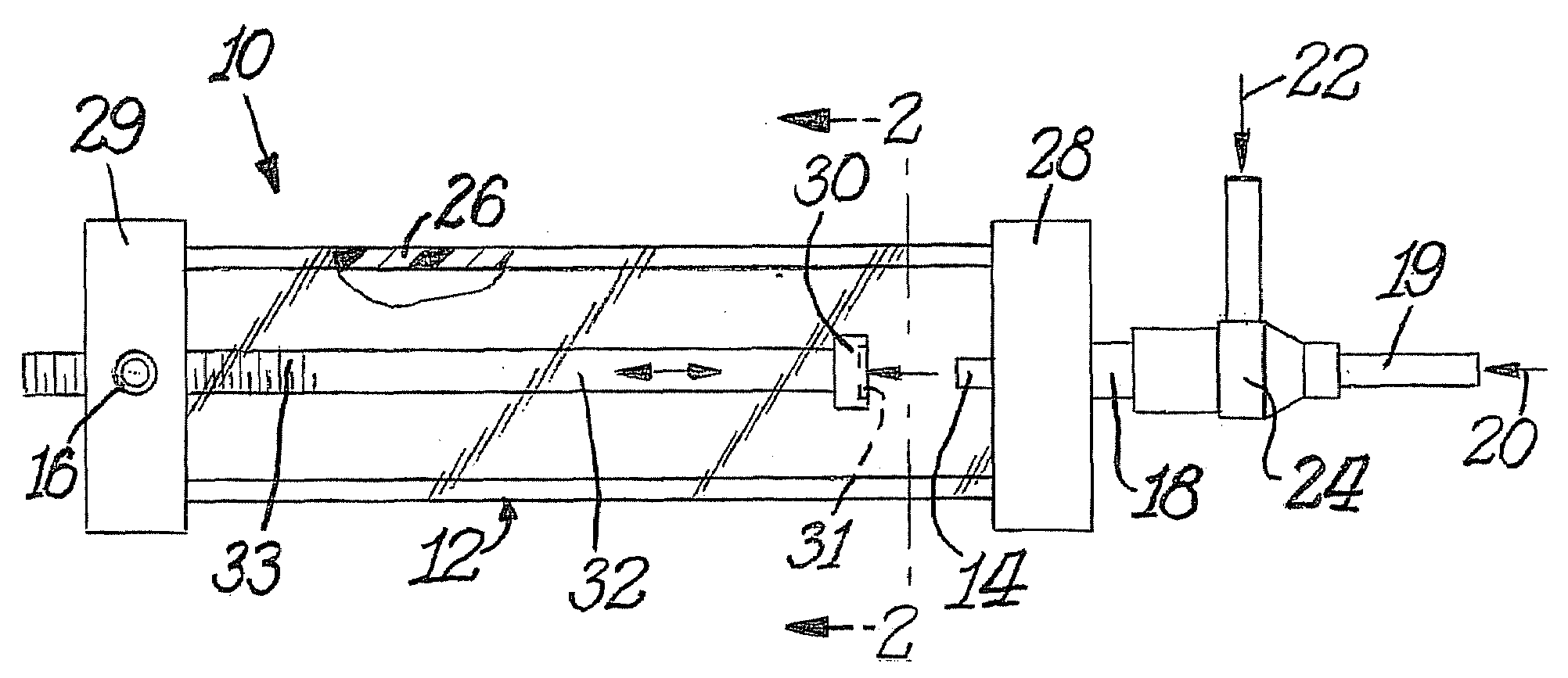

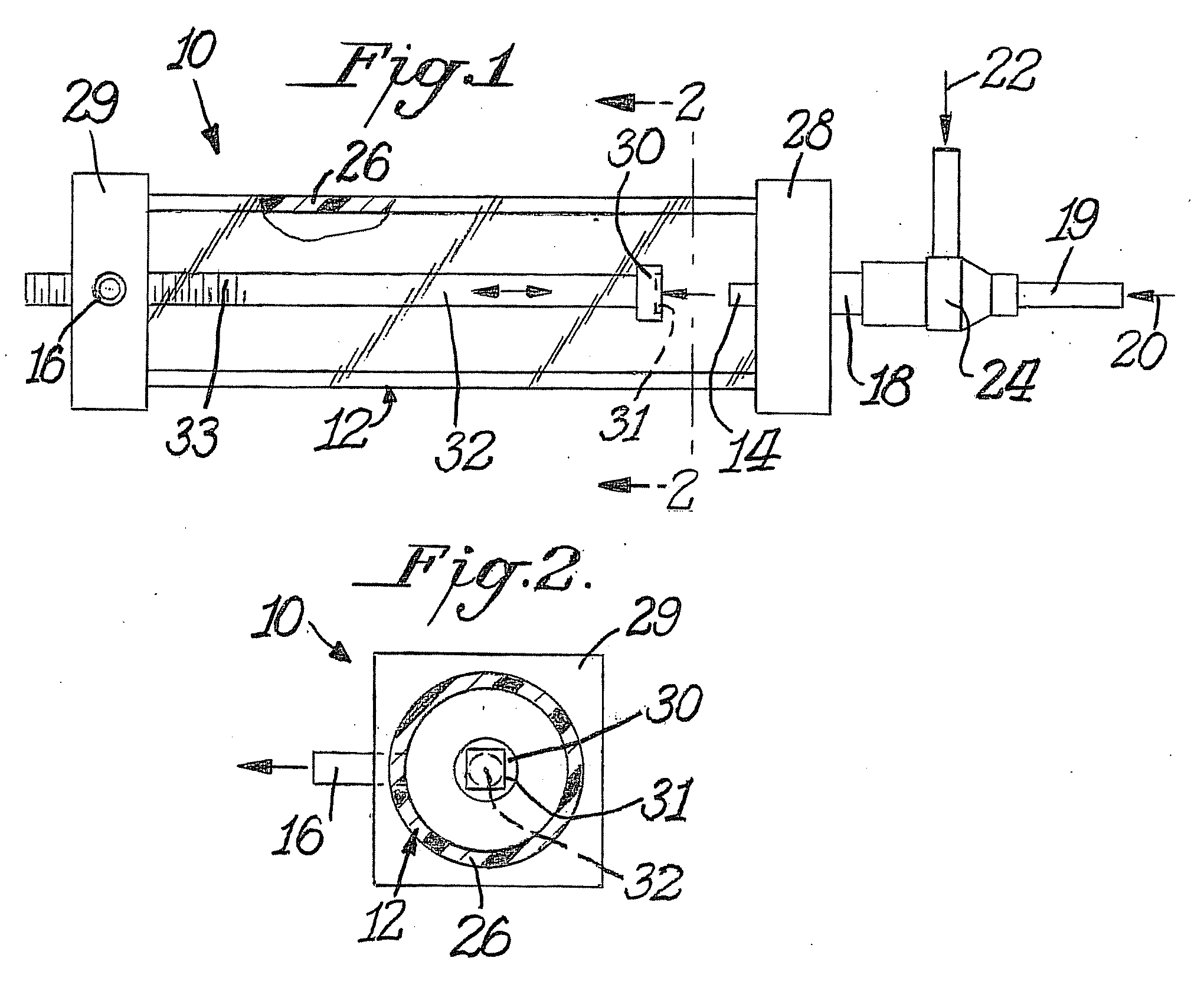

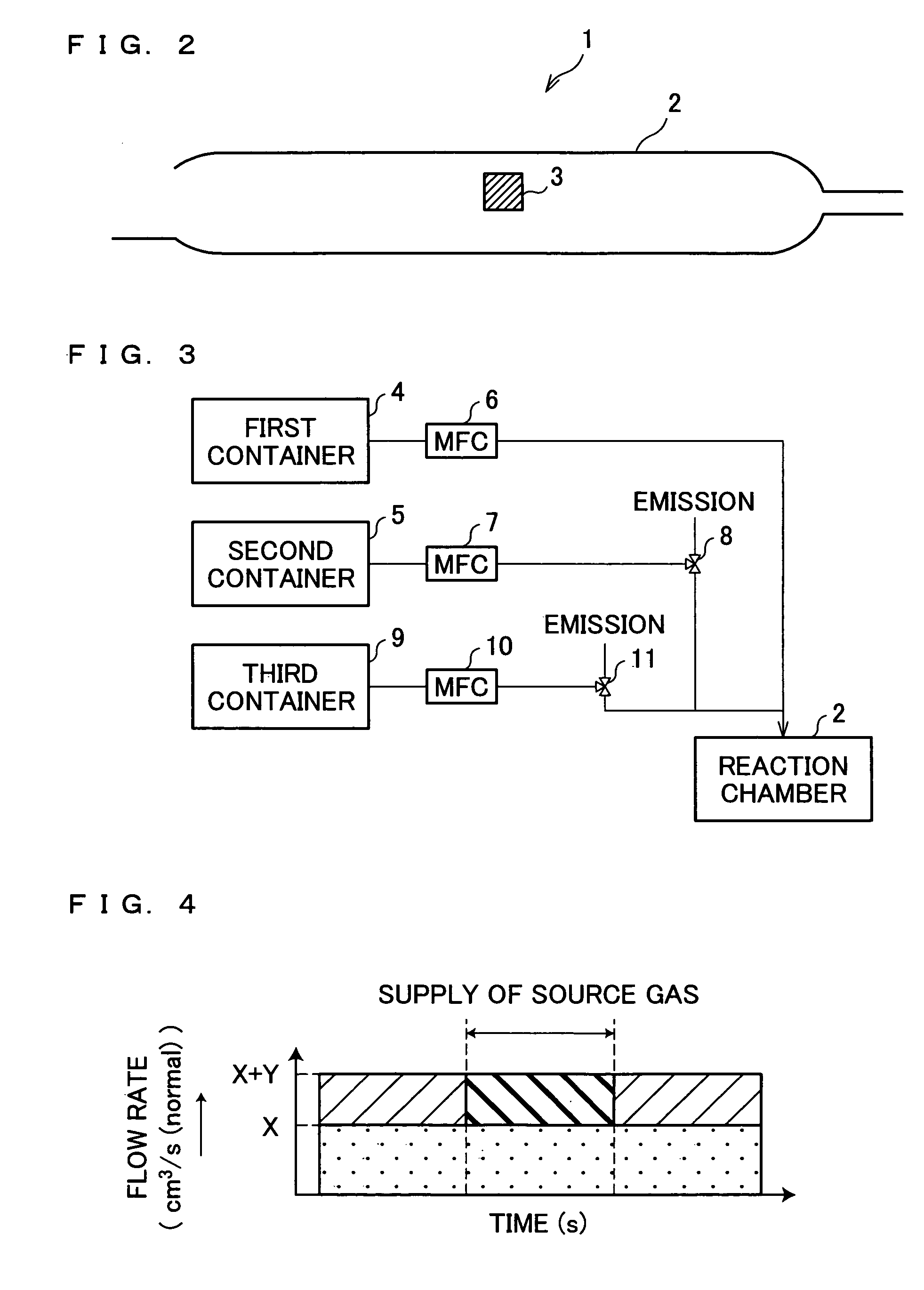

Apparatus and method for producing aligned carbon-nanotube aggregates

ActiveUS20100196600A1Deterioration in quality can be preventedAvoid stickingSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProduct gas

An apparatus of the present invention for producing an aligned carbon-nanotube aggregate is an apparatus for producing an aligned carbon-nanotube aggregate by synthesizing the aligned carbon-nanotube aggregate on a base material having a catalyst on a surface thereof, the apparatus including: a formation unit that processes a formation step of causing an environment surrounding the catalyst to be an environment of a reducing gas and heating at least either the catalyst or the reducing gas; a growth unit that processes a growth step of synthesizing the aligned carbon-nanotube aggregate by causing the environment surrounding the catalyst to be an environment of a raw material gas and by heating at least either the catalyst or the raw material gas; and a transfer unit that transfers the base material at least from the formation unit to the growth unit. Thus provided is a production apparatus and a production method that are capable of improving efficiency in the production of aligned CNT aggregates by preventing a decrease in production volume and deterioration in quality of aligned CNT aggregates in serial production and by making it easy to increase the size of the apparatus.

Owner:ZEON CORP +1

Control of carbon nanotube diameter using CVD or PECVD growth

The diameter of carbon nanotubes grown by chemical vapor deposition is controlled independent of the catalyst size by controlling the residence time of reactive gases in the reactor.

Owner:GLOBALFOUNDRIES US INC

Apparatus and method for producing aligned carbon-nanotube aggregates

ActiveUS7897209B2Deterioration in quality can be preventedAvoid stickingSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProcess engineering

An apparatus of the present invention for producing an aligned carbon-nanotube aggregate is an apparatus for producing an aligned carbon-nanotube aggregate by synthesizing the aligned carbon-nanotube aggregate on a base material having a catalyst on a surface thereof, the apparatus including: a formation unit that processes a formation step of causing an environment surrounding the catalyst to be an environment of a reducing gas and heating at least either the catalyst or the reducing gas; a growth unit that processes a growth step of synthesizing the aligned carbon-nanotube aggregate by causing the environment surrounding the catalyst to be an environment of a raw material gas and by heating at least either the catalyst or the raw material gas; and a transfer unit that transfers the base material at least from the formation unit to the growth unit. Thus provided is a production apparatus and a production method that are capable of improving efficiency in the production of aligned CNT aggregates by preventing a decrease in production volume and deterioration in quality of aligned CNT aggregates in serial production and by making it easy to increase the size of the apparatus.

Owner:ZEON CORP +1

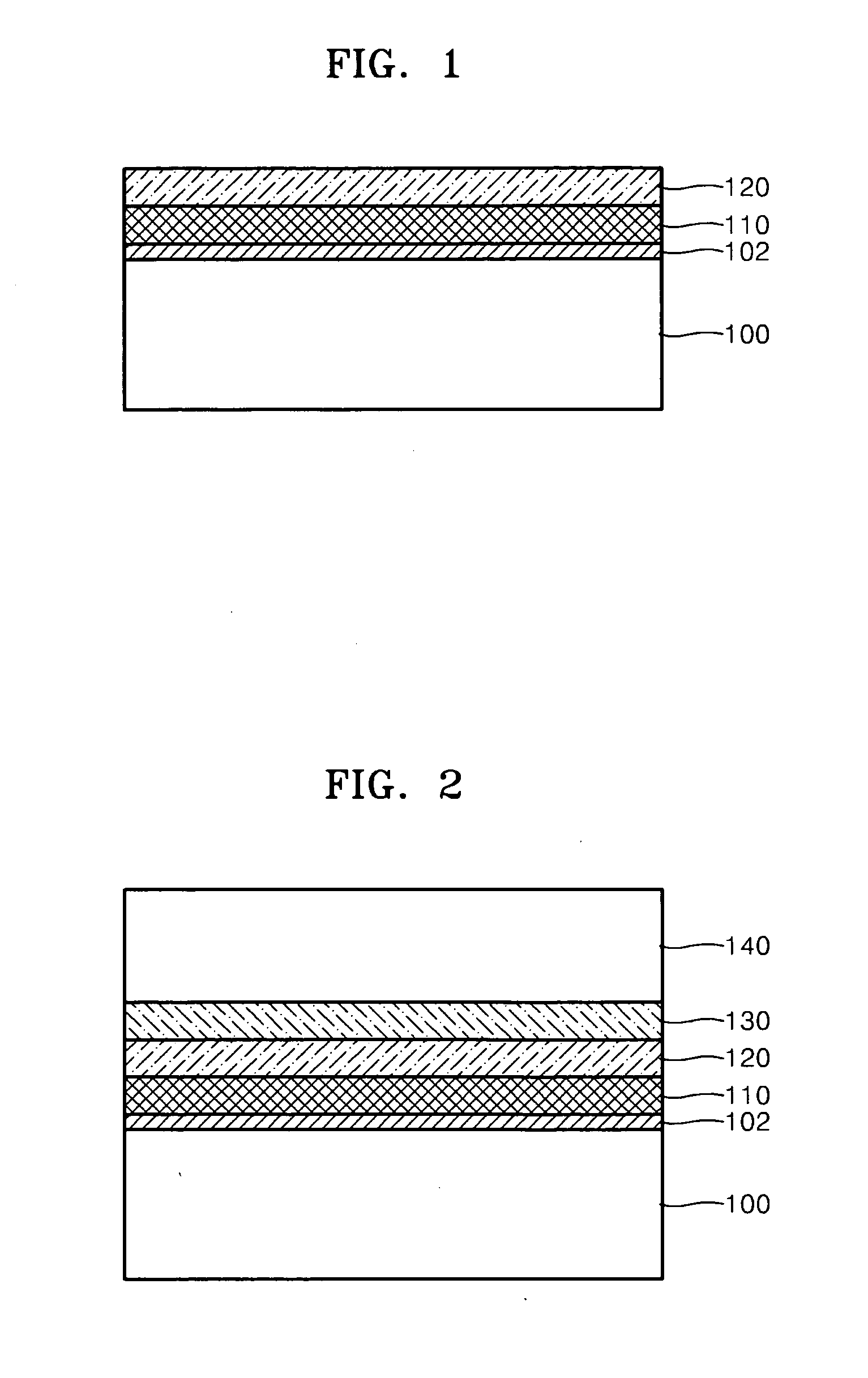

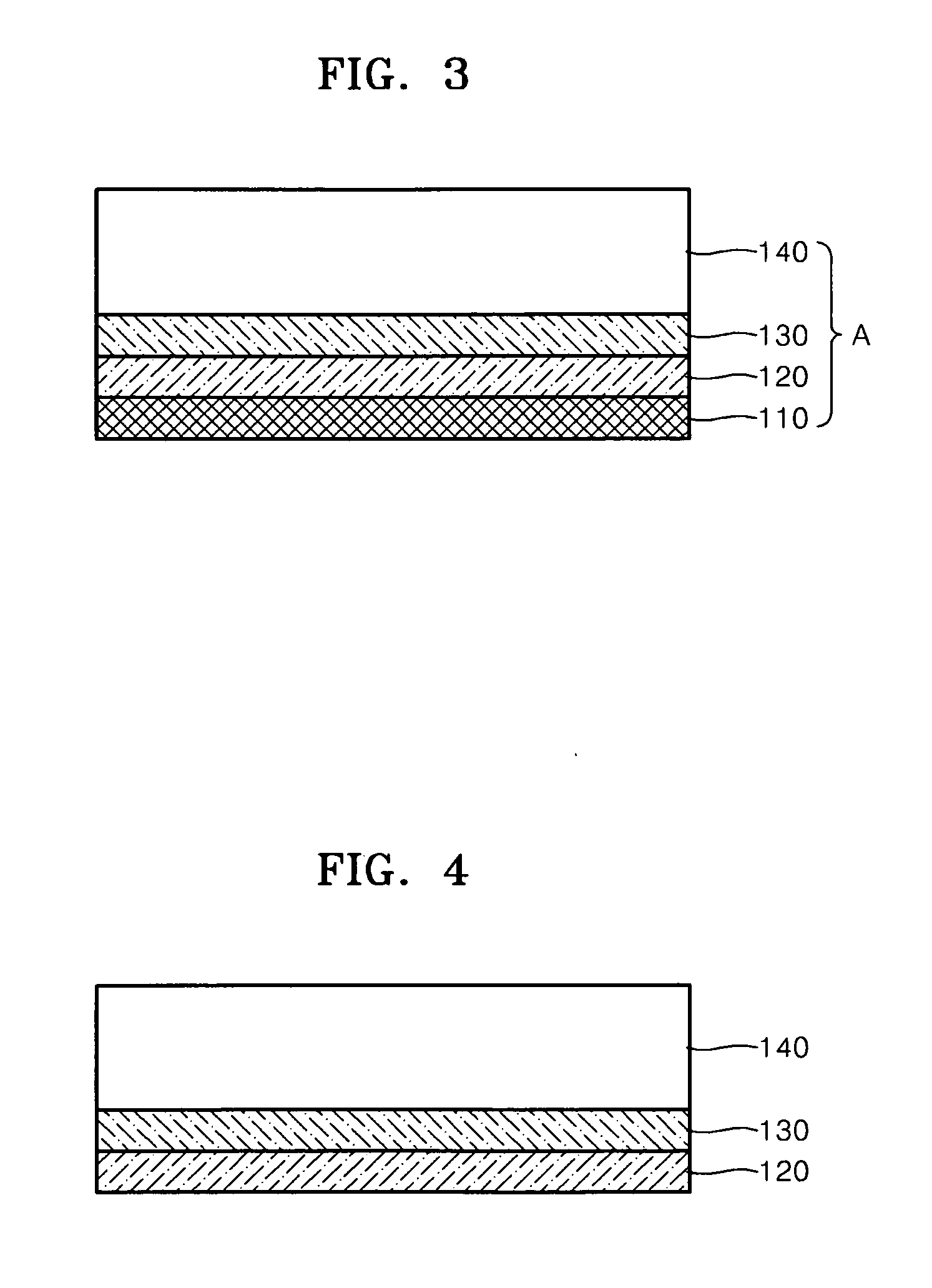

Methods of manufacturing and transferring larger-sized graphene

Example embodiments relate to methods of manufacturing and transferring a larger-sized graphene layer. A method of transferring a larger-sized graphene layer may include forming a graphene layer, a protection layer, and an adhesive layer on a substrate and removing the substrate. The graphene layer may be disposed on a transferring substrate by sliding the graphene layer onto the transferring substrate.

Owner:SAMSUNG ELECTRONICS CO LTD +1

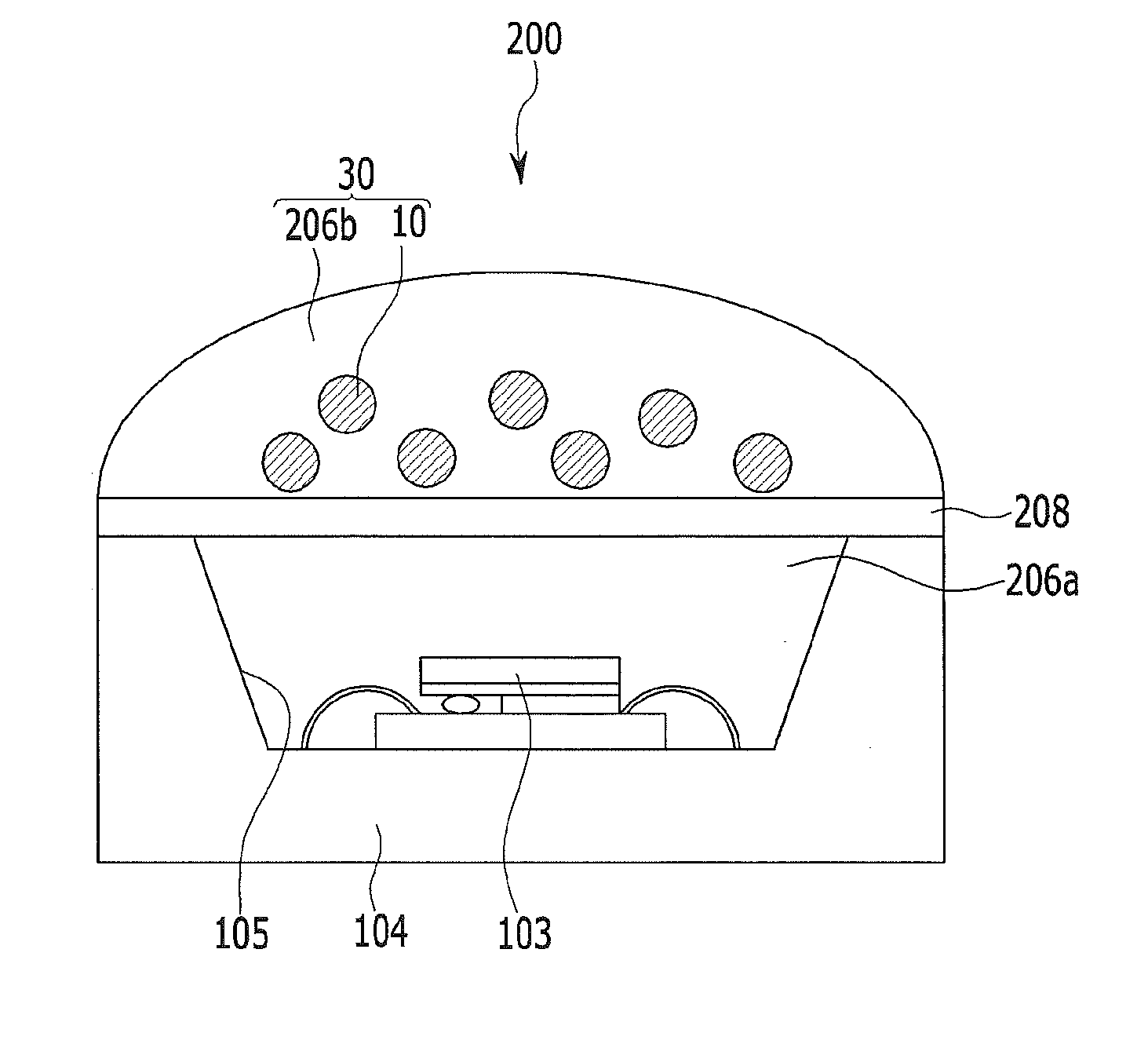

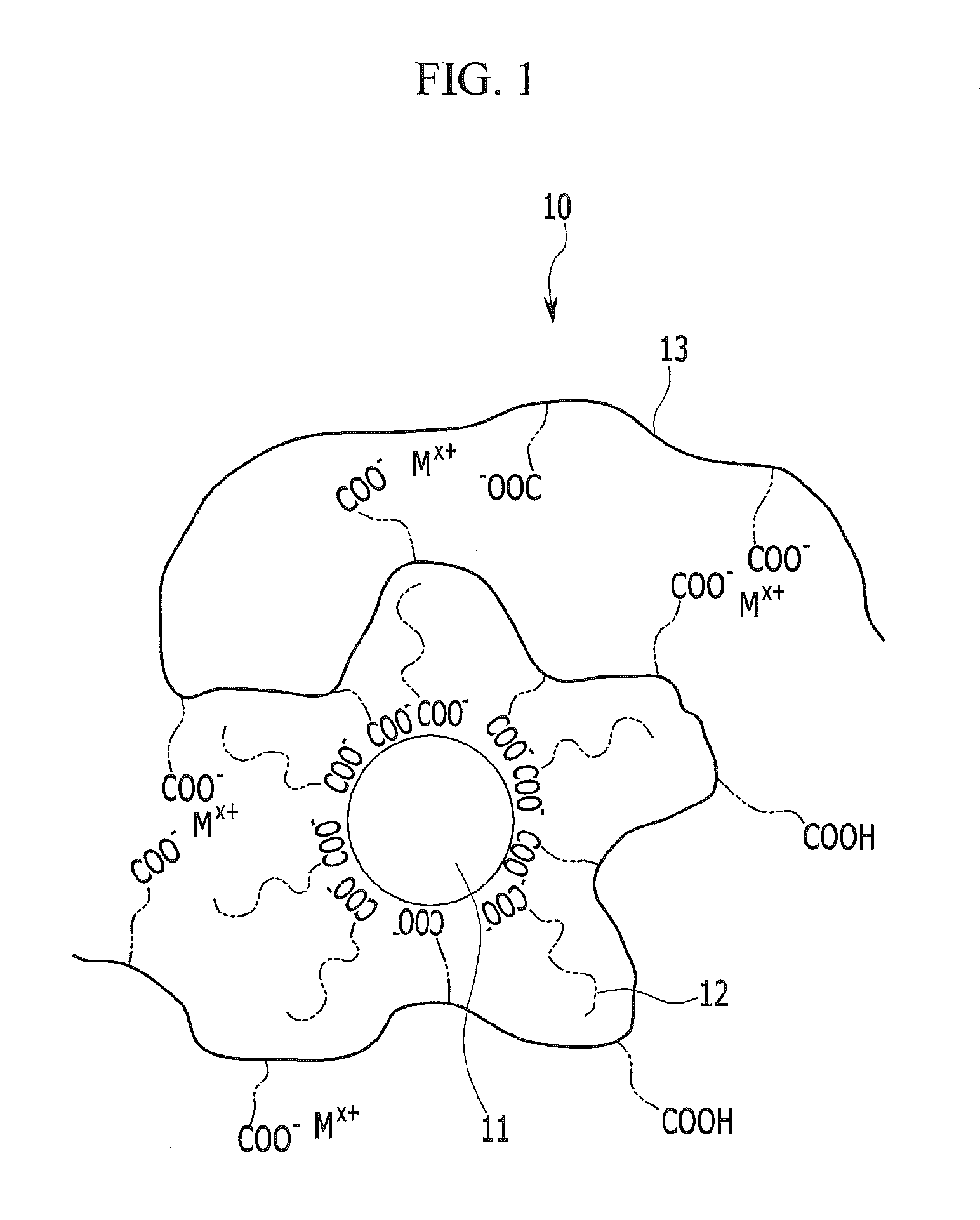

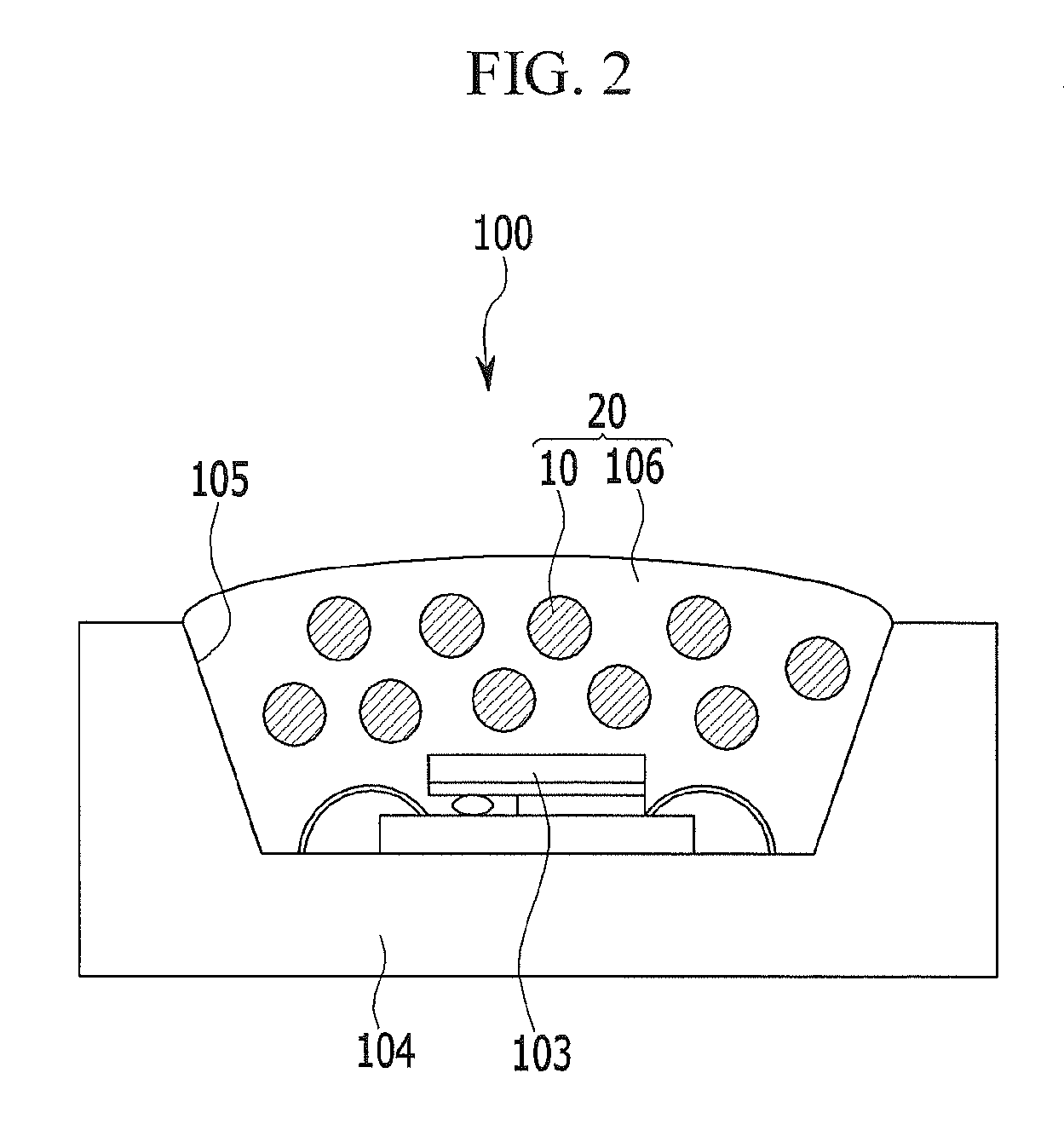

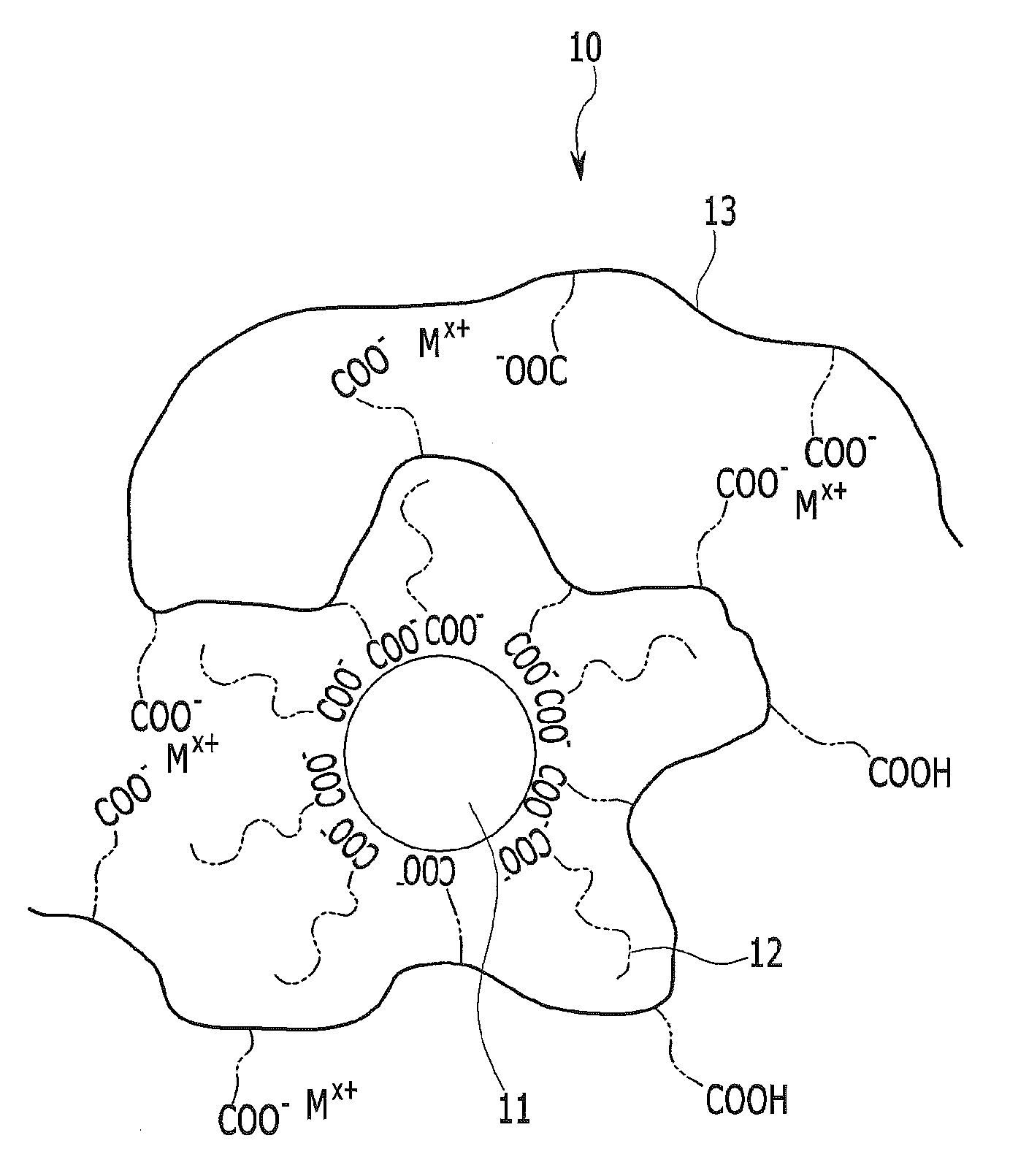

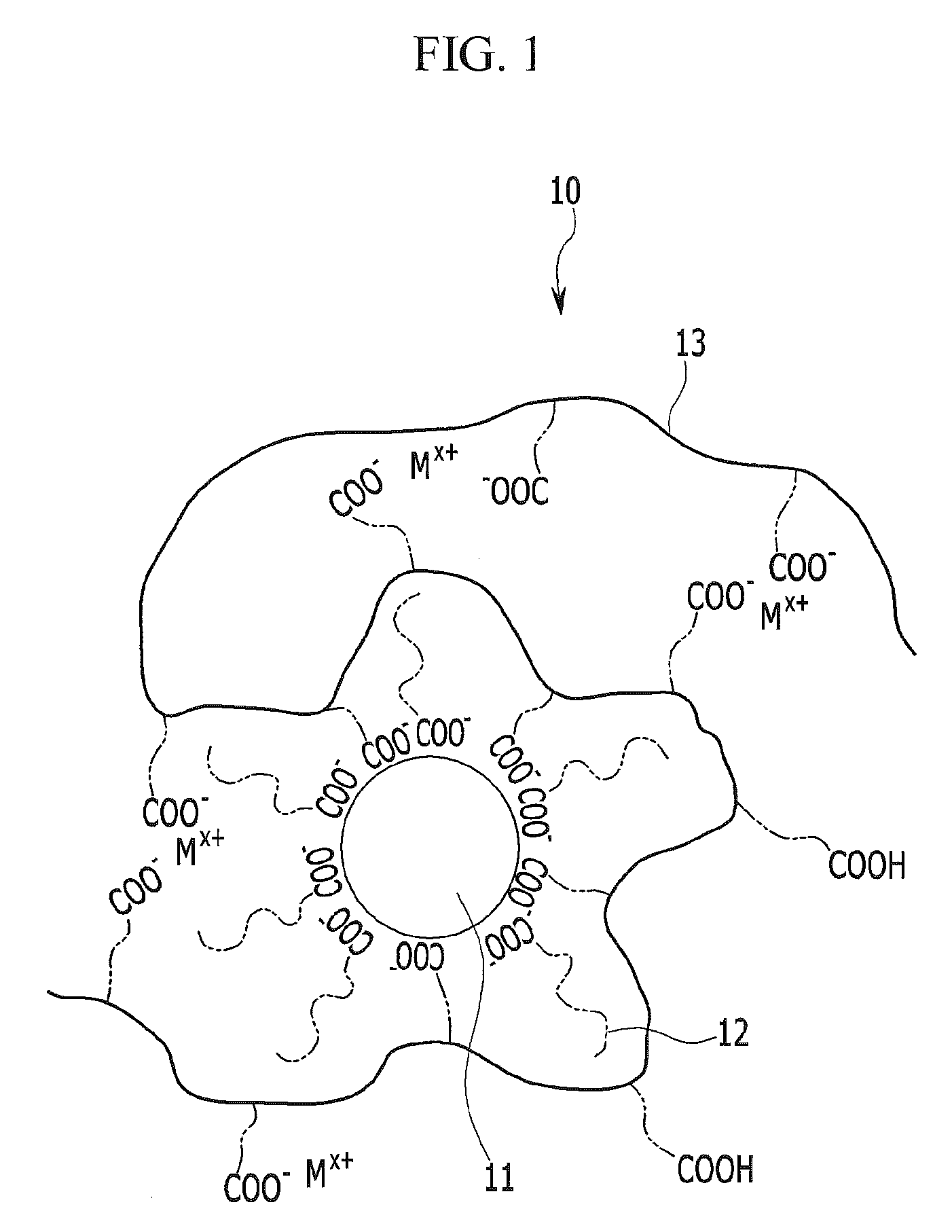

Semiconductor nanocrystal-polymer composite, method of preparing the same, and composite film and optoelectronic device including the same

ActiveUS20130099213A1Improve device efficiencyEnhanced Efficiency StabilityMaterial nanotechnologyConductive materialComposite filmCarboxylic acid

A semiconductor nanocrystal-polymer composite including a semiconductor nanocrystal, a polymer comprising a plurality of carboxylate anion groups (—COO−) bindable to a surface of the semiconductor nanocrystal, and a metal cation bindable to a carboxylate anion group of the plurality of carboxylate anion groups.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of preparing patterned carbon nanotube array and patterned carbon nanotube array prepared thereby

InactiveUS20070273264A1Improved array uniformity and transmittanceEasy to prepareMaterial nanotechnologyCarbon compoundsNanotube array

A method of preparing a patterned carbon nanotube array a patterned carbon nanotube array prepared thereby are provided. The method includes forming carbon nanotubes in channels of porous templates, arranging the templates in a predetermined pattern on a substrate and selectively removing the templates to expose the carbon nanotubes.

Owner:SAMSUNG ELECTRONICS CO LTD

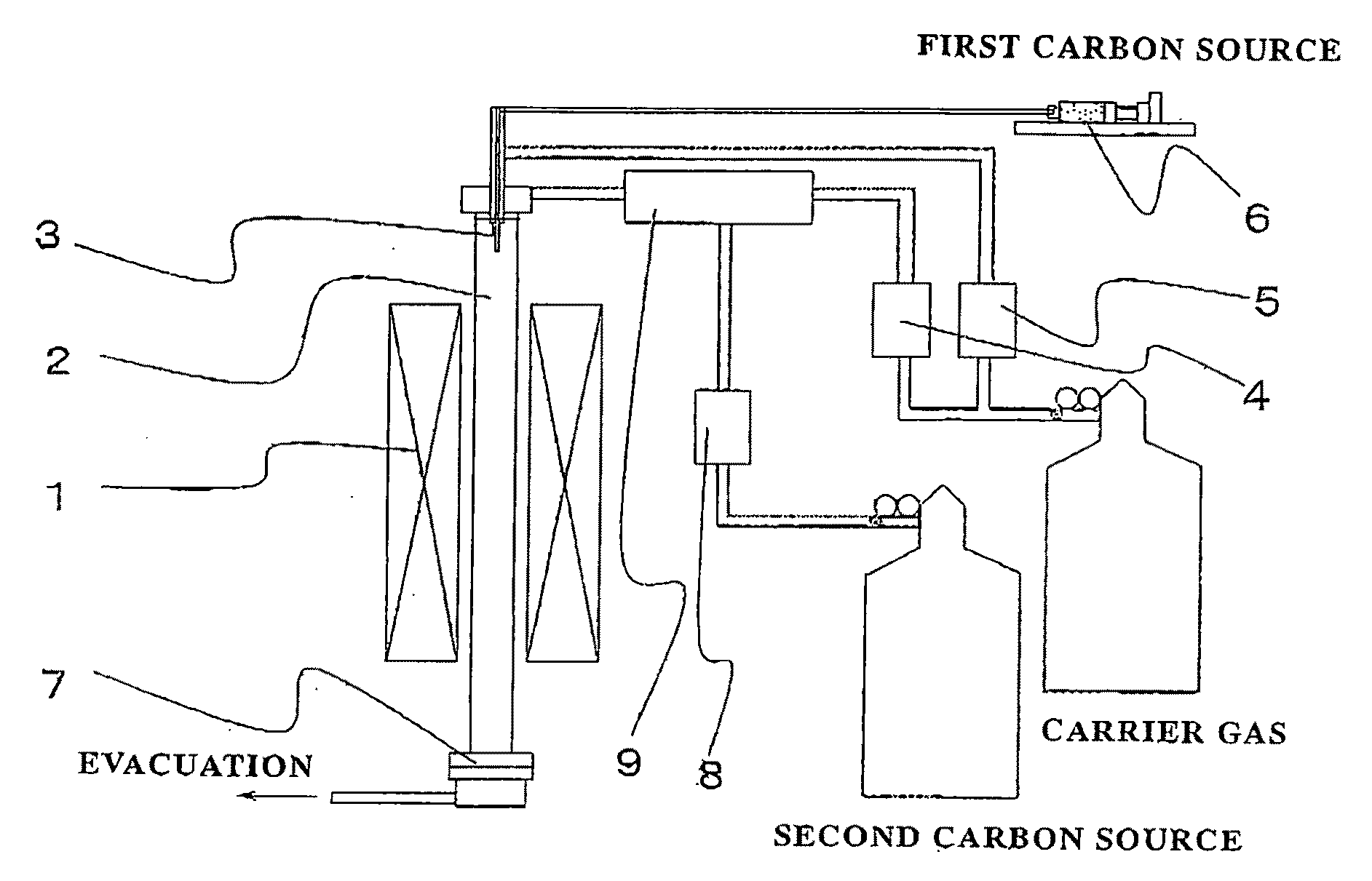

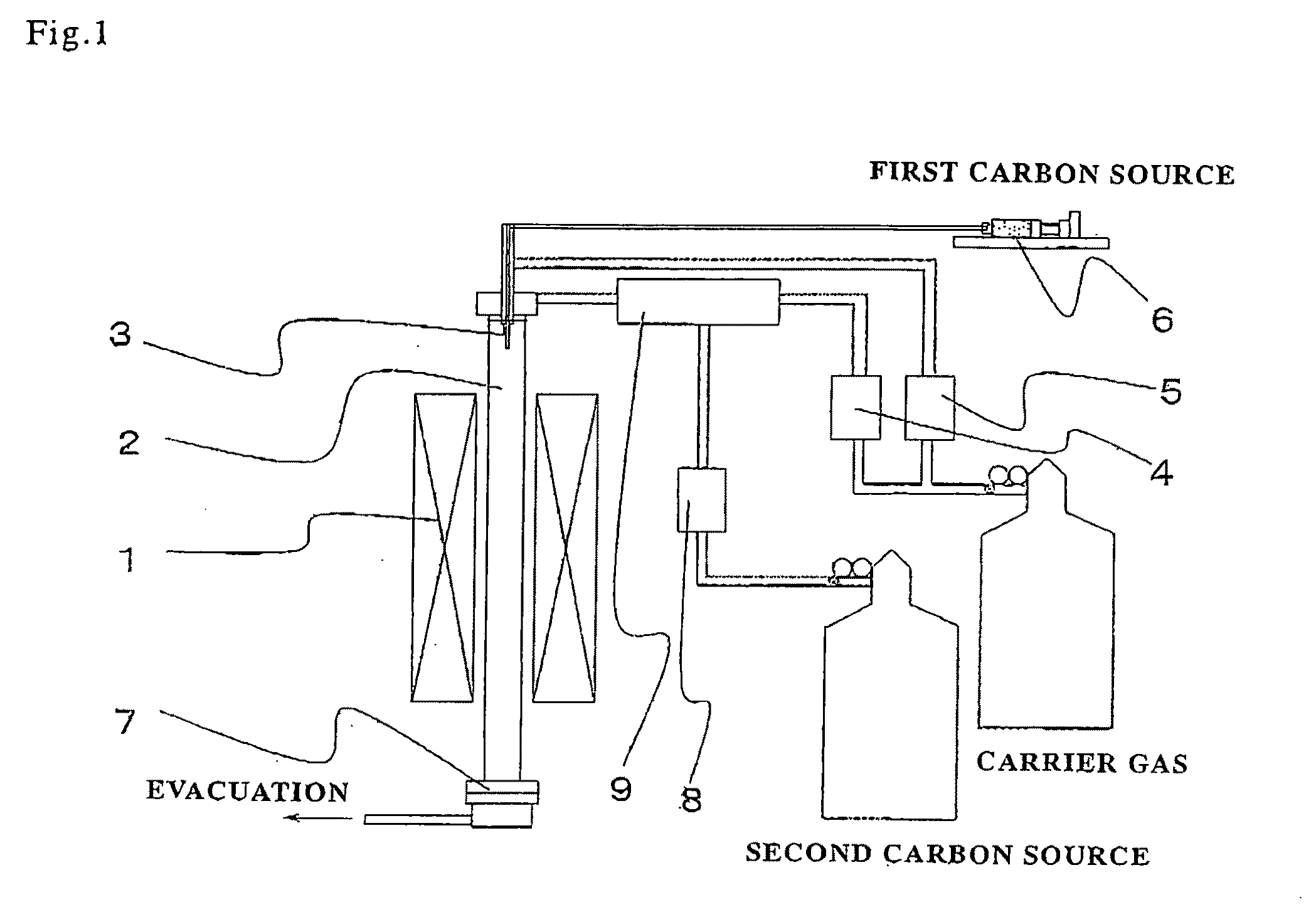

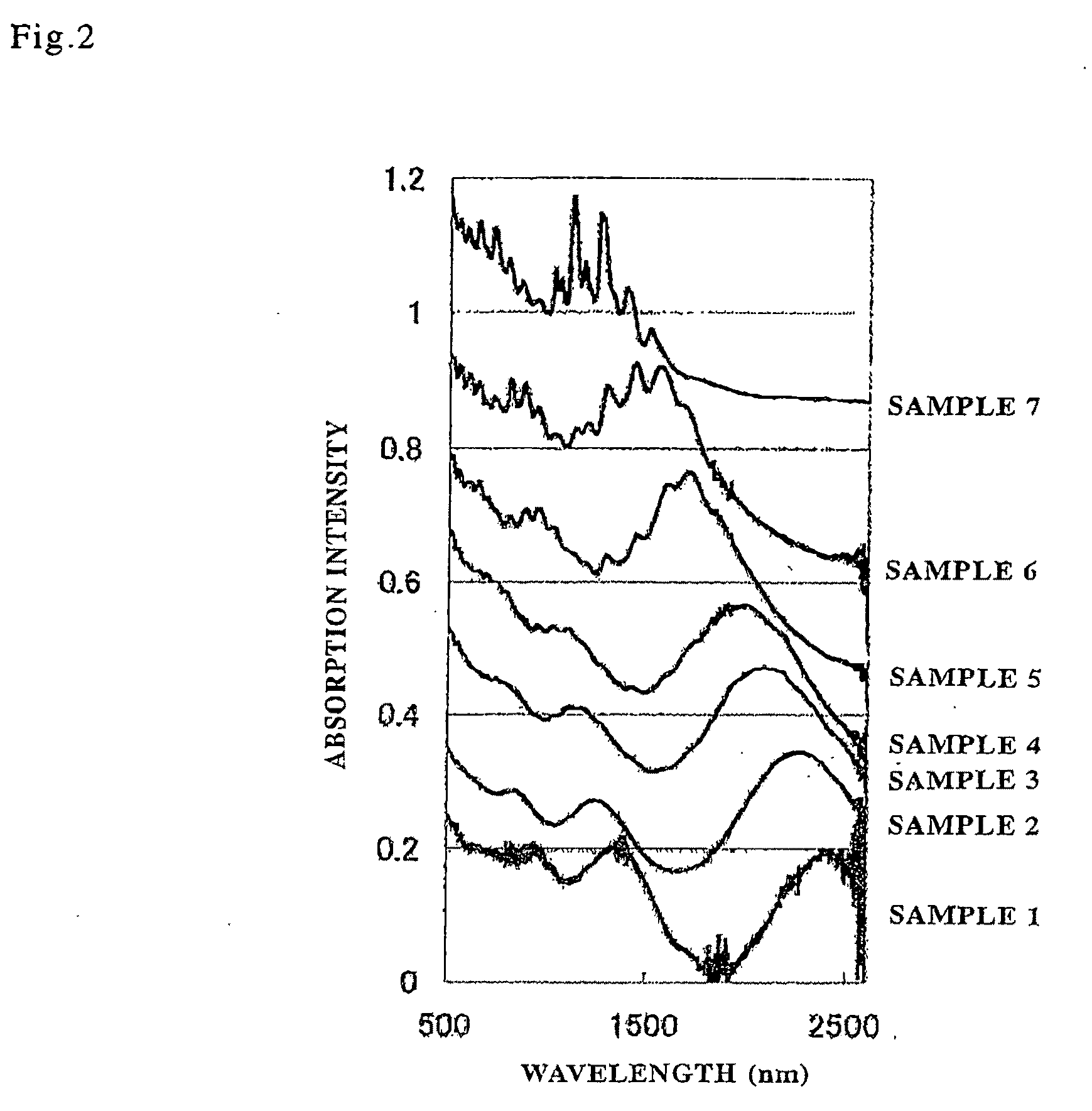

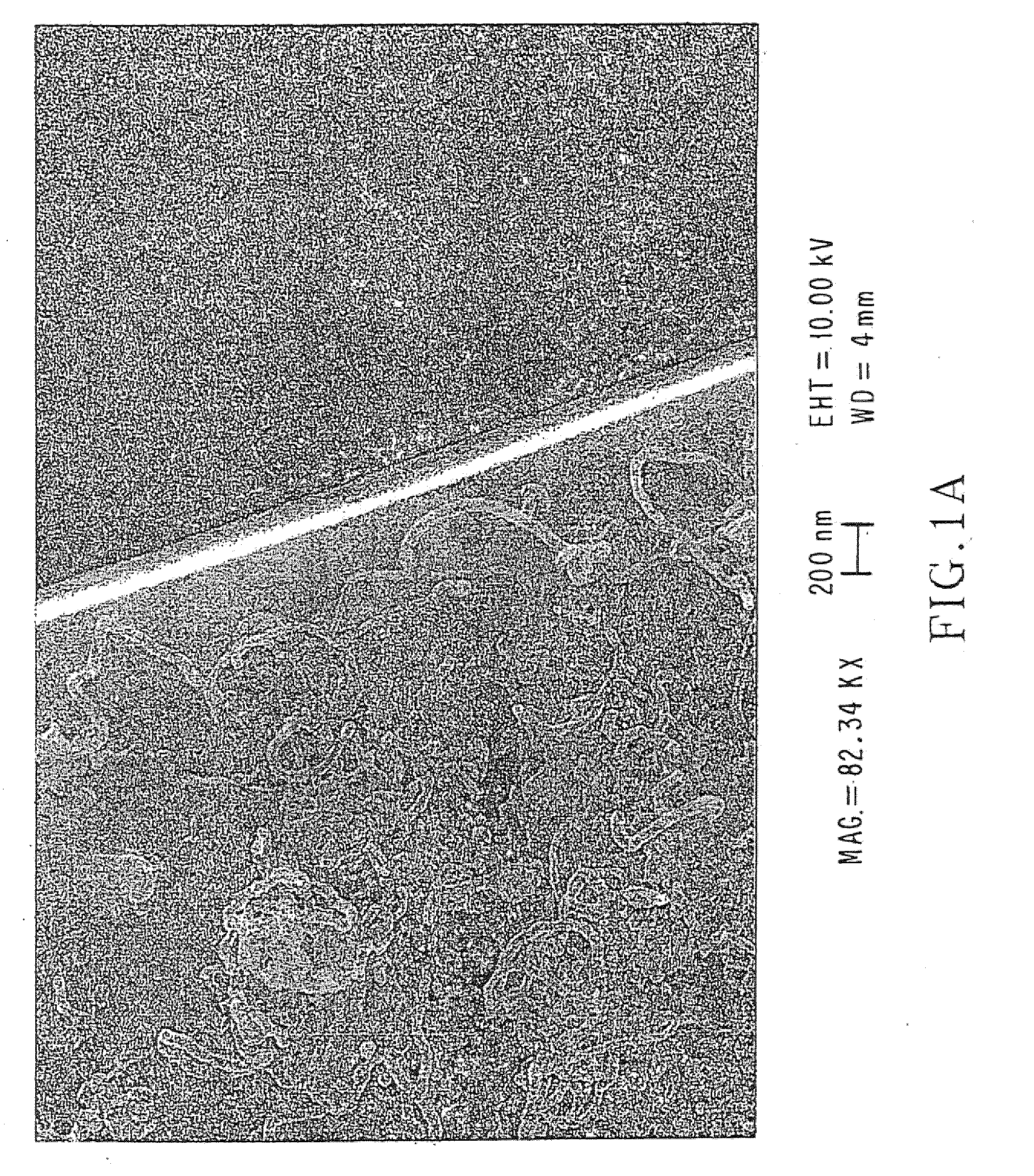

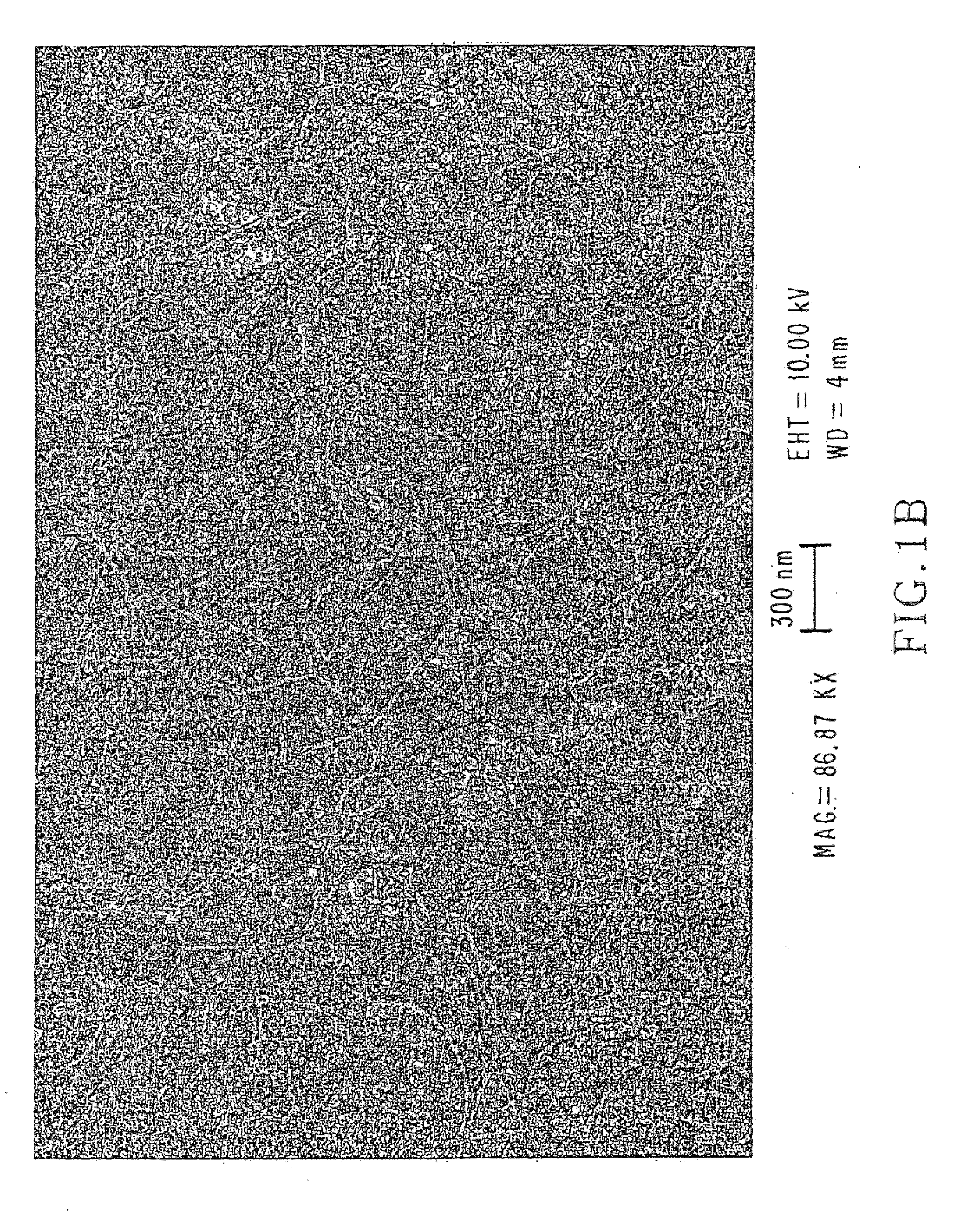

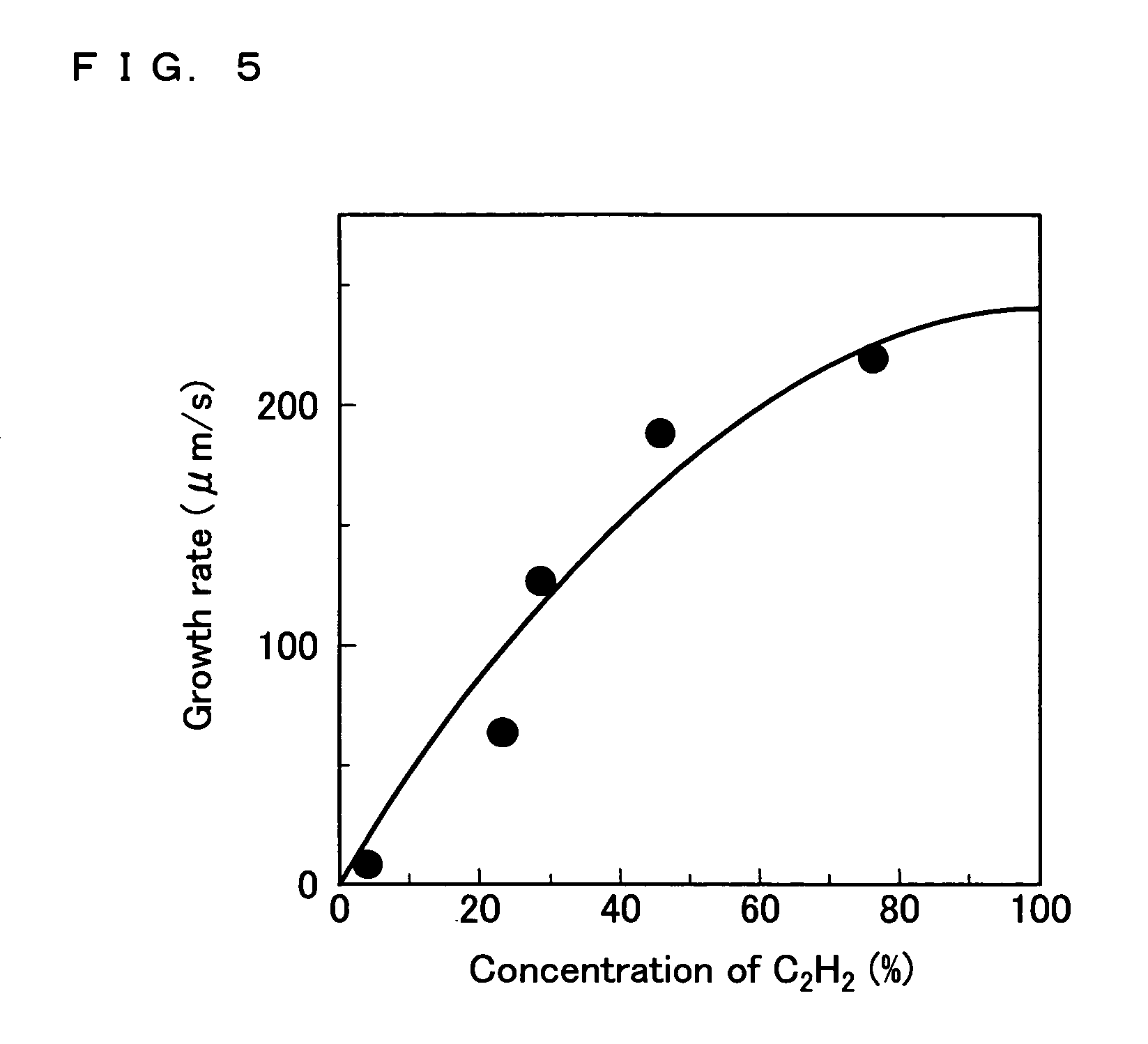

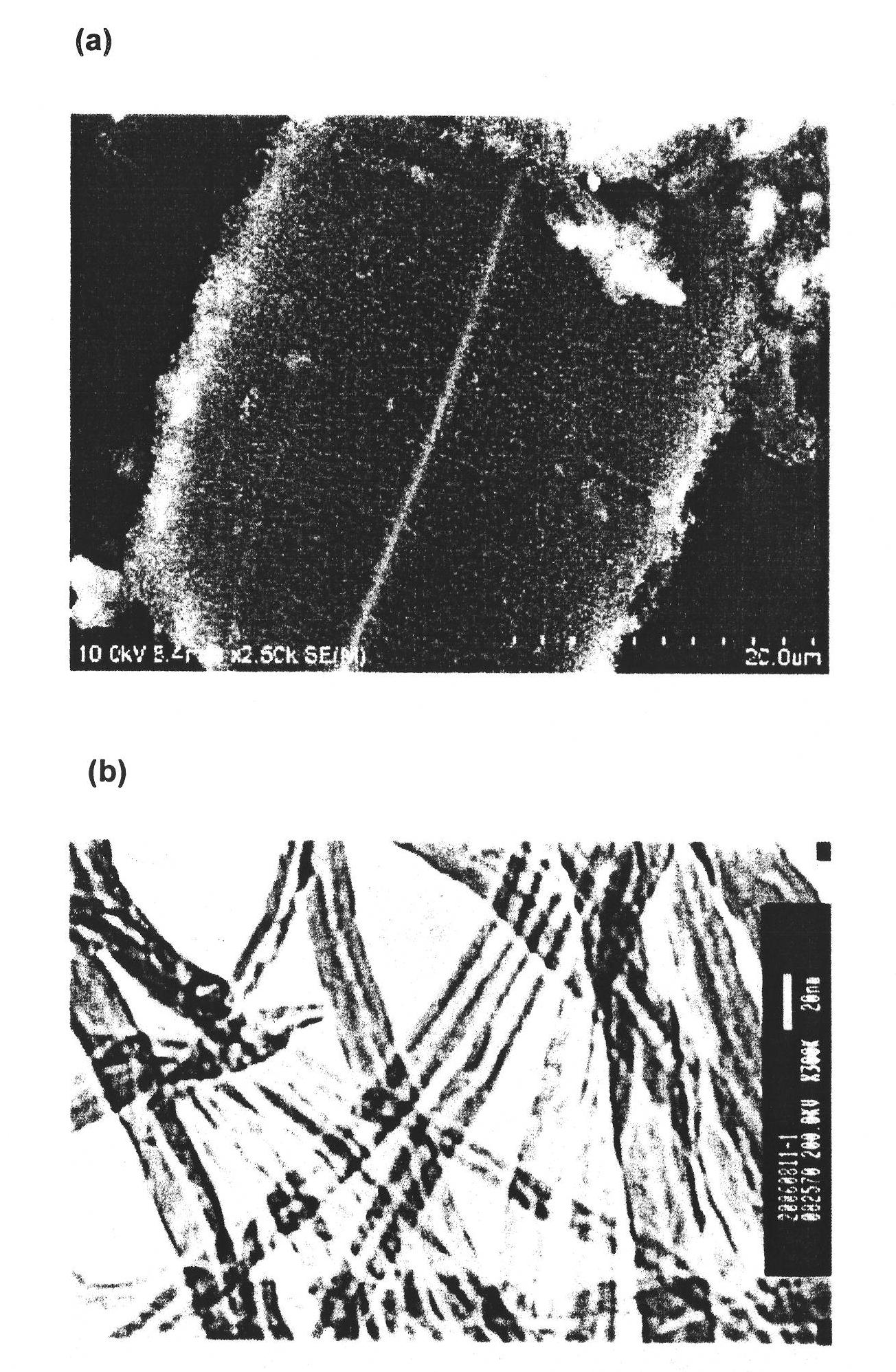

Single-Walled Carbon Nanotubes, Carbon Fiber Aggregate Containing the Single-Walled Carbon Nanotubes, and Method for Producing Those

InactiveUS20090186223A1High purityQuality improvementMaterial nanotechnologyFibre chemical featuresFiberCarbon fibers

It relates to high purity single-walled carbon nanotubes having controlled diameter, useful as industrial materials, including high-strength carbon wire rods, particularly uniform single-walled carbon nanotubes having diameter fallen in a range of from 1.0 to 2.0 nm, and a method for producing the same efficiently, in large amount and inexpensively. The single-walled carbon nanotube obtained is characterized in that its diameter is fallen in a range of from 1.0 to 2.0 nm, and an intensity ratio IG / ID between G-band and D-band in a Raman spectrum is 200 or more. Furthermore, those single-walled carbon nanotubes are synthesized by a gas-phase flow CVD method that uses a saturated aliphatic hydrocarbon which is liquid at ordinary temperature as a first carbon source and an unsaturated aliphatic hydrocarbon which is gas at ordinary temperature as a second carbon source.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Semiconductor nanocrystal-polymer composite, method of preparing the same, and composite film and optoelectronic device including the same

ActiveUS9082982B2Improve efficiencyImprove stabilityMaterial nanotechnologySolid-state devicesComposite filmCarboxylic acid

A semiconductor nanocrystal-polymer composite including a semiconductor nanocrystal, a polymer comprising a plurality of carboxylate anion groups (—COO−) bindable to a surface of the semiconductor nanocrystal, and a metal cation bindable to a carboxylate anion group of the plurality of carboxylate anion groups.

Owner:SAMSUNG ELECTRONICS CO LTD

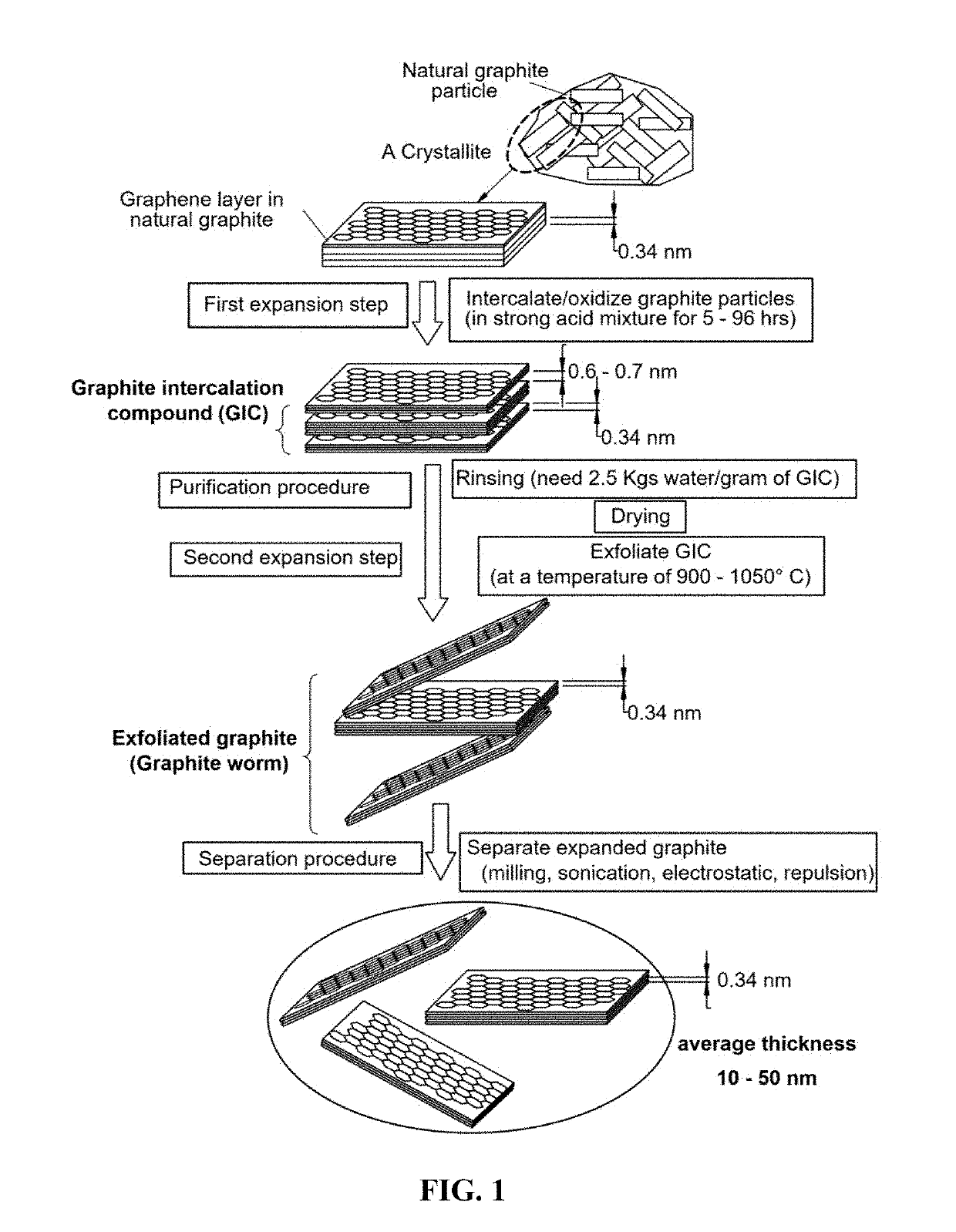

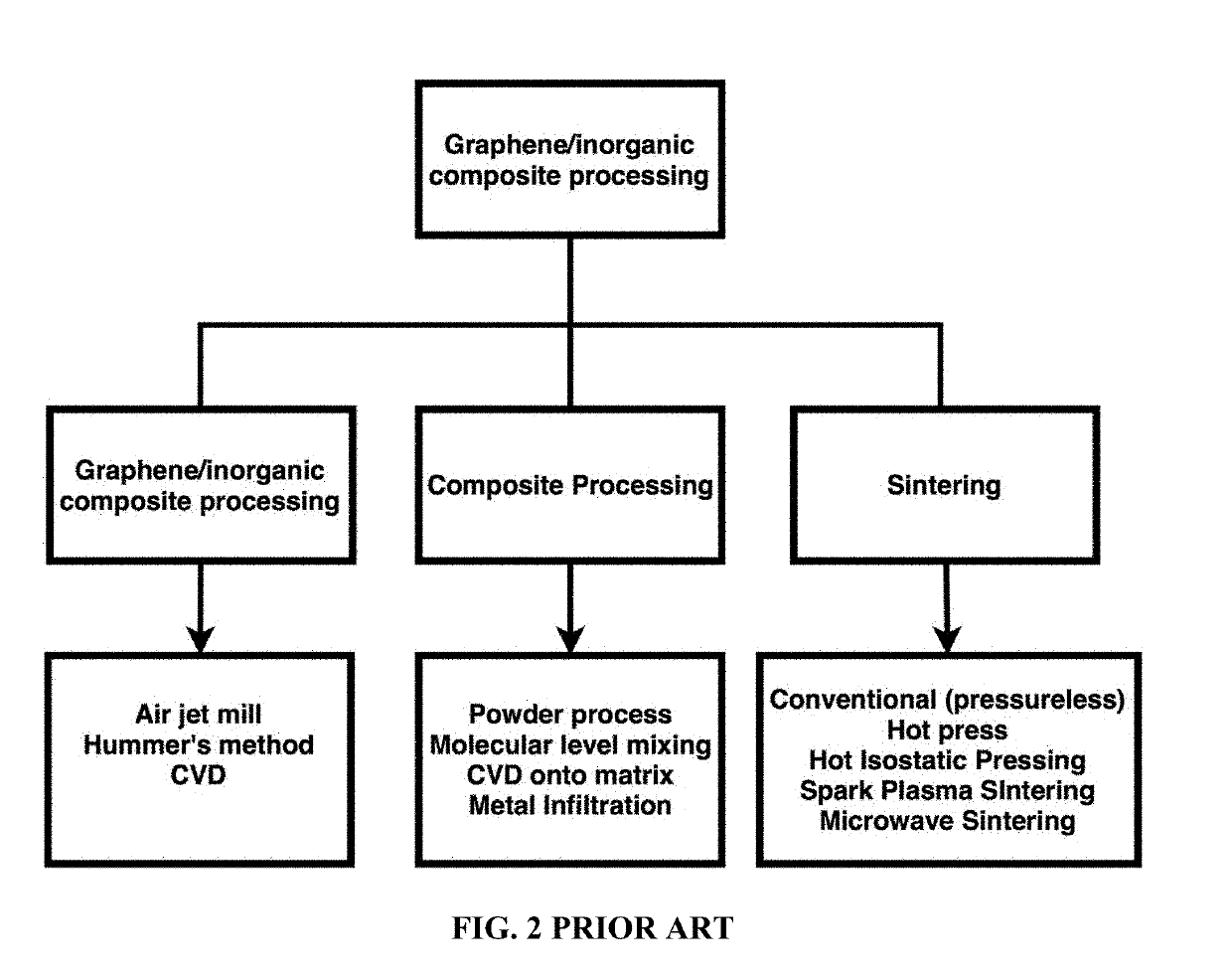

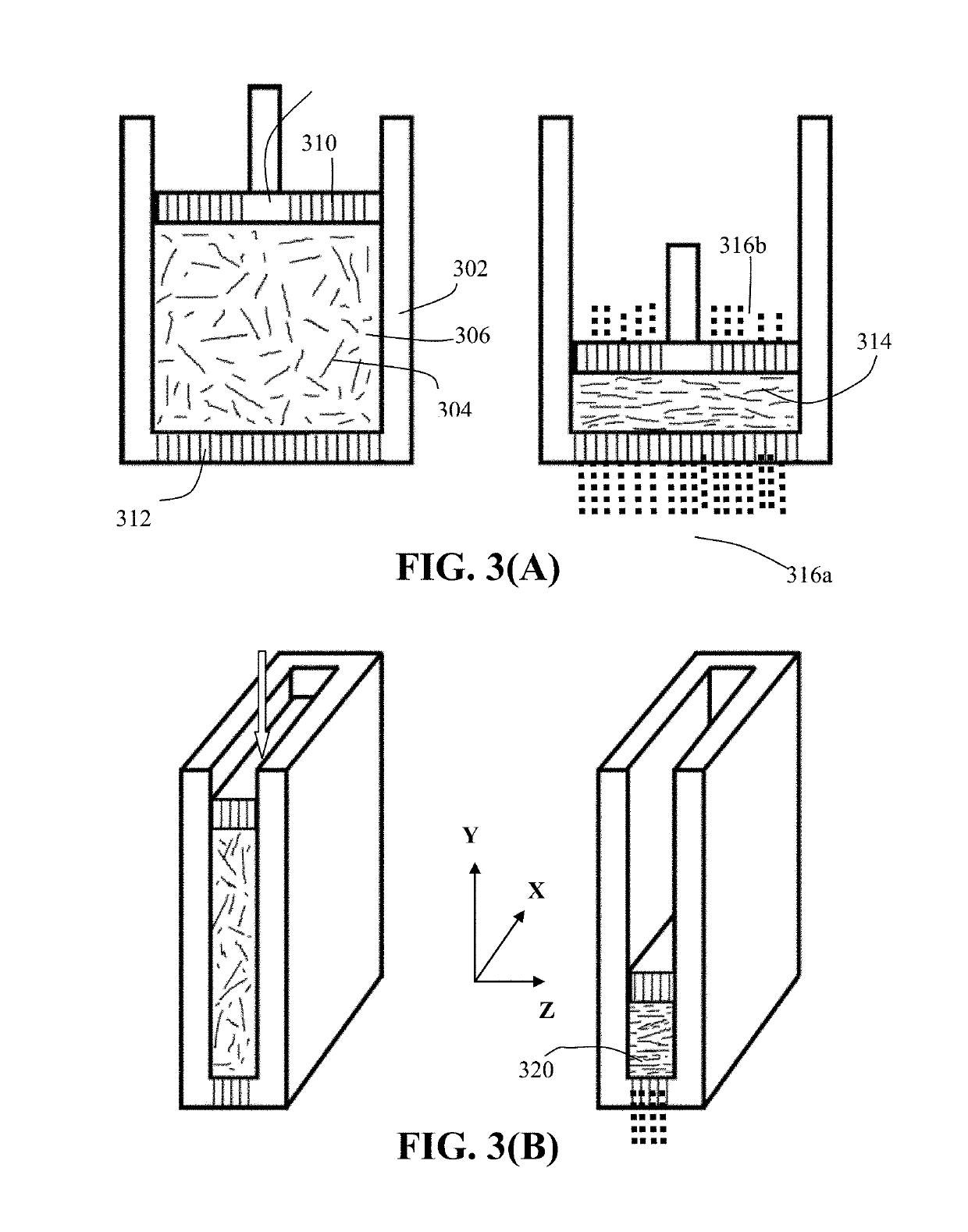

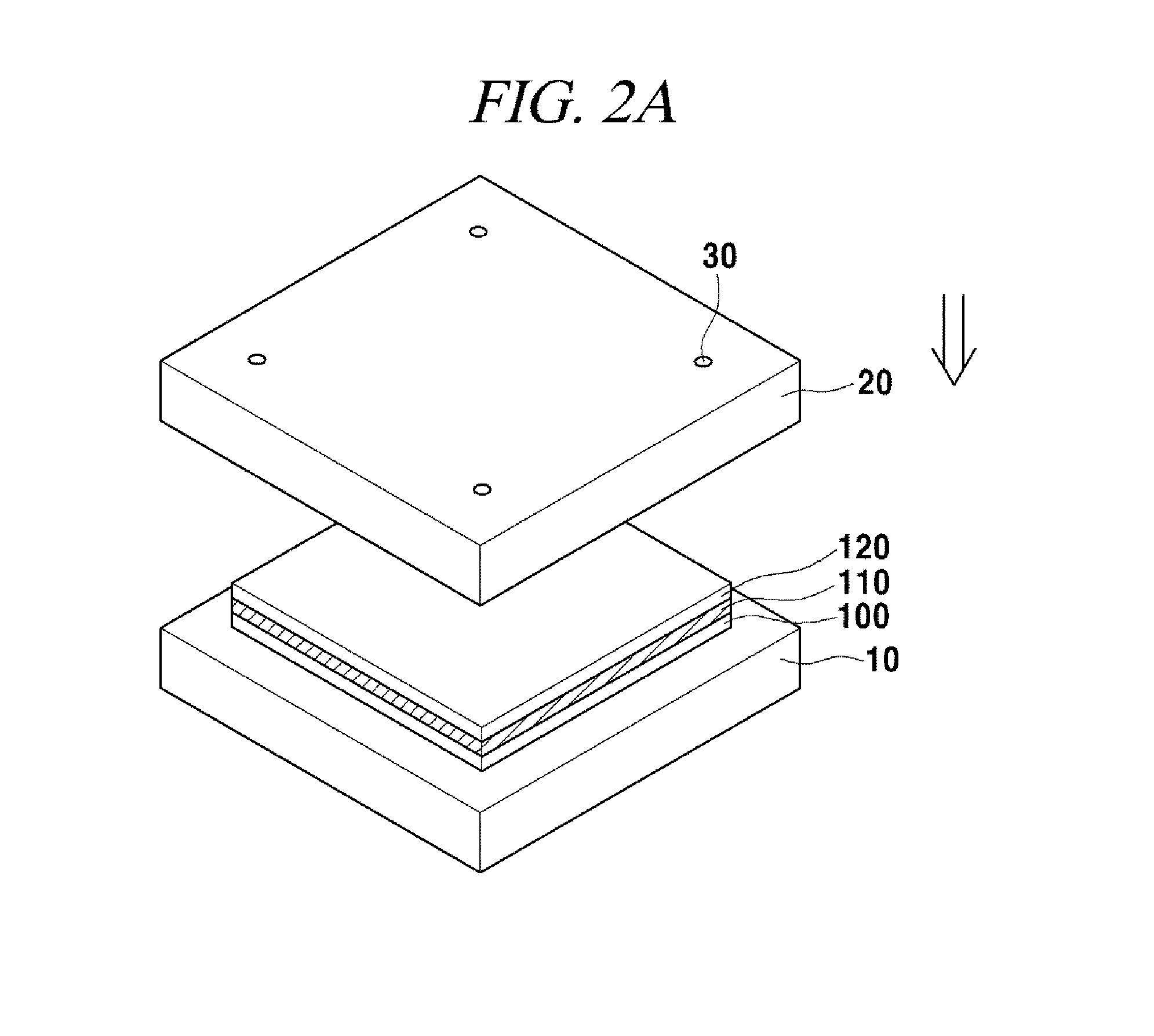

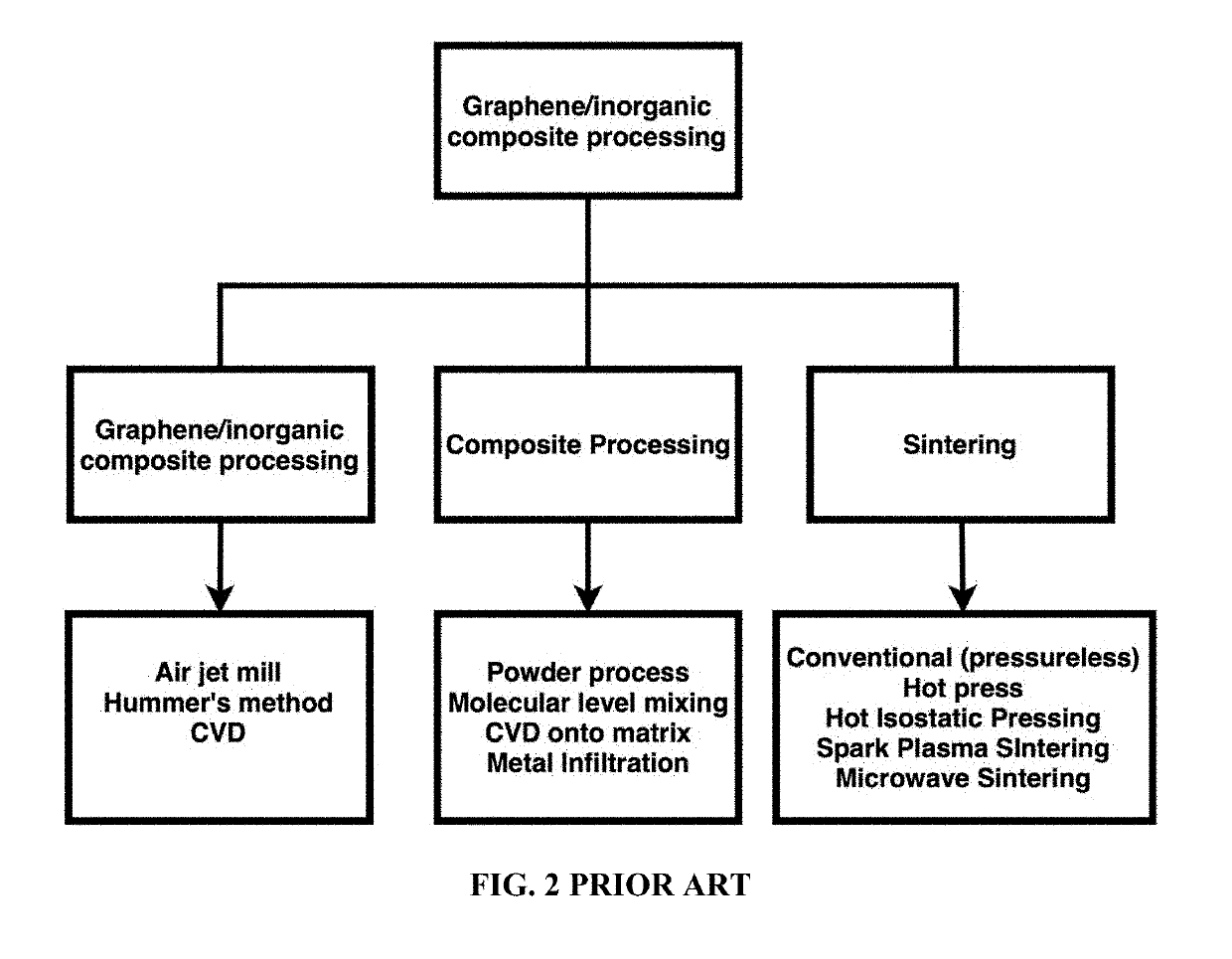

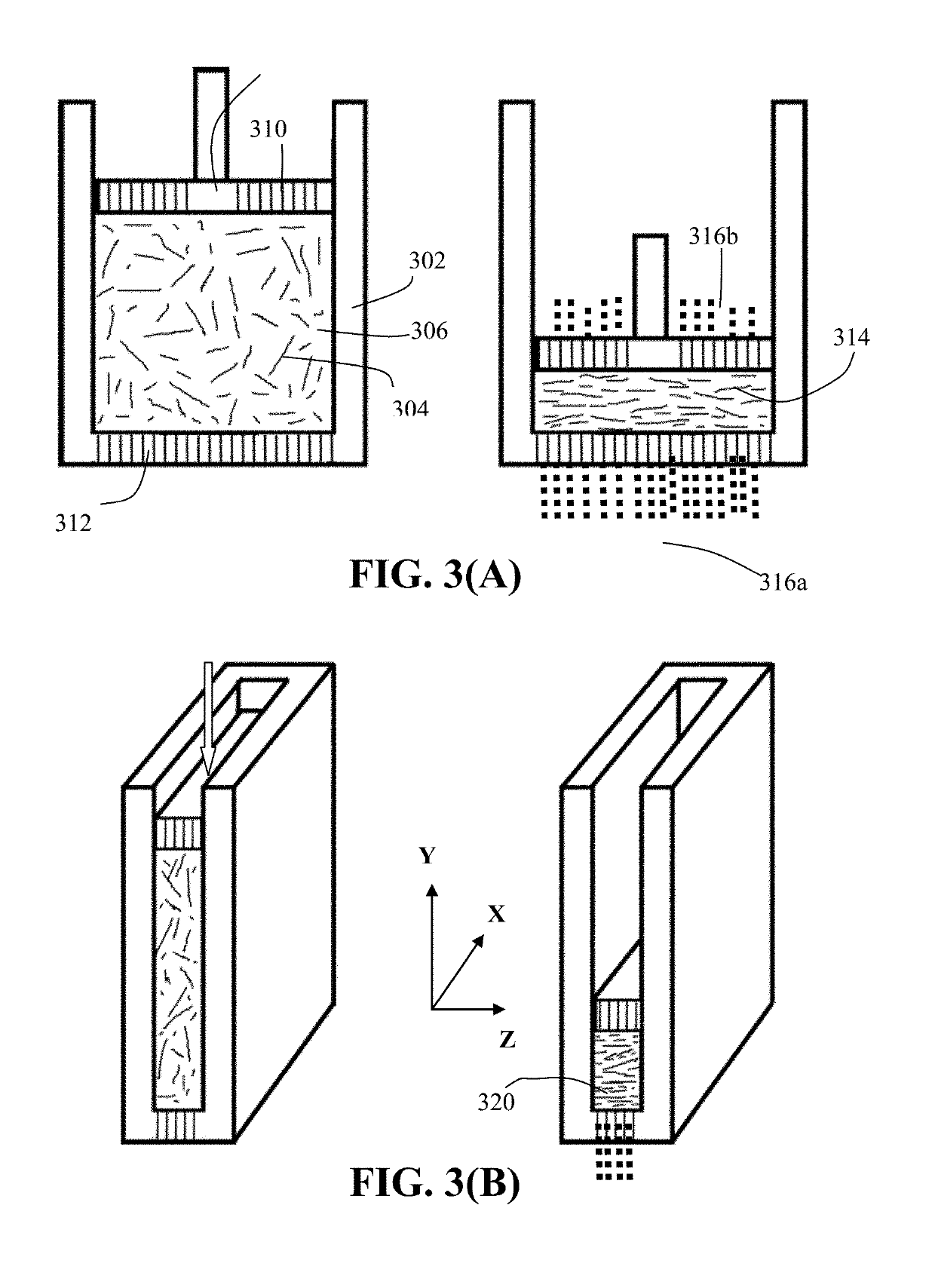

Metal matrix nanocomposite containing oriented graphene sheets and production process

PendingUS20190292671A1Reduce thicknessImprove directionMagnetic/electric field screeningTransportation and packagingDoped grapheneMetal alloy

Provided is a metal matrix nanocomposite comprising: (a) a metal or metal alloy as a matrix material; and (b) multiple graphene sheets that are dispersed in said matrix material, wherein said multiple graphene sheets are substantially aligned to be parallel to one another and are in an amount from 0.1% to 95% by volume based on the total nanocomposite volume; wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from pristine graphene, graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof and wherein the chemically functionalized graphene is not graphene oxide. The metal matrix exhibits a combination of exceptional tensile strength, modulus, thermal conductivity, and / or electrical conductivity.

Owner:GLOBAL GRAPHENE GRP INC

Method for disentanglement of carbon nanotube bundles

Bundled carbon nanotubes are disentangled and dispersed using the principles of extreme pressure reduction of fluids carrying the bundled nanotubes. They are added to a high pressure fluid upstream of a chamber operated at much lower pressure. These high-low pressure ratios are preferably at least 100:1. As the high pressure fluid enters the lower pressure chamber it violently expands causing separation and disentanglement of the bundled carbon fibers. To further assist in this disentanglement a nozzle may be used at the inlet to the lower pressure chamber to direct the high pressure fluid against a hardened anvil in the chamber. This impact further aids disentanglement. Coating the nanotubes with a dispersant also improves disentanglement.

Owner:ADVANCED FIBER TECH +1

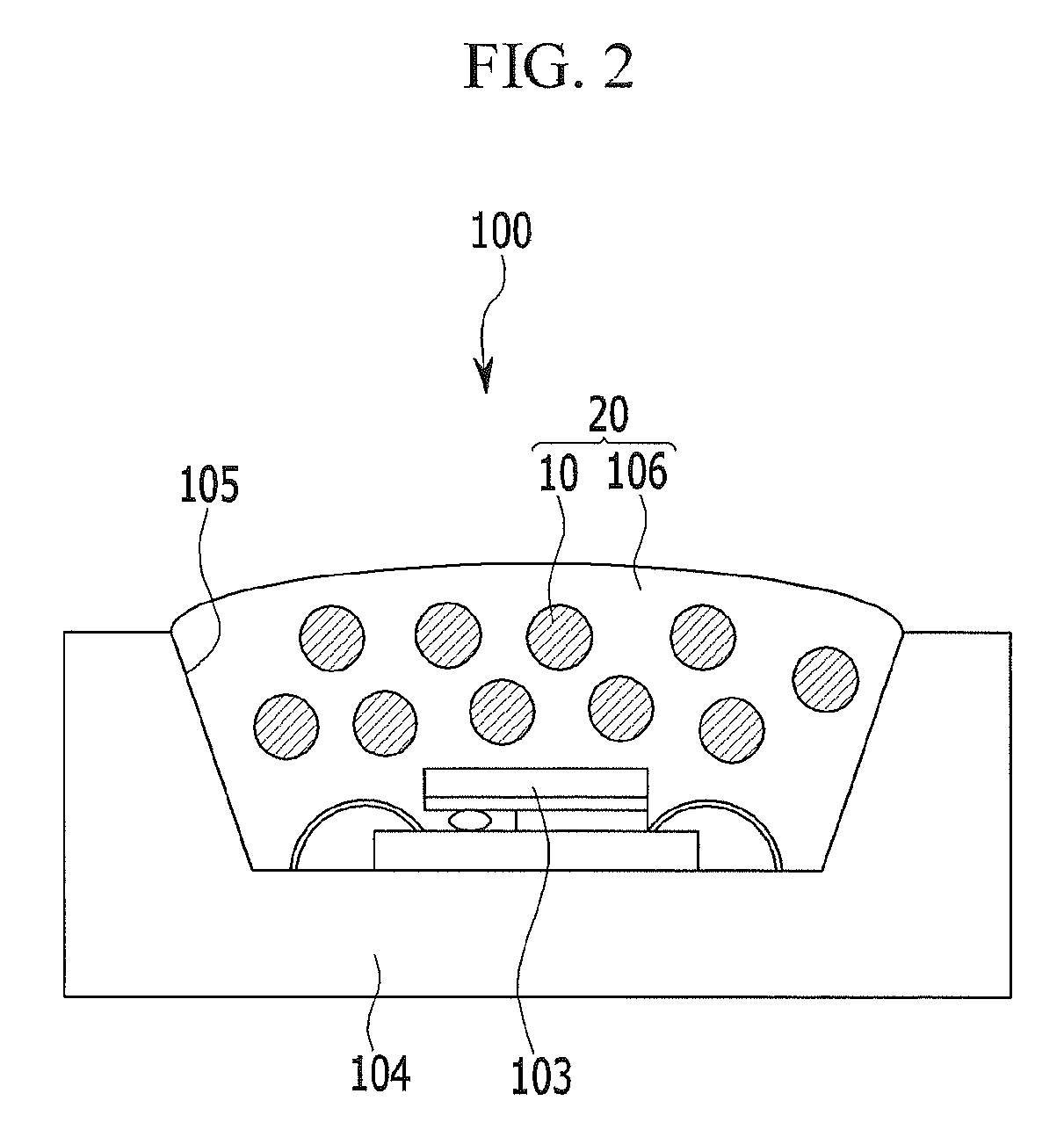

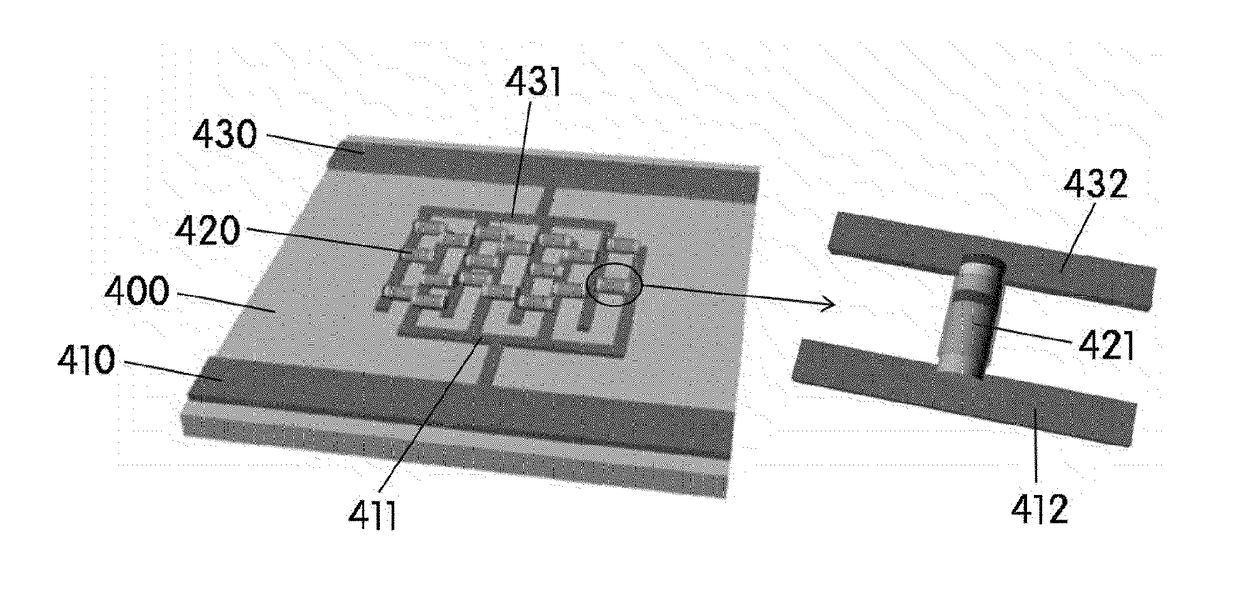

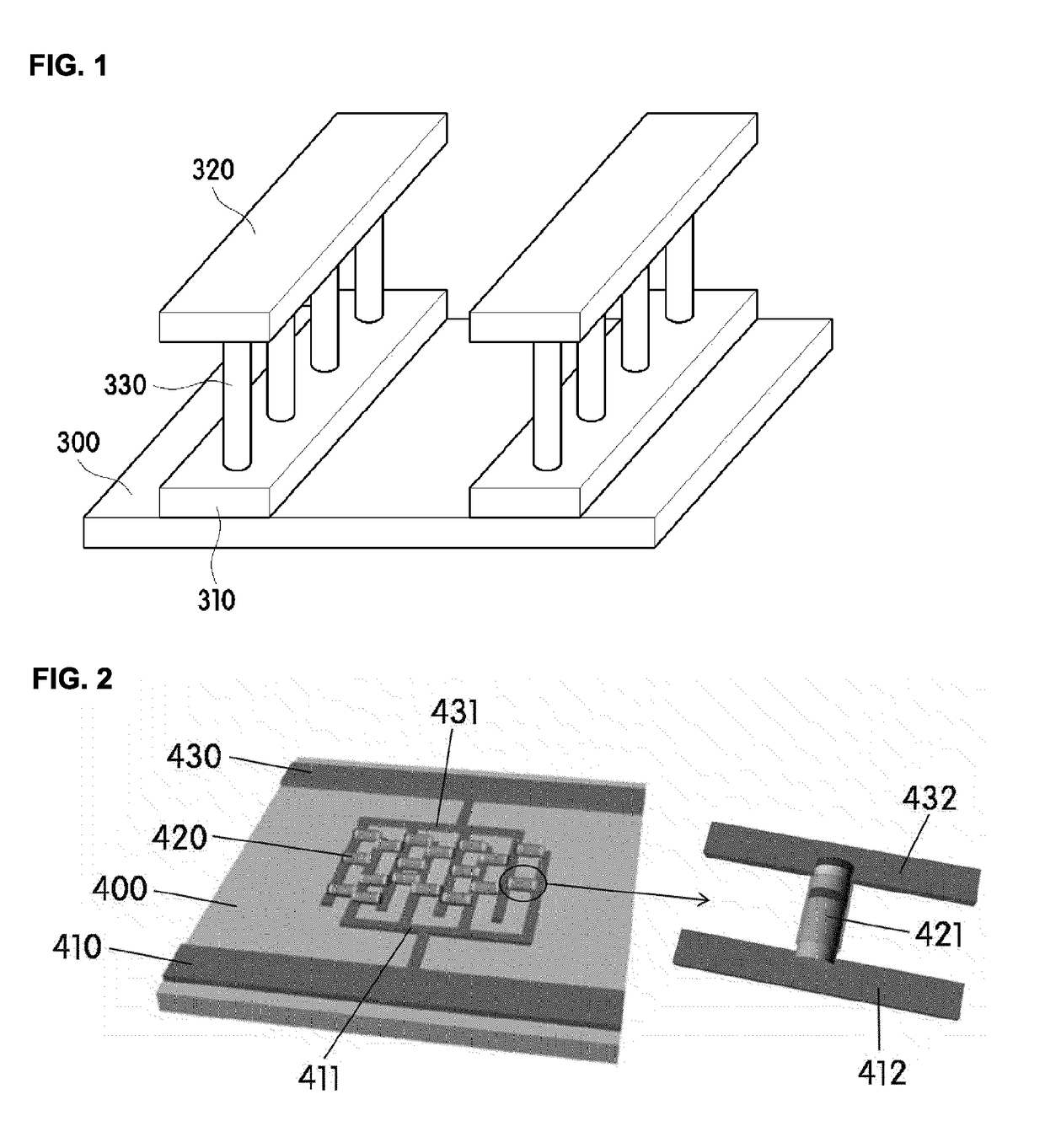

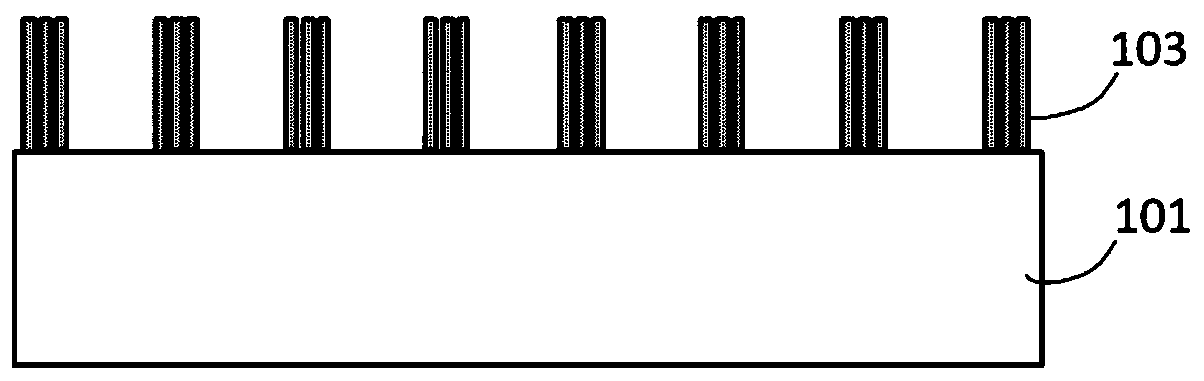

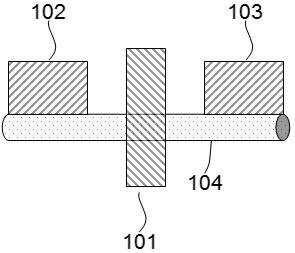

Electrode assembly comprising micro-led elements and method for manufacturing same

ActiveUS20180287010A1Maximize light intensityImprove light extractionSolid-state devicesNanostructure manipulationElectricityEngineering

The present invention relates to an electrode assembly comprising nano-scale-LED elements and a method for manufacturing the same and, more specifically, to an electrode assembly comprising nano-scale-LED elements and a method for manufacturing the same, in which the number of nano-scale-LED elements included in a unit area of the electrode assembly is increased, the light extraction efficiency of individual nano-scale-LED elements is increased so as to maximize light intensity per unit area, and at the same time, nano-scale-LED elements on a nanoscale are connected to an electrode without a fault such as an electrical short circuit.

Owner:SAMSUNG DISPLAY CO LTD

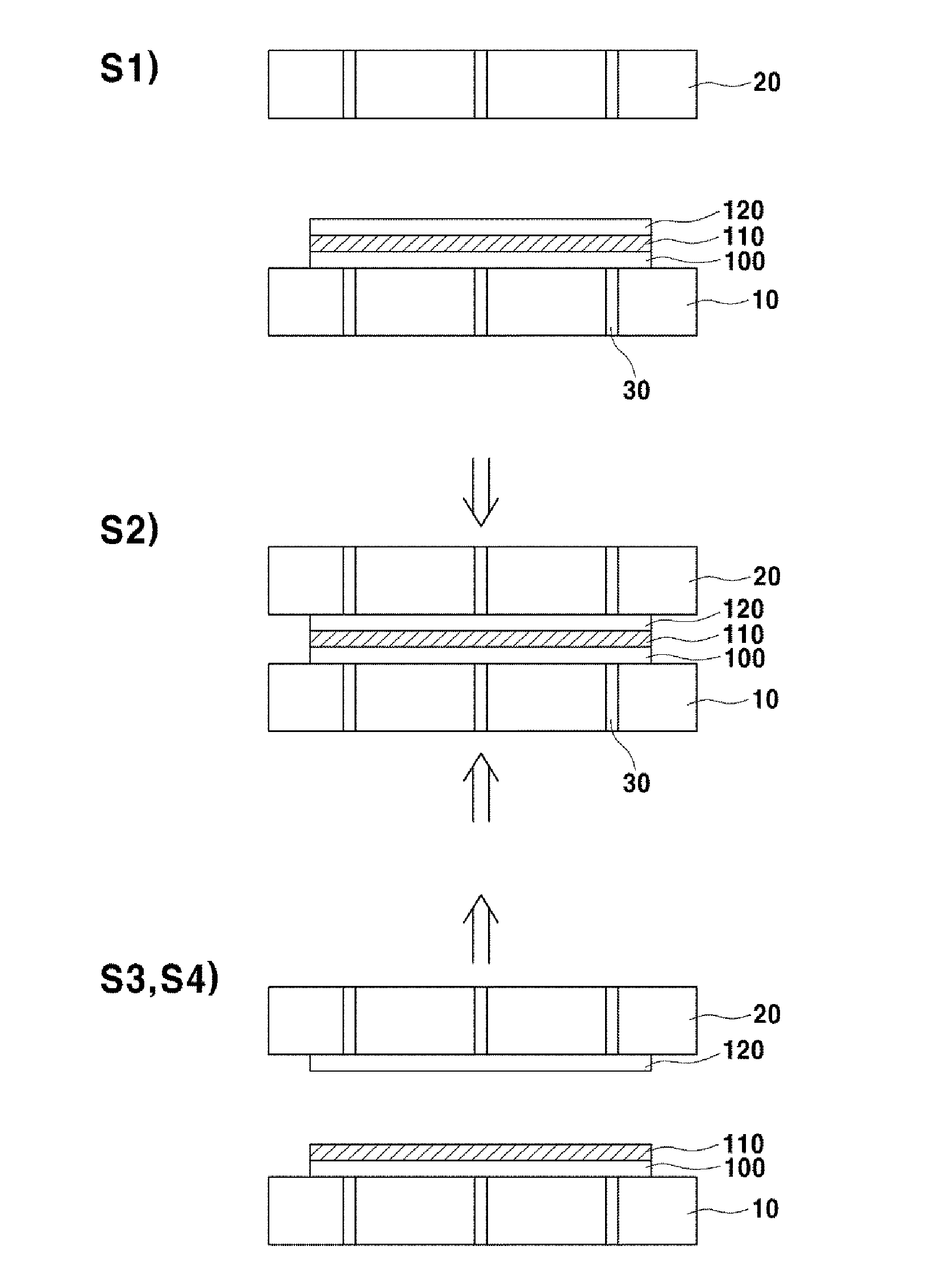

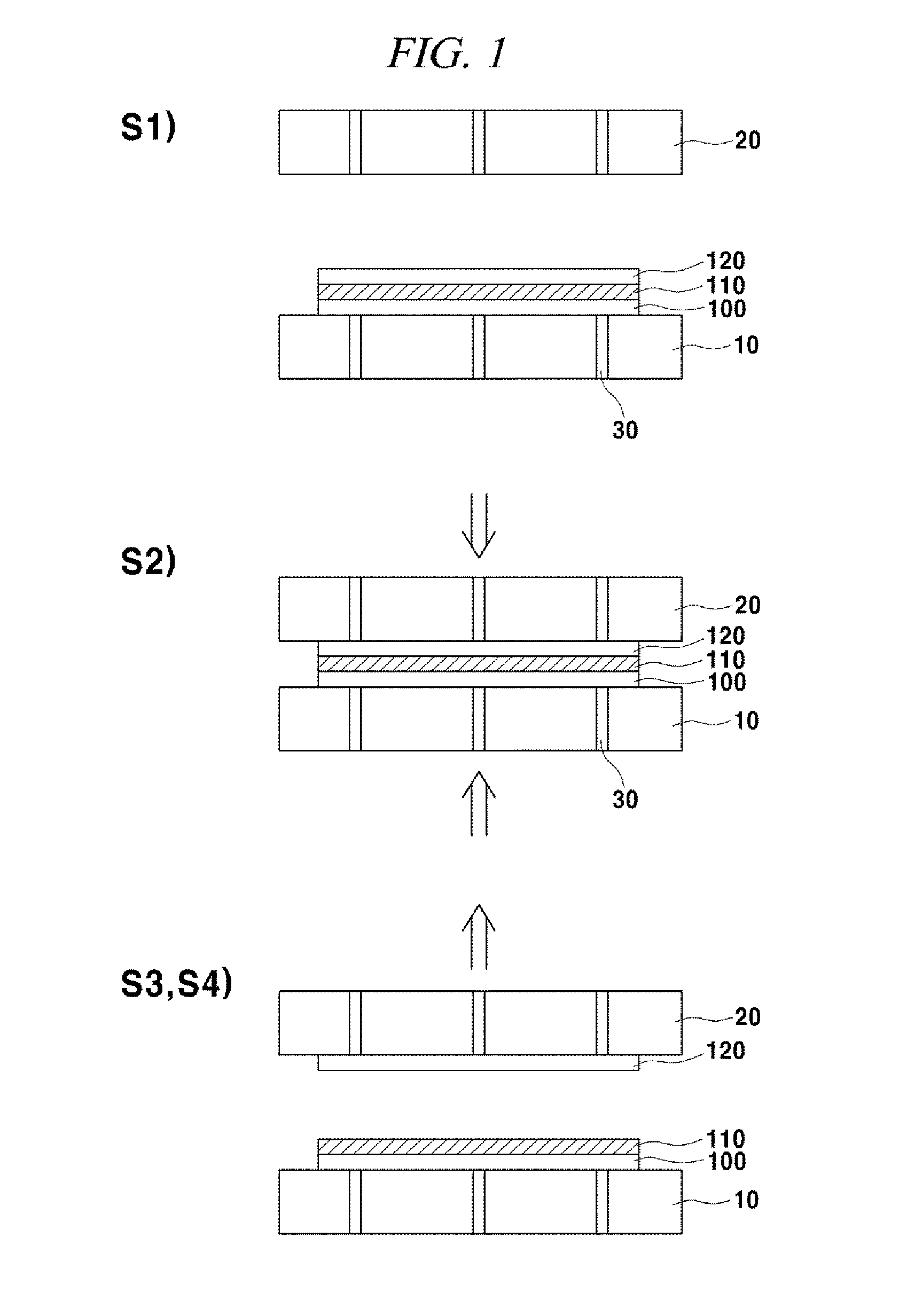

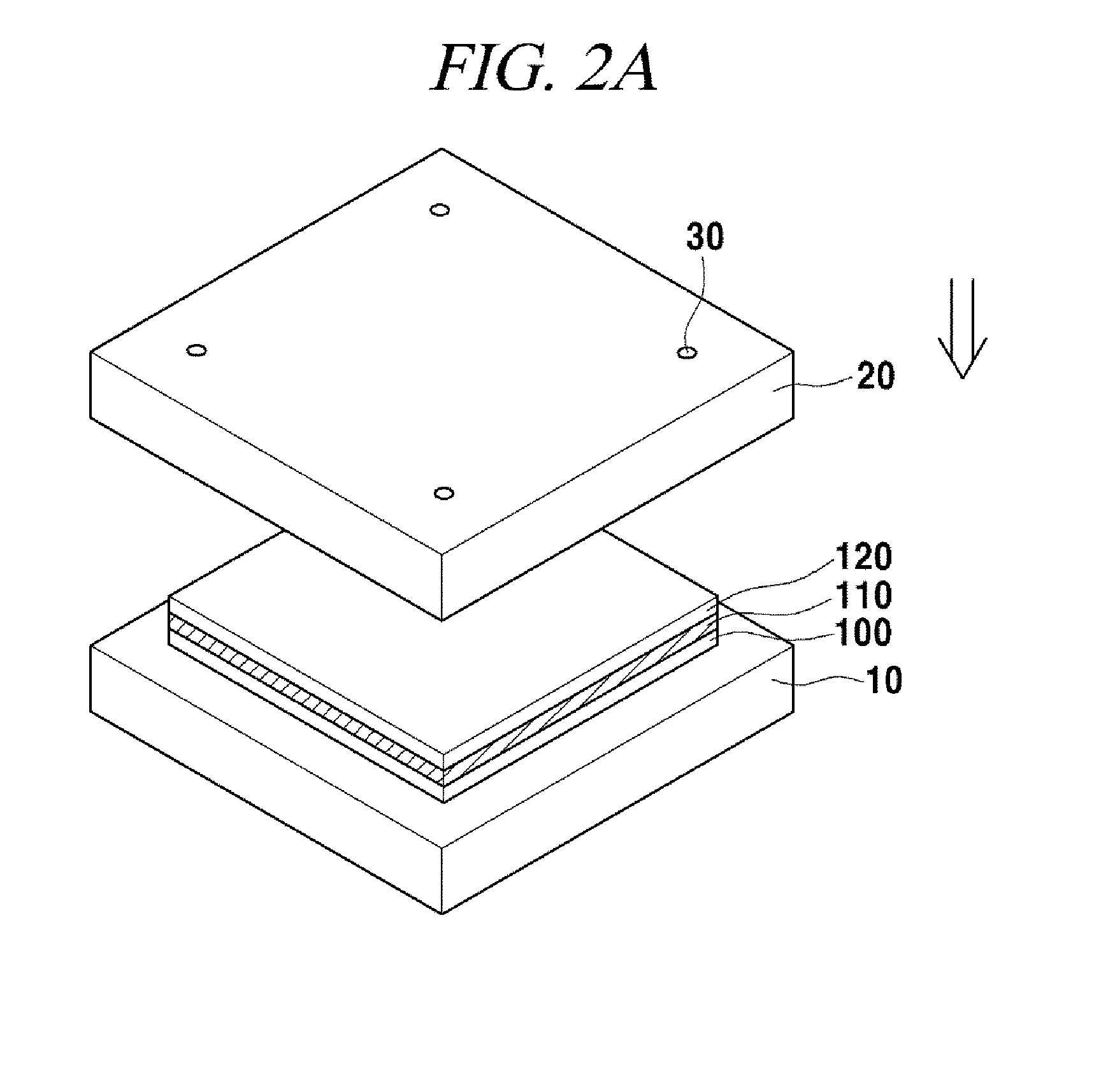

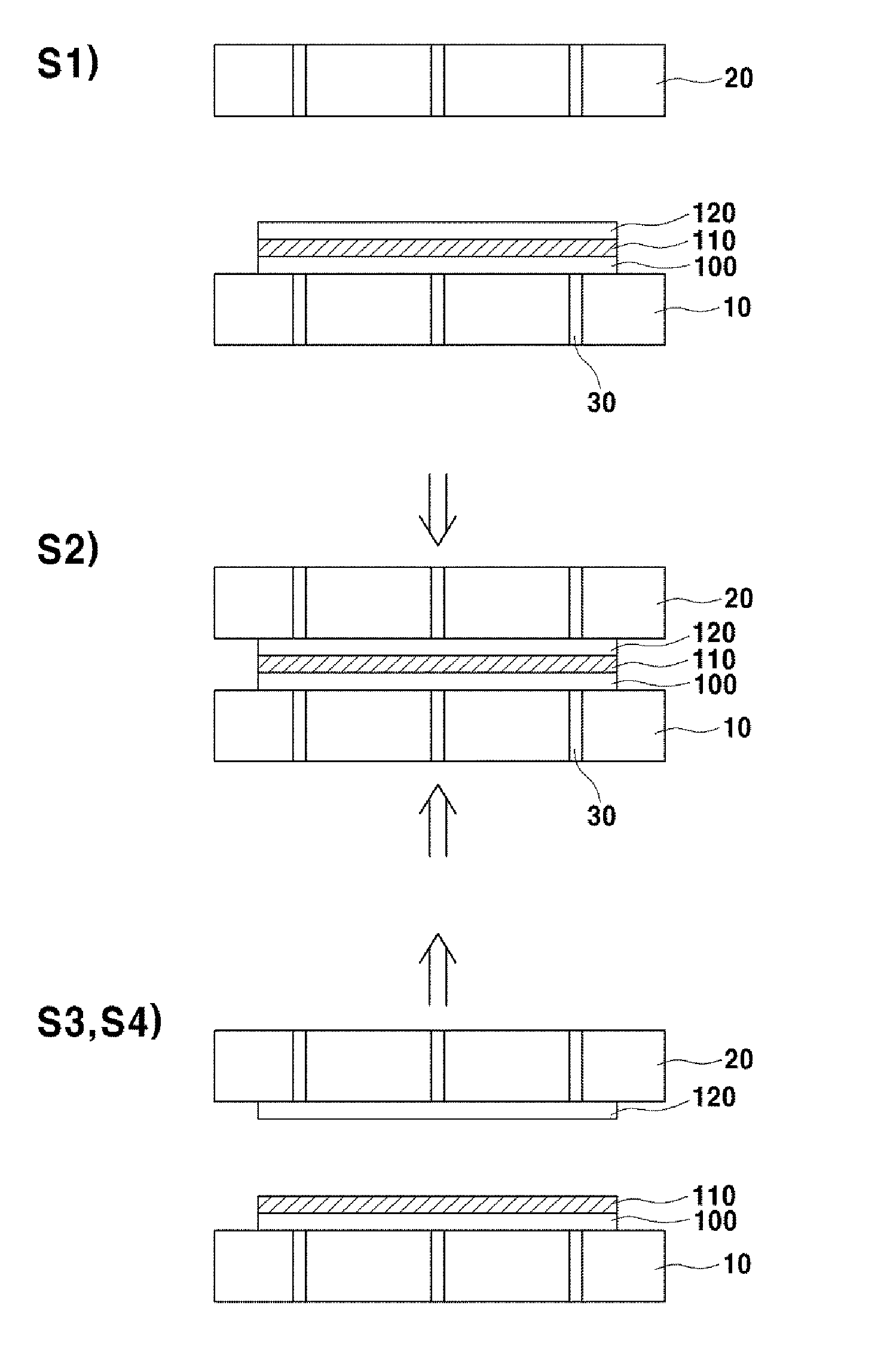

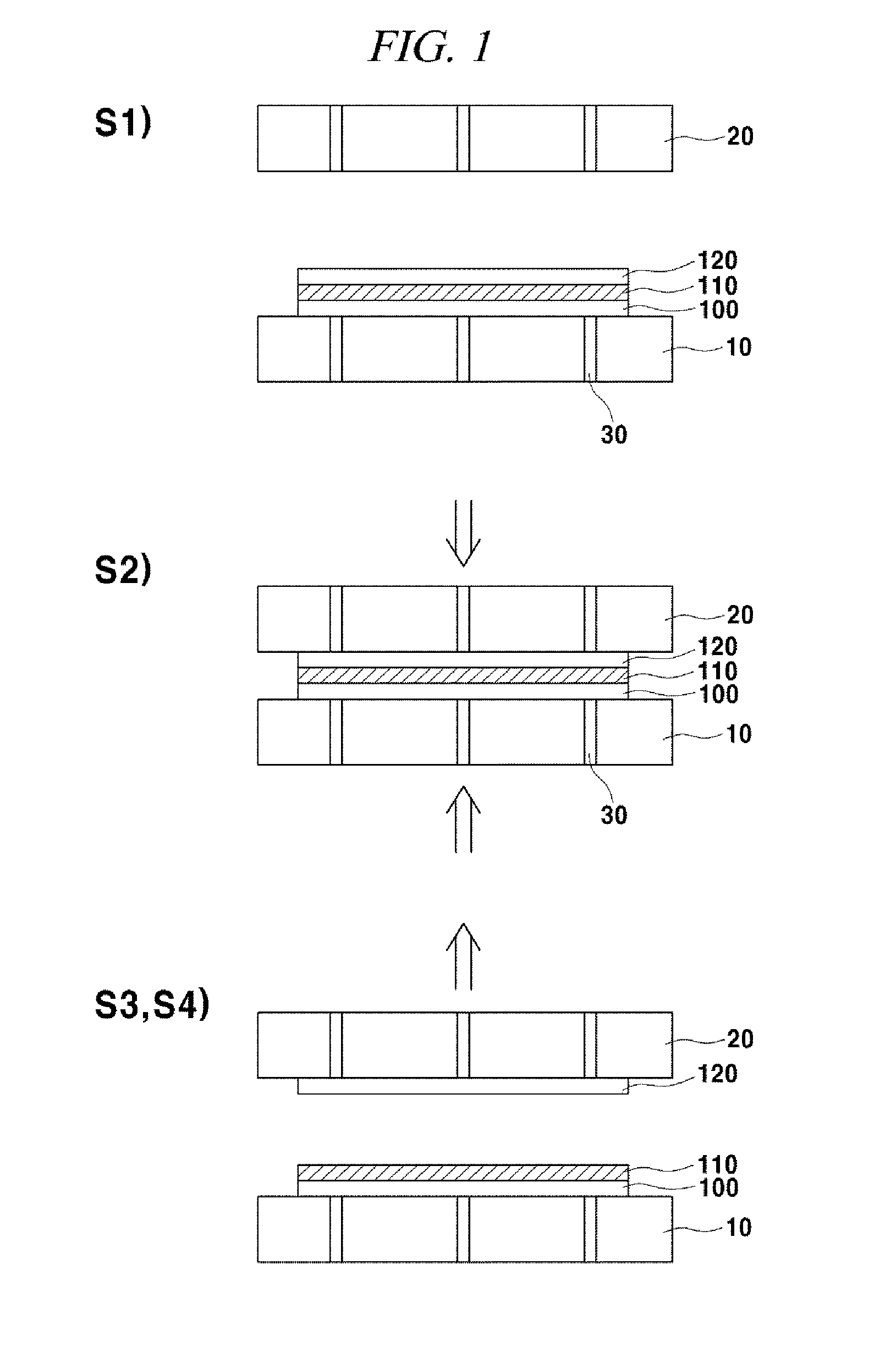

Method for transferring graphene using a hot press

ActiveUS20130299077A1Minimize damageEasy transferNanostructure assemblyLamination ancillary operationsGrapheneMaterials science

The present invention relates to a method for transferring graphene using a hot press, comprising: a step of contacting graphene, having a thermal-releasable sheet attached thereto, with a target substrate; and a step of pressing and heating the graphene having the thermal-releasable sheet attached thereto and the target substrate using the upper press and lower press of a hot press so as to separate the thermal-releasable sheet and the graphene and transfer the separated graphene to the target substrate. The present invention also relates to a graphene-transfer hot press apparatus for said transfer process.

Owner:GRAPHENE SQUARE

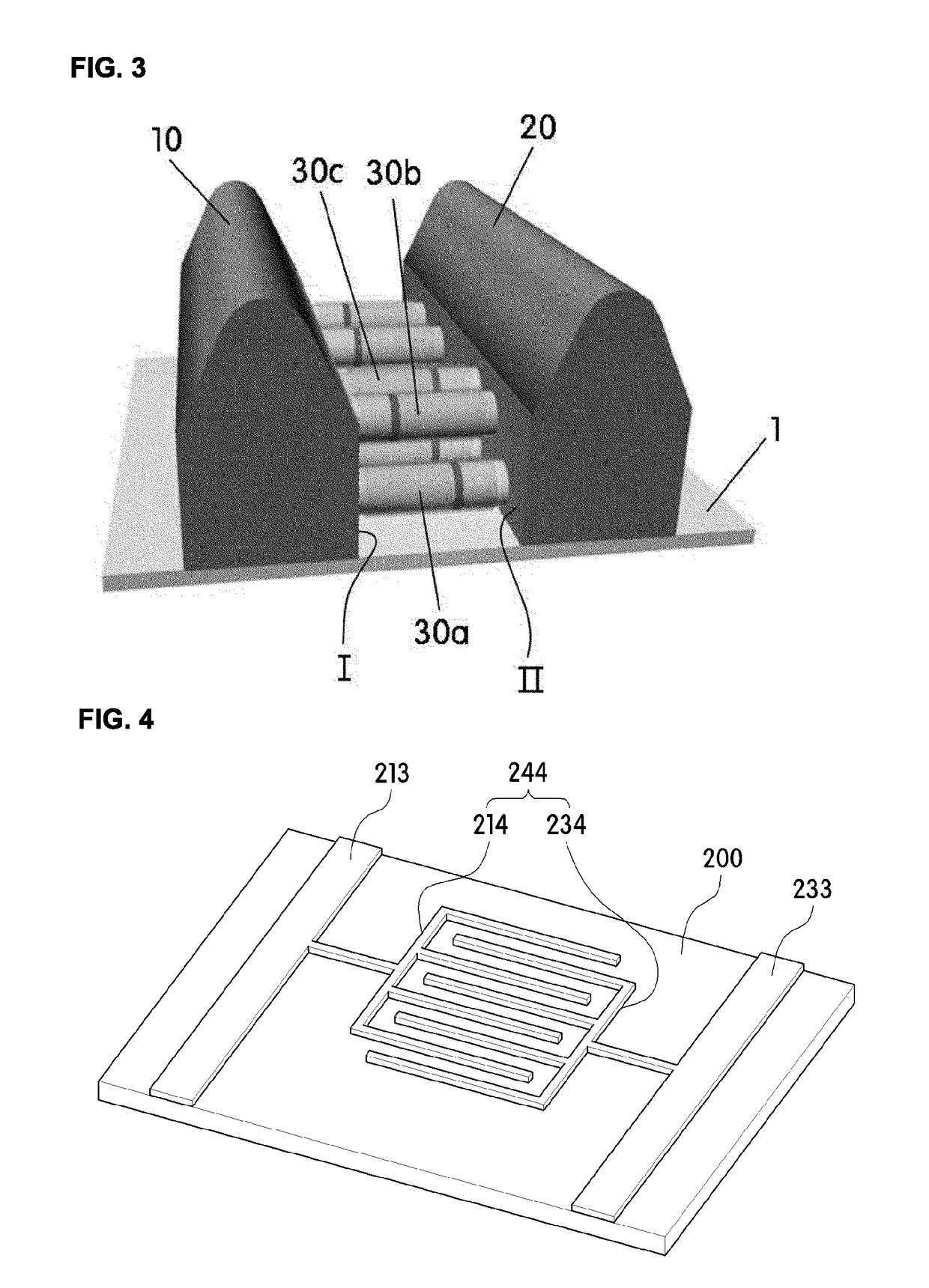

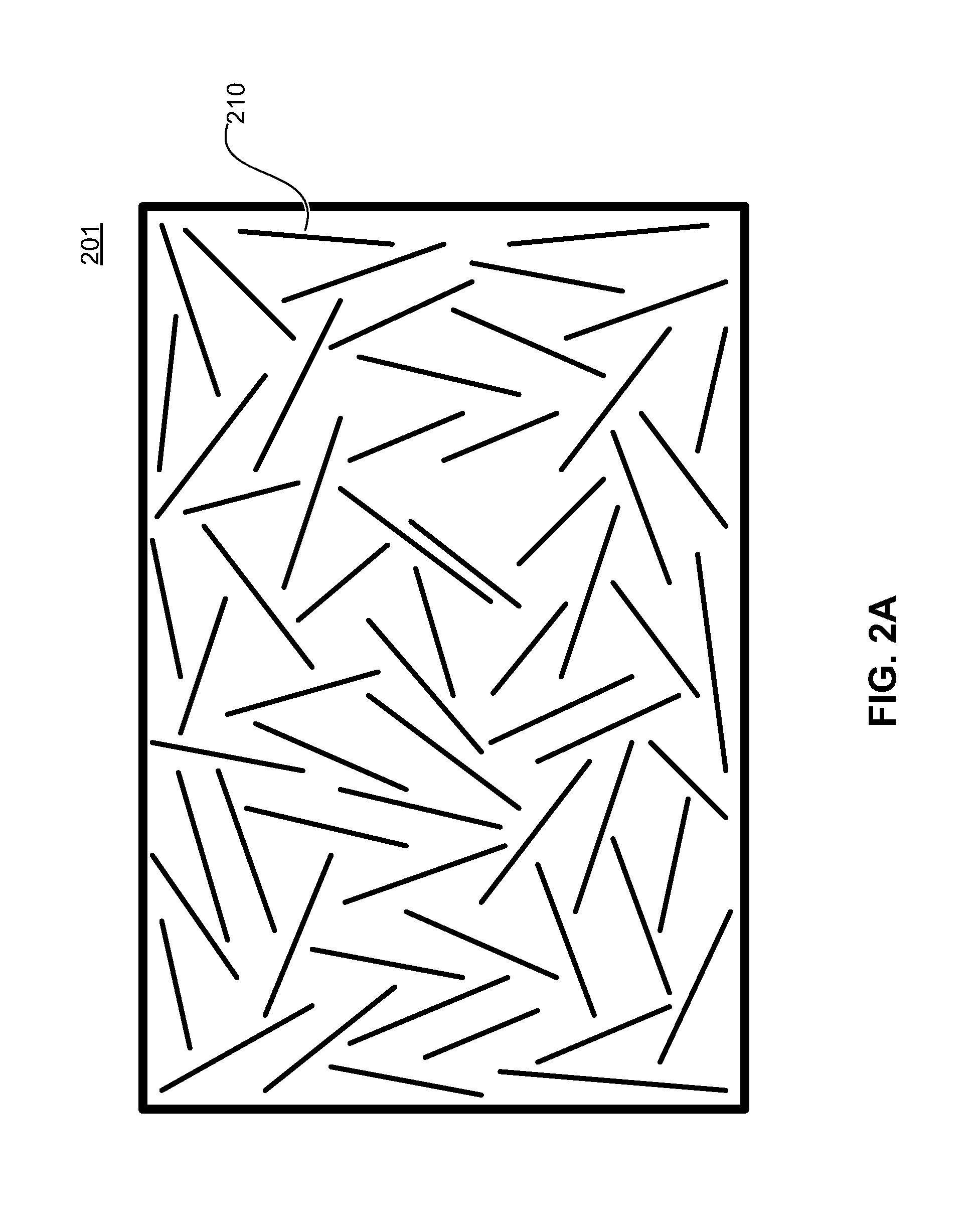

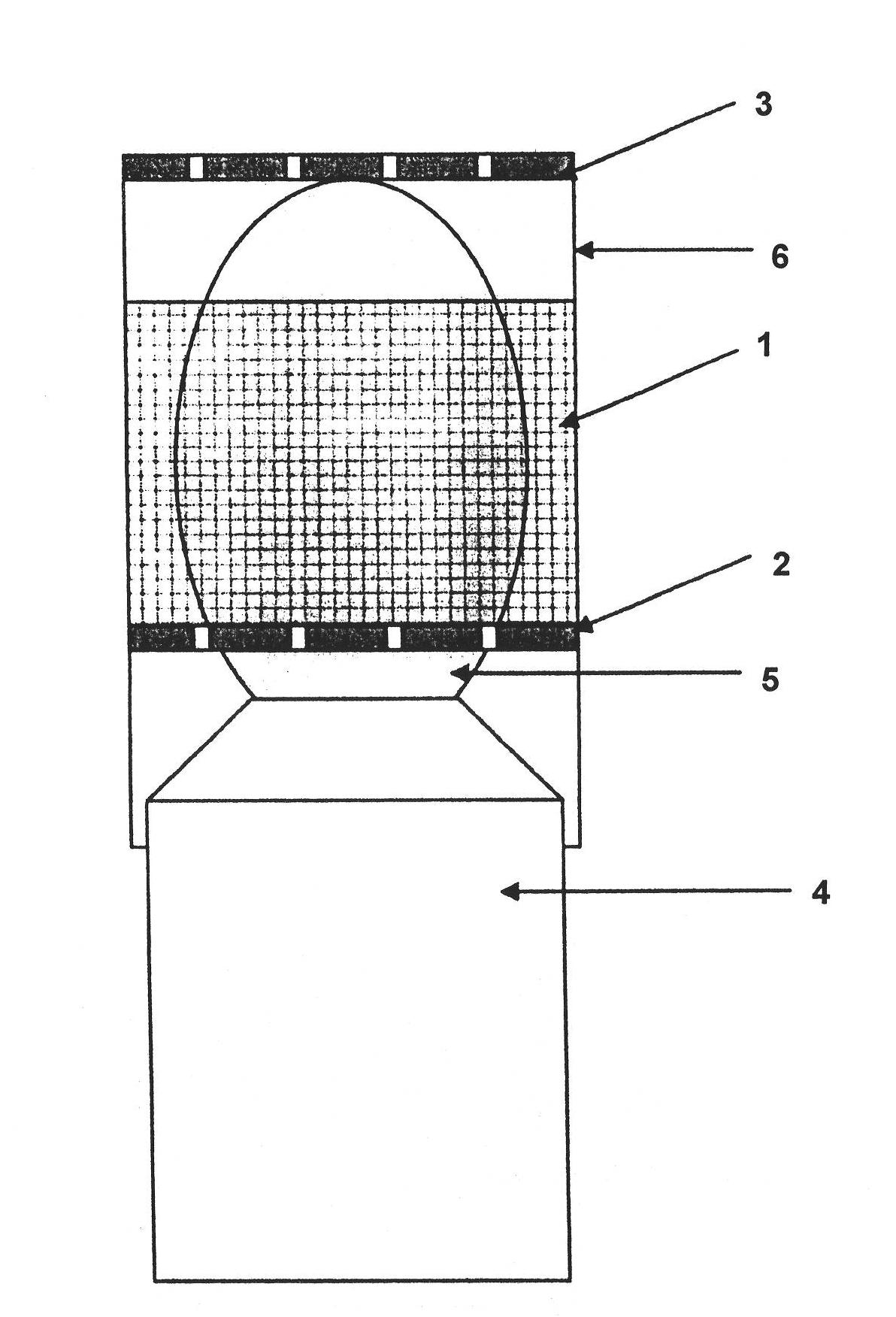

Methods for arranging nanoscopic elements within networks, fabrics, and films

ActiveUS20110291315A1Gap minimizationMaterial nanotechnologyLiquid surface applicatorsEngineeringRubbing

A method for arranging nanotube elements within nanotube fabric layers and films is disclosed. A directional force is applied over a nanotube fabric layer to render the fabric layer into an ordered network of nanotube elements. That is, a network of nanotube elements drawn together along their sidewalls and substantially oriented in a uniform direction. In some embodiments this directional force is applied by rolling a cylindrical element over the fabric layer. In other embodiments this directional force is applied by passing a rubbing material over the surface of a nanotube fabric layer. In other embodiments this directional force is applied by running a polishing material over the nanotube fabric layer for a predetermined time. Exemplary rolling, rubbing, and polishing apparatuses are also disclosed.

Owner:ZEON CORP

Control of carbon nanotube diameter using CVD or pecvd growth

The diameter of carbon nanotubes grown by chemical vapor deposition is controlled independent of the catalyst size by controlling the residence time of reactive gases in the reactor.

Owner:GLOBALFOUNDRIES INC

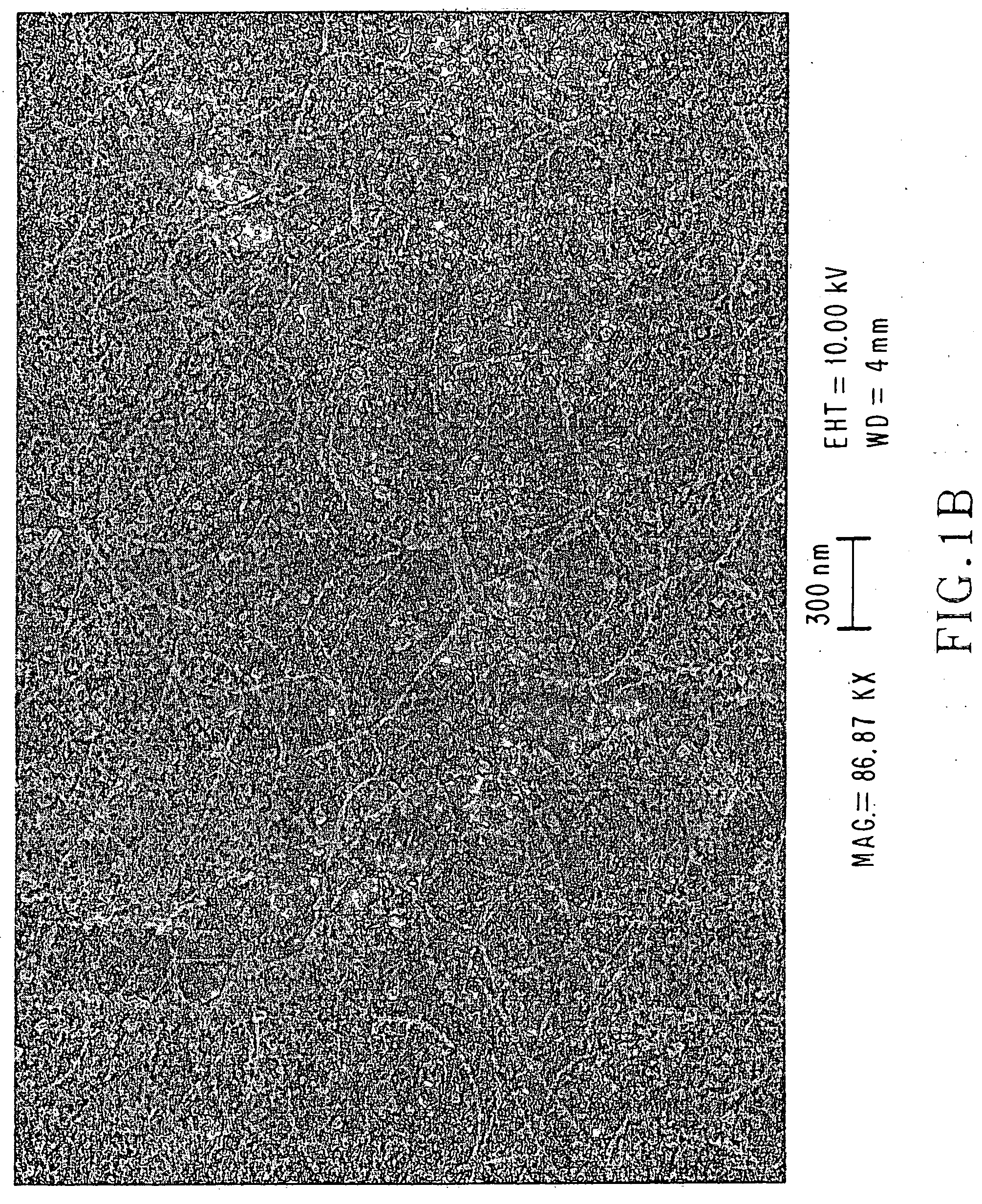

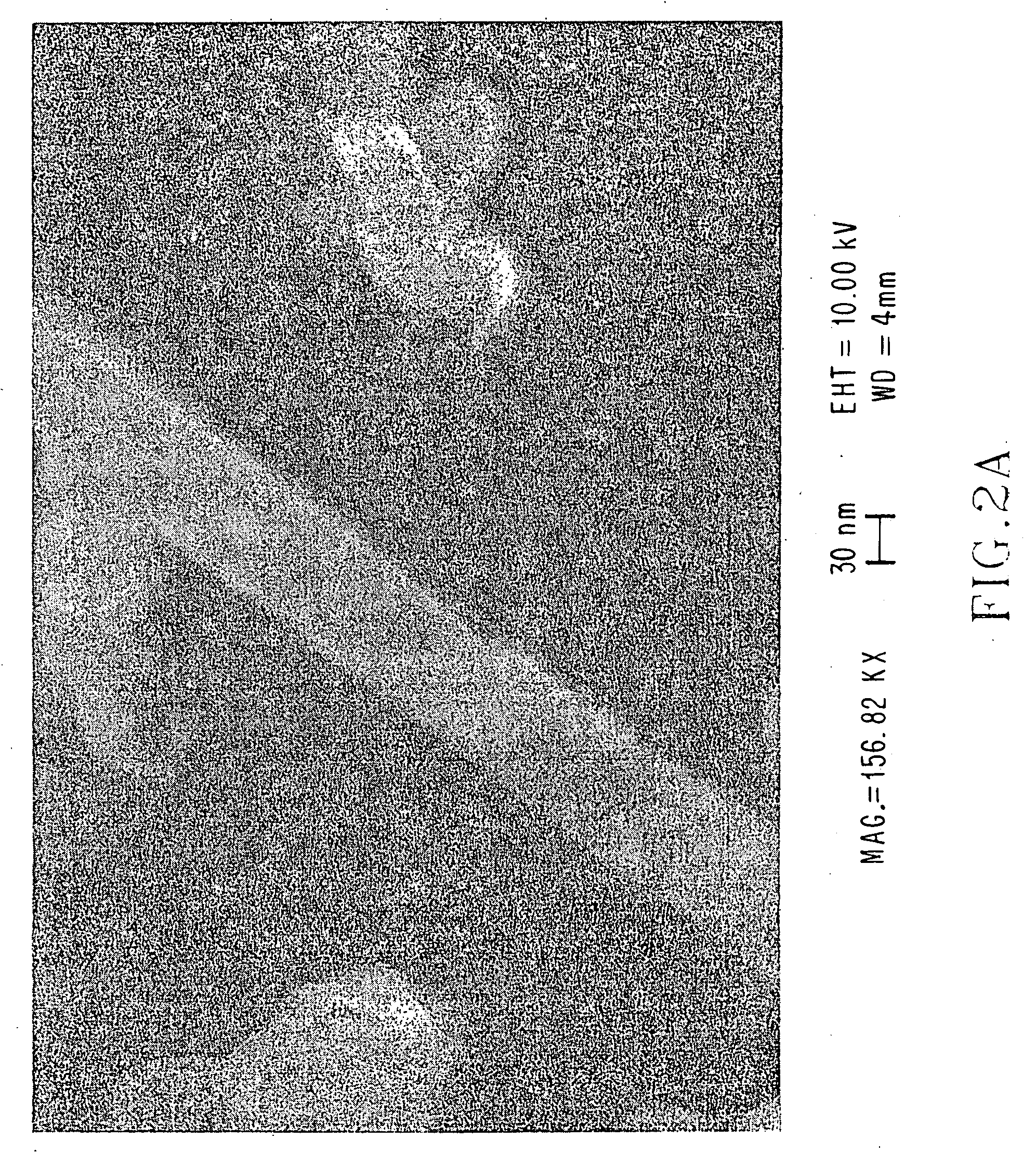

Carbon-based fine structure array, aggregate of carbon-based fine structures, use thereof and method for preparation thereof

ActiveUS8481158B2Increase in sizeImprove handlingMaterial nanotechnologyLayered productsFine structureStrong interaction

An aggregate of carbon-based fine structures in which a plurality of carbon-based fine structures are collected, wherein respective carbon-based fine structures are oriented in the same direction. The above aggregate of carbon-based fine structures is an aggregate of a plurality of carbon-based fine structures in a state they are pulled by one another with strong interaction, and has such a length that allows the improvement of the handleability and workability thereof.

Owner:NIPPON SANSO CORP

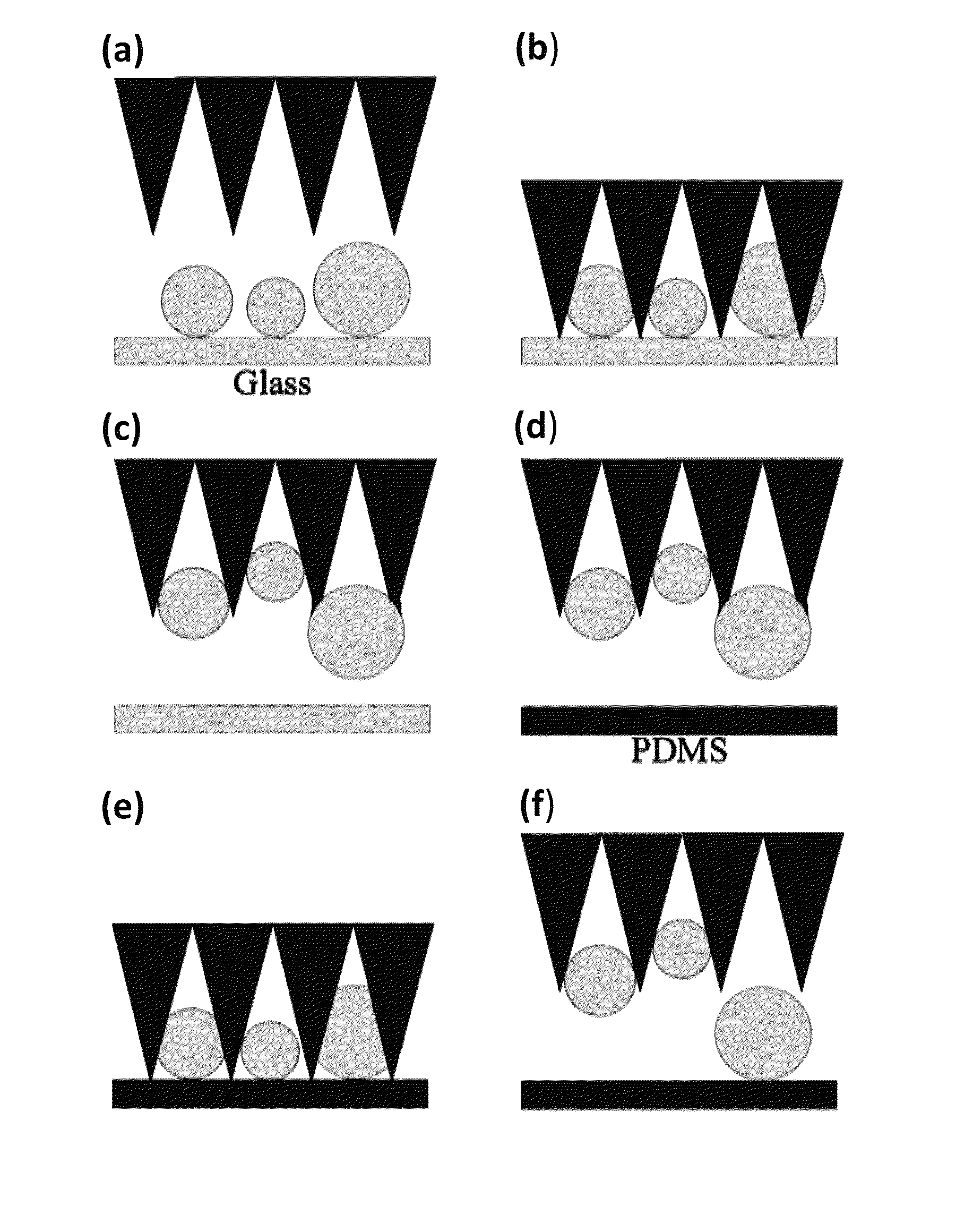

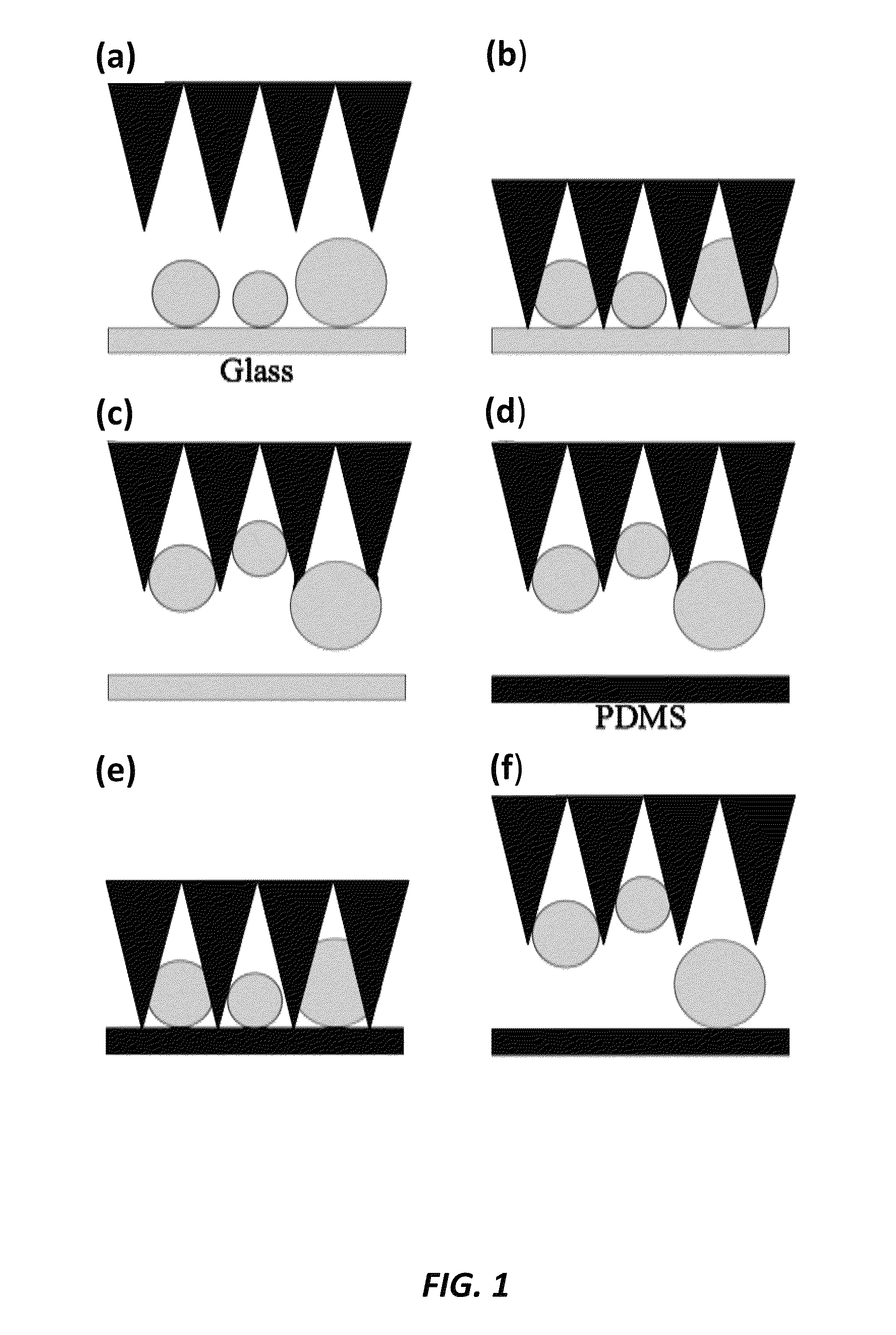

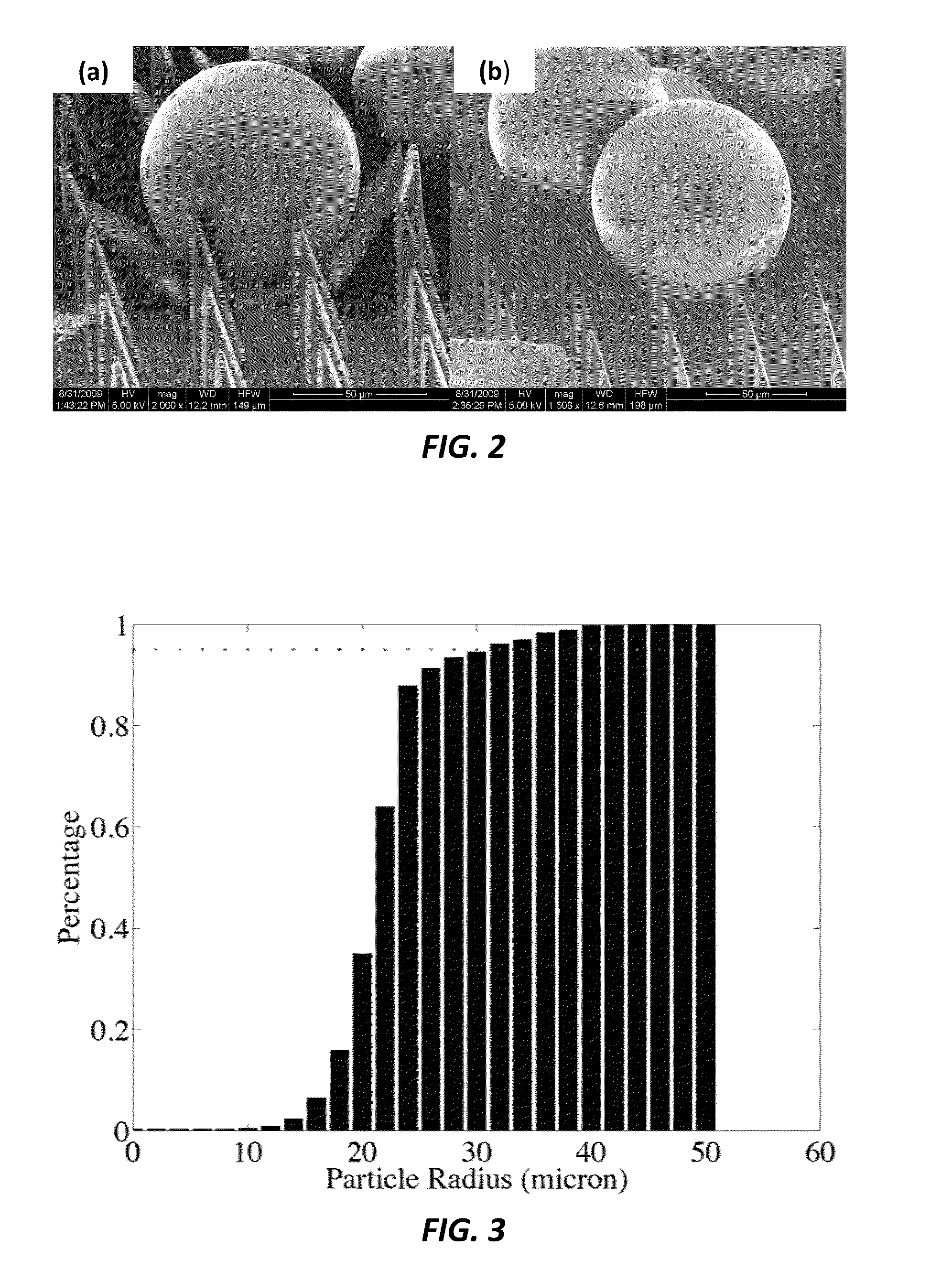

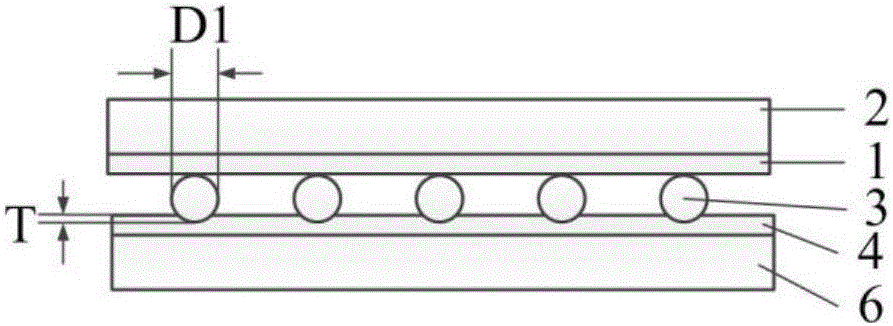

Micro-structure-based adhesives for size-selective particle trapping and sorting

InactiveUS8882996B2Nanostructure manipulationCleaning processes and apparatusParticle trappingMicro structure

A method of separating particles is provided that includes exposing a selective PDMS adhesive to a particle-contaminated surface, where the selective PDMS adhesive captures particles present on the particle-contaminated surface to form a fouled selective PDMS adhesive, and exposing the fouled selective PDMS adhesive to a PDMS transfer sheet, where particles outside of a desired range are transferred over to the PDMS transfer sheet, where the fouled selective PDMS adhesive retains only the particles of a desired range.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

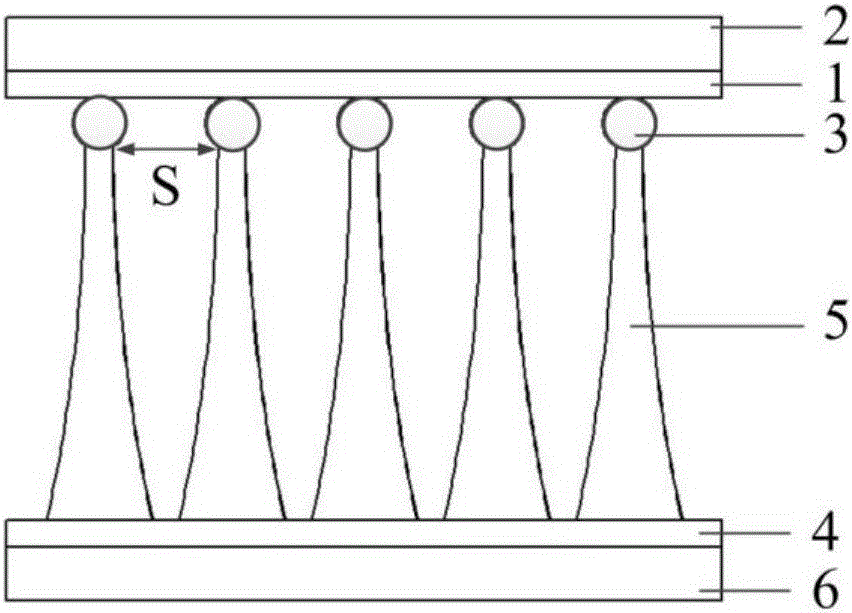

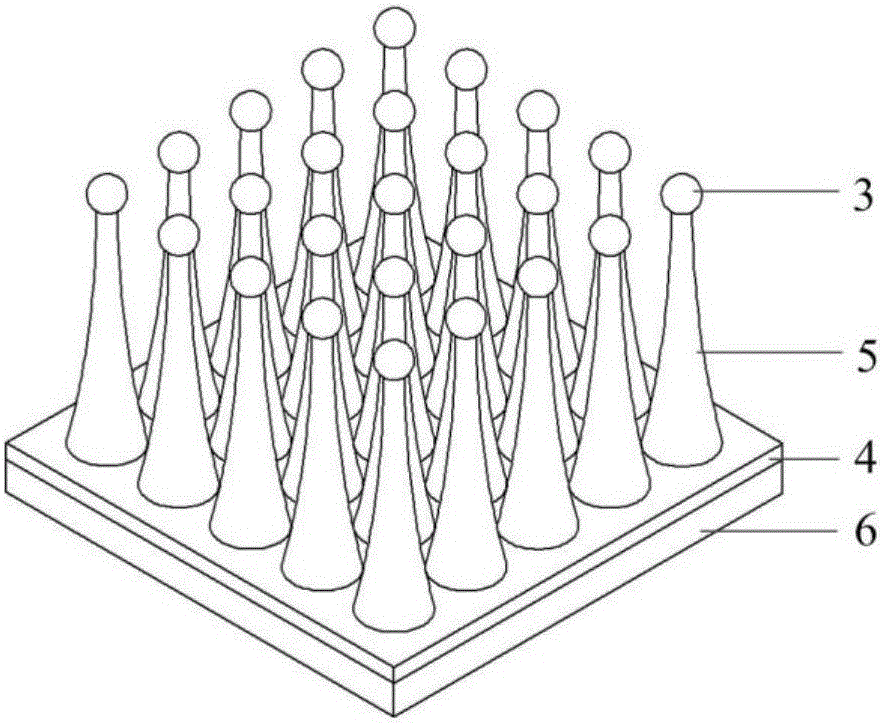

Manufacturing and controlling method of flexible micro-driver for controlling micro-nano particles

ActiveCN105858598AAccurate translationPrecise graspingSpecific nanostructure formationNanostructure manipulationMicro nanoEngineering

A manufacturing and controlling method of a flexible micro-driver for controlling micro-nano particles includes the steps of manufacturing a patterning template of magnetic micro-nano particles, coating the surface of a nonmagnetic substrate with polymers, making the polymers make contact with and embedded in the micro-nano particles on the surface of the patterning template to lift the patterning template and stretch the polymers into a mushroom-shaped micro-nano column array, heating the patterning template to make the patterned magnetic micro-nano particles disengaged from a hydrosol adhesion layer to obtain a flexible mushroom-shaped micro-nano column array with magnetic micro-nano particles at the top end, namely, the flexible micro-driver, making to-be-controlled micro-nano particles drip onto the surface of the flexible mushroom-shaped micro-nano column array, adjusting and controlling the position and the horizontal / vertical movement speed of a magnet under the nonmagnetic substrate so that the translation, grabbing and jumping of the micro-nano particles can be controlled, and adjusting and controlling the positions and rotating speeds of a pair of magnets on the nonmagnetic substrate so that the rotating of the micro-nano particles can be controlled. The flexible micro-driver is easy to manufacture and good in controllability.

Owner:XI AN JIAOTONG UNIV

Method of fabricating carbon nanotubes uniformly coated with titanium dioxide

InactiveUS20110135827A1Wide industrial applicabilityWide applicabilitySpecific nanostructure formationMaterial nanotechnologyNanowireField emission display

Provided is CNTs on which TiO2 is uniformly coated. The method includes: functionalizing CNTs with hydrophilic functional groups; mixing the CNTs functionalized with hydrophilic functional groups in a solution that contains with TiO2 precursors; refining TiO2 precursor-coated CNTs from the solution in which the CNTs and the TiO2 precursors are mixed; and heat treating the refined TiO2-coated CNTs. The TiO2-coated CNTs formed in this manner simultaneously retain the characteristics of CNTs and TiO2 nanowires, and thus, can be applied to solar cells, field emission display devices, gas sensors, or optical catalysts.

Owner:ELECTRONICS & TELECOMM RES INST

Method for transferring graphene using a hot press

ActiveUS8916013B2Minimize damageEasy transferNanostructure assemblyLamination ancillary operationsGrapheneMaterials science

The present invention relates to a method for transferring graphene using a hot press, comprising: a step of contacting graphene, having a thermal-releasable sheet attached thereto, with a target substrate; and a step of pressing and heating the graphene having the thermal-releasable sheet attached thereto and the target substrate using the upper press and lower press of a hot press so as to separate the thermal-releasable sheet and the graphene and transfer the separated graphene to the target substrate. The present invention also relates to a graphene-transfer hot press apparatus for said transfer process.

Owner:GRAPHENE SQUARE

Production process for metal matrix nanocomposite containing oriented graphene sheets

Provided is a metal matrix nanocomposite comprising: (a) a metal or metal alloy as a matrix material; and (b) multiple graphene sheets that are dispersed in said matrix material, wherein said multiple graphene sheets are substantially aligned to be parallel to one another and are in an amount from 0.1% to 95% by volume based on the total nanocomposite volume; wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from pristine graphene, graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof and wherein the chemically functionalized graphene is not graphene oxide. The metal matrix exhibits a combination of exceptional tensile strength, modulus, thermal conductivity, and / or electrical conductivity.

Owner:GLOBAL GRAPHENE GRP INC

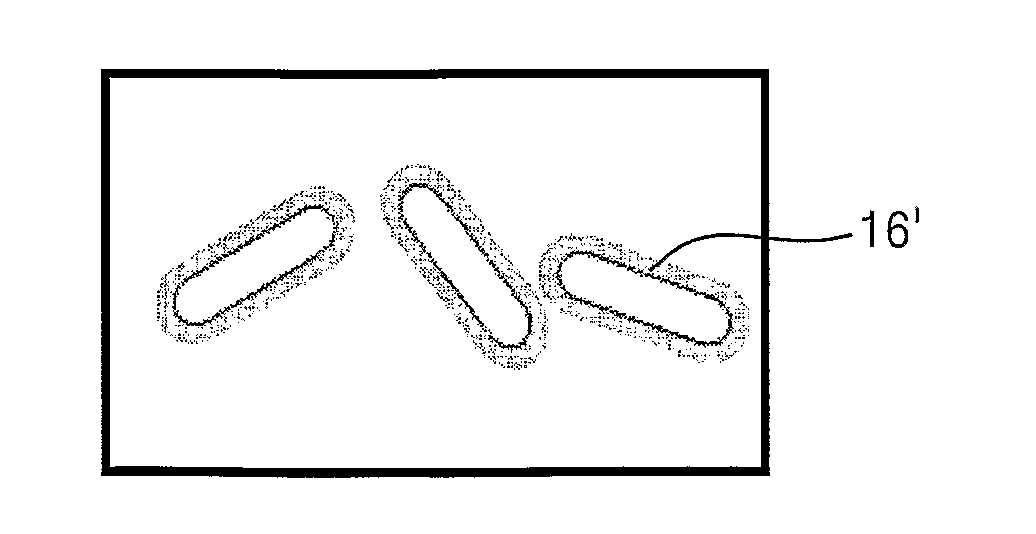

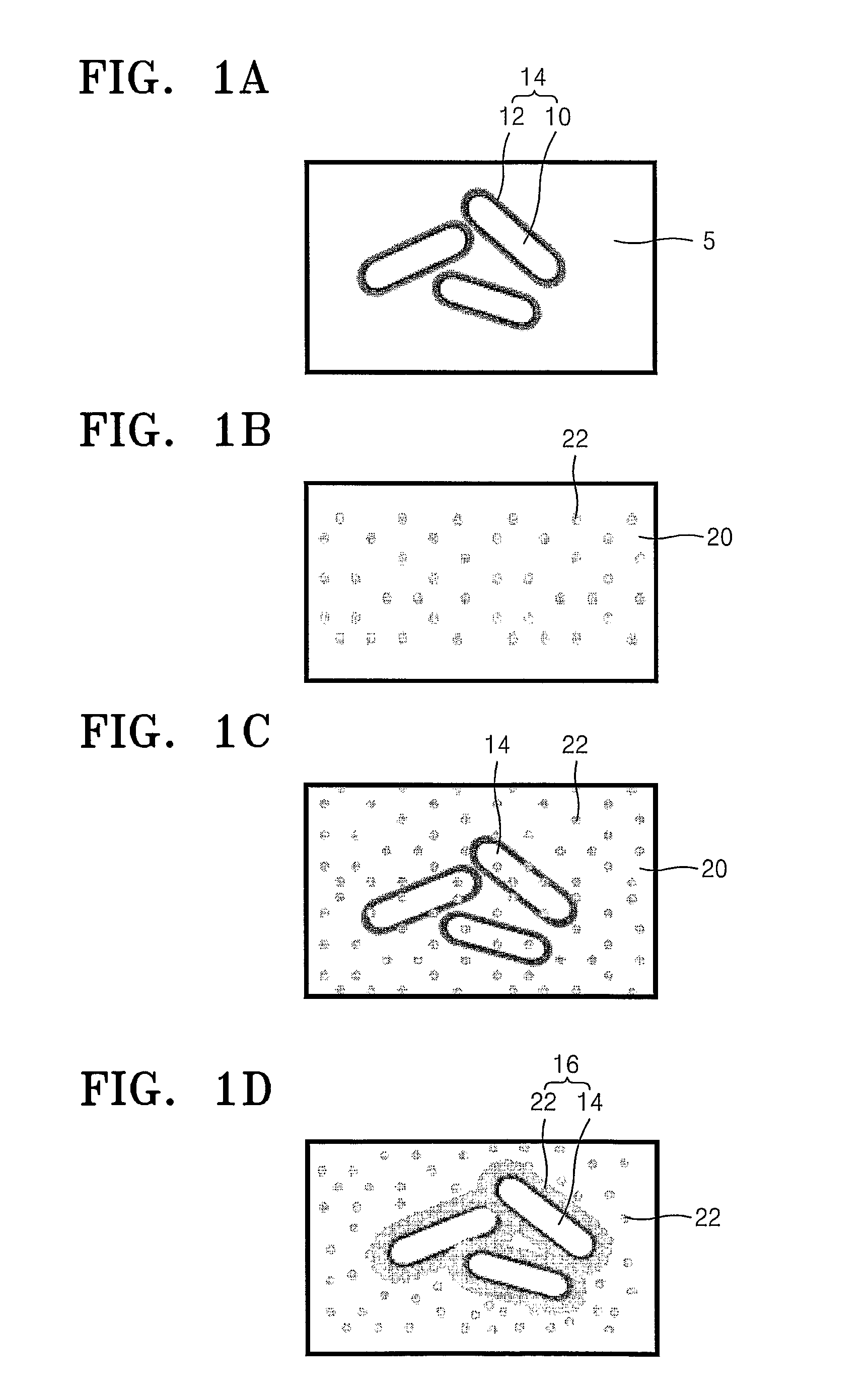

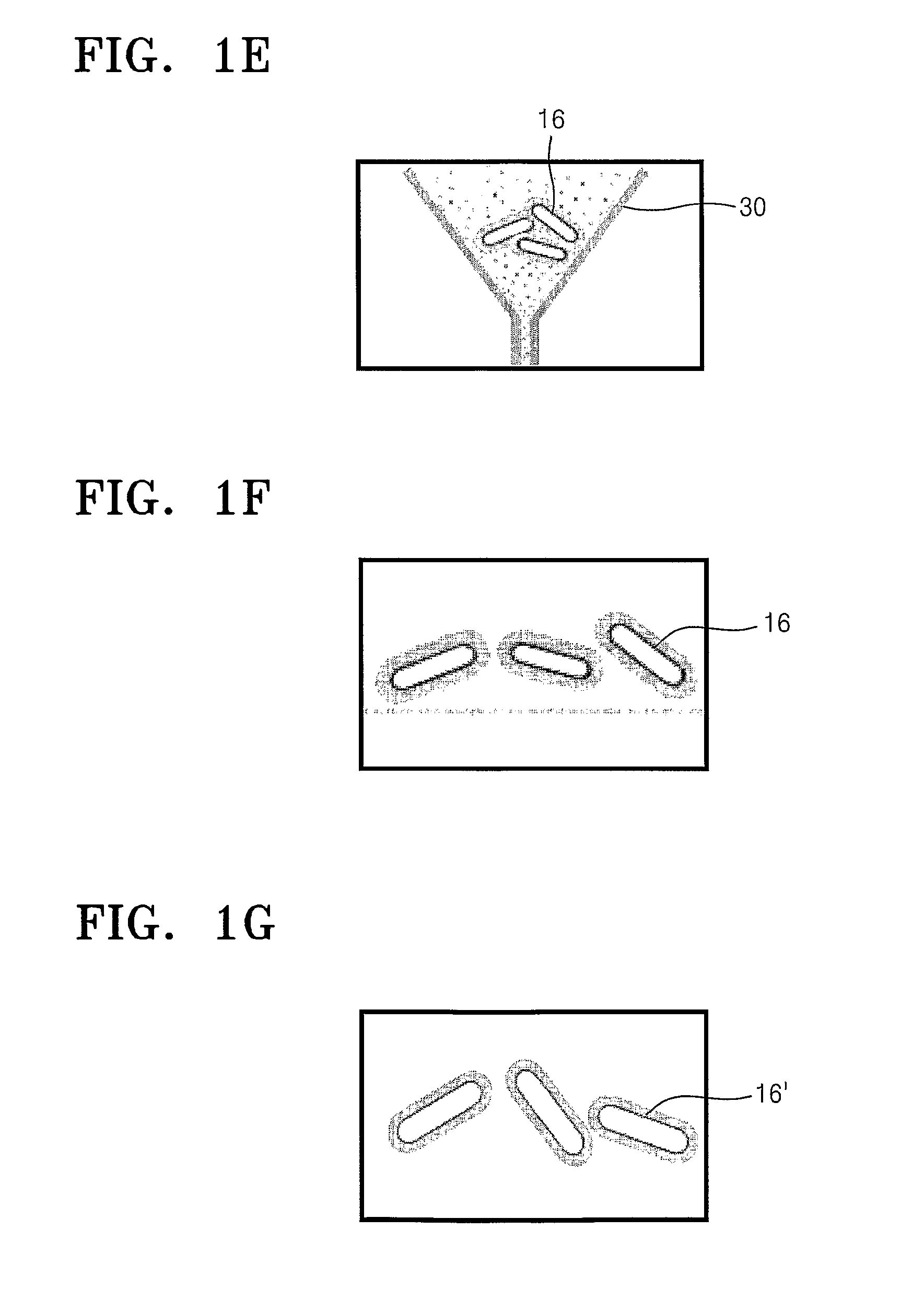

Preparation method for forest nanostructure and regulation and control method for forest nanostructure

ActiveCN109987580ARealize regulationRealize diversified controlNanostructure manipulationOrganic groupNanostructure

The invention provides a preparation method for a forest nanostructure and a regulation and control method for the forest nanostructure. The preparation method for the forest nanostructure comprises the following steps: S1. employing a mixture comprising a couplant and a polymer to form a film layer on a substrate; and carrying out plasma bombardment on the film layer, thereby forming the forest nanostructure. Through carrying out bombardment on a polymer layer by adopting plasma, part of products produced by the polymer can be repolymerized to form a forest nanostructure; and the couplant isadded on the basis of the polymer, during plasma bombardment, groups of the polymer and the couplant in the film layer are activated, organic groups and inorganic groups of the couplant are interconnected with organic groups and inorganic groups of the polymer separately, and meanwhile, the organic groups of the couplant are in a crosslinked action, so that active groups produced from plasma bombardment are repolymerized, an original mixture layer disappears, and similarly, the forest nanostructure is formed.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

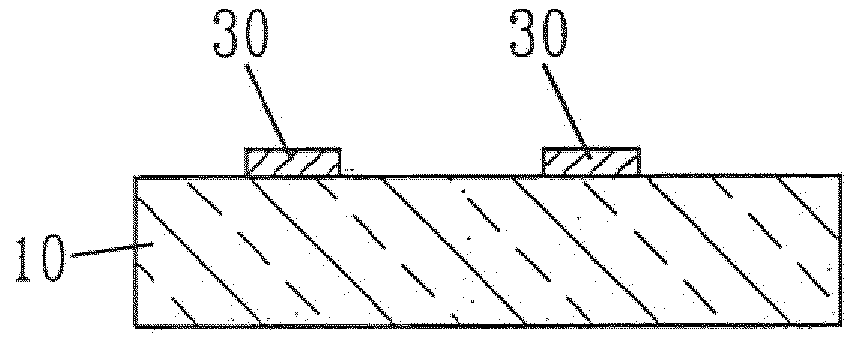

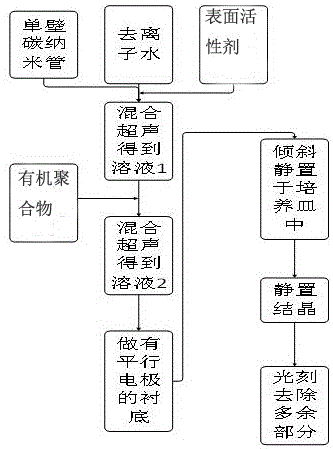

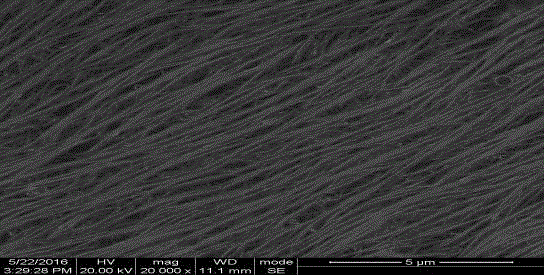

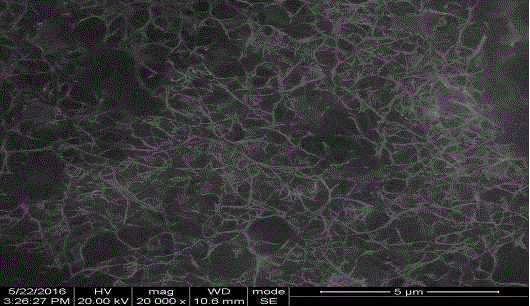

Method for preparing single-walled carbon nanotubes in oriented arrangement with solution standing method

ActiveCN106219516AGood orientationImprove electrical performanceNanostructure manipulationCarbon nanotubeField-effect transistor

The invention discloses a method for preparing single-walled carbon nanotubes in oriented arrangement with a solution standing method. A substrate with parallel electrodes on the surface obliquely stands in colloidal liquid obtained by mixing single-walled carbon nanotubes, deionized water, a surfactant and an organic polymer, and due to the size effect of the parallel electrodes on the carbon nanotubes, the carbon nanotubes can be arranged between the parallel electrodes in an oriented mode. Compared with a traditional chemical vapor deposition method for preparing orientated carbon nanotubes in vertical arrangement, operation is easy, and the carbon nanotubes in horizontal oriented arrangement are prepared and can be applied to field-effect tubes, field emitters and chemical sensors.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

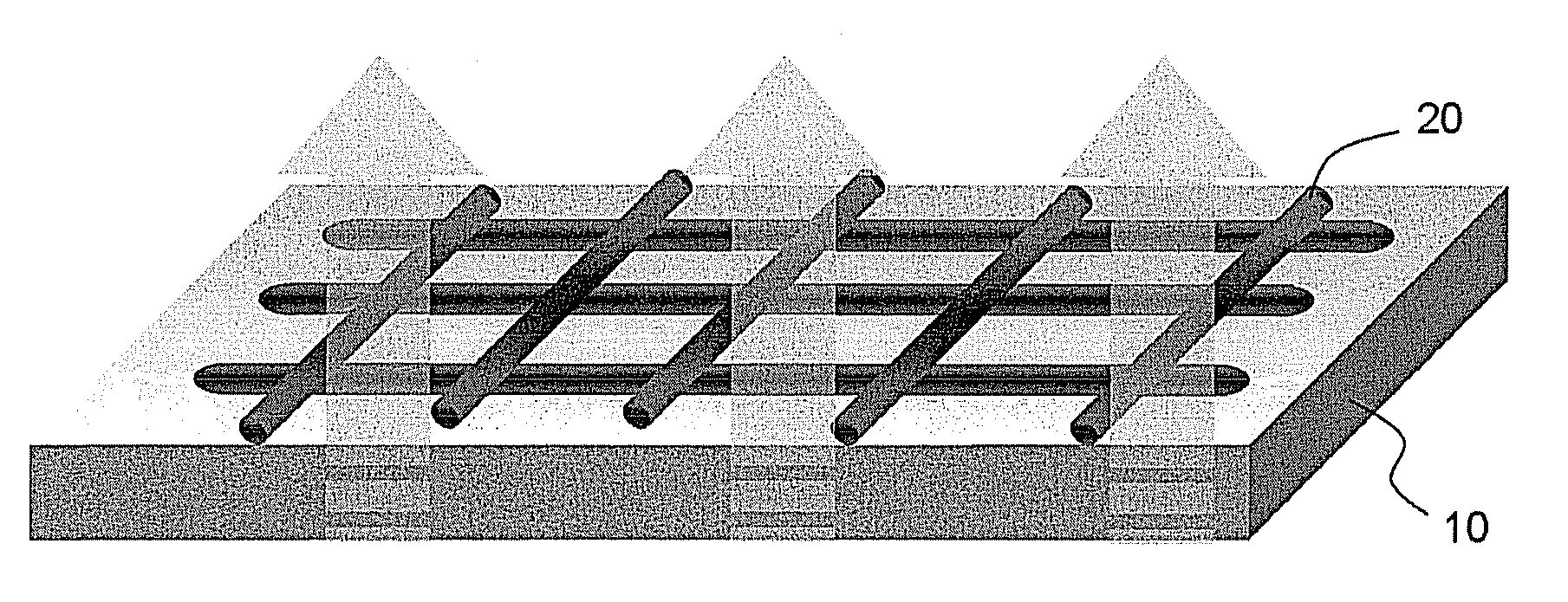

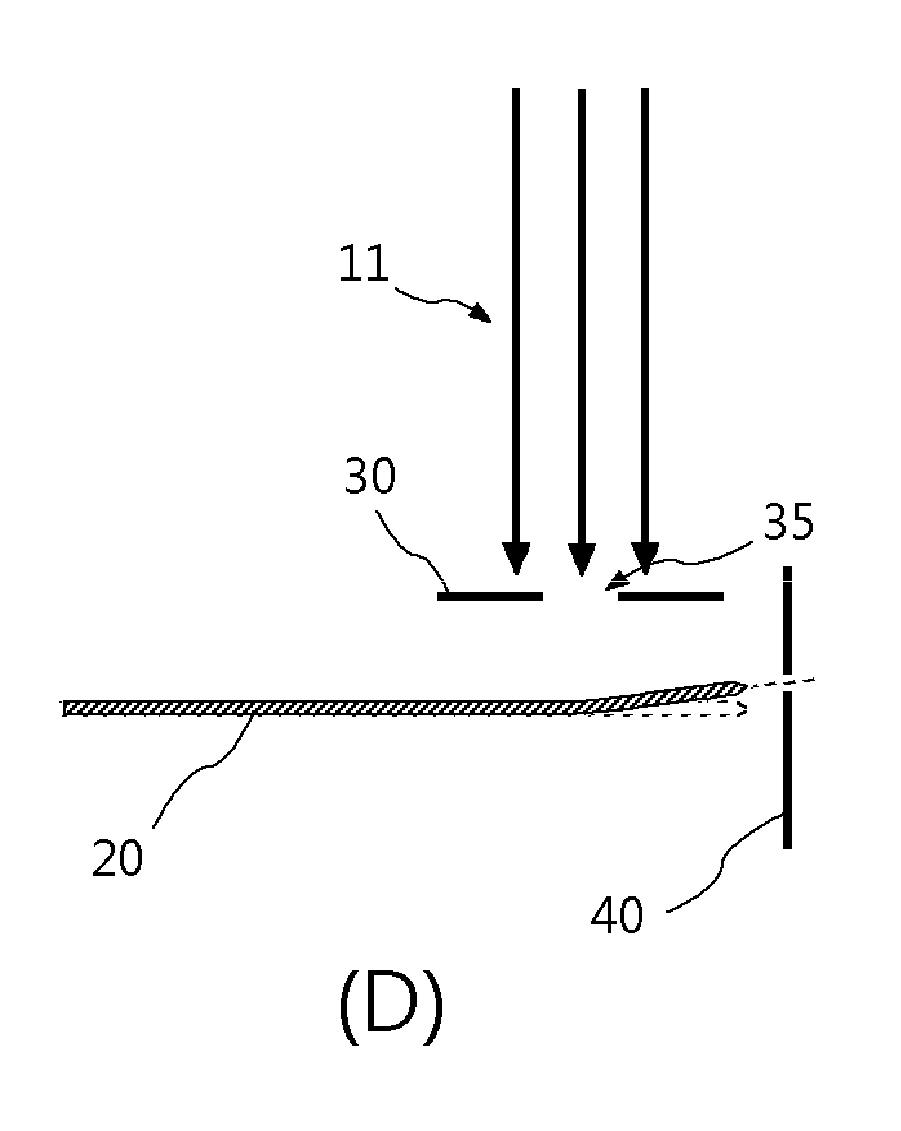

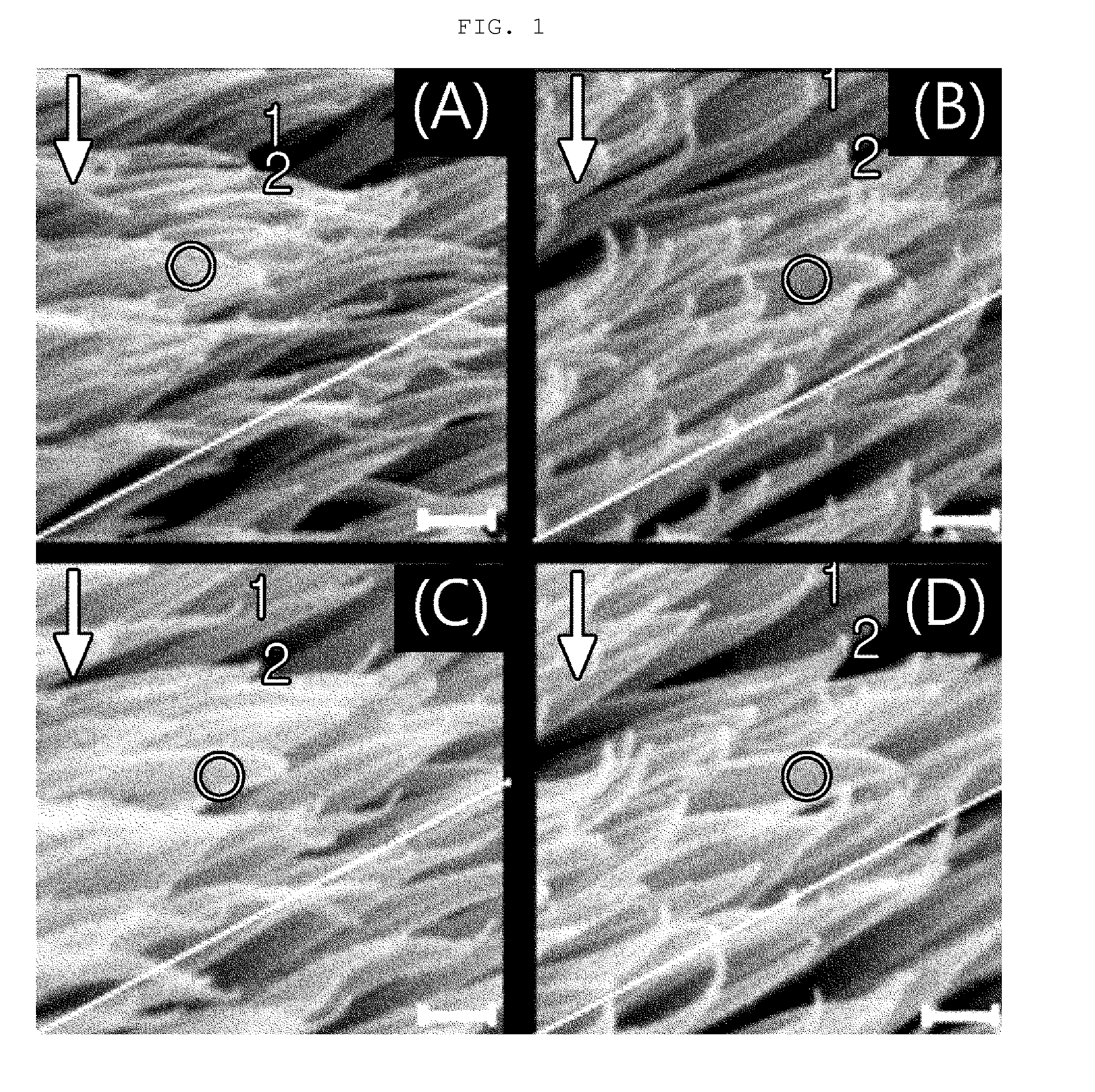

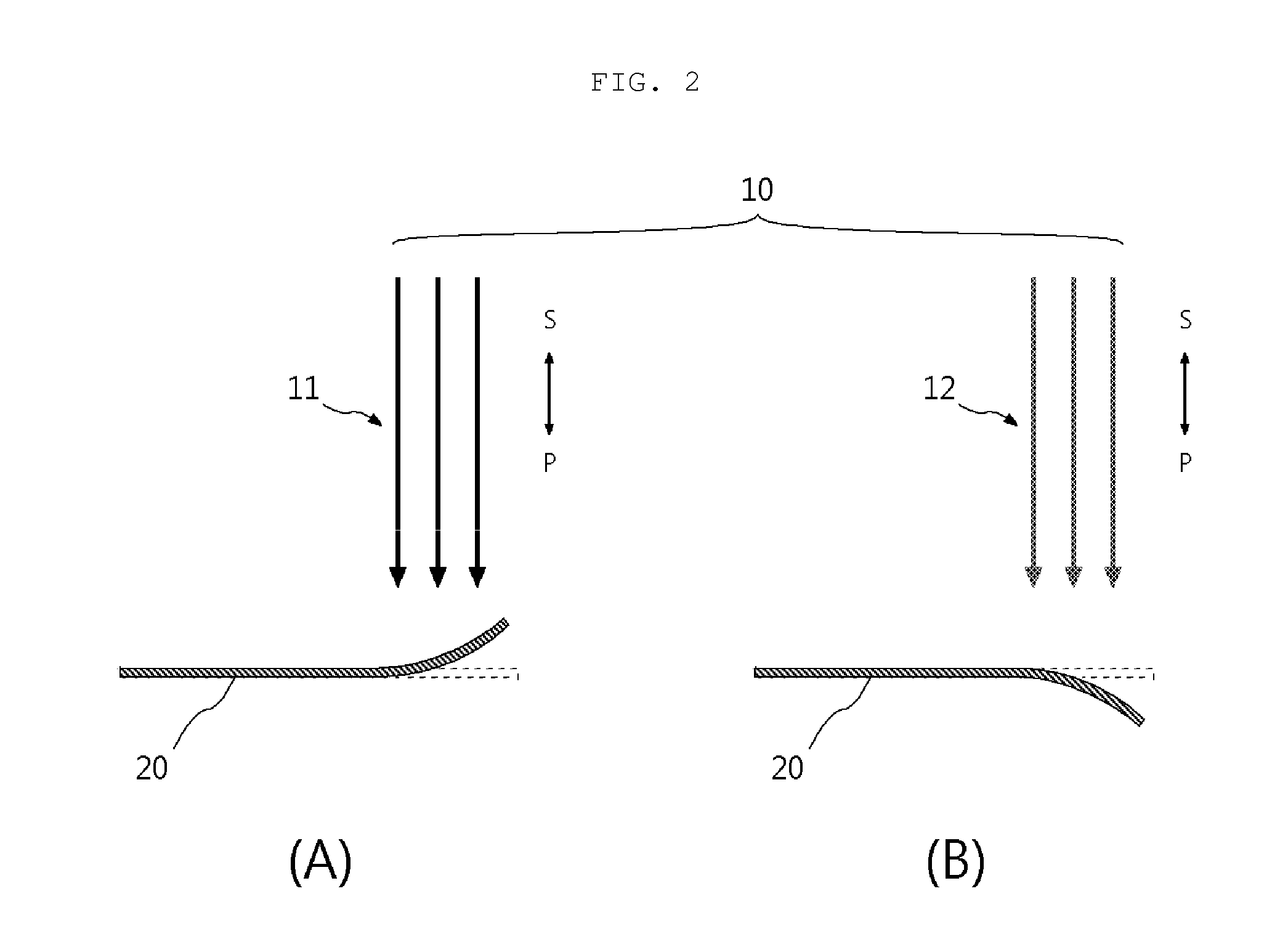

Movement-free bending method for one-dimensional or two-dimensional nanostructure using ion beam

ActiveUS20140110608A1Save resourcesRapid mass productionSpecific nanostructure formationNanostructure manipulationEnergy controlIon beam

The movement-free bending method means the one of deformation methods for a one- or two-dimensional nanostructures using an ion beam capable of bending and deforming them and furthermore, changing a bending direction without requiring a motion such as a rotation of the nanostructures. The present invention affords a movement-free bending method for deforming the nanostructure 20 having the one-dimensional or two-dimensional shape by irradiating the ion beam 10, wherein a bending direction of the nanostructure 20 is controlled depending on energy of the ion beam 10 or a thickness of the nanostructure 20.

Owner:KOREA RES INST OF STANDARDS & SCI

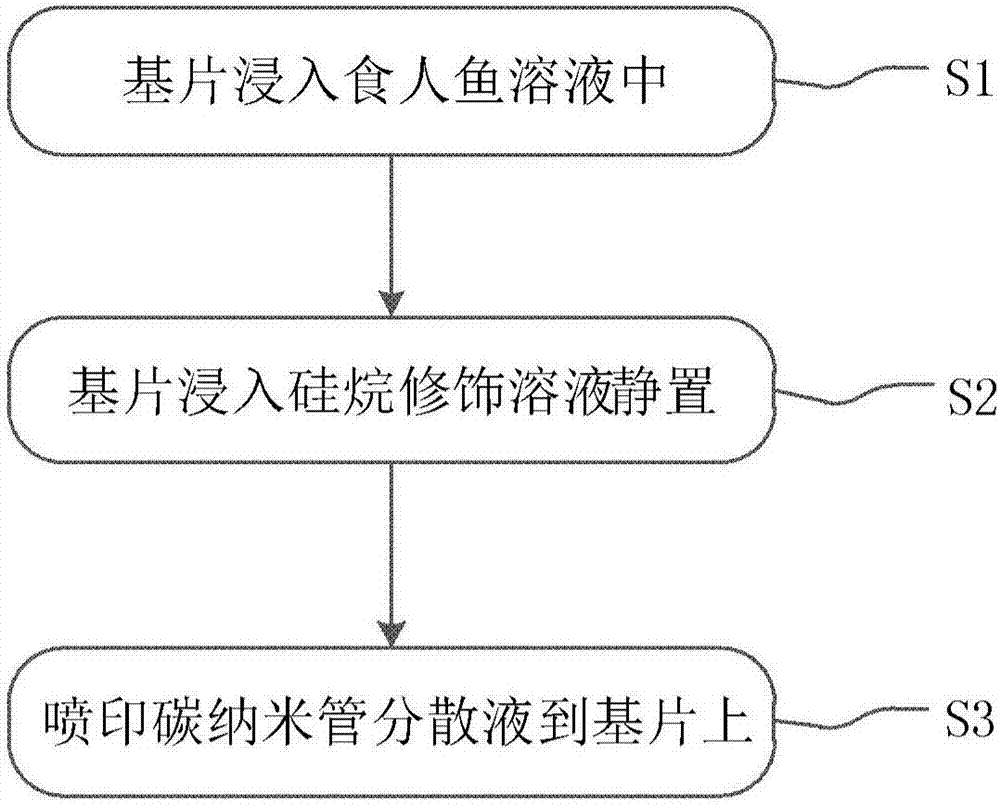

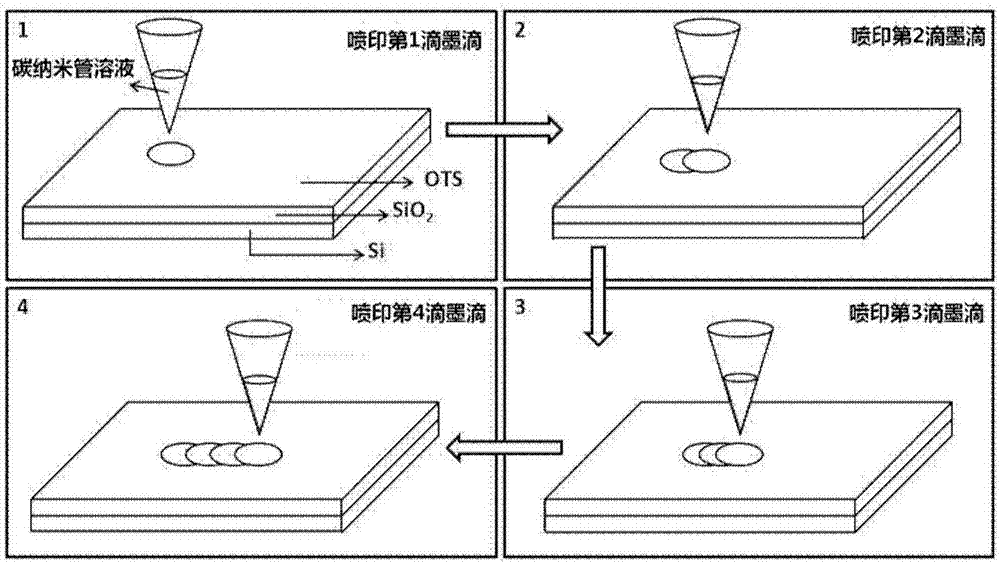

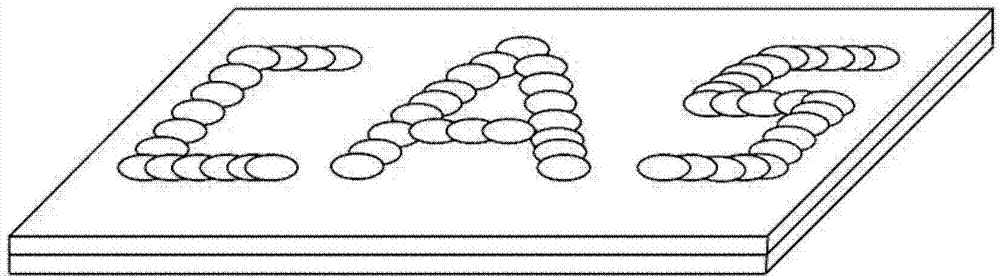

Single aligned carbon nano tube jet-printing arrangement method

ActiveCN107963610ASimple processAchieve patterningMaterial nanotechnologyNanostructure manipulationOctadecyltrichlorosilaneNano-device

The invention provides a single aligned carbon nano tube jet-printing arrangement method. The method comprises the steps that a substrate is modified with octadecyltrichlorosilane (OTS), so that the surface of the substrate has a hydrophobic property; precise control over the thin film position, the aligned density and patterning of aligned carbon nano tubes is achieved on the functional hydrophobic substrate through ink-jet printing, and a carbon nano tube thin film which is uniform in density and consistent in orientation and has different patterns is arranged. By means of the method, the carbon nano tube arrangement area of the size from several micrometers to the wafer level can be effectively controlled; the problems can be solved that in all existing arrangement methods, the arrangement position, the arrangement orientation, the arrangement density and the thin film array patterning of one-dimensional nano materials on the substrate cannot be efficiently and precisely controlled;the method can be widely used for preparing various high-performance photoelectric devices, logic circuits and functional thin films based on the carbon nano tubes, and the method also has a wide application prospect in the field of flexible wearable nano devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for manufacturing carbon nanotube

InactiveCN101977841AGood and easy to manufactureSpecific nanostructure formationMaterial nanotechnologyCombustionCarbon nanotube

Carbon nanotubes oriented in one direction are efficiently and easily manufactured. The method is provided with a step of bringing a solution, which contains metal ions to be a catalyst for growing carbon nanotubes, into contact with crystalline metal oxide particles, and adhering the catalyst on the surfaces of the metal oxide particles; a step of growing carbon nanotubes on the surfaces of the metal oxide particles whereupon the catalyst is adhered, by a CVD method or a combustion method, and manufacturing metal oxide particles which support the carbon nanotubes grown parallel to a direction substantially vertical to the surfaces of the metal oxide particles; and a step of removing the metal oxide particles from the metal oxide particles supporting the carbon nanotubes.

Owner:OTSUKA CHEM CO LTD

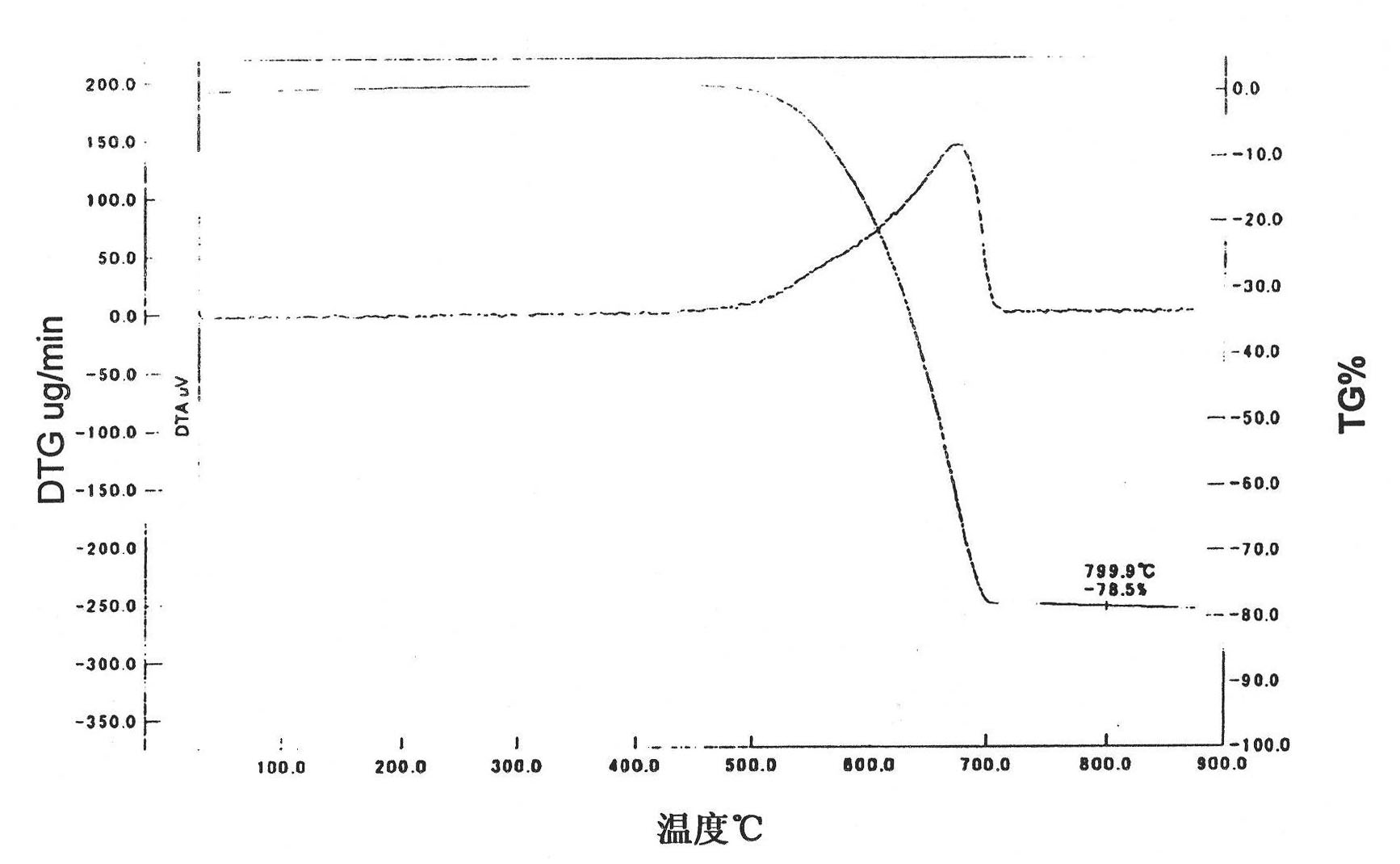

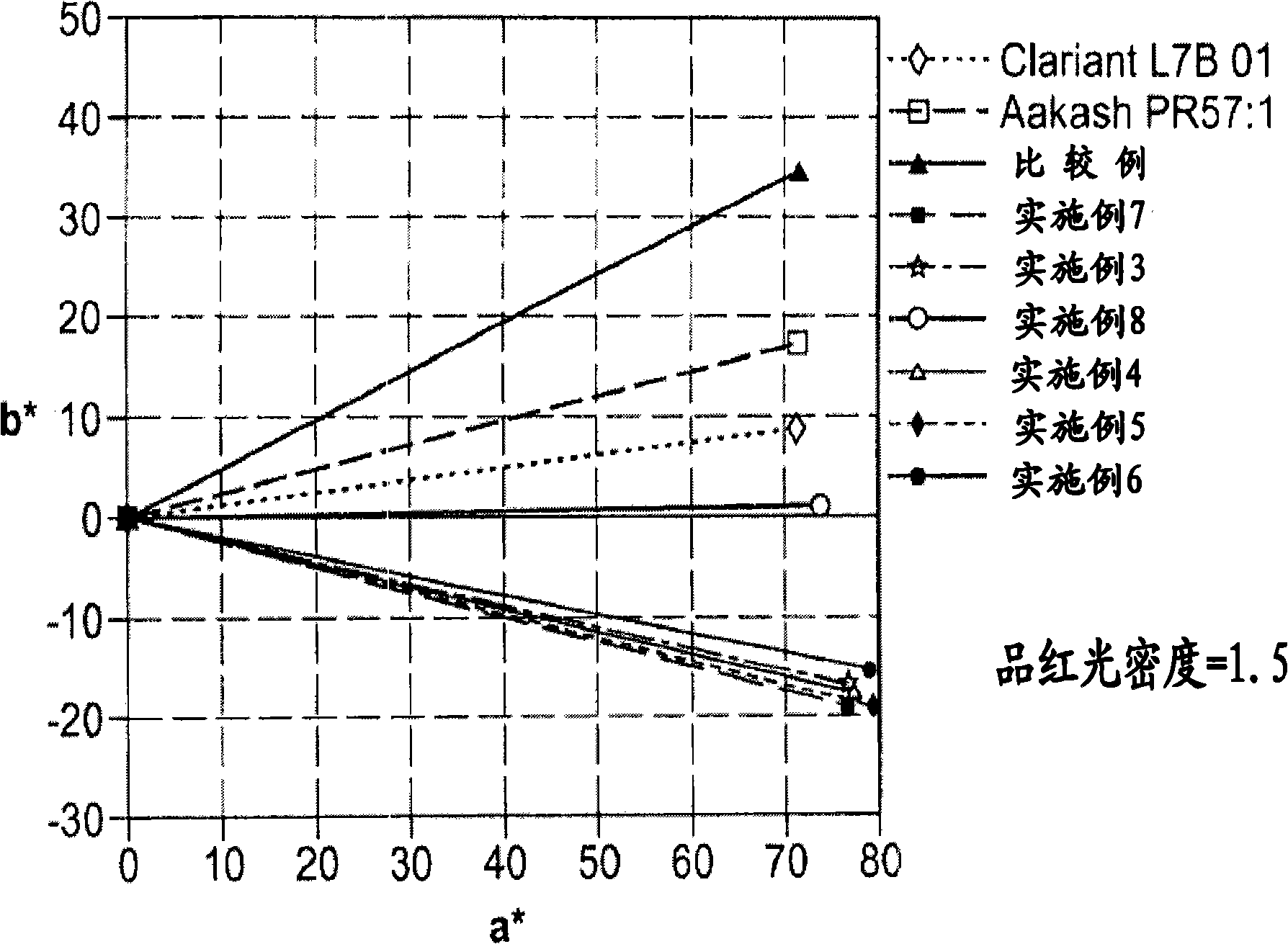

Nanosized particles of monoazo laked pigment

A nanoscale pigment particle composition includes an organic monoazo laked pigment including at least one functional moiety, and a sterically bulky stabilizer compound including at least one functional group, wherein the functional moiety associates non-covalently with the functional group; and the presence of the associated stabilizer limits the extent of particle growth and aggregation, to afford nanoscale-sized pigment particles.

Owner:XEROX CORP

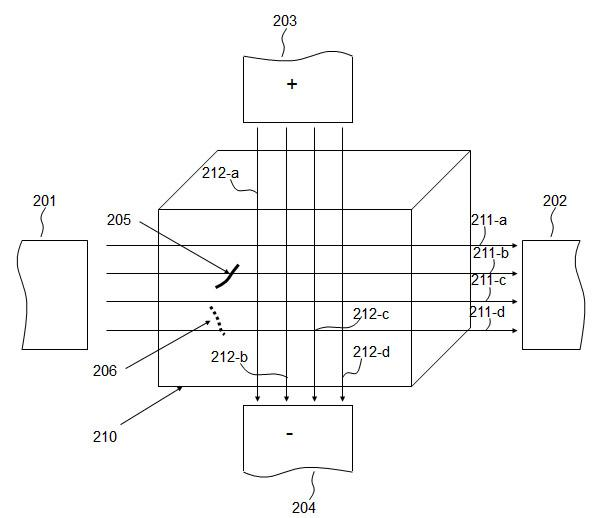

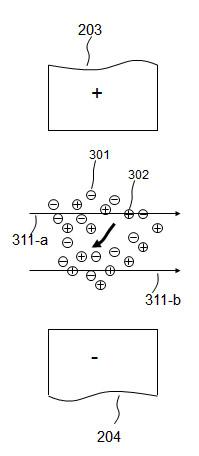

Method for separating carbon nanotubes with different conductive performances

InactiveCN102320592AHigh selectivityHigh purityMaterial nanotechnologyCarbon compoundsForce linesCarbon nanotube

The invention belongs to the technical field of integrated-circuit manufacture, in particular to a method for separating carbon nanotubes with different conductive performances. The method disclosed by the invention comprises the following steps of: soaking an integrated-circuit material containing metallic carbon nanotubes and semiconducting carbon nanotubes into liquid, then enabling the liquid to enter the same container from the same inlet, and arranging an electric field and a pair of magnetic poles with formed magnetic-force lines vertical to the electric field around the container; and converting the directions and the sizes of power lines of the electric field and the directions and the sizes of the magnetic-force lines to separate the metallic carbon nanotubes from the semiconducting carbon nanotubes. The metallic carbon nanotubes and the semiconducting carbon nanotubes obtained by using the method disclosed by the invention have high purity, and the yield product of an integrated circuit using the semiconducting carbon nanotubes can be greatly improved. The method disclosed by the invention is simple and easy to operate, the cost is low, and the manufacturing cost of the high-purity carbon nanotubes can be greatly lowered.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com