Roll-to-roll patterning equipment based on die cutting

A patterning, roll-to-roll technology, applied in winding strips, thin material processing, metal processing, etc., can solve the problems of slow processing speed, high cost, complicated operation, etc., achieve high production efficiency, low cost, and realize collection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

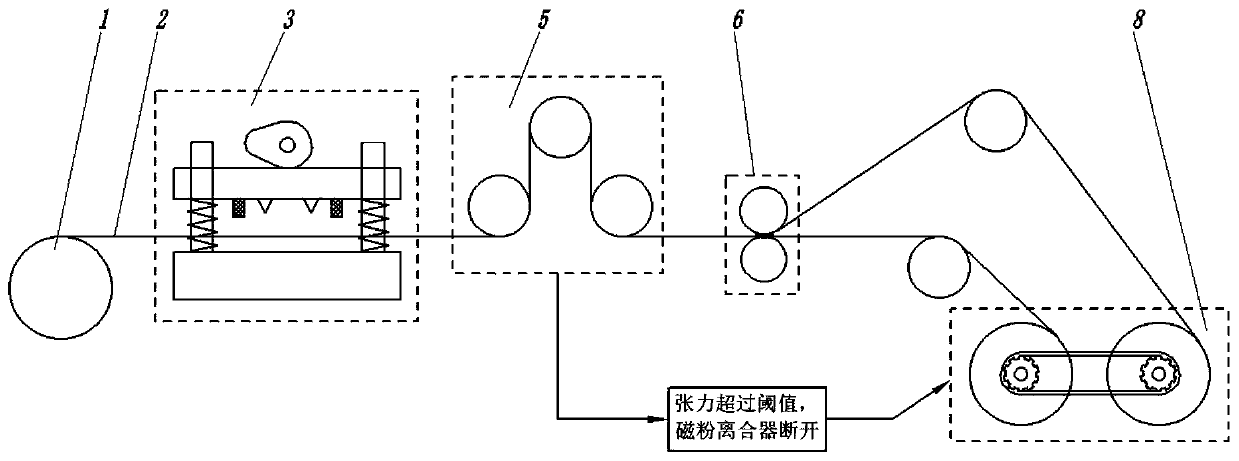

[0033] see figure 1 , image 3 , Figure 5 , Figure 7 and Figure 8, the die-cutting-based roll-to-roll patterning equipment provided in Embodiment 1 of the present invention, the equipment includes an unwinding roller 1, a flexible belt 2, a plane die-cutting mechanism 3, a tension detection mechanism 5, a first peeling mechanism 6 and a take-up The rolling mechanism 8, the unwinding roller 1, the plane die-cutting mechanism 3, the tension detection mechanism 5, the first peeling mechanism 6 and the winding mechanism 8 are arranged at intervals in sequence, and the flexible belt 2 One end is stored in the unwinding roller 1 , and the other end passes through the plane die-cutting mechanism 3 , the tension detection mechanism 5 , and the first peeling mechanism 6 in sequence and then is connected to the winding mechanism 8 . The planar die-cutting mechanism 3 is used to pattern the flexible belt 2 , and the tension detection mechanism 5 is used to detect the tension of th...

Embodiment 2

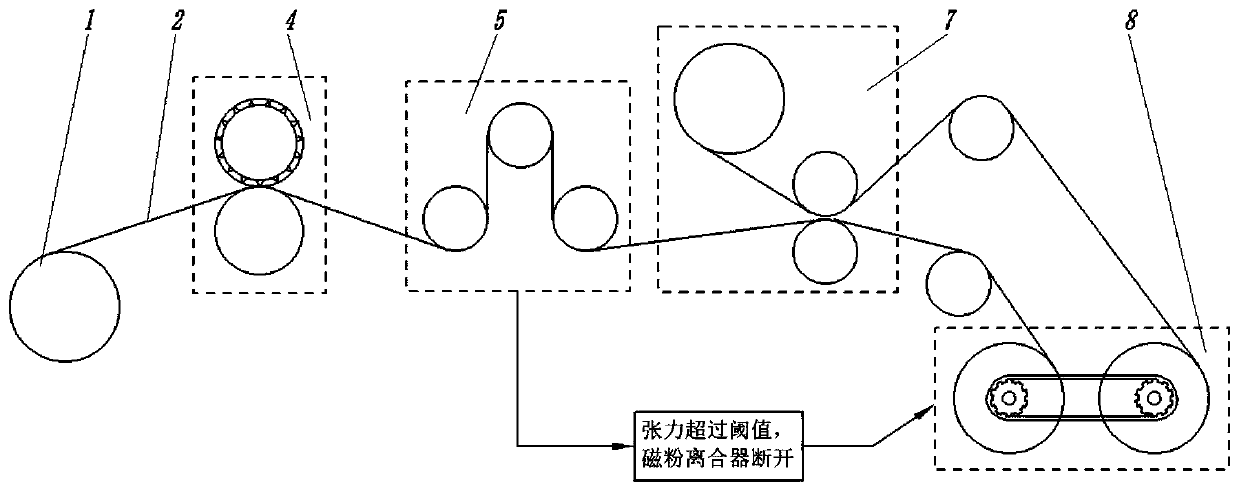

[0044] see figure 2 , Figure 4 and Figure 6 , the die-cutting-based roll-to-roll patterning device provided in Embodiment 2 of the present invention is basically the same as the die-cutting-based roll-to-roll patterning device provided in Embodiment 1 of the present invention, the difference lies in: the The die-cutting mechanism and the peeling mechanism adopted by the roll-to-roll patterning equipment based on die-cutting are the rolling die-cutting mechanism 4 and the second peeling mechanism 7 respectively.

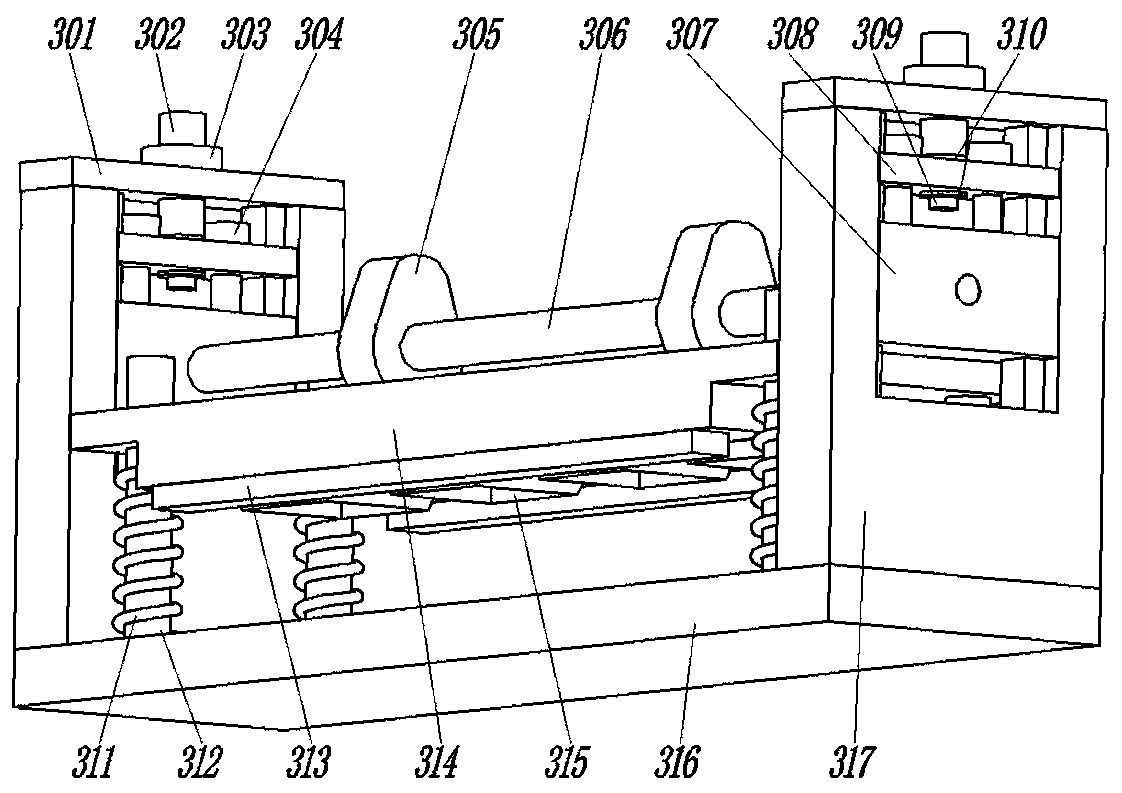

[0045] The rolling die-cutting mechanism 4 includes a die-cutting adjustment support plate 301, an adjustment screw 302, a lock nut 303, a connecting bolt 304, a die-cutting adjustment module 307, a die-cutting adjustment partition 308, a compression bolt 309, a base 316, Die-cutting adjustment fixture 317 , die-cutting roller 401 , curved surface die-cutting knife 402 and bearing roller 403 .

[0046] The two die-cutting adjustment fixing frames 317 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com