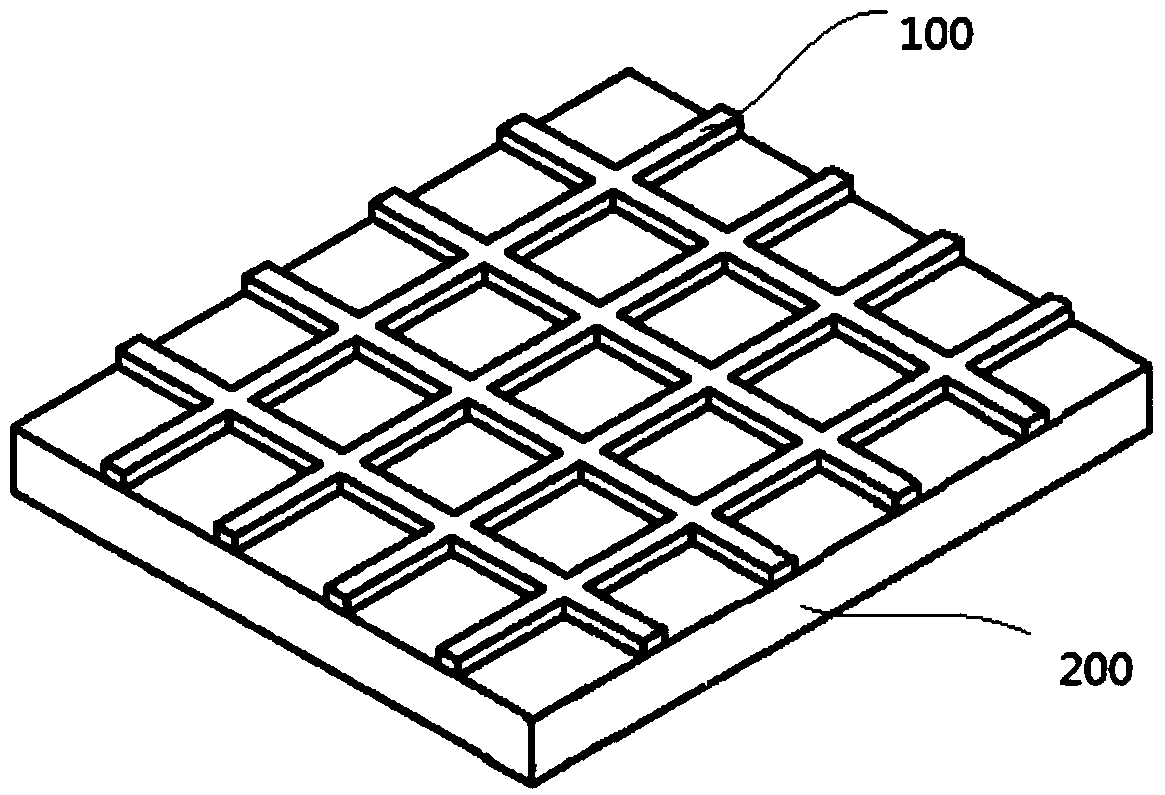

Manufacturing method of metal grid conductive film, metal grid conductive film and touch panel

A technology of metal grid and manufacturing method, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of high ITO resistance, high cost, poor flexibility, etc., and achieve high response speed , enhanced adhesion, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

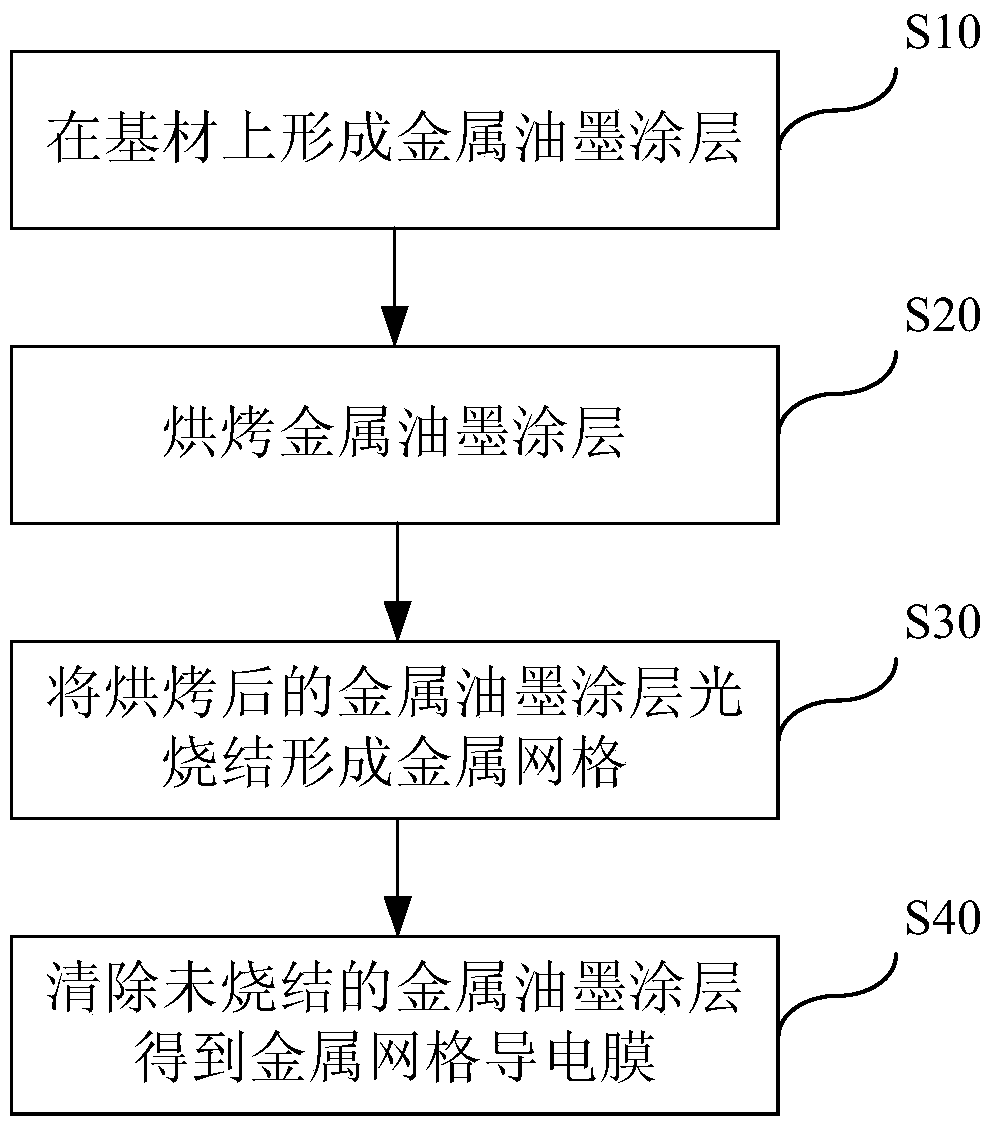

[0054] The manufacturing method of the metal grid conductive film provided in this embodiment includes the following steps:

[0055] S10: forming a metallic ink coating on the substrate.

[0056] Prepare the nano-copper ink coating and CPI film (transparent polyimide film), and apply the nano-copper ink to the CPI film by slit coating. The nano-copper ink coating is composed of copper nanoparticles (average particle size is 45nm), dispersant (manufactured by HUNTSMAN Company of the United States), 1,2-propanediol and propylene glycol monobutyl ether, wherein the content of copper nanoparticles is about 20wt%. The thickness of the CPI film is 50 μm.

[0057] S20: Baking the metallic ink coating.

[0058] Transfer the CPI film coated with nano-copper ink to a hot air drying oven and bake at 100°C for 30 minutes to remove the solvent, and obtain a layer of nano-copper ink coating with a dry film thickness of about 1 μm on the surface of the CPI film.

[0059] S30: Photo-sint...

Embodiment 2

[0064] The manufacturing method of the metal grid conductive film provided in this embodiment includes the following steps:

[0065] S10: forming a metallic ink coating on the substrate.

[0066] Prepare the nano-copper ink coating and the CPI film, and apply the nano-copper ink to the CPI film by spin coating. The nano-copper ink coating is composed of copper nanoparticles (average particle size is 45nm), dispersant (manufactured by HUNTSMAN Company of the United States), 1,2-propanediol and propylene glycol monobutyl ether, wherein the content of copper nanoparticles is about 20wt%. The thickness of the CPI film is 50 μm.

[0067] S20: Baking the metallic ink coating.

[0068] Transfer the CPI film coated with nano-copper ink to a hot air drying oven and bake at 80°C for 30 minutes to remove the solvent, and obtain a layer of nano-copper ink coating with a dry film thickness of about 0.5 μm on the surface of the CPI film.

[0069] S30: Photo-sintering the baked metal in...

Embodiment 3

[0074] The manufacturing method of the metal grid conductive film provided in this embodiment includes the following steps:

[0075] S10: forming a metallic ink coating on the substrate.

[0076] Prepare the nano-silver ink coating and the PEN film, and apply the nano-silver ink to the PEN film by slit coating. Nano-silver ink coating consists of silver nanoparticles (average particle size is 20nm), dispersant (manufactured by U.S. HUNTSMAN company), 1,2-propanediol and propylene glycol monobutyl ether, wherein the content of silver nanoparticles is about 20wt%. The thickness of the PEN film was 188 μm.

[0077] S20: Baking the metallic ink coating.

[0078] Transfer the PEN film coated with nano-silver ink to a hot air drying oven and bake at 80°C for 30 minutes to remove the solvent, and obtain a layer of nano-silver ink coating with a dry film thickness of about 2 μm on the surface of the PEN film.

[0079] S30: Photo-sintering the baked metal ink coating to form a met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com