Semiconductor device, manufacturing method thereof and electronic device

A technology of electronic devices and semiconductors, applied in semiconductor/solid-state device components, manufacturing microstructure devices, microstructure devices, etc., can solve problems in the patterning of metal bonding layers, patterns cannot be transferred and transferred well, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

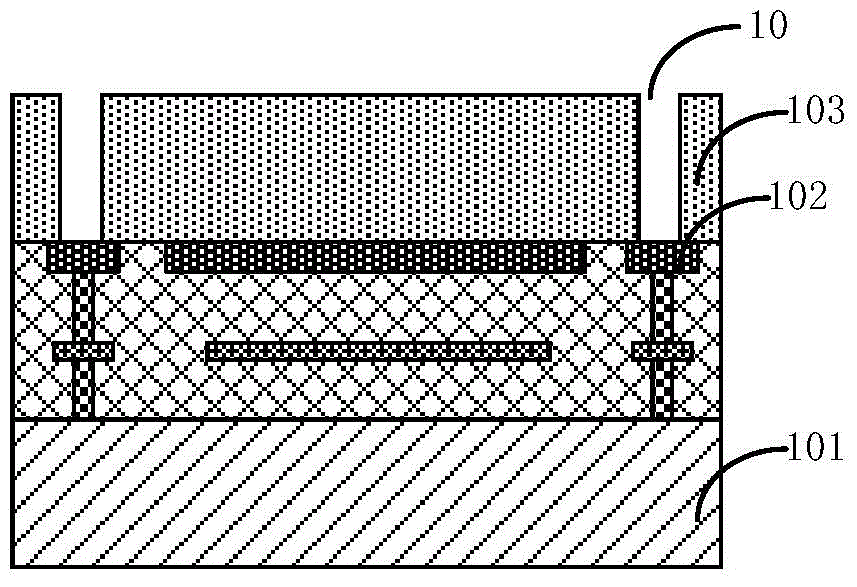

[0044] Current methods of fabricating semiconductor devices such as Figures 1a-1f As shown, firstly a substrate 101 is provided, a CMOS device is formed in the substrate 101, a first dielectric layer is formed on the substrate, and a metal interconnection structure 102 is formed in the first dielectric layer, and then Depositing a second dielectric layer 103 on the first dielectric layer, and patterning the second dielectric layer 103 to form an annular opening 10, exposing the metal interconnection structure 102, such as Figure 1a shown.

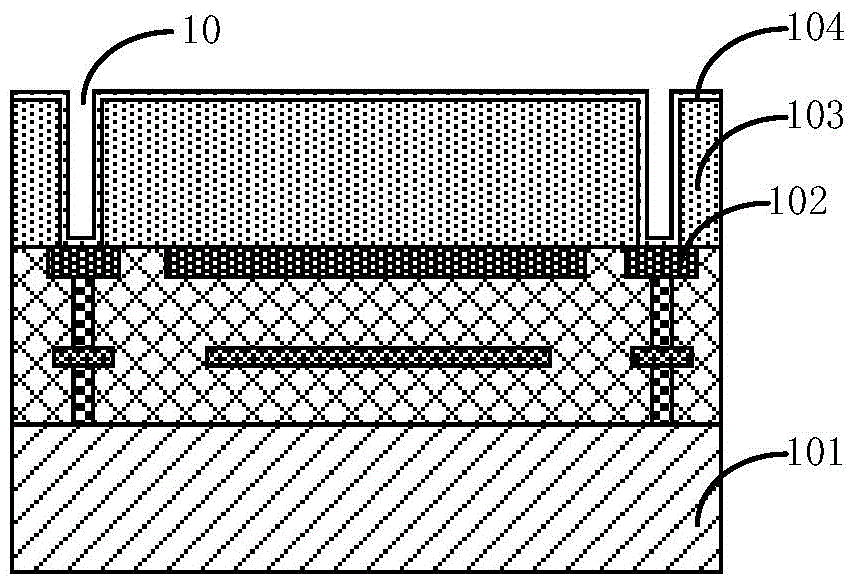

[0045]Next, deposit a metal bonding layer 104 to cover the second dielectric layer 103 and the exposed metal interconnection structure 102, and form the metal bonding layer 104 on the sidewall and bottom of the opening 10, The metal bonding layer 104 can be selected from metal Ti, such as Figure 1b shown.

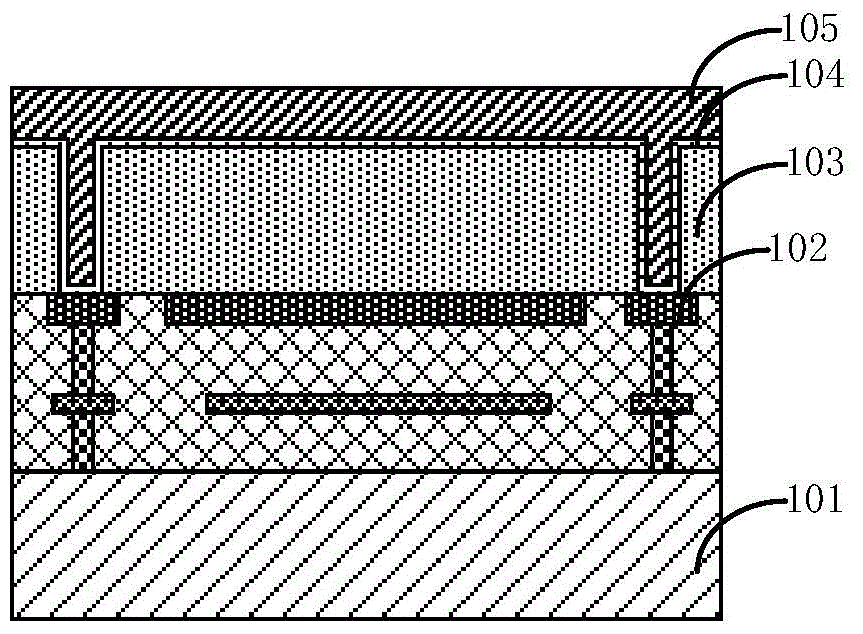

[0046] Conductive material 105 is then deposited in the opening 10 to fill the opening 10, as Figure 1c As shown, the conductive...

Embodiment 1

[0052] In order to solve the problems in the prior art, the present invention provides a method for preparing a semiconductor device, such as Figures 2a-2g As shown, the method will be further described below in conjunction with the accompanying drawings.

[0053] First, step 201 is performed to provide a substrate 201 in which components, a metal interconnection structure 202 and a dielectric layer 203 are sequentially formed.

[0054] Specifically, such as Figure 2a As shown, a base is provided first, and the base includes at least a semiconductor substrate, wherein the semiconductor substrate can be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator ( SSOI), silicon germanium on insulator (S-SiGeOI), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0055] Various active devices are formed on the semiconductor substrate, for example, CMOS devices, components of pressure sensors, and ot...

Embodiment 2

[0105] The present invention also provides a semiconductor device, which is prepared by the method described in Embodiment 1, and the semiconductor device includes a pressure sensor. In the method of the present invention, the metal bonding layer will not be damaged during the etching process in the formation of the semiconductor device, and it can accurately realize the transfer of the pattern in the subsequent patterning process, which improves the performance and good quality of the semiconductor device. Rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com