Single aligned carbon nano tube jet-printing arrangement method

A technology of orienting carbon nanotubes and carbon nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manipulation, etc., can solve the problems of limited use and promotion, and the inability to realize the orientation and arrangement of carbon nanotube films, and achieve good periodicity , easy to operate and reduce material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

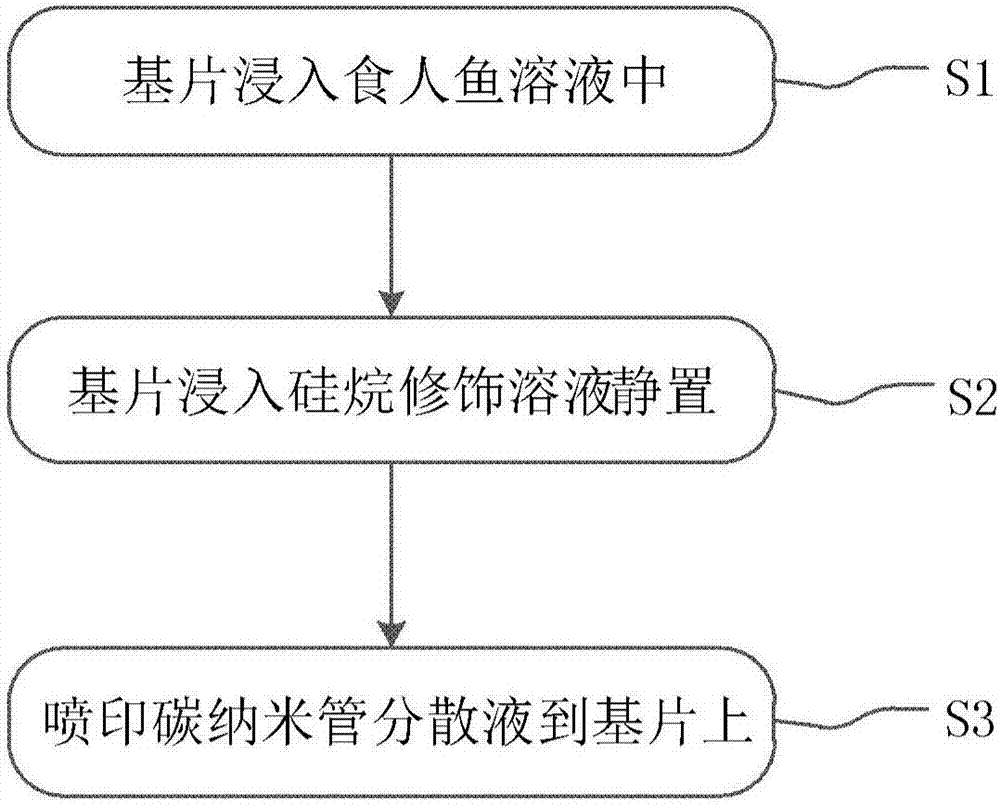

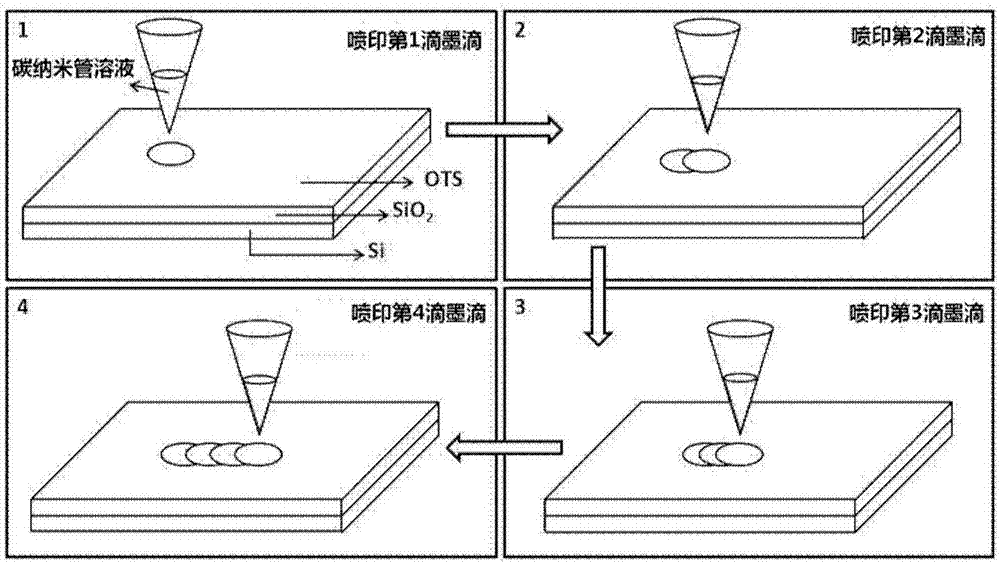

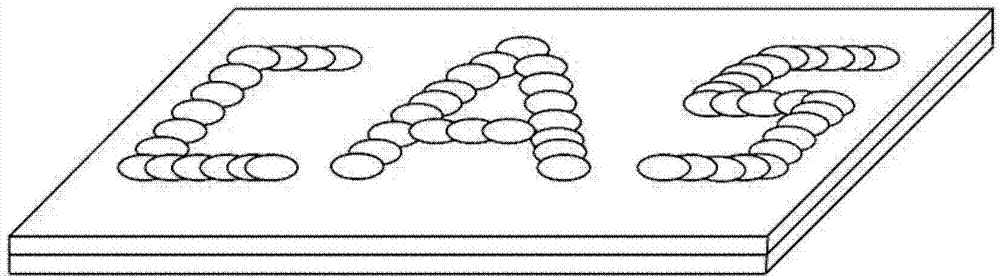

[0052] This embodiment proposes a single-oriented carbon nanotube jet printing arrangement method, the specific steps are as follows figure 1 Shown:

[0053] S1. Immerse the substrate in the piranha solution: take a piece of SiO 2 sheet, where SiO 2 The thickness of the layer is 500nm, followed by ultrasonic cleaning with acetone, ethanol, and water for 20 minutes, rinsed with a large amount of ultrapure water after each ultrasonic wave, then immersed in piranha solution, and treated in piranha solution at 80°C for 10 minutes; finally Rinse with a large amount of ultrapure water and blow dry with nitrogen. The piranha solution is a strong oxidizing mixed solution of concentrated sulfuric acid: hydrogen peroxide = 3:1, which can convert SiO 2 The organic matter on the surface is oxidized and greatly increases the number of hydroxyl groups on the surface of SiO2, increasing its wettability;

[0054] S2, immerse the substrate into the silane modification solution and let it st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com