Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

188 results about "Vanadium oxide thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

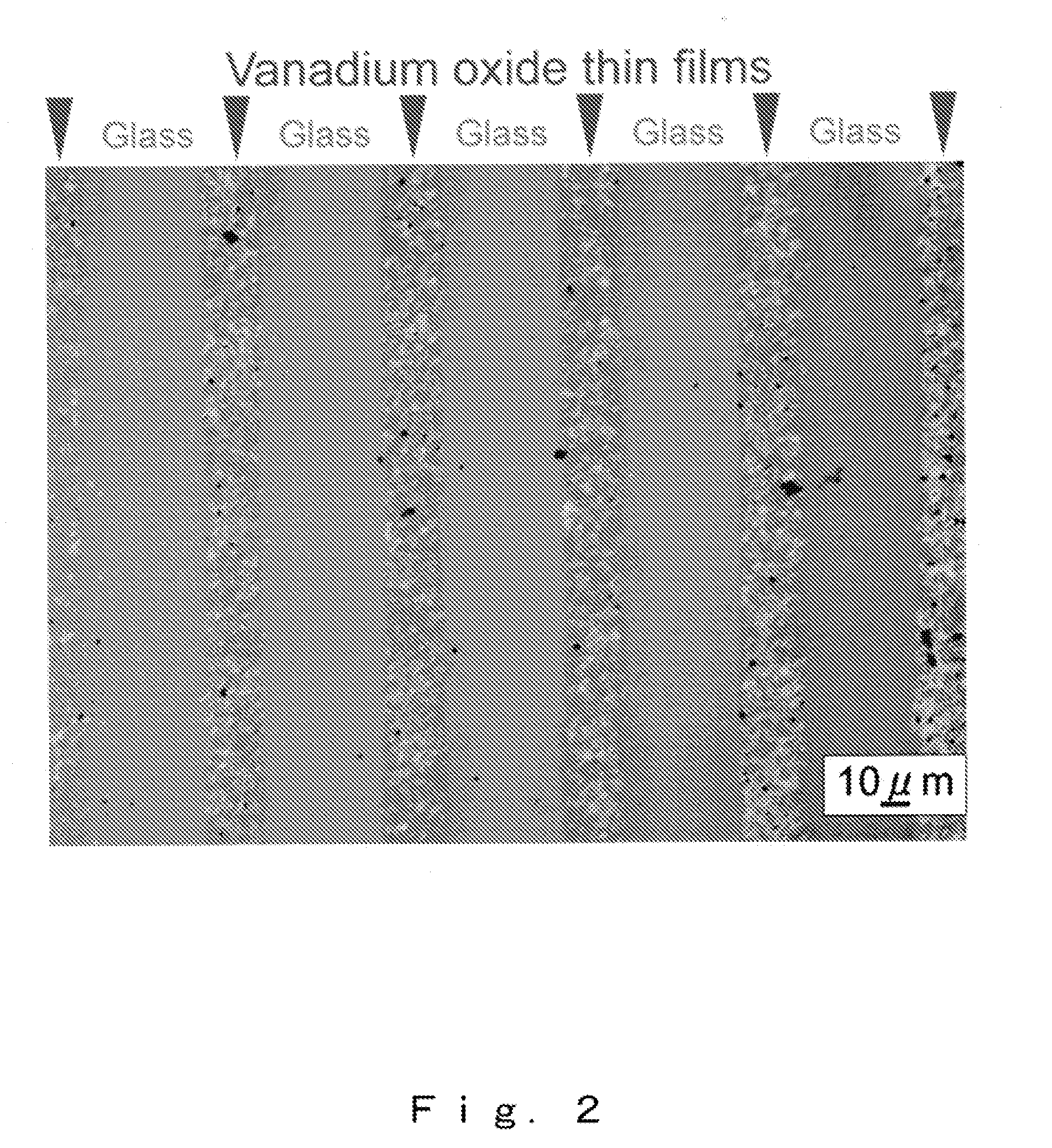

Method of Manufacturing Vanadium Oxide Thin Film

InactiveUS20090011145A1Uniform thicknessComposition is stableChemical vapor deposition coatingPlasma techniqueOxygenMaterials science

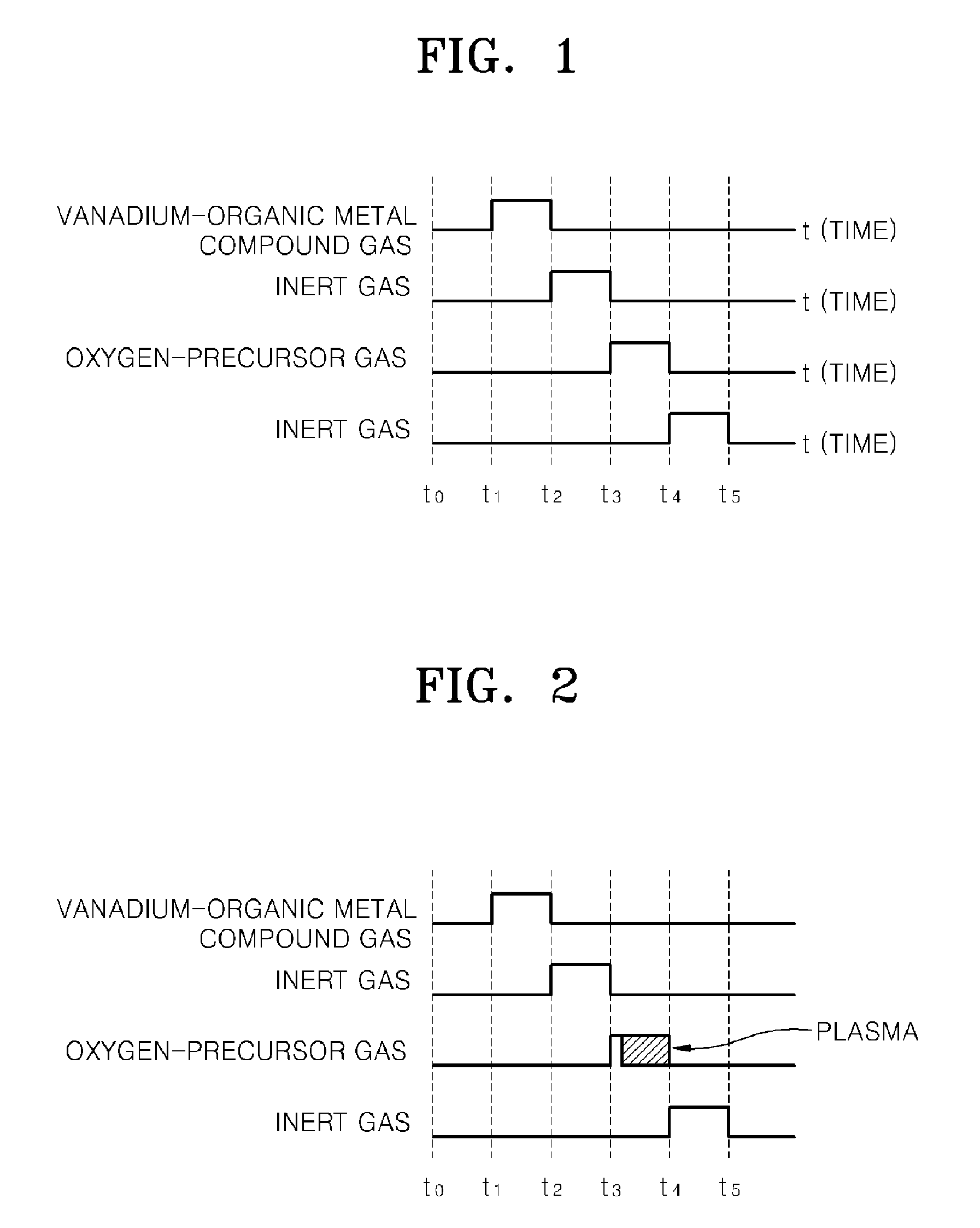

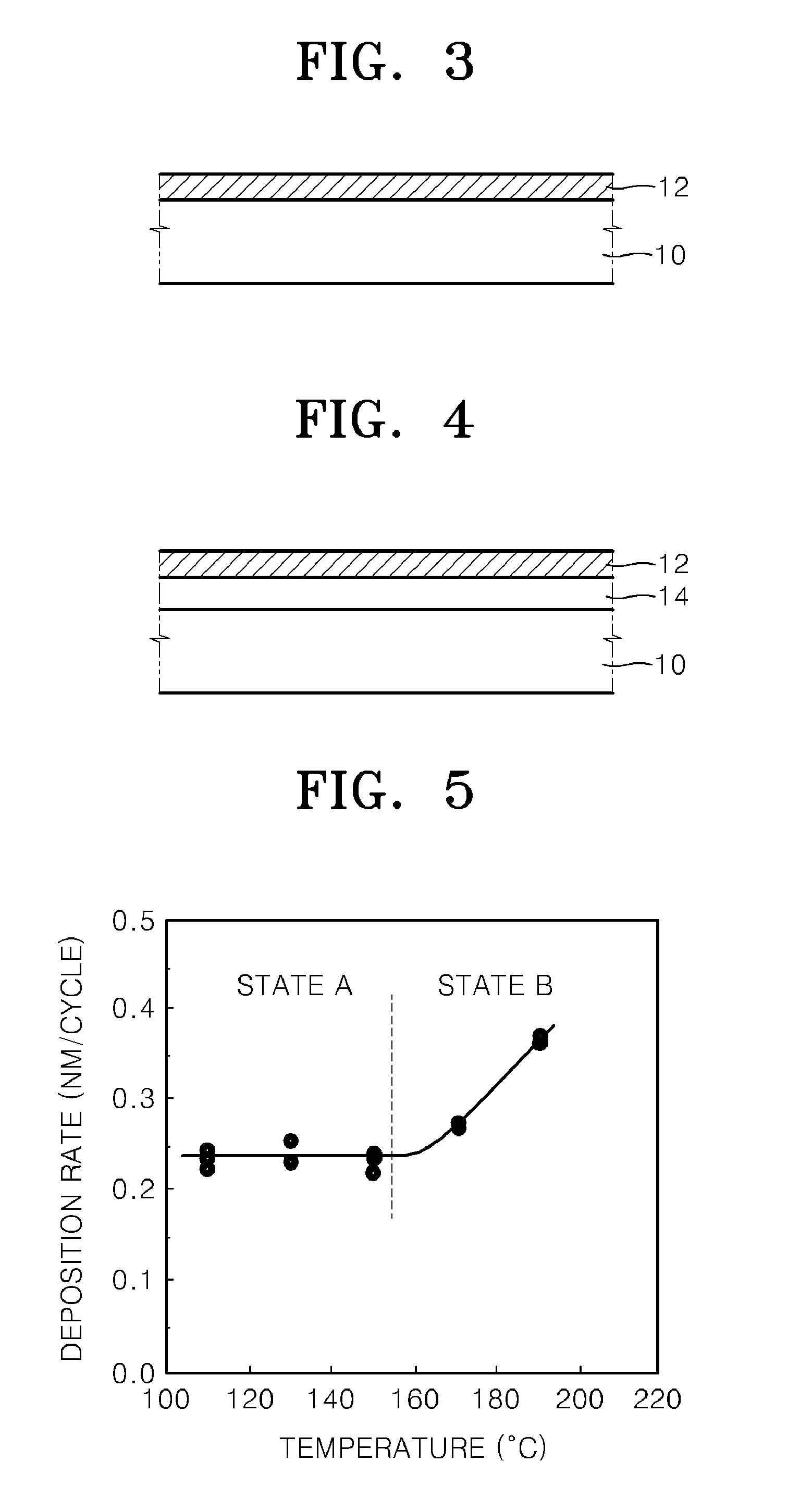

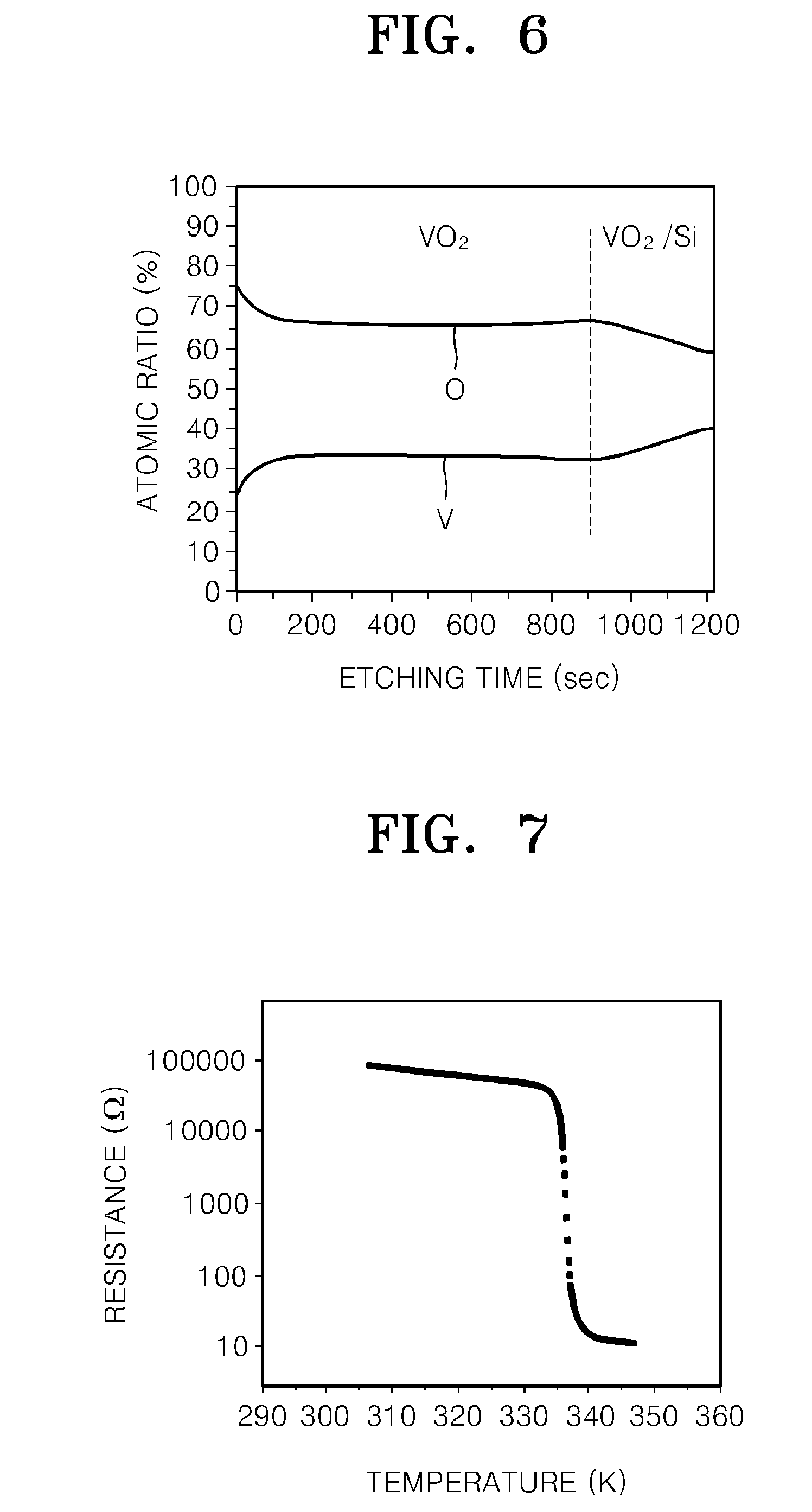

Provided is a method of manufacturing a large-sized vanadium oxide thin film having a uniform surface, uniform film thickness and stable composition. According to the method, a vanadium-organometallic compound gas is injected into a chamber to form adsorption layer where molecules of the vanadium-organometallic compound are adsorbed on the surface of a substrate. After that, an oxygen precursor is injected into the chamber and thus allowed to accomplish surface-saturation reaction with the adsorbed materials to fabricate a vanadium oxide thin film.

Owner:ELECTRONICS & TELECOMM RES INST

Hypovanadic oxide-based composite film with adjustable radiance and preparation method thereof

InactiveCN101817644AHigh and high far infrared reflectionLow emissivityVacuum evaporation coatingSputtering coatingThermochromismComposite film

The invention discloses a hypovanadic oxide-based composite film with adjustable radiance and a preparation method thereof. The hypovanadic oxide-based composite film comprises a transparent underlay and a composite film; the composite film comprises a hypovanadic oxide film positioned on the underlay and a conductive metal film positioned on the hypovanadic oxide film; the composite film also comprises an inorganic transparent film; the thickness of the conductive metal film is between 2 and 30 nanometers; metal particles exist in a continuous particle form; and an inert transition layer is deposited on the transparent underlay. The preparation method disclosed by the invention has a simple process; and on the premise of keeping the thermochromism performance of the hypovanadic oxide, the obtained hypovanadic oxide-based composite film can effectively reduce the radiance of low-temperature phase thereof, is favorable for improving the thermal insulation performance of the low-temperature phase, and enlarges the application range of the hypovanadic oxide-based composite film serving as an energy-saving window.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Uncooled microbolometer and preparation method thereof

InactiveCN101881667AImprove performanceReduce residual stressDecorative surface effectsChemical vapor deposition coatingCarbon nanotubeHeat sensitive

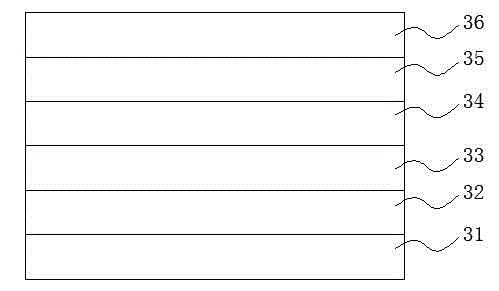

The invention discloses an uncooled microbolometer, which comprises a microbolometer microbridge structure used for an uncooled detector, wherein the thermistor material and the light absorbing material in the microbridge structure are vanadium oxide-carbon nano tube composite membranes, the vanadium oxide-carbon nano tube composite membranes are formed by compounding one-dimensional carbon nano tubes and two-dimensional vanadium oxide membranes, and the microbridge structure is in a three-layer sandwich structure: the bottom layer is provided with an amorphous silicon nitride membrane which is used as the supporting and insulating material of the microbridge, the middle layer is provided with one or more layers of vanadium oxide-carbon nano tube composite membranes which are used as the heat sensitive layer and the light absorbing layer of the microbolometer; and the surface layer is provided with another layer of amorphous silicon nitride membrane which is used as the passivation layer of the heat sensitive membrane and a stress control layer. The microbolometer and the preparation method thereof can overcome the defects of the prior art, improve the working performance of devices, reduce the cost of raw materials, and are suitable for large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing vanadium dioxide film

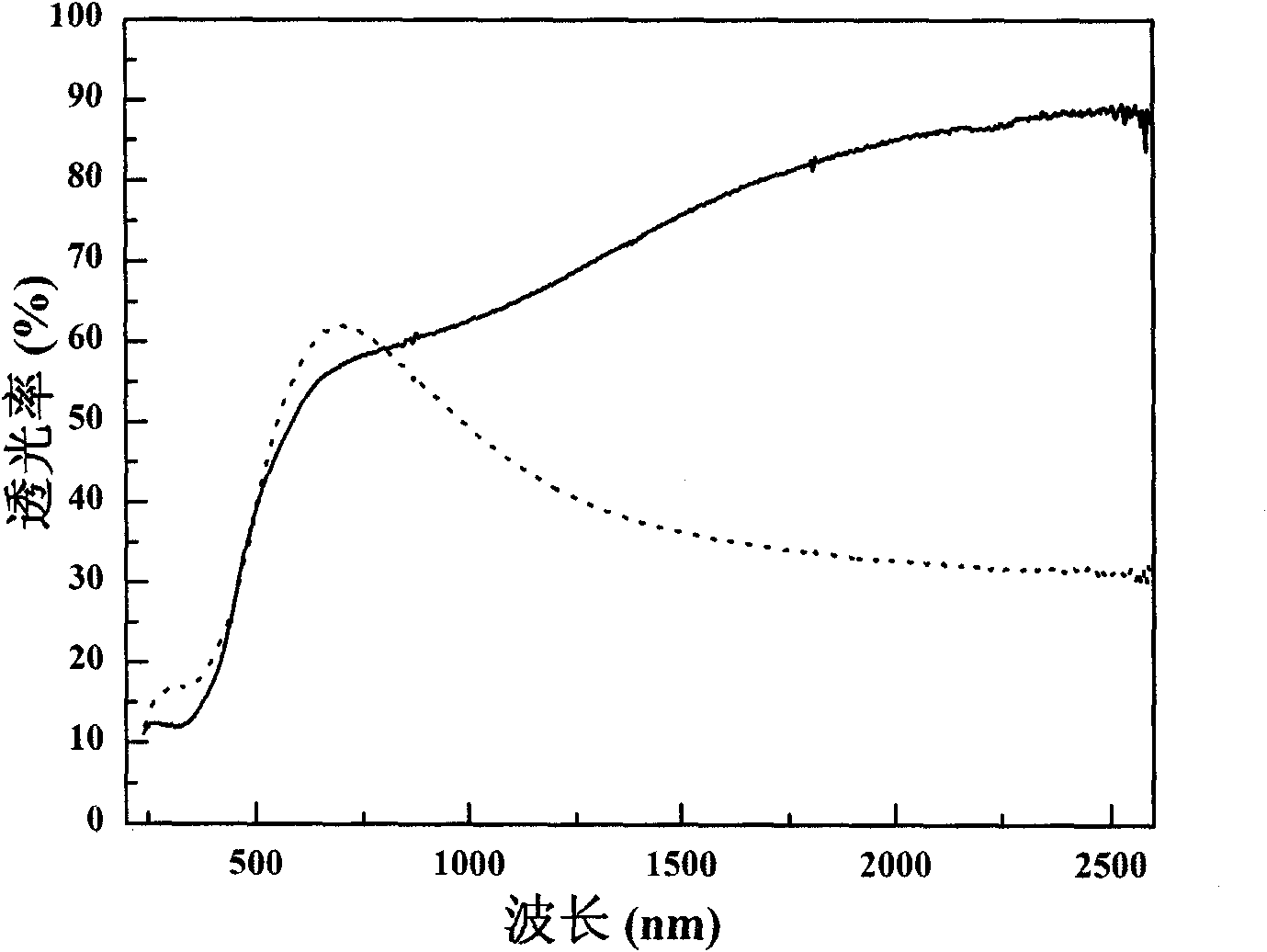

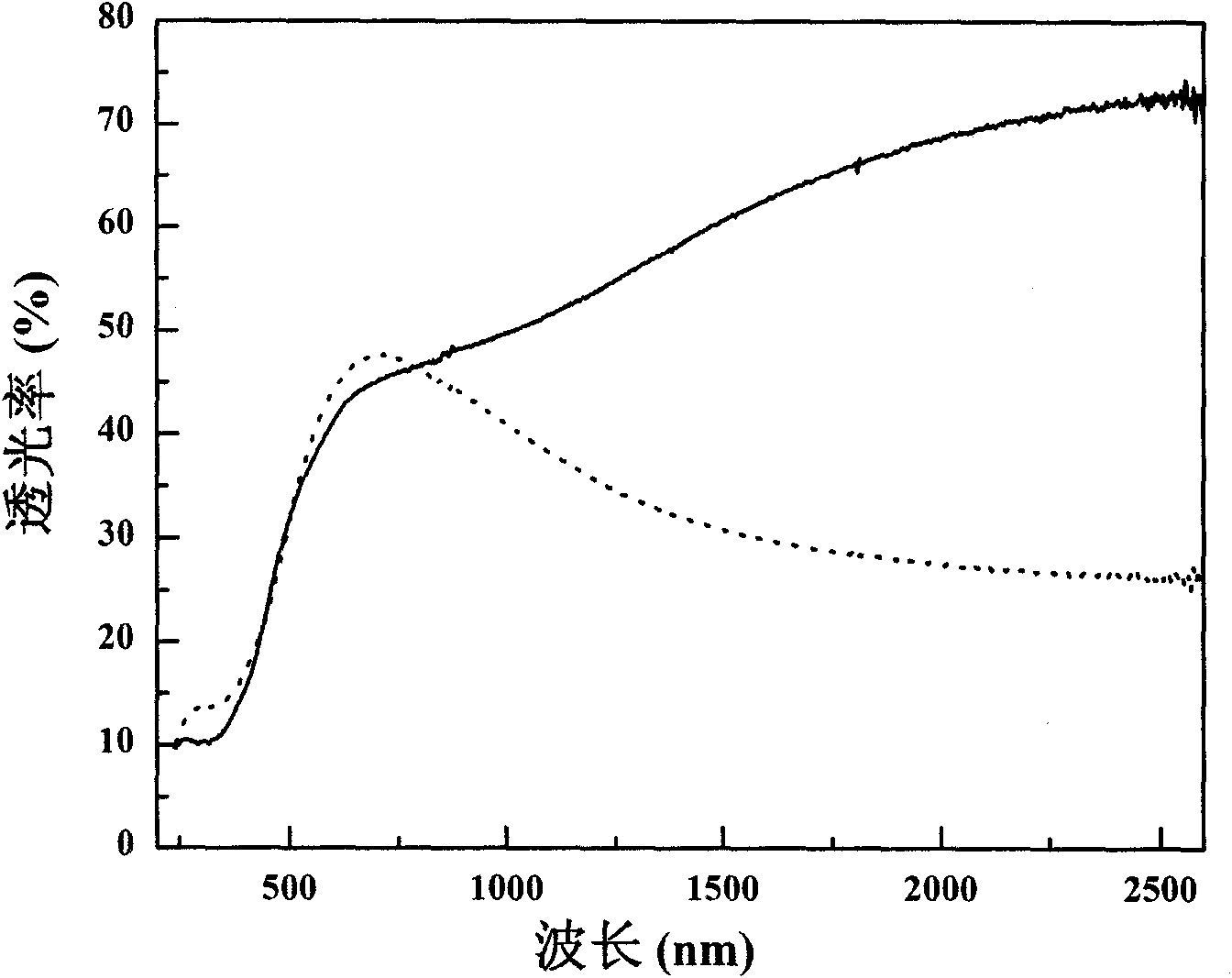

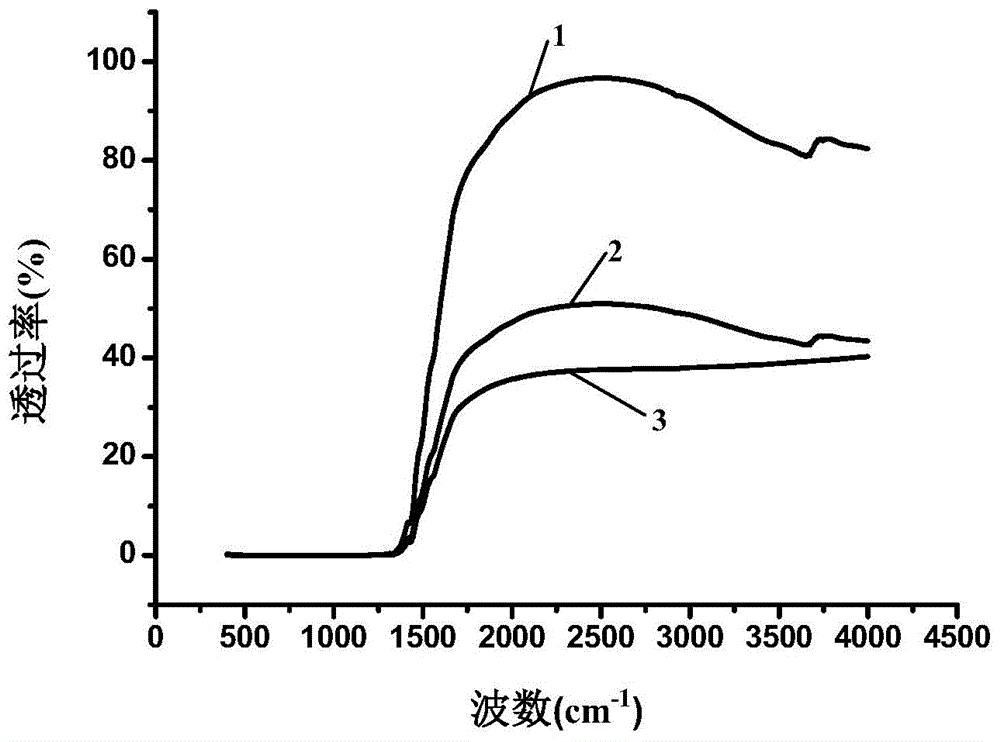

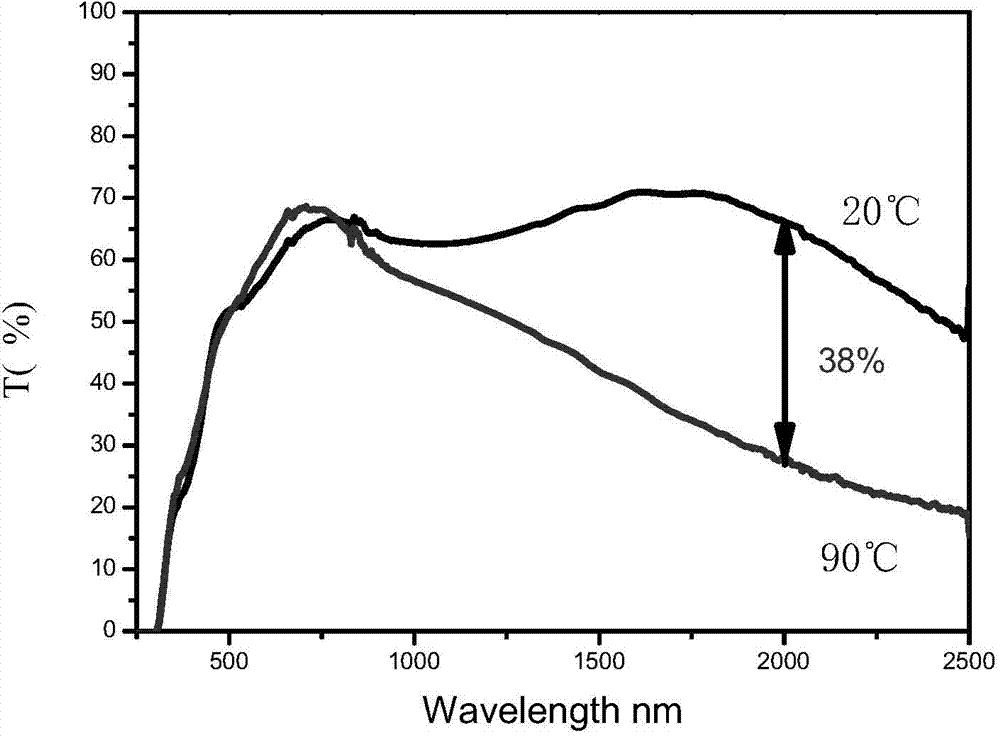

InactiveCN104032278AImprove performanceGood repeatabilityVacuum evaporation coatingSputtering coatingVanadium dioxideTransmittance

The invention discloses a method for preparing a vanadium dioxide film. According to the method, metal vanadium or low-valence vanadium oxide film is annealed in oxygen and vacuum to obtain a phase-transition vanadium dioxide film; the most proper oxygen partial pressure, the annealing temperature and the annealing time are selected according to the type and thickness of the low-valence vanadium oxide to obtain a vanadium dioxide film with excellent performance, wherein the infrared regulation rate at 2,400nm can be 58 percent, and the visible light transmittance can be 43 percent; the doped low-valence vanadium oxide film is oxidized to obtain the doped vanadium dioxide film, and the phase transition temperature of the vanadium dioxide can be regulated by means of doping to adapt to different requirements. The vanadium dioxide film can be applied to optical information storage, photoelectric switches, intelligent windows and uncooled infrared focal plane imaging; the method is compatible with large-scale coated glass production process, and a vanadium dioxide film with excellent performance can grow on amorphous glass.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

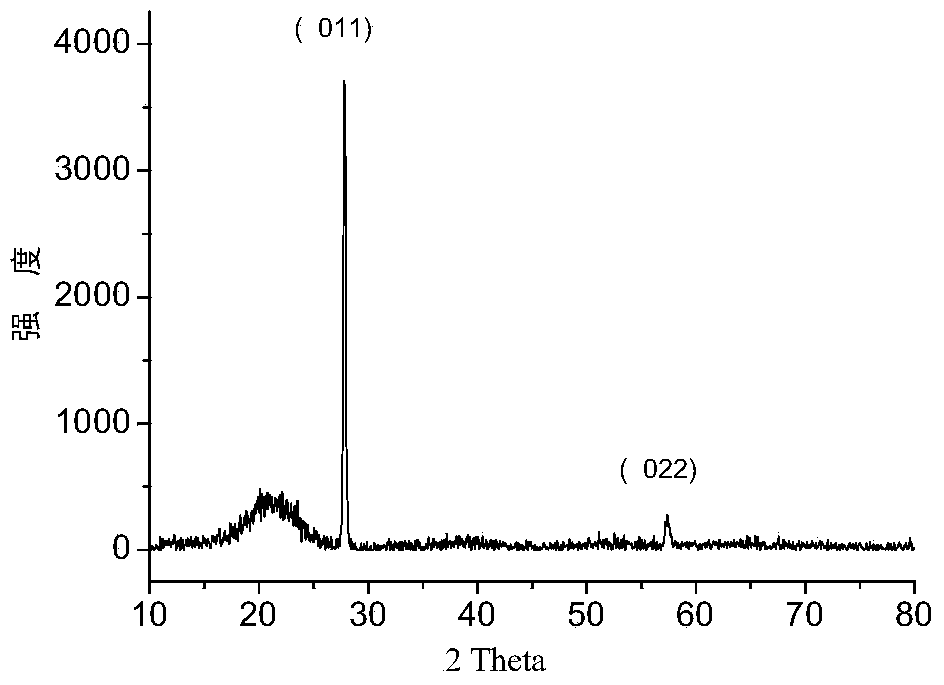

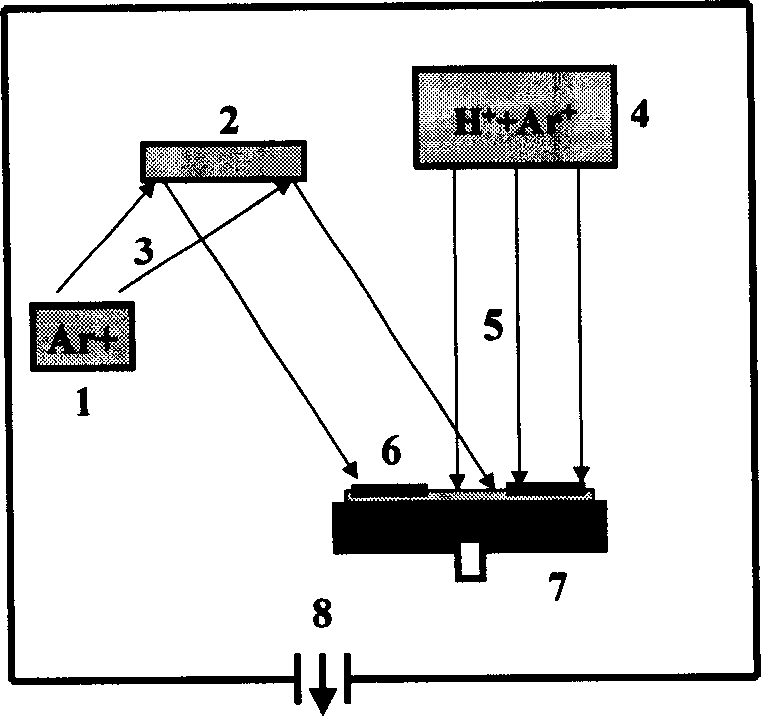

Process for preparing vanadium oxide film capable of regulating phase change temp.

InactiveCN1598040AEasy to moveReduce infrared transmittanceVacuum evaporation coatingSputtering coatingNitrogen gasVanadium oxide

This invention provides a preparation method of vanadium oxides film whose phase change temperature is variable. Siliconoxide film and silicon nitride film deposit on the silicon slice. The method of ion beam reactive sputtering is used to deposit vanadium oxide film. The processing conditions as followings: back bottom vacuum 4X10-4Pa-3X10-3Pa, oxygen pressure 6X10-4Pa-8X10-3Pa, argon gas pressure: 1X10-2Pa-2.3X10-2Pa,ion beam power: 8W-60W, substrate temperature: 120deg.C-450deg.C, sputter time: 10-45min, the vanadium target is butt material. The annealing treatment is for the sample. The processing conditions gas: argon or nitrogen gas, annealing temperature: 250deg.C-580deg.C, annealing time: 20-240 min, and then getting phase change vanadium oxide film.

Owner:HUAZHONG UNIV OF SCI & TECH

Vanadium dioxide intelligent temperature control film and preparation method thereof

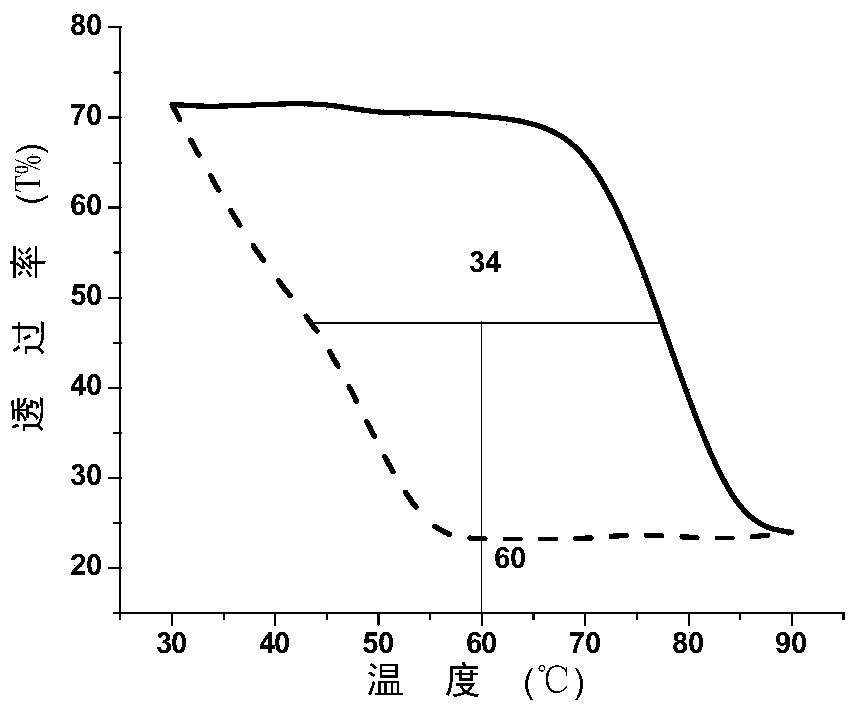

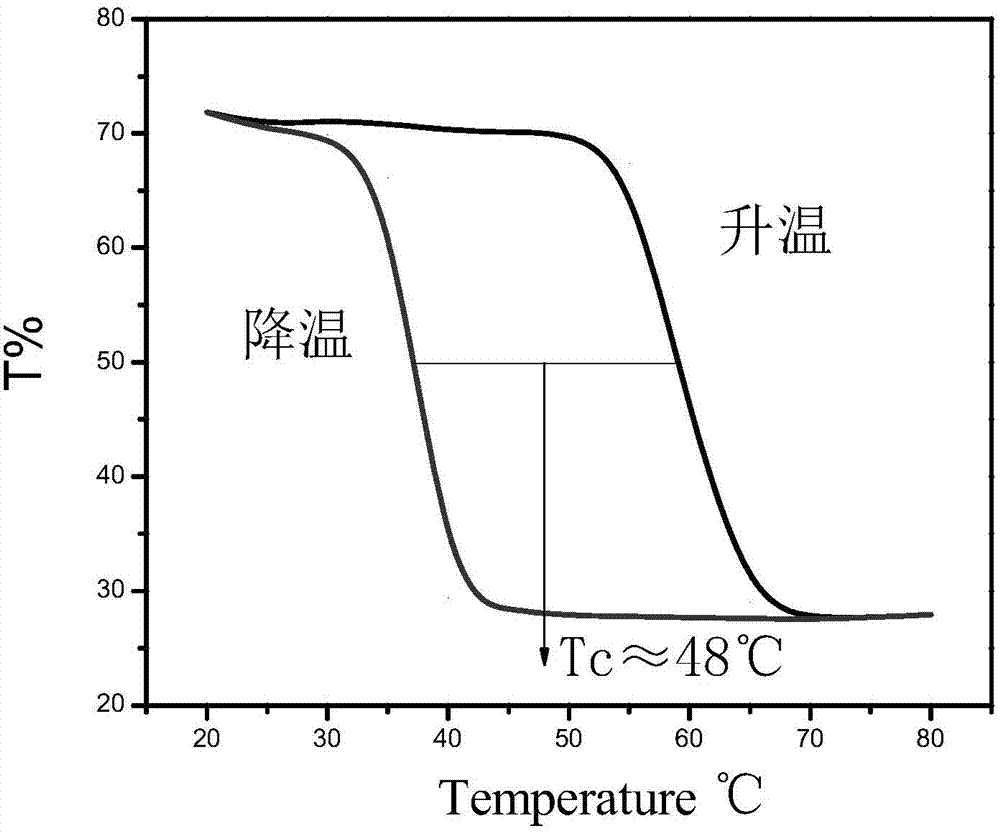

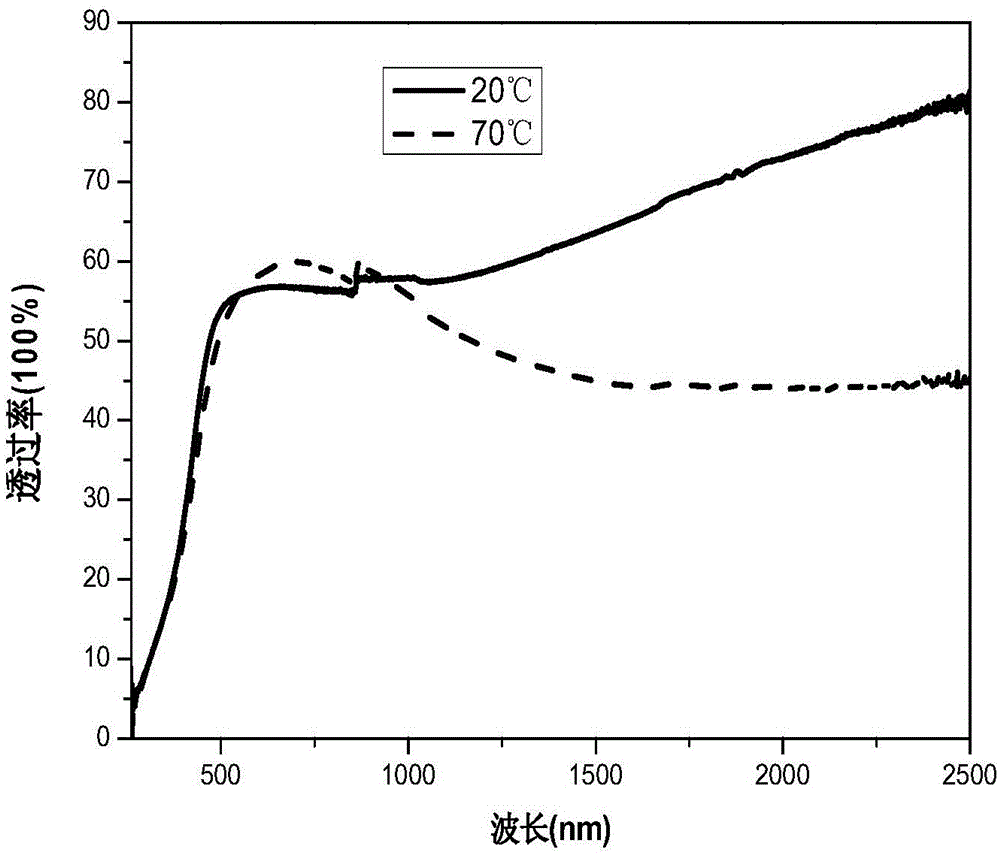

The invention relates to a vanadium dioxide intelligent temperature control film and a preparation method thereof. The preparation method comprises the following steps of: uniformly dispersing and dissolving vanadic oxide powder in an organic solvent with weak reductibility by adopting a wet chemical solution method; adding PVP (Polyvinyl Pyrrolidone) or PEG (polyethylene glycol) and a metal salt to prepare a doped VOx film (x is more than 2.0 and less than 2.5); and performing thermal treatment to form a doped porous hypovanadic oxide (VO2) film. In a better embodiment, the preparation method comprises the following steps of: adding polyvinyl pyrrolidone and a wolfram salt into a system consisting of vanadic oxide powder, benzyl alcohol and isopropyl alcohol to prepare a wolfram-doped VOx film; and annealing in hydrogen / argon atmosphere at the temperature 410 DEG C for 3 hours to prepare a wolfram-doped porous VO2 film, wherein the metal-insulator phase-transition temperature of the wolfram-doped porous VO2 film can be adjusted between 30 DEG C and 68 DEG C according to doping amount of wolfram, the penetration rate of a visible light region is 70 percent, the difference between the penetration rate before phase transition and the penetration rate after phase transition at the position of which the wavelength is 2,500 nanometers is 62 percent, 3-4 orders of magnitude of specific resistance is changed, and higher practical value is achieved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

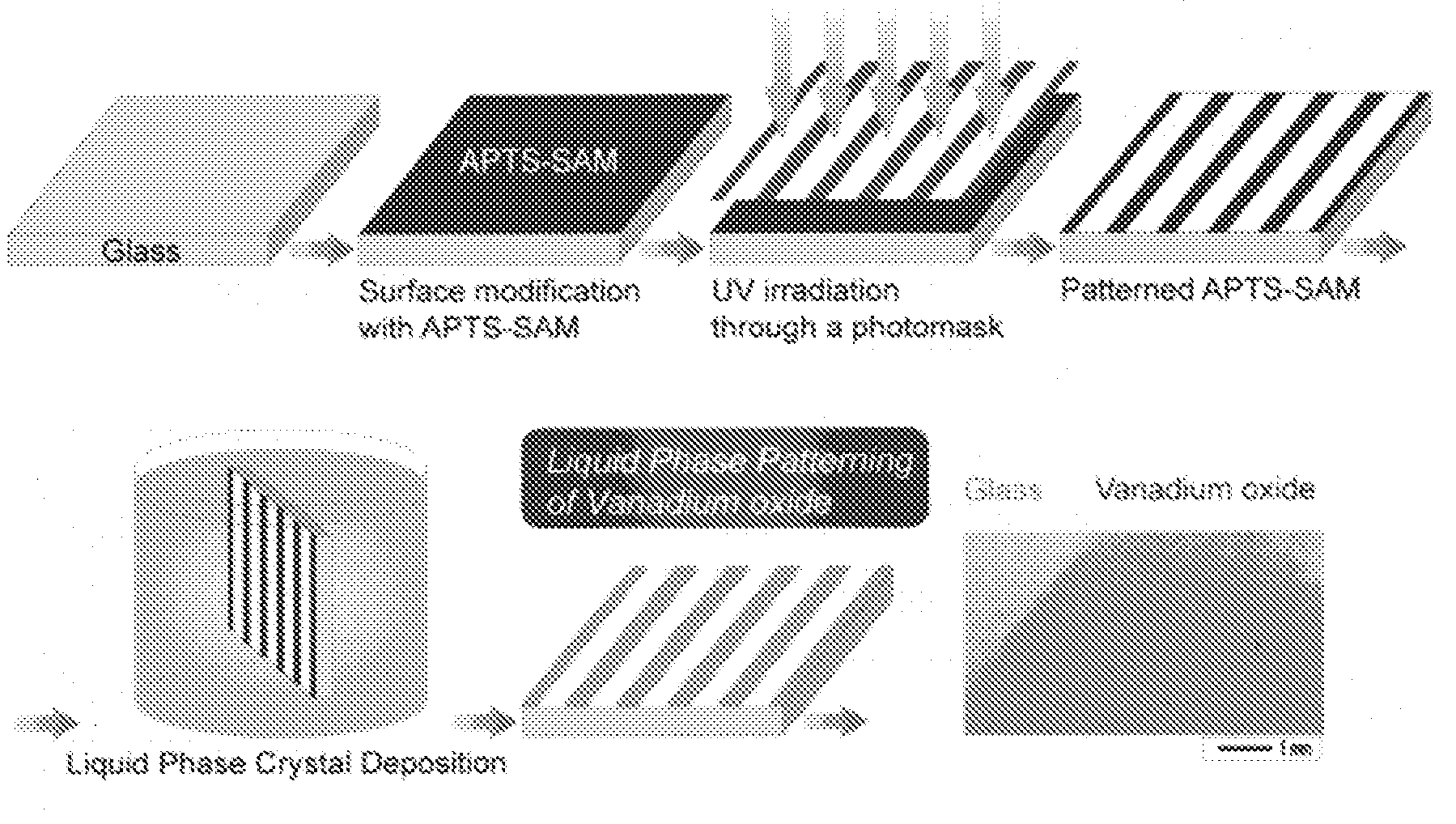

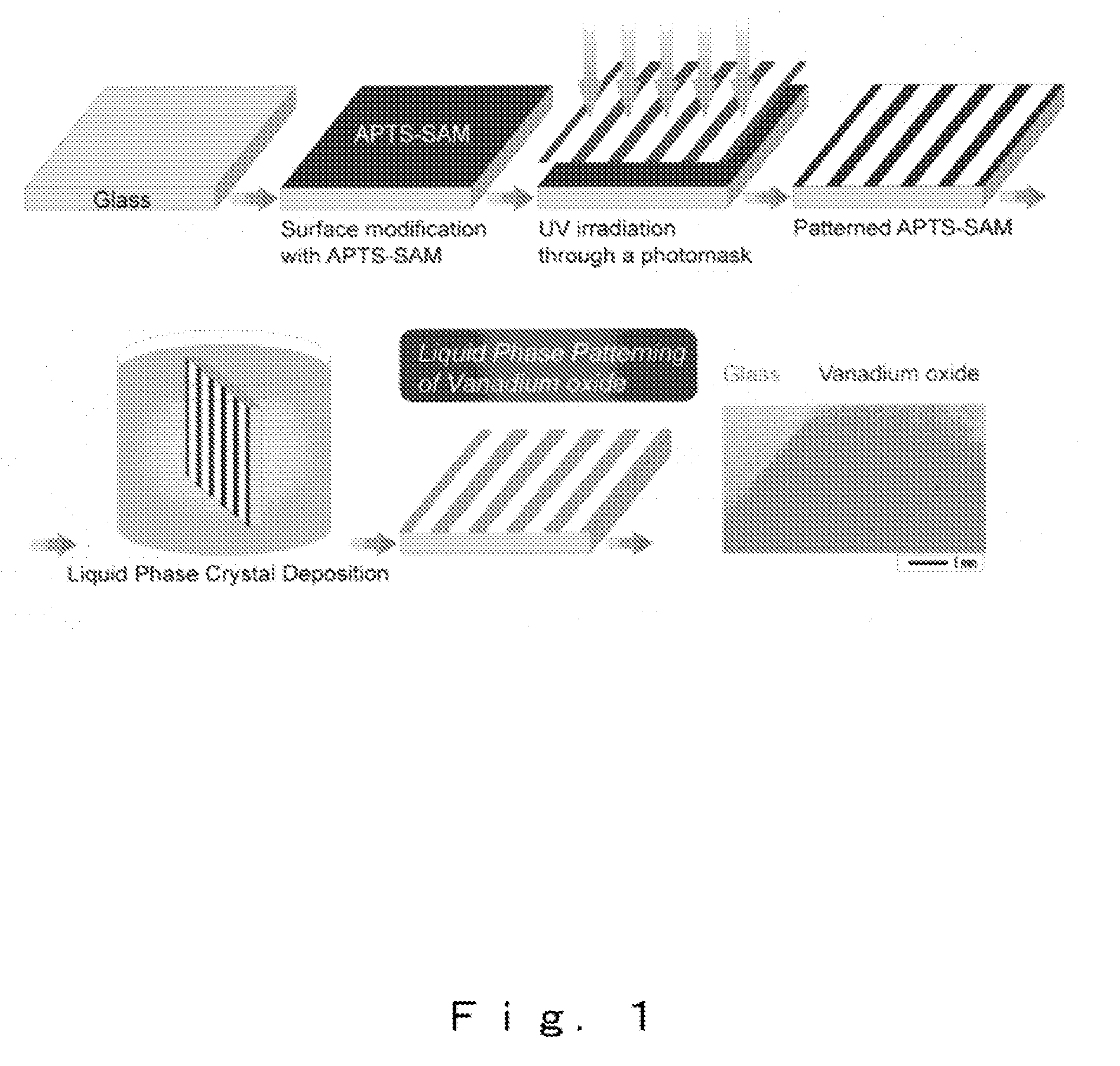

Vanadium Oxide Thin Film Pattern and Method of Fabricating the Same

InactiveUS20100183854A1Convenient coatingReduce transfer rateMaterial nanotechnologyLiquid surface applicatorsSilanesSelf-assembled monolayer

The present invention relates to a vanadium oxide thin film pattern which is fabricated by using APTS (3-aminopropyltriethoxysilane, H2NC3H5Si(OCH3)3) or the like to prepare an APTS-SAM or the like on the surface of a substrate, irradiating this APTS-SAM with vacuum ultraviolet light through a photomask to thereby modify amino-terminal silanes into silanol groups in the exposed area, and then depositing vanadium oxide in a liquid phase using a patterned self-assembled monolayer having the amino-terminated silane surface and silanol group surface as a template for patterning the vanadium oxide, to a method of fabricating the same, and to a vanadium oxide device.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Low temperature deposition method of hypovanadic oxide thin film on glass

InactiveCN101280413ALow deposition temperatureReduce difficultyVacuum evaporation coatingSputtering coatingVanadium dioxideLow temperature deposition

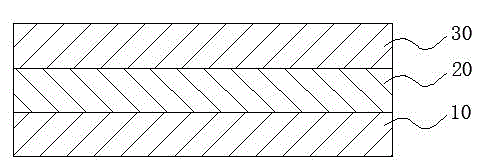

The invention provides a low temperature deposition method of vanadium dioxide thin film on a glass substrate by utilizing a principle of template induction function for the crystal growth. Glass is taken as a substrate, and the low temperature deposition method comprises the steps in sequence that firstly, the glass substrate is cleaned and pre-heated; secondly, a silicon dioxide diffusing blocked layer is prepared; thirdly, a metal oxide buffer layer is prepared; fourthly, a vanadium dioxide thermal color layer is prepared. The material of the metal oxide buffer layer adopted by the invention is transparent in the visible light area and has low crystallization temperature, the crystal shape of the material can be well matched with the vanadium dioxide, and the template induction function can be generated during the growing process of the vanadium dioxide thin film, therefore, the deposition temperature of the vanadium dioxide thin film can be greatly reduced. The preparing process of the vanadium dioxide intelligent glass is simplified, the cost is reduced, the energy consumption is saved, and the difficulty of the industrialization process of the vanadium dioxide intelligent glass is greatly reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

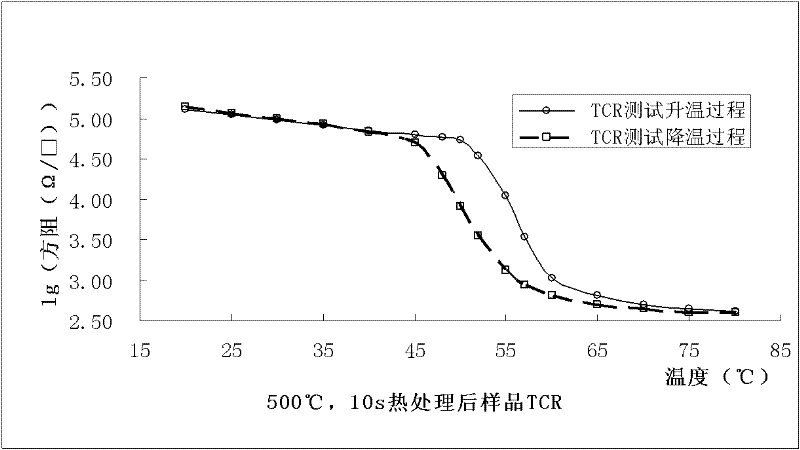

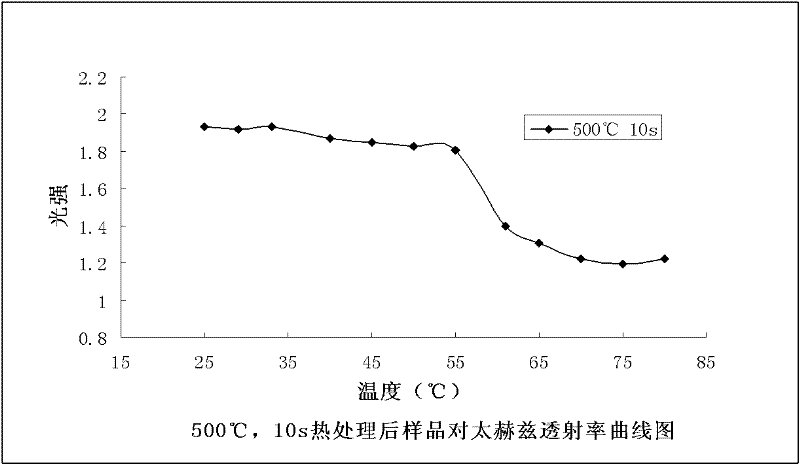

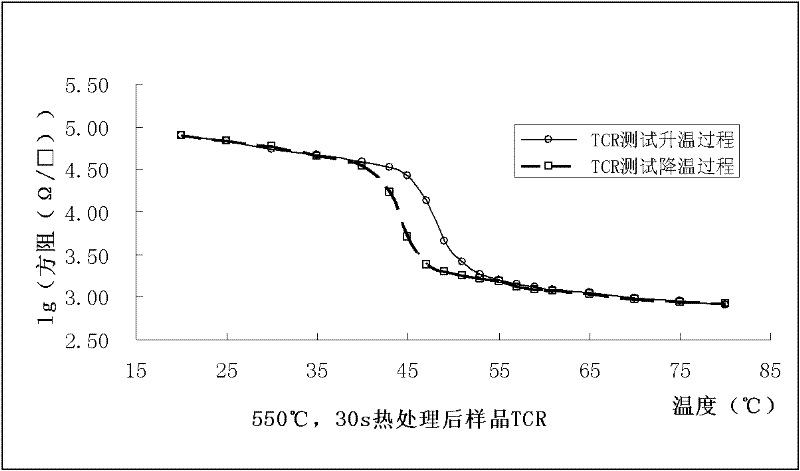

Quick thermal treatment method for preparing vanadium dioxide film

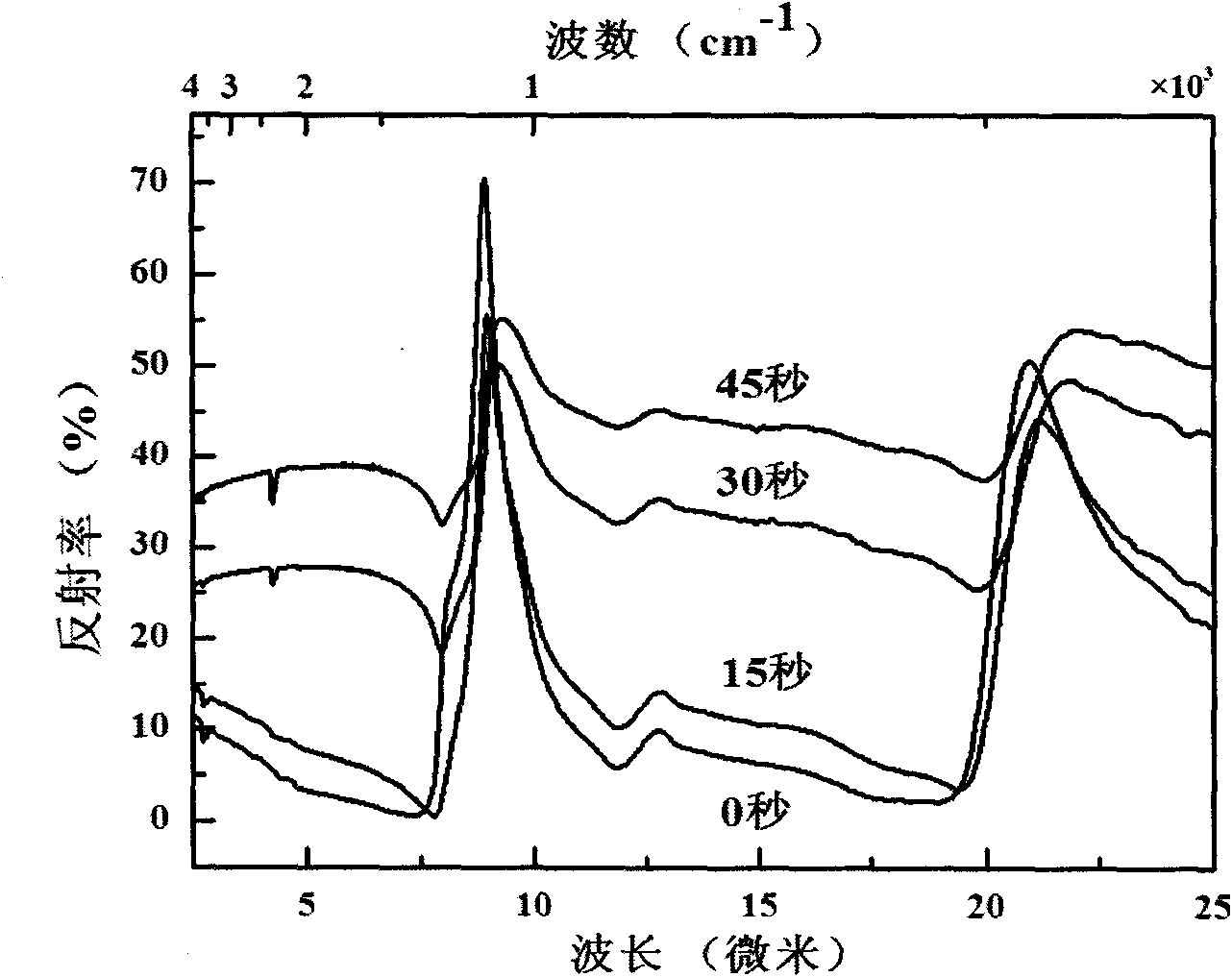

InactiveCN102212782ARapid heat treatment methodExcellent ElectricalVacuum evaporation coatingSputtering coatingVanadium dioxideShielding gas

The invention discloses a quick thermal treatment method for preparing a vanadium dioxide film. The method comprises the following steps of: (1) cutting a silicon chip to form a substrate, and cleaning and drying the silicon substrate; (2) placing the silicon substrate of the step (1) in a vacuum chamber, and depositing a vanadium dioxide film on the silicon substrate by adopting a target magnetron sputtering method, wherein the target is 99.99 percent metallic vanadium, argon is used as a working gas and oxygen is used as a reaction gas; (3) putting the vanadium dioxide film product sputtered in the step (2) into a quick annealing furnace to prepare a vanadium dioxide film, wherein the annealing temperature is 500 to 550 DEG C, the heating rate is 50 DEG C per second, the heat preservation time is 10 to 30 seconds, cooling is performed within 3 minutes, and the protective gas is nitrogen; and (4) measuring. By the method, the thermal treatment time is shortened, and obvious phase change property can be obtained after the vanadium dioxide film product is quickly and thermally treated for 10 to 30 seconds; the method is simple in process control, high in repeatability and suitable for large-area production; and electric and optical properties of the vanadium dioxide film are optimized. The method is widely applied in the fields of infrared detectors, memories, optical communications and the like.

Owner:TIANJIN UNIV

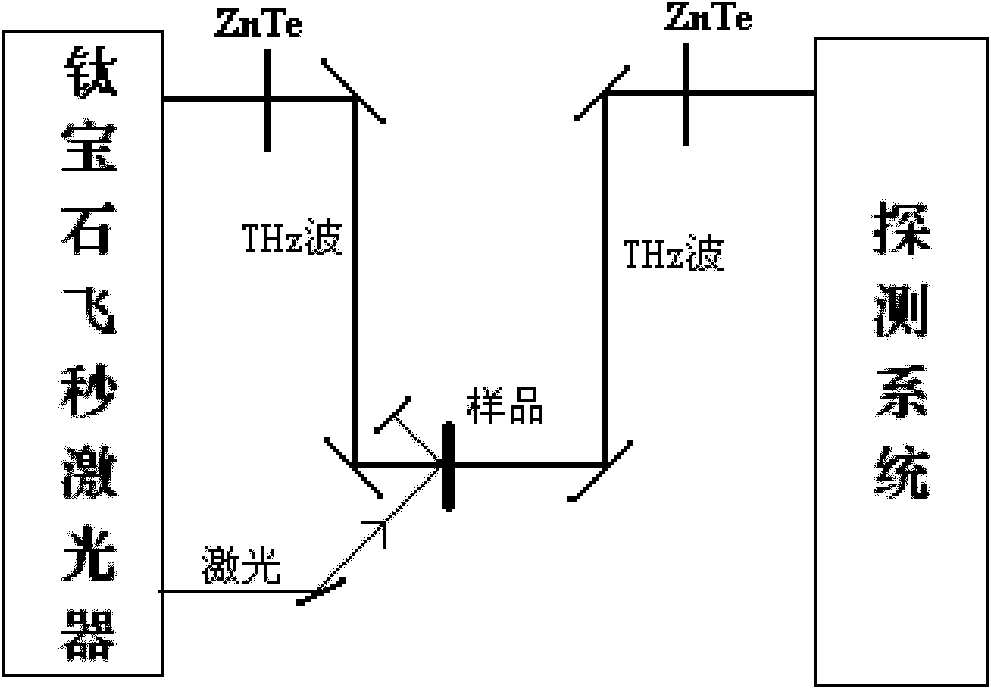

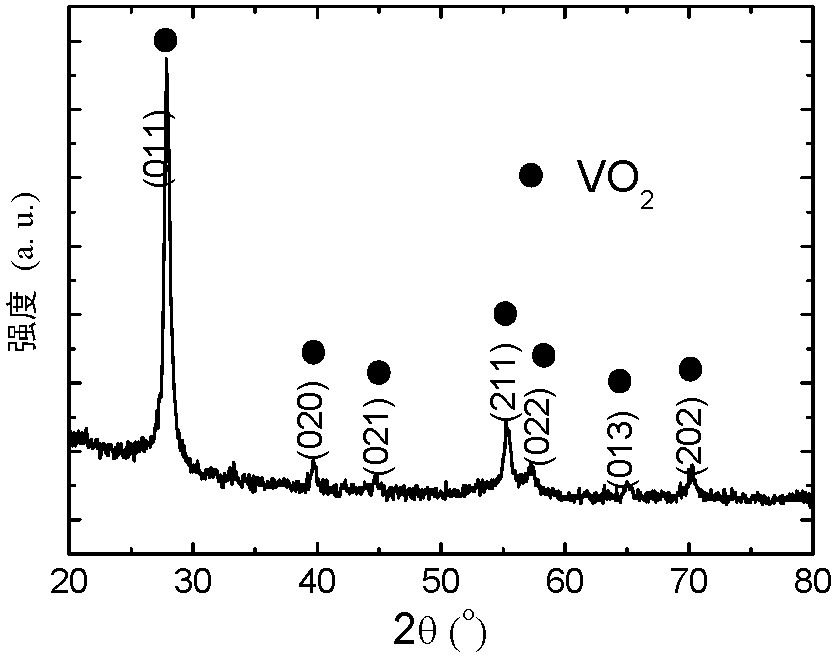

Terahertz wave band vanadium oxide optical switch and preparation method thereof

InactiveCN101950092ALow insertion lossHigh extinction ratioVacuum evaporation coatingSputtering coatingTime domainModem device

The invention discloses a terahertz (THz) wave band vanadium oxide optical switch and a preparation method thereof and relates to the technical field of optical communication. The vanadium oxide optical switch is formed by the vanadium oxide film and is loaded in a THz time-domain spectrum system or modem. The method comprises the following steps: using the reactive magnetic sputtering method to prepare a vanadium oxide film on the silicon substrate material; using the THz time-domain spectrum system to generate THz wave, performing laser exciation to the vanadium oxide film during the transmission of the THz wave to ensure that the THz wave can not penetrate through the vanadium oxide film and turn off the vanadium oxide optical switch; and using the THz time-domain spectrum system to generate THz wave, removing laser during the transmission of the THz wave to ensure that the THz wave penetrates through the vanadium oxide film and turn on the vanadium oxide optical switch. By adopting the optical switch and preparation method thereof provided by the invention, the effects of fast switching speed, low insertion loss and high extinction ratio can be realized.

Owner:TIANJIN UNIV

Method for preparing vanadium dioxide film by using magnetron sputtering process

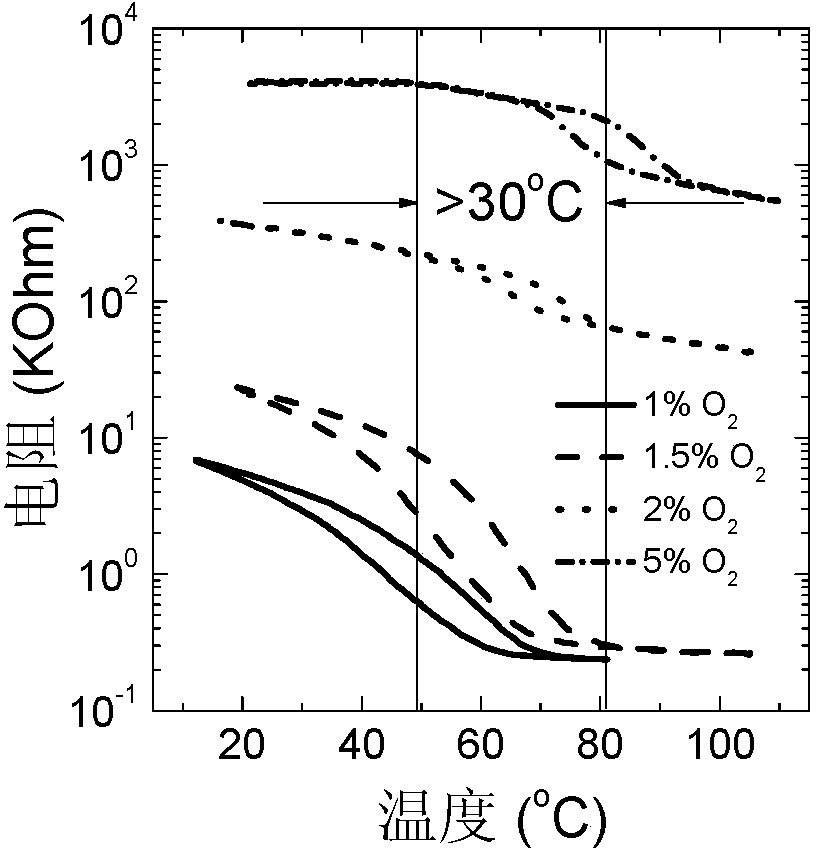

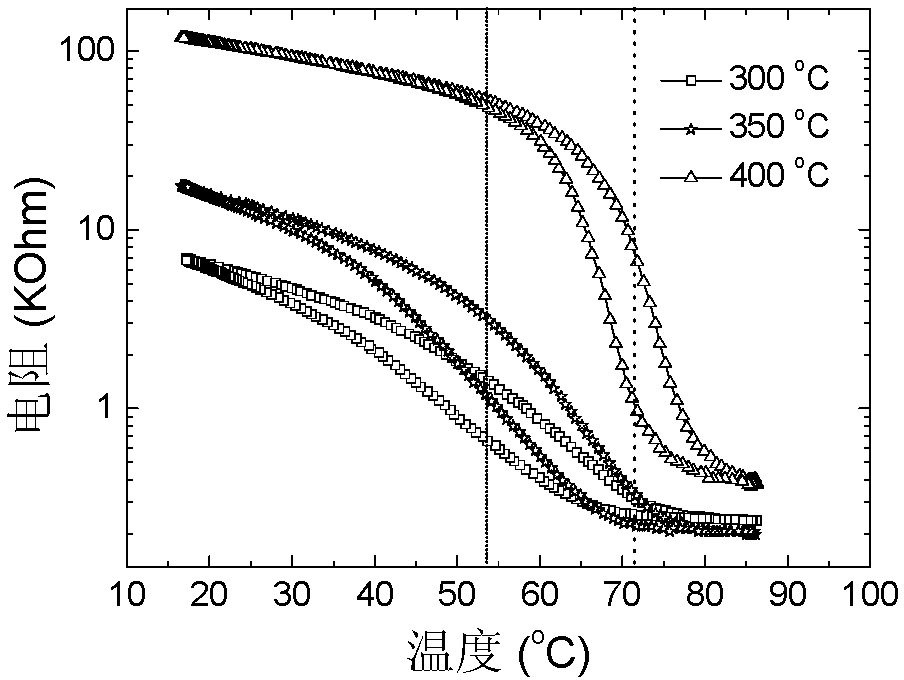

InactiveCN104099563AControl thermochromic propertiesNo change in thermochromic propertiesVacuum evaporation coatingSputtering coatingVanadium dioxideSputtering

A method for preparing a vanadium dioxide film by using a magnetron sputtering process comprises: taking metal vanadium as a target material, taking argon as a sputtering gas, and taking oxygen as a reaction gas, performing sputtering so as to form the vanadium dioxide film on a substrate, and specifically controlling the deposition temperature to be 300-500 DEG C, the deposition total pressure to be 0.5-2.0 Pa and the oxygen partial pressure to be 1-5%. The method helps to overcome the disadvantage that a conventional preparation technology for a vanadium oxide film is complex, and also the prepared vanadium oxide film is a vanadium dioxide film with adjustable phase-transition temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Vanadium oxide film for infrared detector and manufacturing method thereof

InactiveCN101900607AMeet special needsImprove performancePyrometry using electric radation detectorsChemical structureComposite film

The invention discloses a vanadium oxide film for an infrared detector and a manufacturing method thereof. The film is a vanadium oxide-carbon nanotube composite film, which is formed by compositing one-dimensional carbon nanotubes and a two-dimensional vanadium oxide film. The film is used as a thermistor material and an infrared absorption material of the infrared detector. The infrared detector is manufactured by using the vanadium oxide-carbon nanotube composite film, so that negative effect on the chemical structure of a sensitive film in the conventional manufacturing technology is overcome, shortcomings of simple carbon nanotubes or a simple vanadium oxide material in the aspects of electrical property, optical property and the like can be overcome, and the comprehensive performance of the infrared detector can be improved at the same time. The manufacturing method of the vanadium oxide-carbon nanotube composite film disclosed by the invention is simple, does not need any complex and expensive film-forming equipment, reduces manufacturing cost, improves the serviceability of the infrared detector and is suitable for massive industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

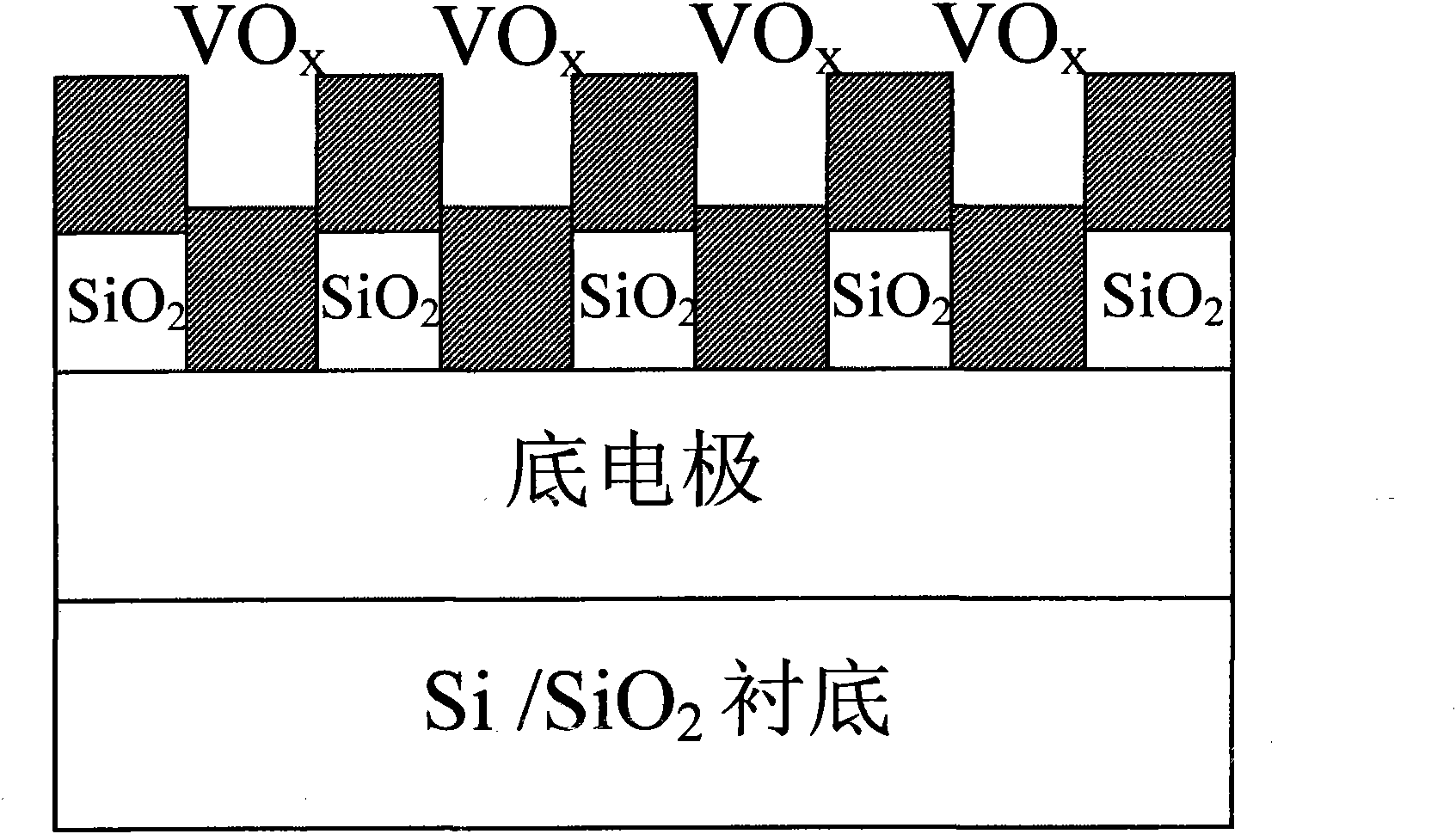

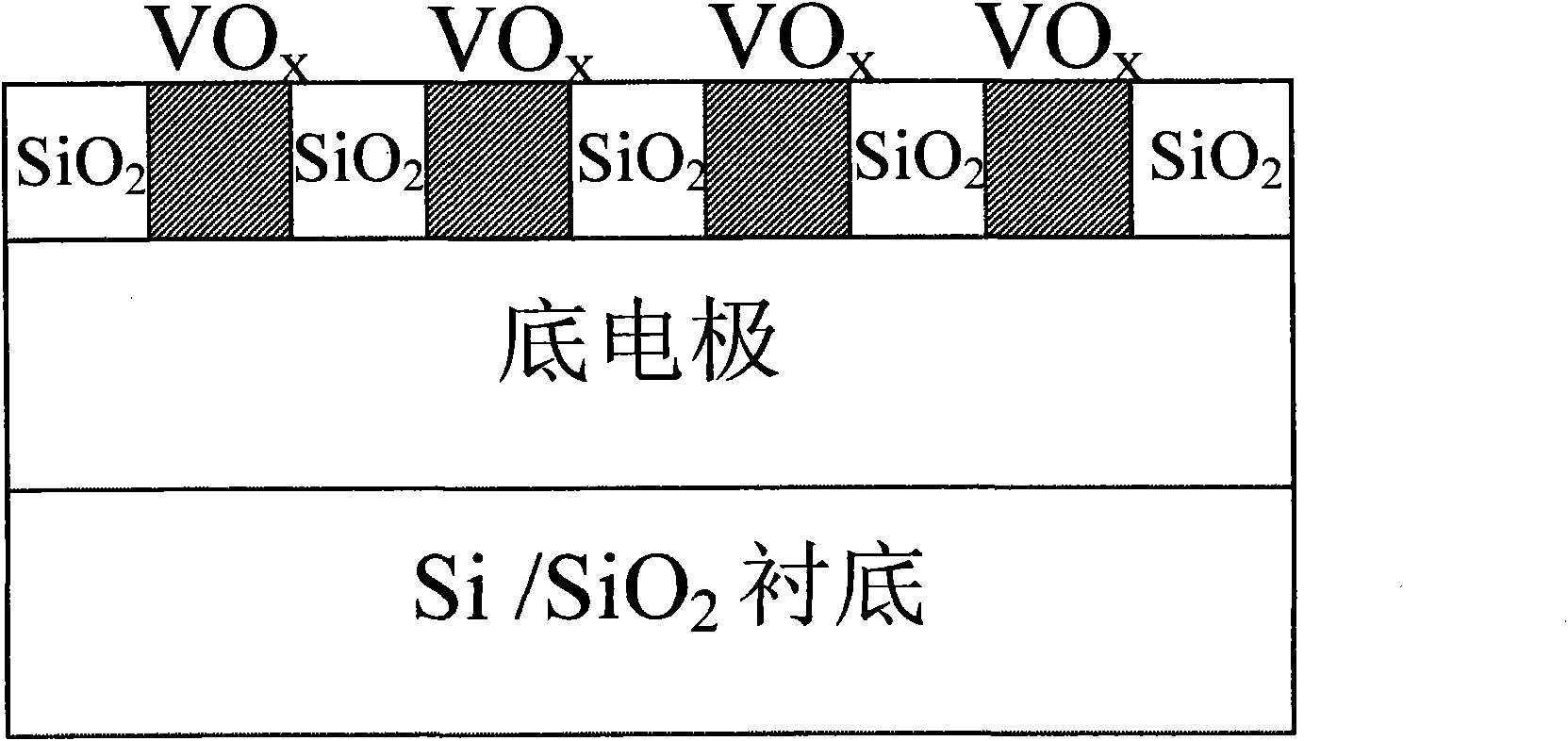

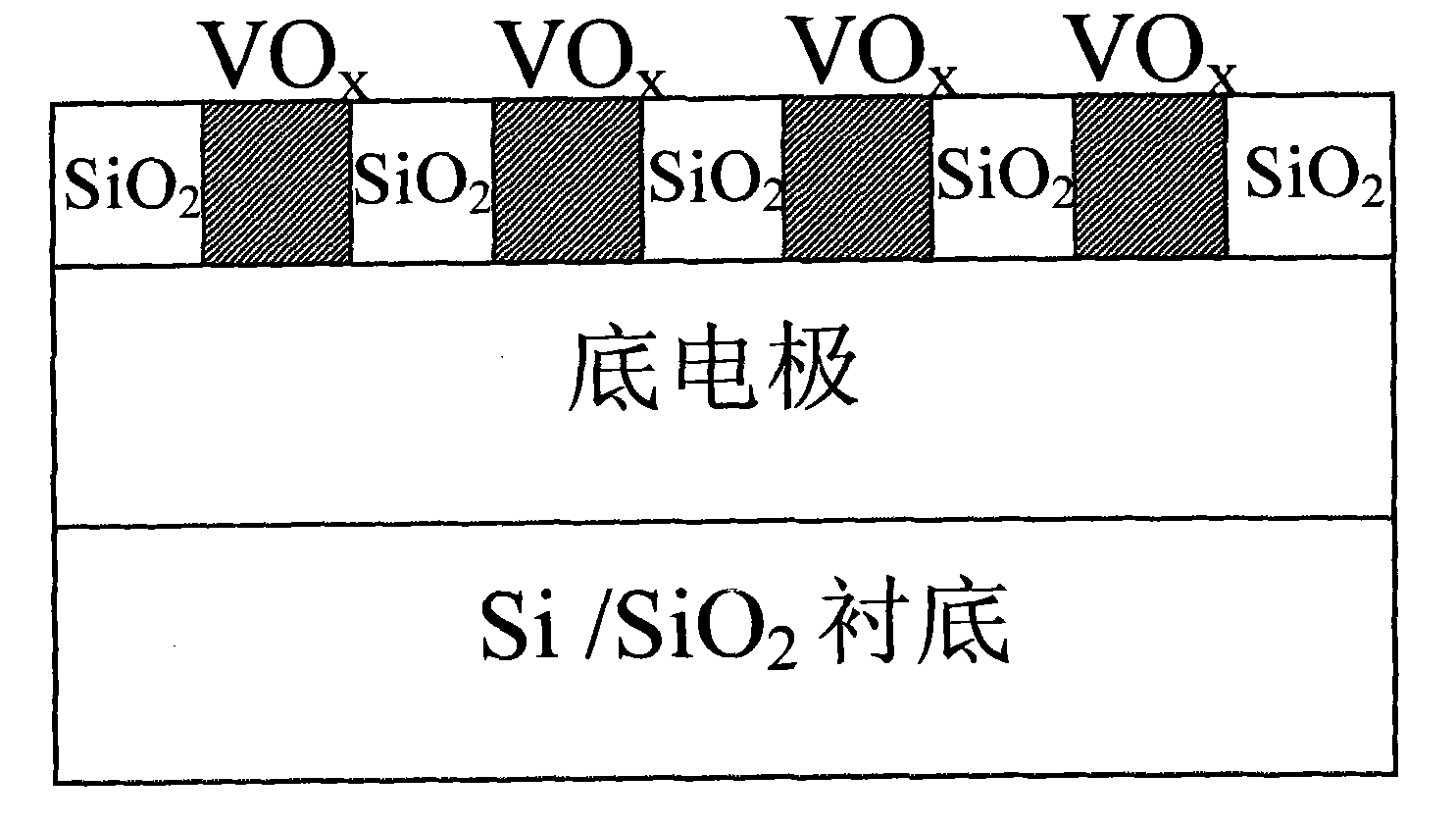

Nano polishing solution for chemically mechanical polishing of vanadium oxide and application thereof

ActiveCN102127372AEasy to corrodeEasy to polluteBiocideOther chemical processesOrganic basePolyethylene glycol

The invention relates to nano polishing solution for chemically mechanical polishing of vanadium oxide, which consists of a nano-abrasive, a pH regulator, a surfactant, a defoaming agent, a bactericide, a cleaning aid and a solvent, wherein the nano-abrasive is zirconium oxide, titanium oxide, plutonium oxide or silica; the pH regulator comprises inorganic base of KOH and organic base of tetramethylammonium, tetraethyl ammonium hydroxide or hydroxy amine; the surfactant is silicane polyethylene glycol ether, polyethylene glycol ether or 2-(2-dodecyloxyethoxy)ethanol; the defoaming agent is poly(dimethylsilane); the bactericide is isomerous thiazolidinone; the cleaning aid is isopropanol; and the solvent is deionized water. The invention has the advantages that: the polishing rate is stably controllable, the damage is low, the cleaning is simple, equipment is not corroded, the environment is not polluted, and the storage time is long; and a vanadium oxide film material is subjected to the chemically mechanical polishing by the nano polishing solution for preparing a resistive random access memory, and the method is simple and practicable, and is completely compatible with an integrated circuit process.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Process for prapring vanadium oxide film

InactiveCN1392286AAvoid damageImprove compactnessVacuum evaporation coatingSputtering coatingArgon atmosphereOxygen

The preparation process of vanadium oxide film includes: cleaning substrate surface; sputtering vanadium film to the substrate in vacuum chamber after the substrate and the target being cleaned with parallel particle beam and focused particle beam; oxidizing the vanadium film in an annealing furnace heated in argon atmosphere and filled with oxygen to prepare vanadium oxide film; annealing the vanadium oxide film in pure argon atmosphere; and cooling in argon environment to room temperature. The said process results in compact film with high adhesion to the substrate, no need of strict control in reaction gas flow rate, high repeatability and capacity of preparing vanadium oxide film with different chemical composition for different requirement.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of thermosensitive-film infrared detector

ActiveCN102315329APrevent valence changesChange heatFinal product manufactureSemiconductor devicesHeat sensitiveOptoelectronics

The invention relates to a preparation method of a thermosensitive-film infrared detector. The method comprises the following steps: depositing successively a sacrificial layer, a thermal-sensitive layer and a protective layer on a readout circuit of an infrared detector, wherein a material of the thermal-sensitive layer is vanadium oxide and the material of the protective layer is silicon nitride; simultaneously, imaging the protective layer and the thermal-sensitive layer; depositing a dielectric layer; etching a via and a contact, wherein the via etching ends at an electrode of the readoutcircuit and the contact etching ends at the thermal-sensitive layer surface; depositing a metal electrode layer and imaging the metal electrode layer; carrying out structure release of the sacrificial layer. In the method of the invention, the silicon nitride layer or SiO2 is added to be used as a protective layer of a vanadium oxide thermal-sensitive layer so that the vanadium oxide film, which is the thermal-sensitive layer, can be prevented from generating changes of a thermal property and an electrical property and influence on the detector performance can be reduced. Simultaneously, by using a high selection ratio of the silicon nitride etching to the vanadium oxide etching, the contact and the via can be used to complete the imaging of hole graphics through one lithographic plate.

Owner:YANTAI RAYTRON TECH

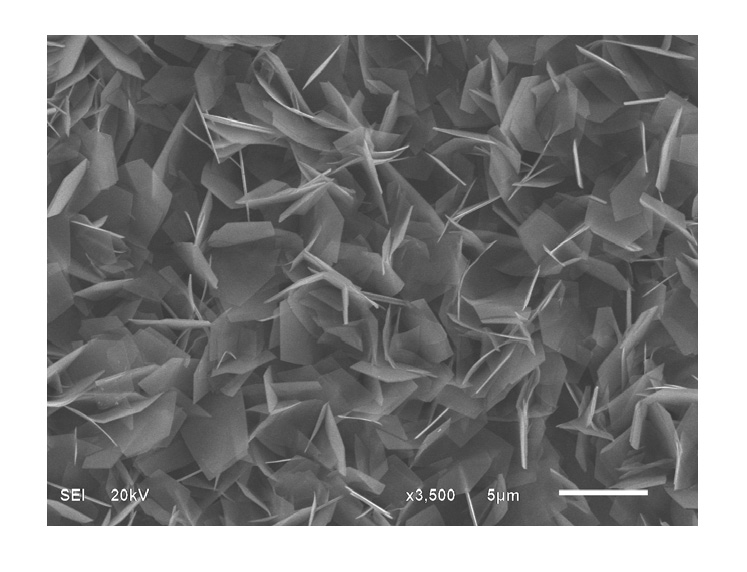

Vanadium dioxide thin film and preparation method thereof

InactiveCN102383114AImprove bindingHigh crystallinityLiquid/solution decomposition chemical coatingVanadium dioxideSputtering

The invention relates to a vanadium dioxide thin film and a preparation method thereof. The method comprises the following steps of: preparing a quadrivalent vanadium precursor growth solution; directly soaking a cleaned substrate in the growth solution and transferring into a high-pressure reaction kettle; performing hydrothermal reaction at the temperature of 150-250 DEG C for 0.5-96 hours; and preparing the vanadium dioxide thin film with flaky VO2 accumulation through induction effect of the substrate. The vanadium dioxide thin film prepared by the invention has a specific microcosmic shape (for example, flaky or rod-like VO2 accumulation), and is a thin film with a certain nanostructure, which cannot be realized by using the conventional thin film preparation process (for example, sol-gel, sputtering and the like); in addition, the nanostructure of the thin film has a certain difference from the microcosmic shape of the directly synthesized powder. The hydrothermally grown VO2 thin film has better crystallinity without being annealed.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

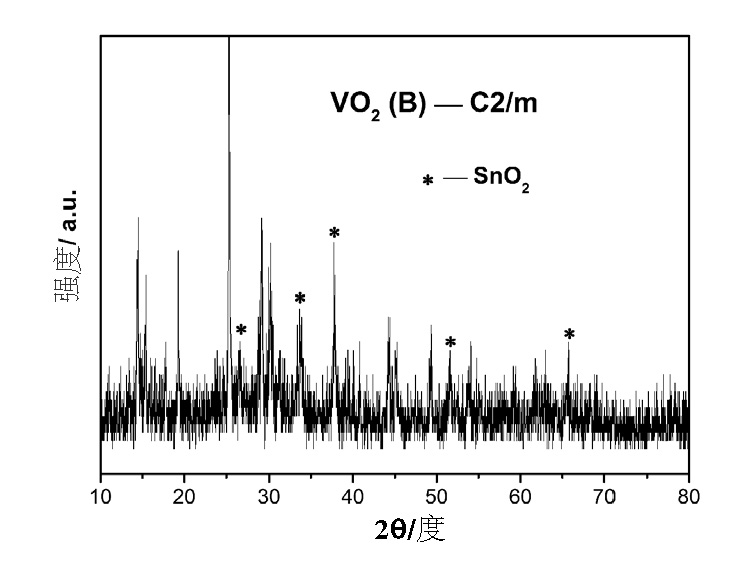

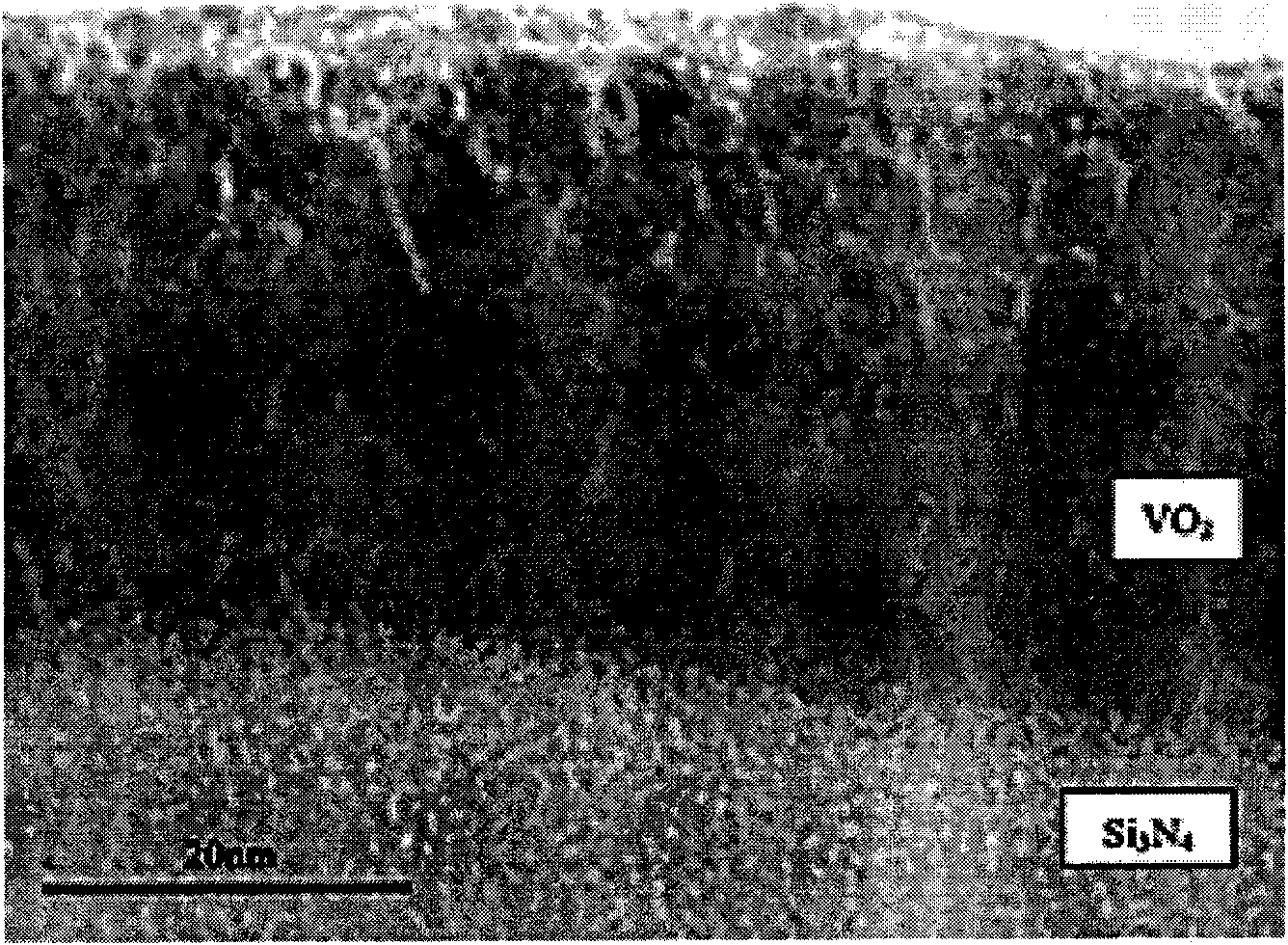

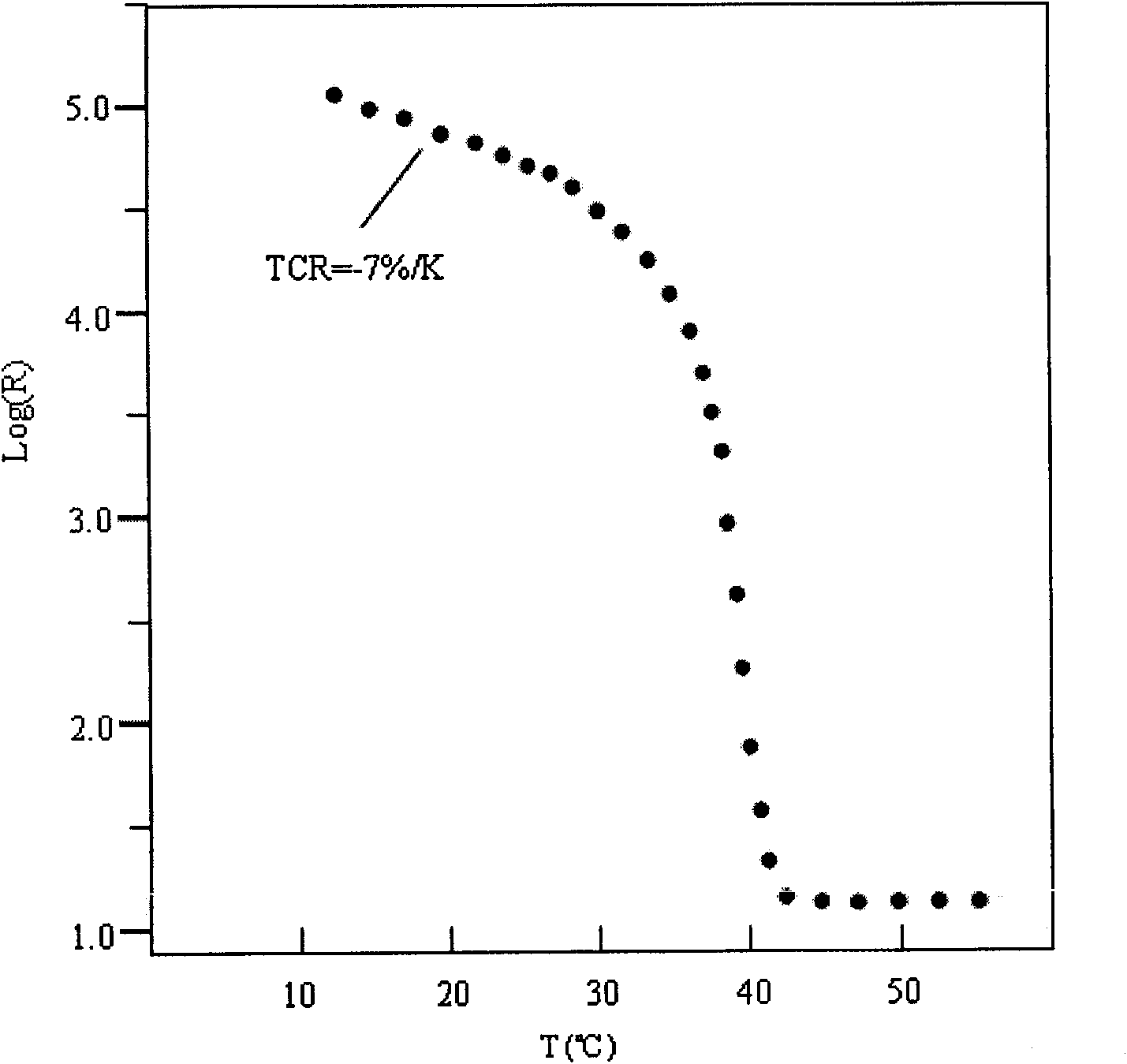

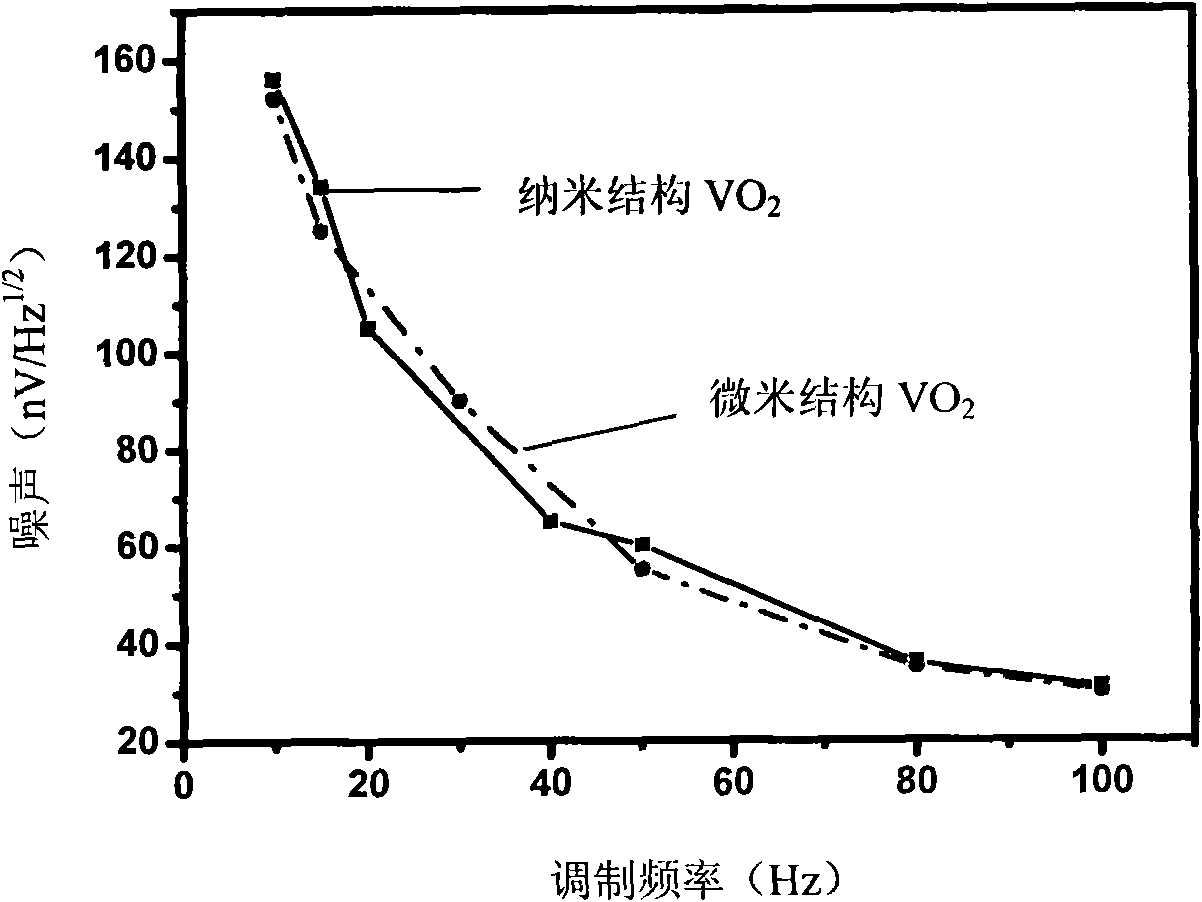

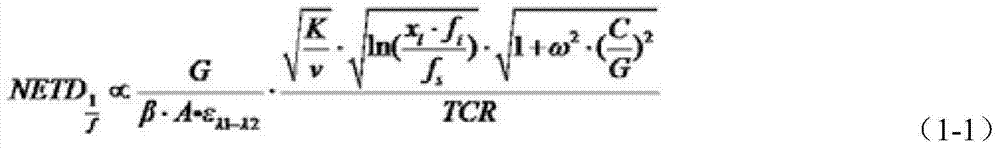

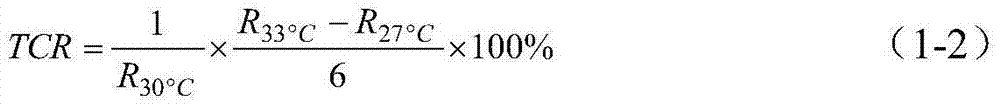

Method for preparing vanadium dioxide thin film with high temperature coefficient of resistance

InactiveCN101626047AImprove bindingWill not cause failureFinal product manufactureVacuum evaporation coatingVanadium dioxideFree cooling

The invention discloses a method for preparing a vanadium dioxide thin film with high temperature coefficient of resistance, which can be used for uncooled infrared detection. The method comprises the following steps: on a silicon substrate on which Si3N4 thin film or SiO2 thin film is deposited, a vanadium oxide thin film which is 50-200nm thick is deposited by using a reactive ion bean sputtering method; after the thin film is naturally cooled, sample wafers are taken out, and annealing is then performed. The thin film prepared using the method of the invention has a nanometer structure with 5-20nm of average crystalline grain, and has appropriate square resistance with temperature coefficient of resistance (TCR) from -5% / K to -7% / K in semiconductor region; in addition the prepared thin film has as equivalent noise level as the common nanometer structure vanadium dioxide. Therefore, the vanadium dioxide thin film is quite a potential uncooled infrared detection material.

Owner:HUAZHONG UNIV OF SCI & TECH

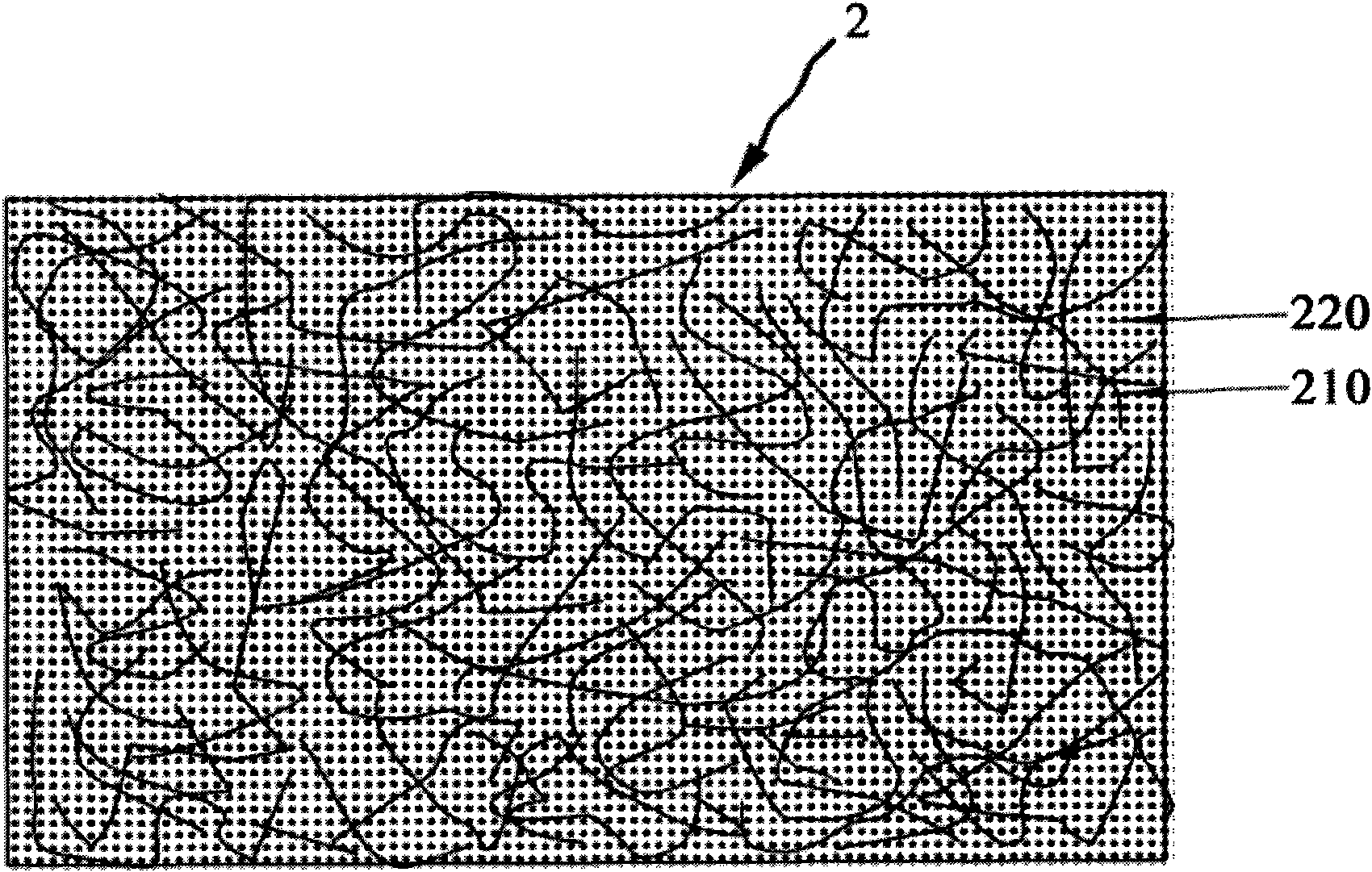

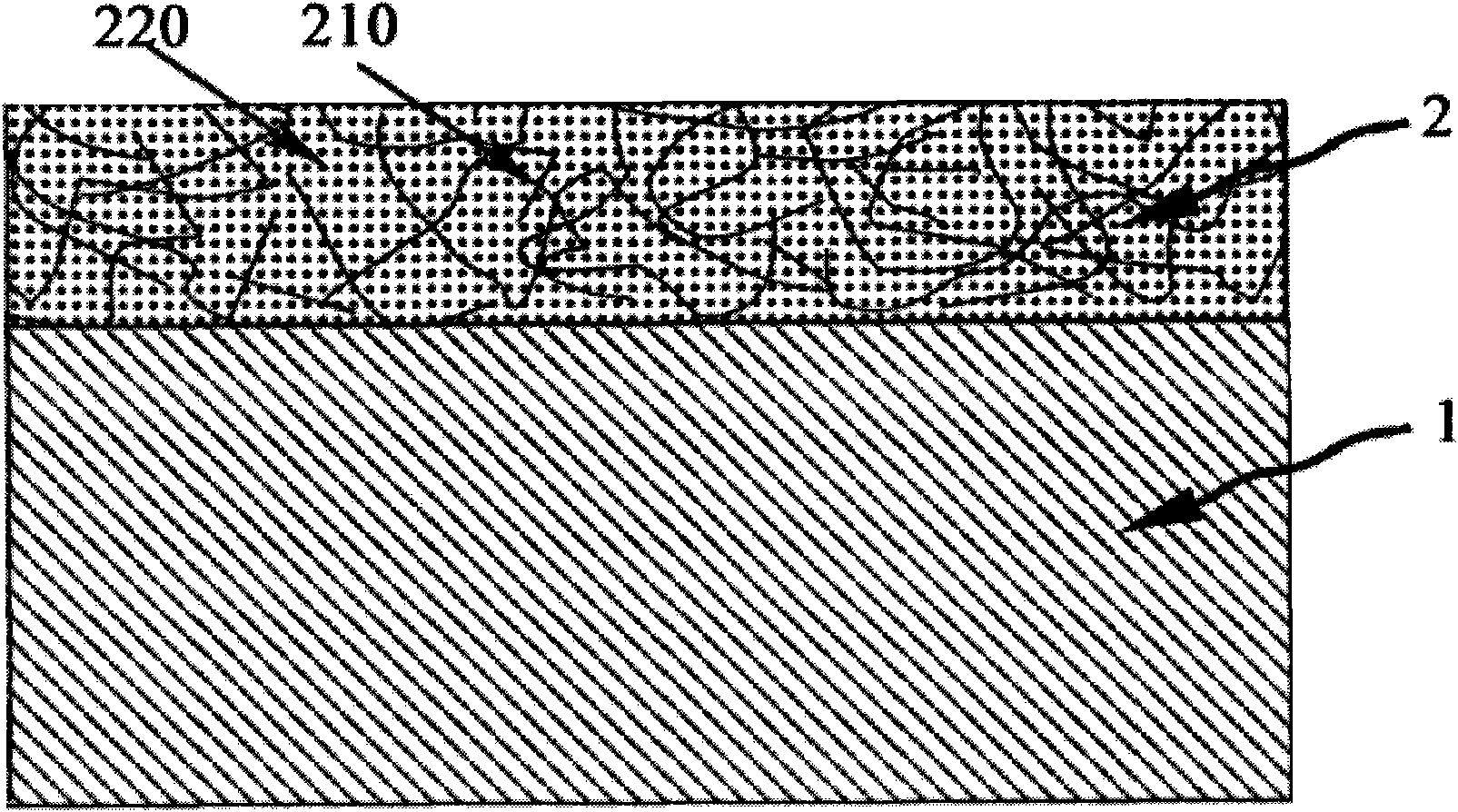

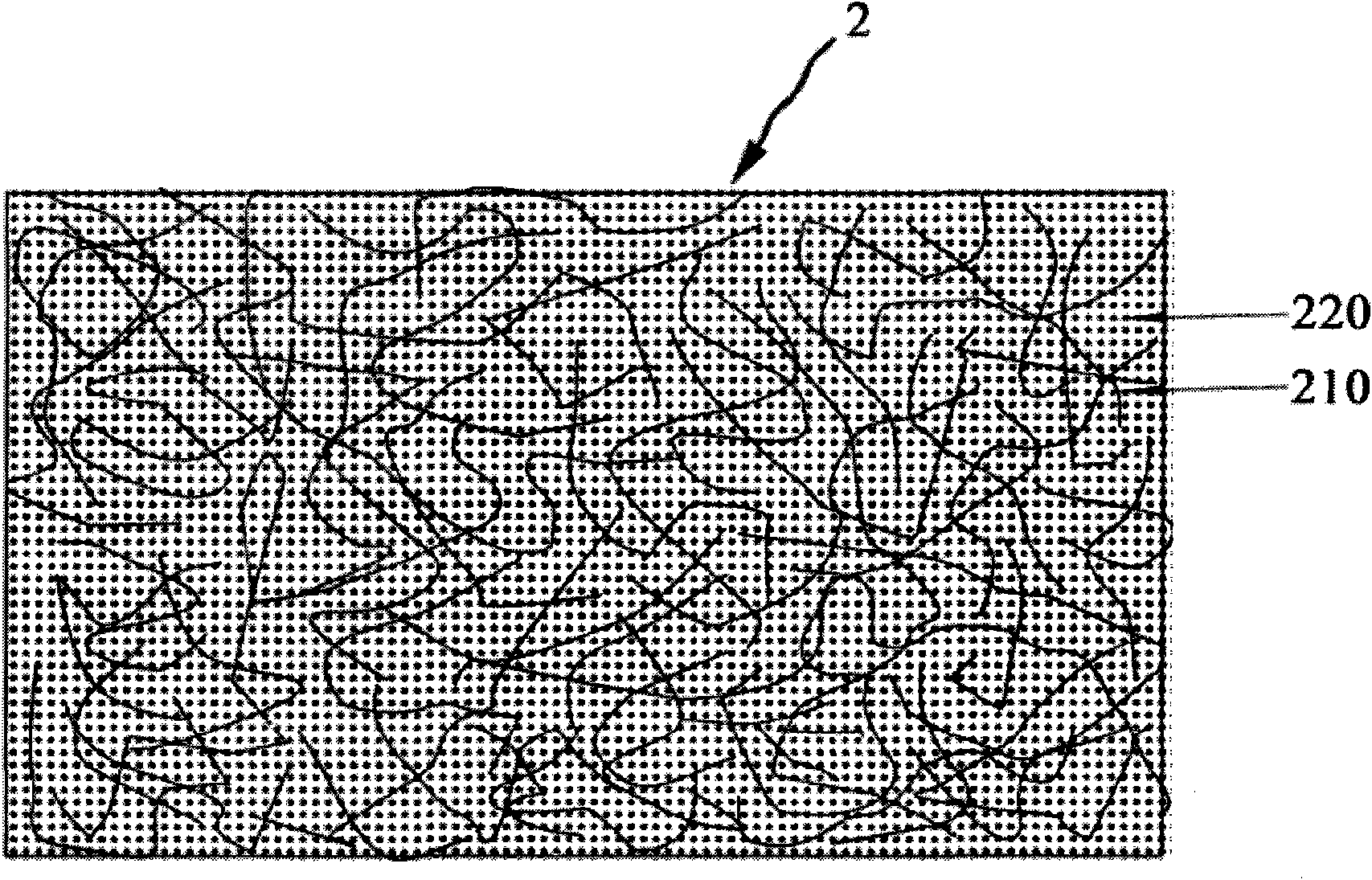

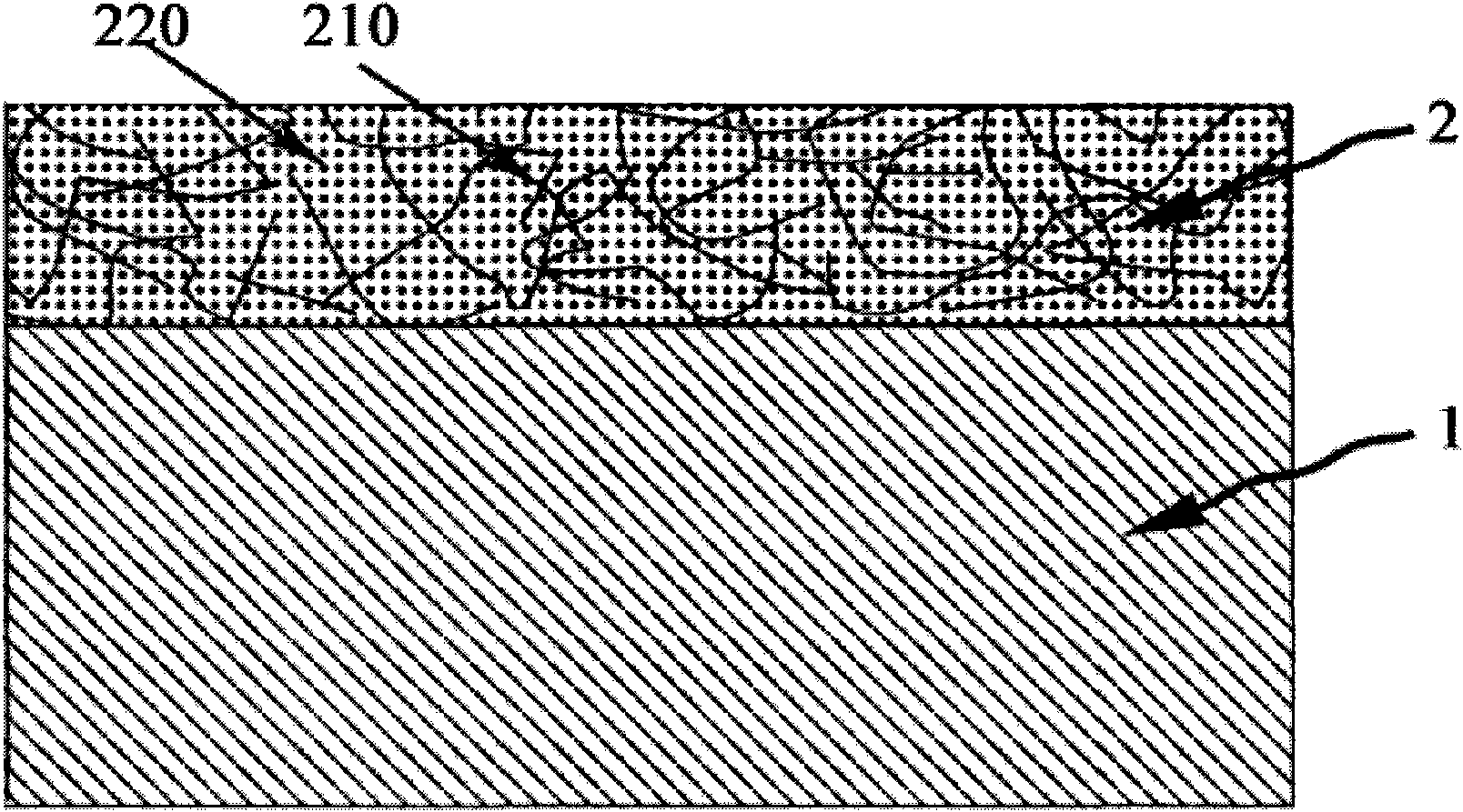

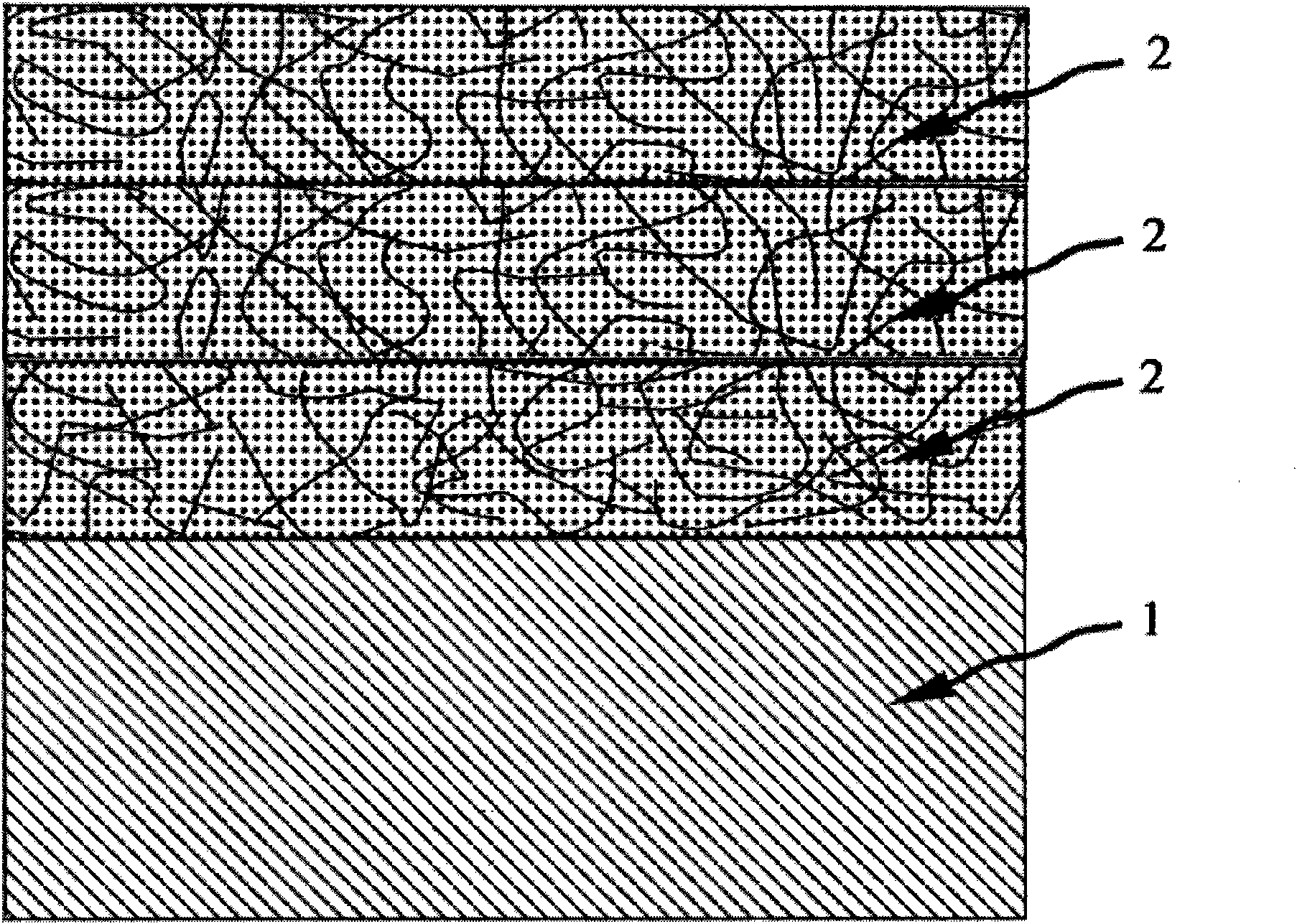

Vanadium oxide thin film for micro-metering bolometer and manufacturing method thereof

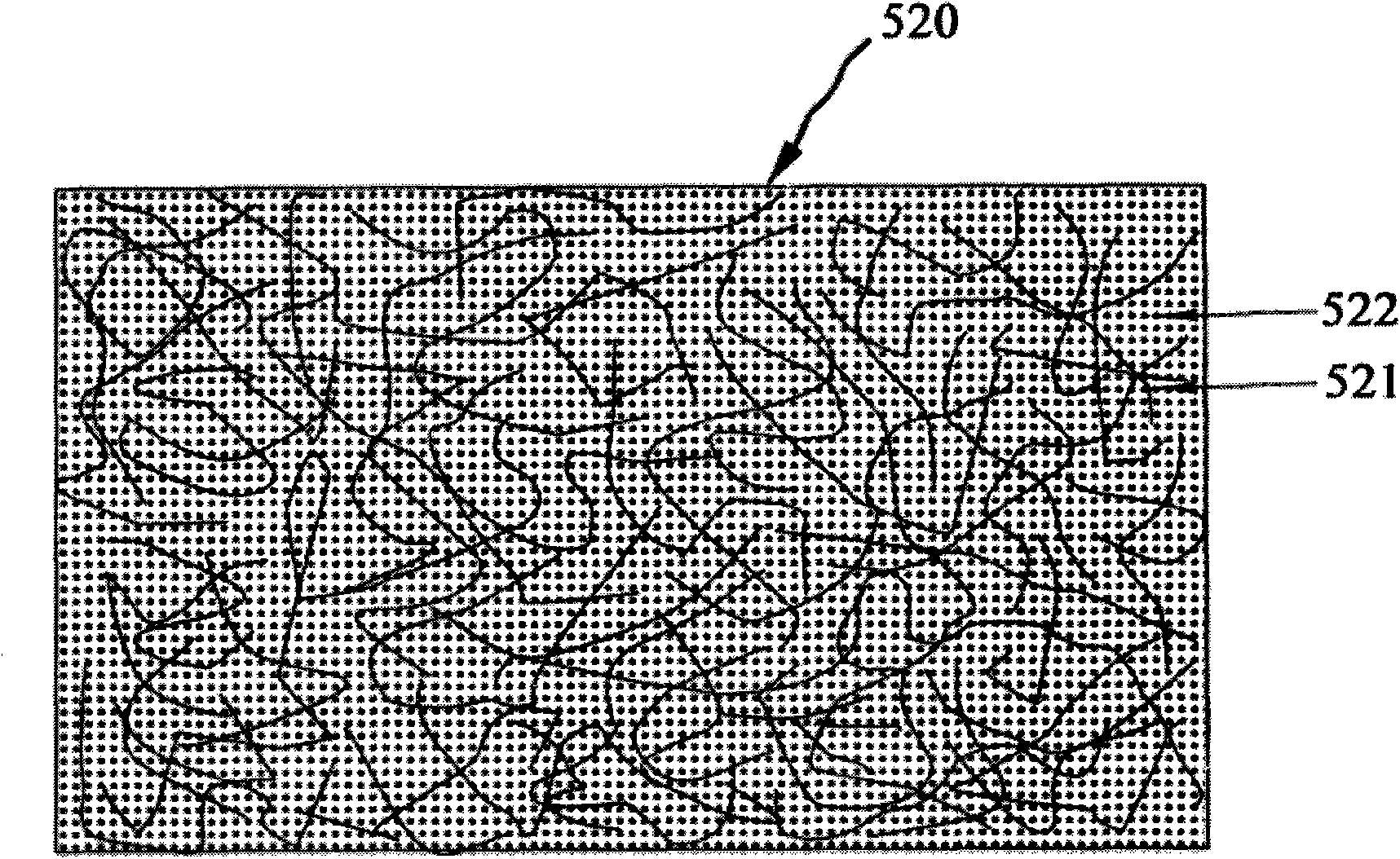

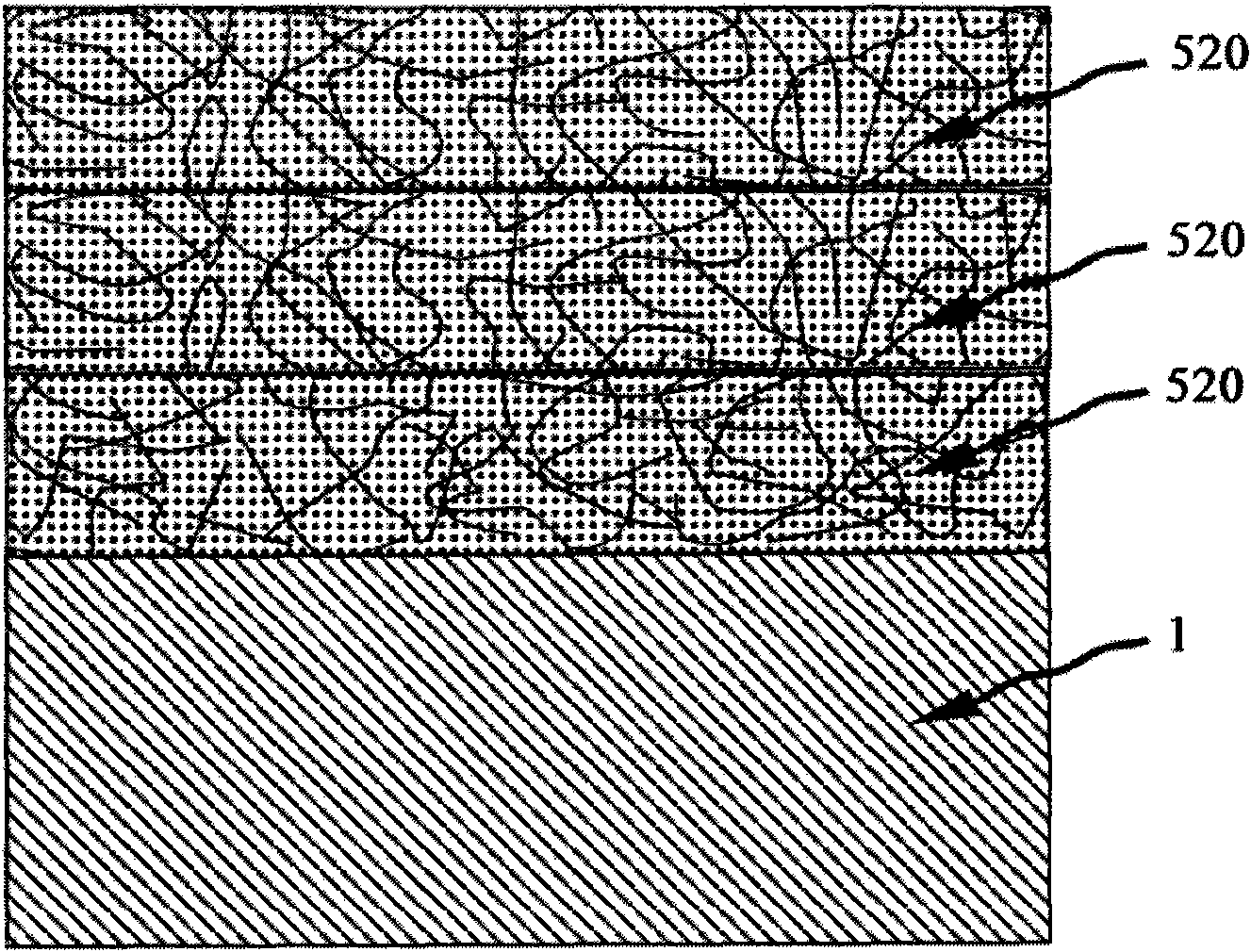

InactiveCN101886261AMeet special needsImprove performanceMetallic material coating processesPyrometry using electric radation detectorsComposite filmOrganic solvent

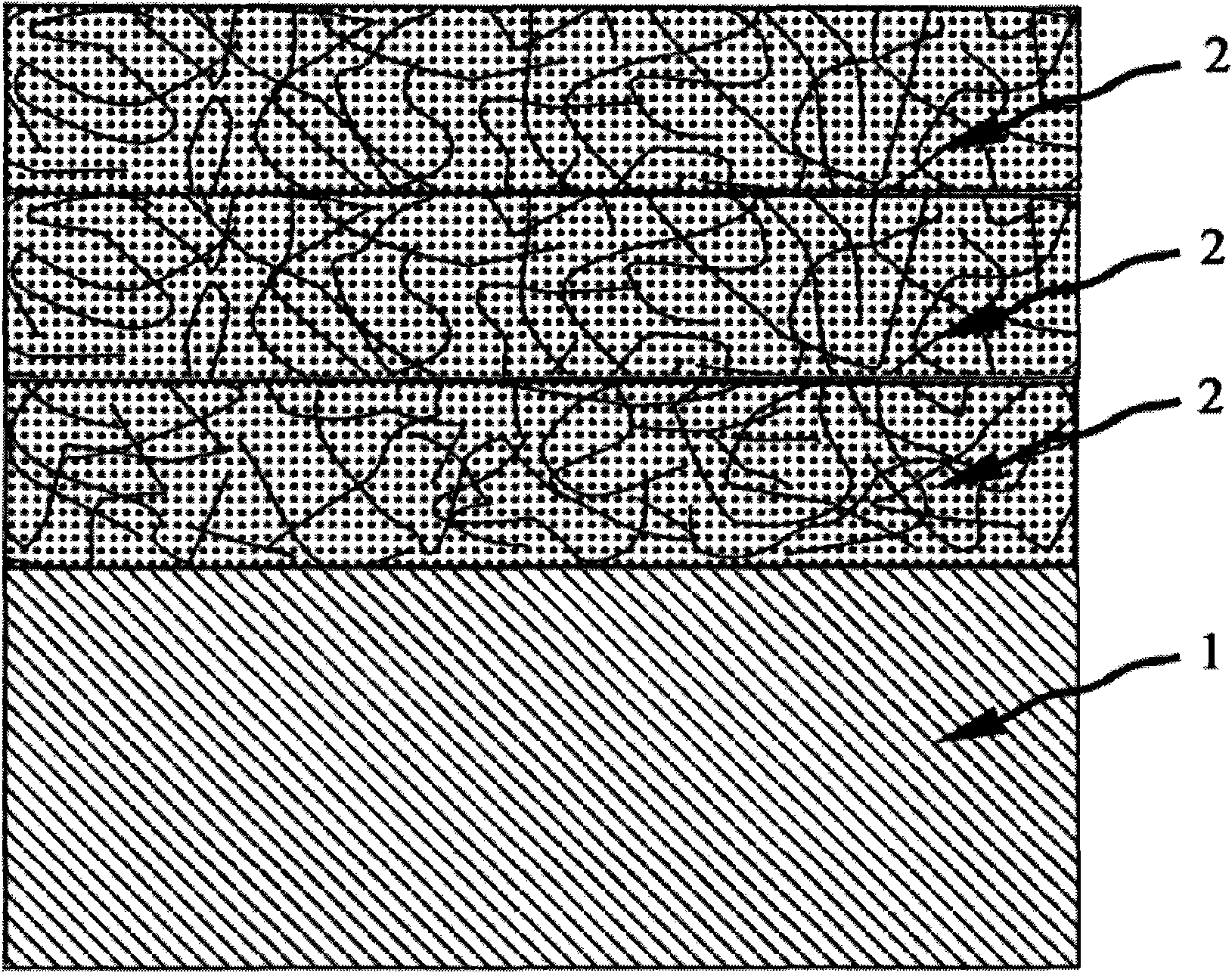

The invention discloses a vanadium oxide thin film for a micro-metering bolometer and a preparation method thereof. The preparation method comprises the following steps of: (1) cleaning a substrate, and then blow-drying the substrate for later use; (2) putting a prepared original or functionalized carbon nanotube into a beaker to mix with an organic solvent, performing ultrasonic dispersion, and then transferring dispersion liquid to the surface of the cleaned substrate to volatilize the solvent and form crisscross and interconnected carbon nanotube films; (3) putting the substrate diffused with the carbon nanotube films and obtained in the step (2) in to a vacuumized reactor, growing a layer of vanadium oxide film by using the reactor, and performing annealing to form a vanadium oxide-carbon nanotube composite film structure, wherein the grown vanadium oxide film is diffused on the surface of the carbon nano-tube and in gaps between tubes; (4) cooling the vanadium oxide-carbon nanotube composite film structure to the room temperature, and taking the vanadium oxide-carbon nanotube composite film structure out of the reactor; and (5) repeating the steps of carbon nanotube diffusion, vanadium oxide sedimentation and annealing in turn as required to form a vanadium oxide-carbon nanotube multi-layer composite film structure.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Preparation method of intelligent temperature control color changing vanadium oxide film

InactiveCN103695874ALower phase transition temperatureHigh chemical activityLiquid/solution decomposition chemical coatingTemperature controlColor changes

The invention relates to a preparation method of an intelligent temperature control color changing vanadium oxide film, which is characterized by comprising the following steps: (1) preparing tungstenic sol; (2) preparing sol comprising vanadium ions; (3) preparing tungsten-doped vanadium oxide sol, i.e. adding the tungstenic sol obtained in the step (1) into the sol comprising vanadium ions, which is obtained in the step (2), so as to obtain the tungsten-doped vanadium oxide sol; and (4) preparing a tungsten-doped vanadium oxide film, i.e. plating the tungsten-doped vanadium oxide sol obtained in the step (3) on the surface of a washed substrate and then carrying out annealing processing in the inert atmosphere or under the vacuum condition so as to obtain the tungsten-doped vanadium oxide film with an intelligent temperature control color changing function. The method disclosed by the invention has low energy consumption, adopts a simple preparation process, has high safety and has wide application prospect in the field of photoelectronic functional materials.

Owner:WUHAN UNIV OF TECH

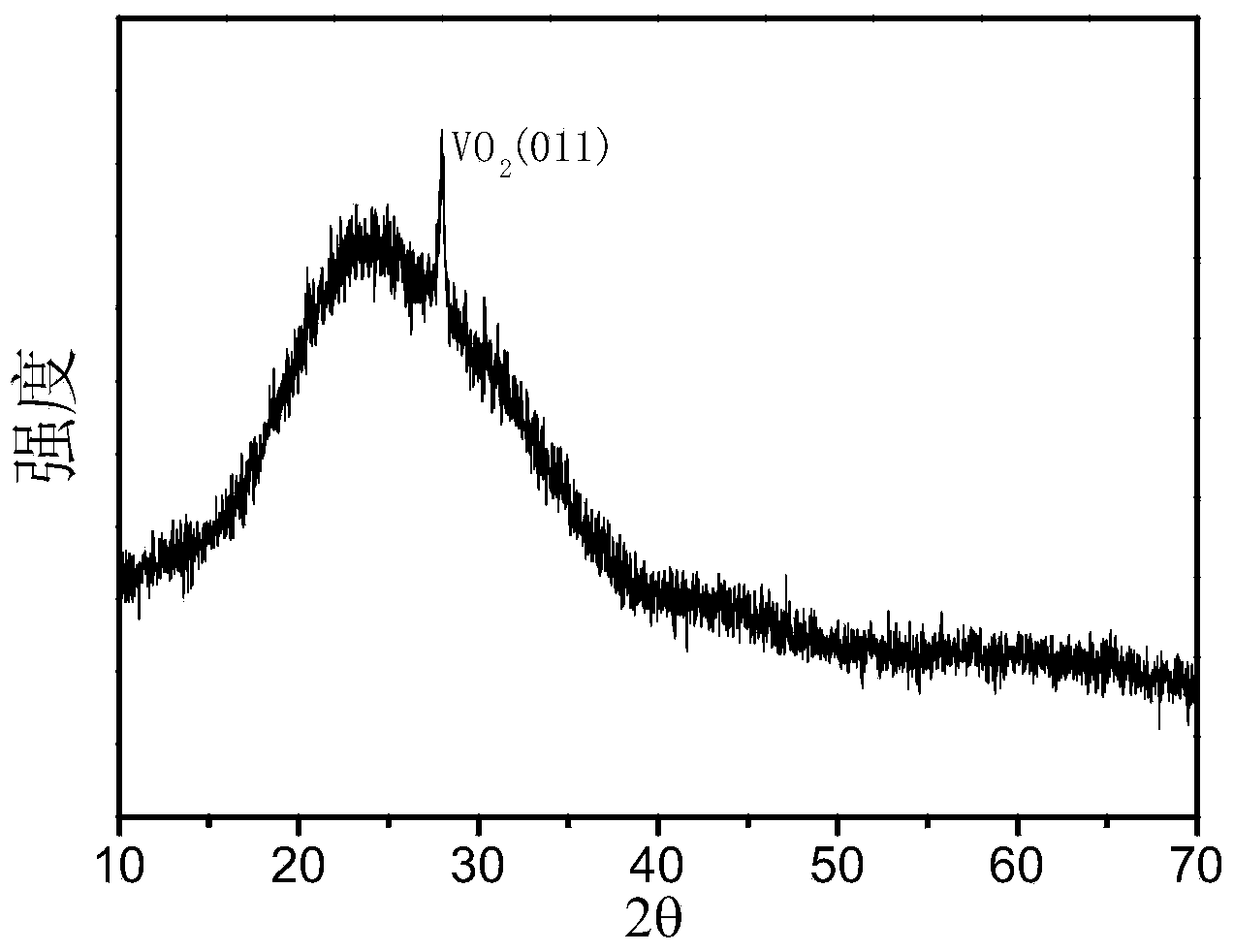

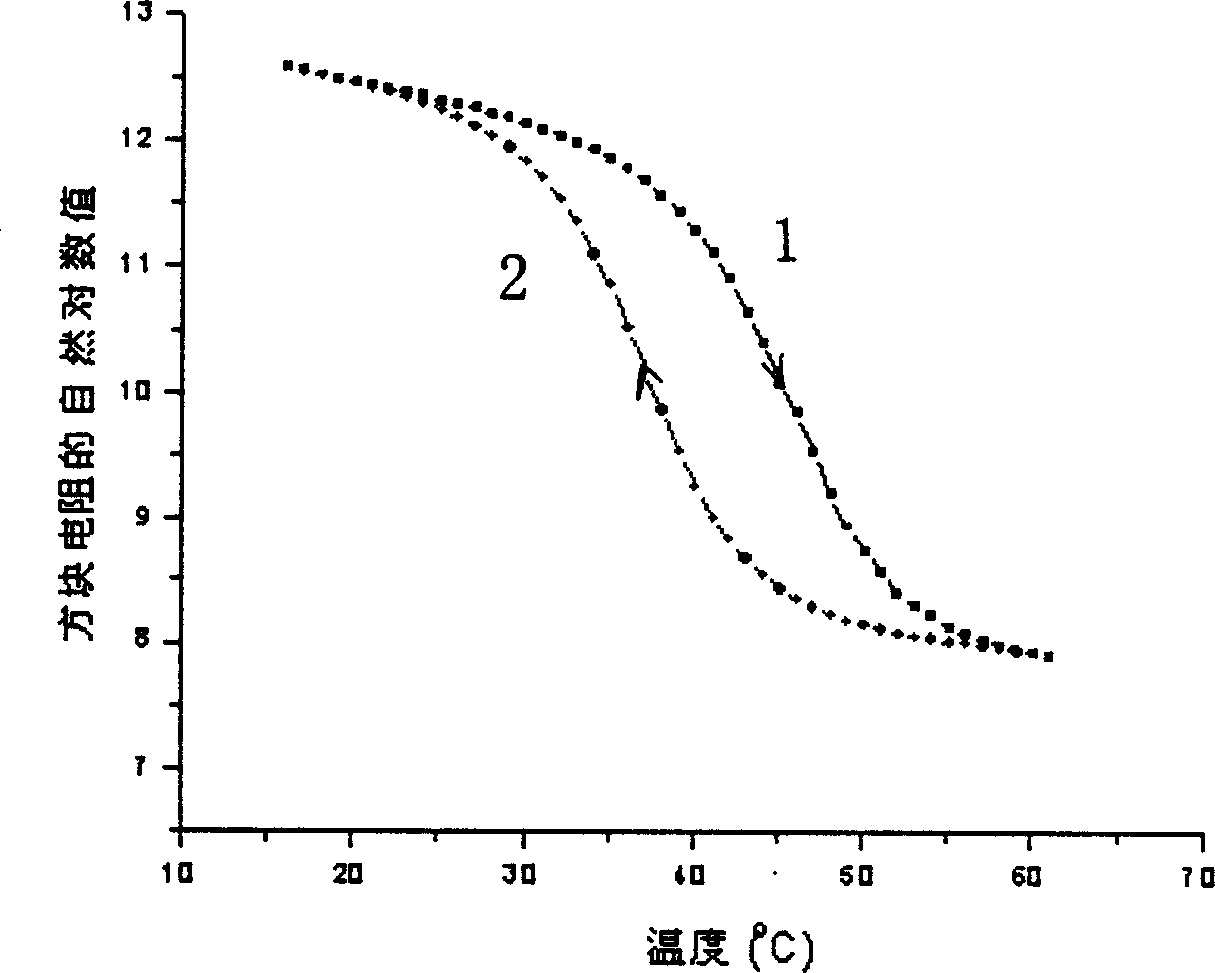

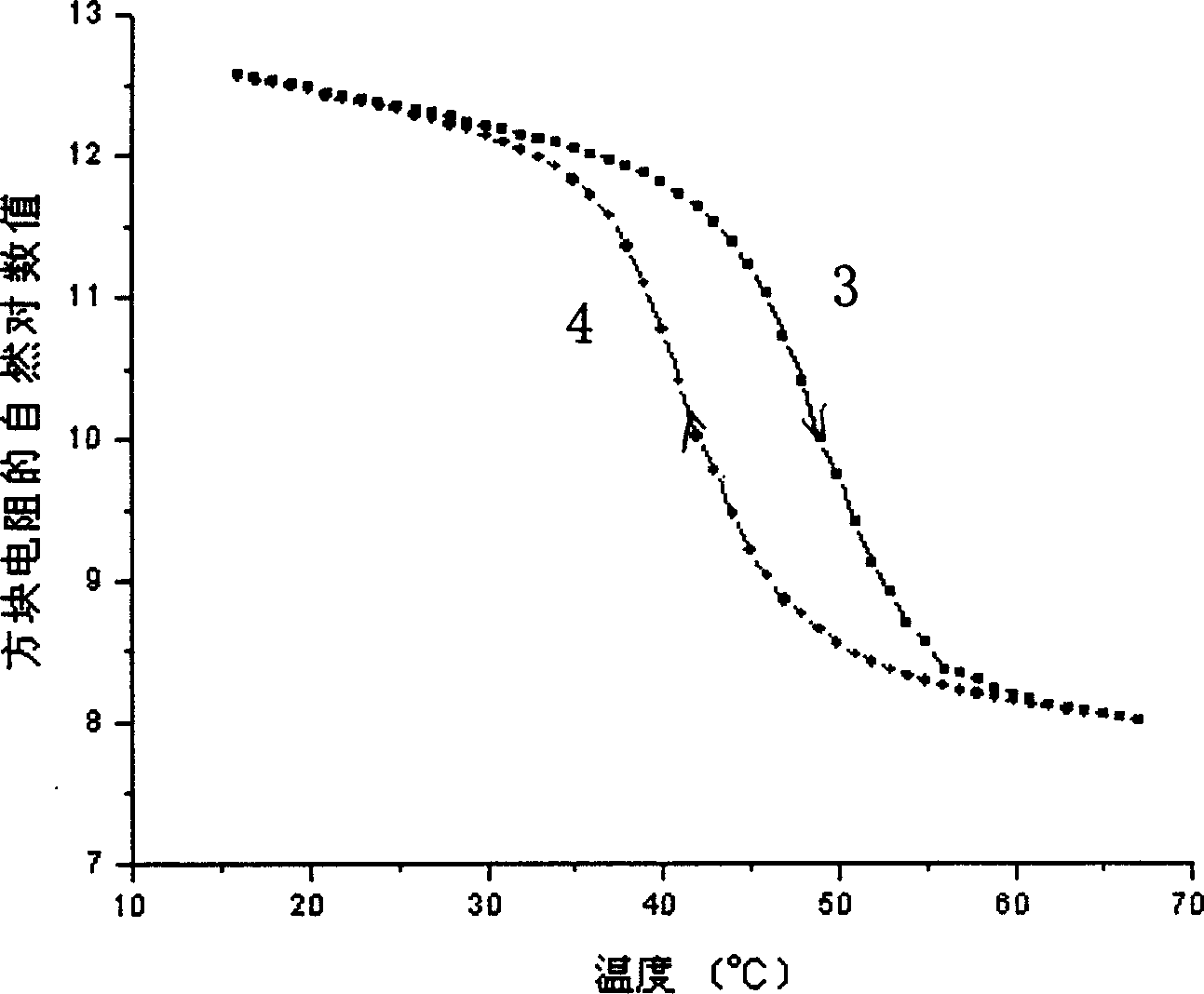

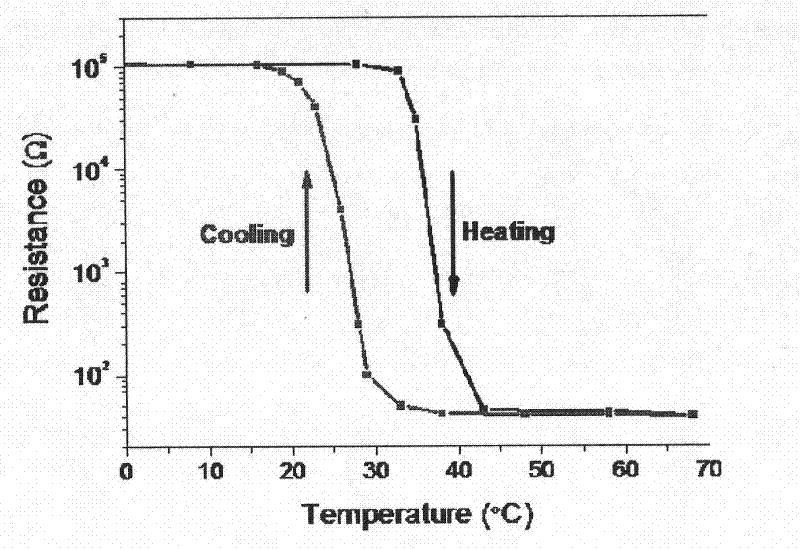

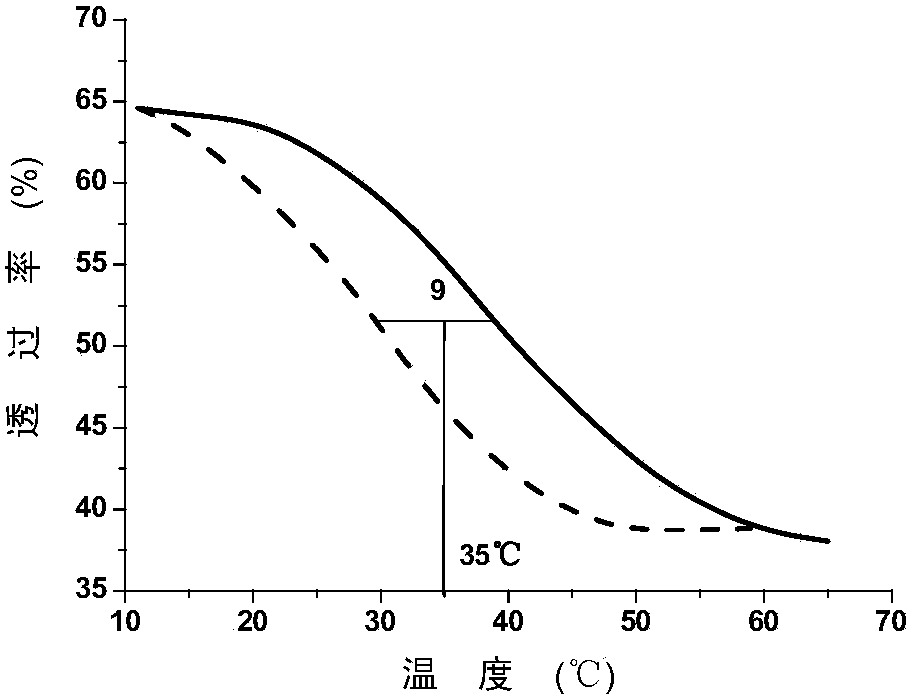

Preparation method of polycrystalline vanadium dioxide film with room temperature resistance temperature coefficient higher than 10%K

ActiveCN1800440APhase transition hysteresis is smallTCR improvementVacuum evaporation coatingSputtering coatingVanadium dioxideFilm material

The invention relates to a functional thin film material preparing technology, which adopts improved ion beam amplify deposited method to make the film and combines the subsequent crystallization and annealing to achieve the impurity element even immersing and the effective place-replacing to vanadium so that the phase starting temperature of the thin film reduces to 12-16 deg. It adjusts the argon / hydrogen ratio film craft and crystallizing heat treatment condition so that when the polycrystalline VO2 thin film transfers to the mental phase from the semiconductor phase, the change of the resistance ratio over 2 magnitude orders.

Owner:溧阳常大技术转移中心有限公司

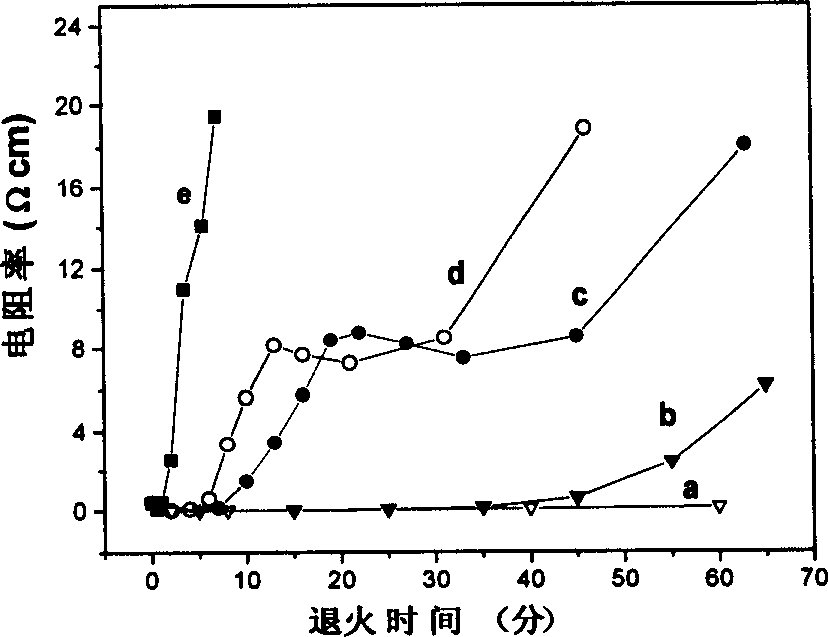

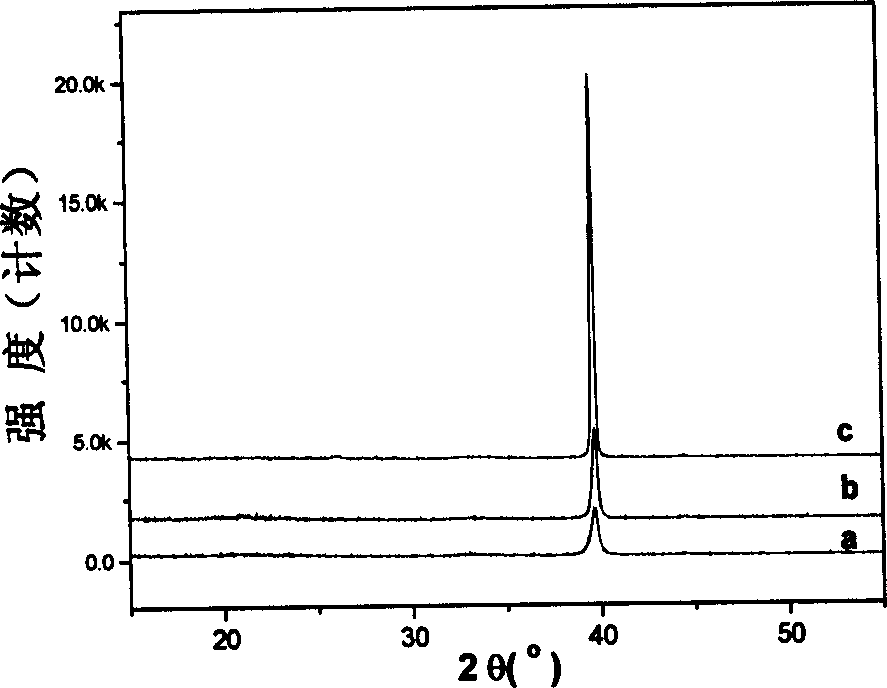

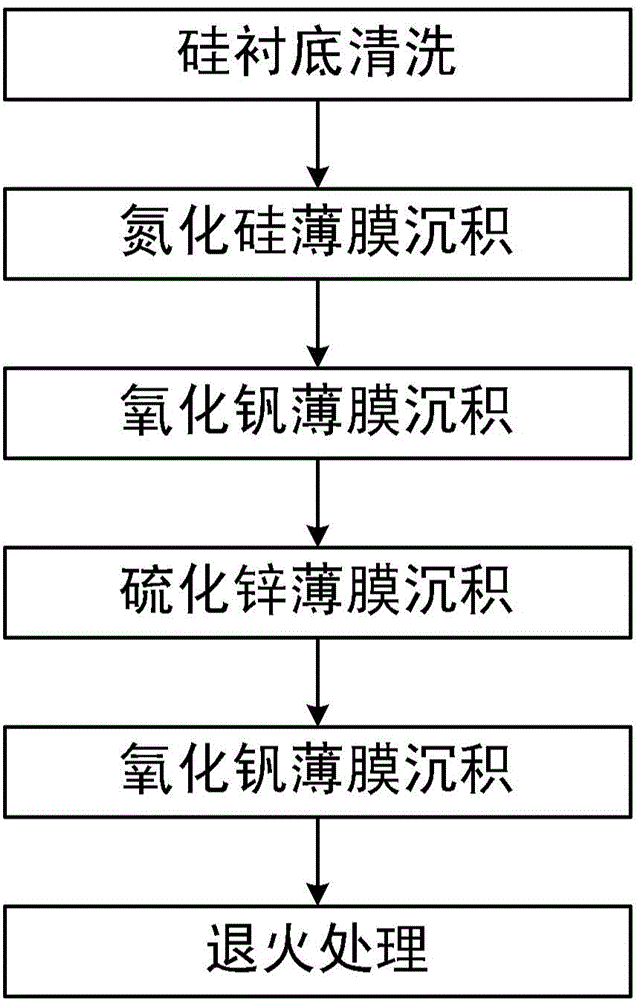

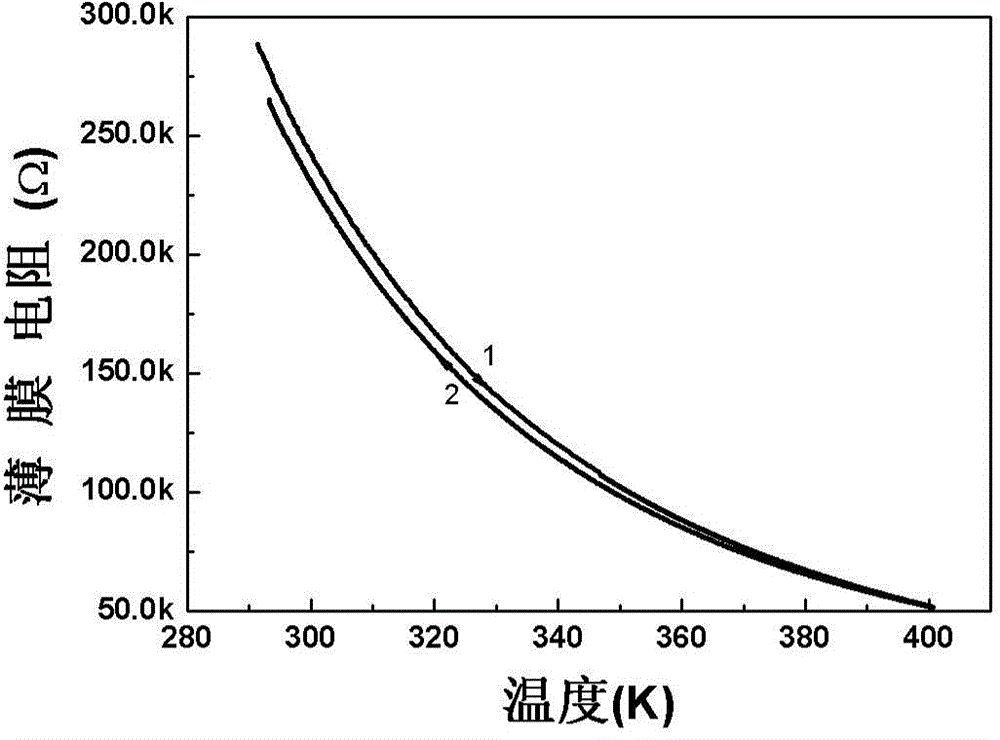

Preparation method of vanadium oxide film with high resistance temperature coefficient

InactiveCN104611670AGuaranteed CompatibilityFulfil requirementsVacuum evaporation coatingSputtering coatingHigh resistanceSputtering

The invention discloses a preparation method of a vanadium oxide film with a high resistance temperature coefficient. The preparation method comprises steps as follows: the surface of a monocrystal silicon substrate is cleaned, and the monocrystal silicon substrate is assembled in a growth chamber of a magnetron sputtering device; a silicon nitride film is sputtered on the surface of the monocrystal silicon substrate; a vanadium oxide film is deposited on the silicon nitride film; a zinc sulfide film is deposited on the vanadium oxide film; a vanadium oxide film is deposited on the zinc sulfide film; a deposited film sample is subjected to annealing treatment. According to the preparation method, high-temperature annealing treatment is not required, compatibility of vanadium oxide film preparation as well as an MEMS (micro-electromechanical systems) process and an integrated circuit technology is guaranteed, a vanadium oxide film material with moderate resistivity can be obtained, and the requirements of a high-performance vanadium oxide based uncooled infrared detector can be met.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Vanadium oxide thermo-sensitive film material with high temperature coefficient of resistance and a preparing method thereof

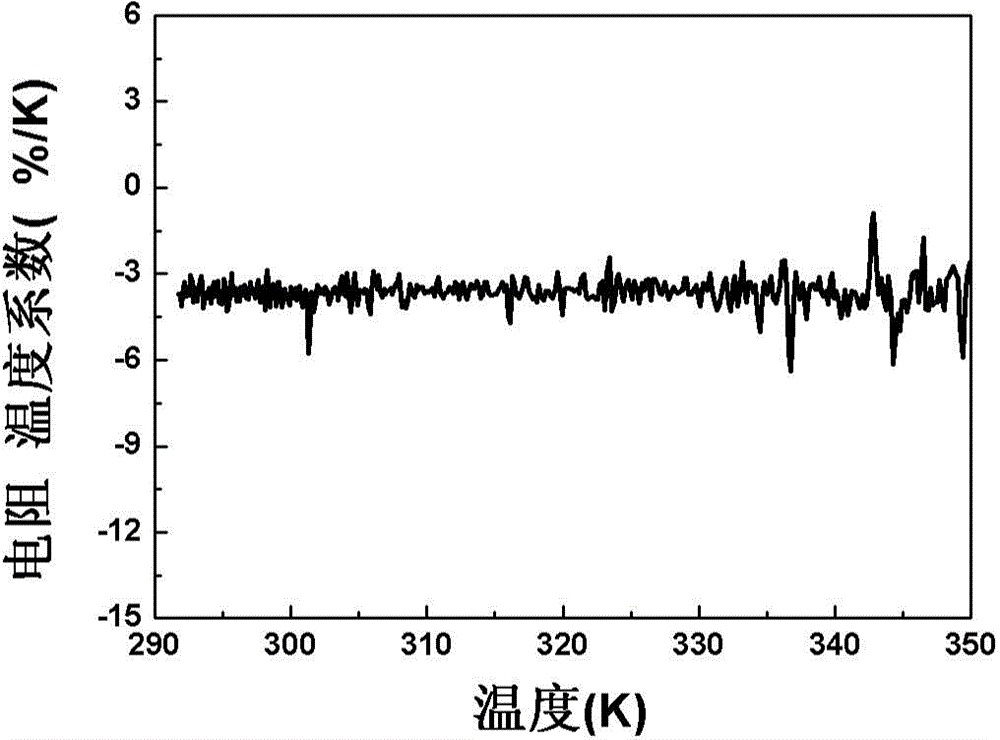

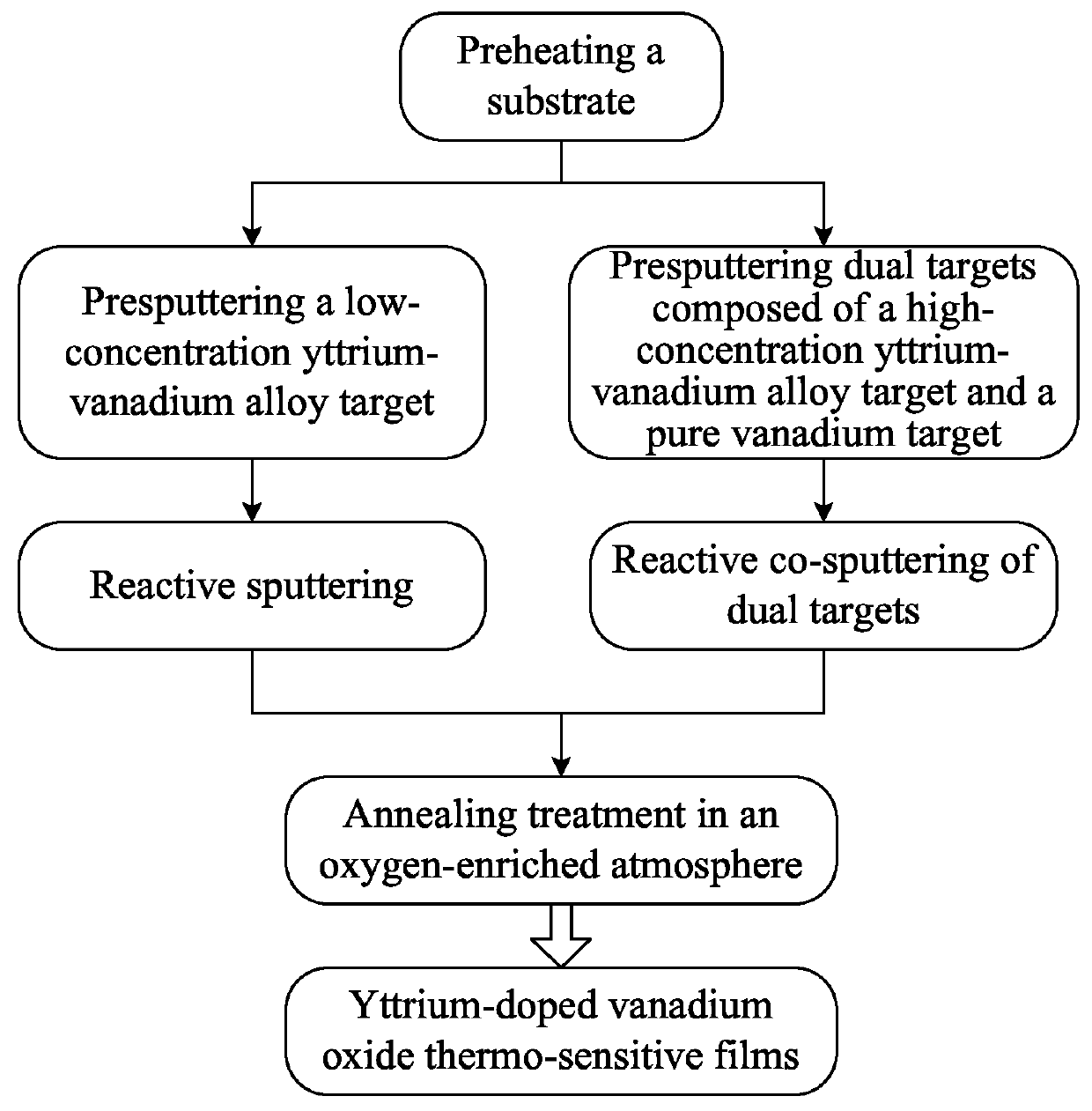

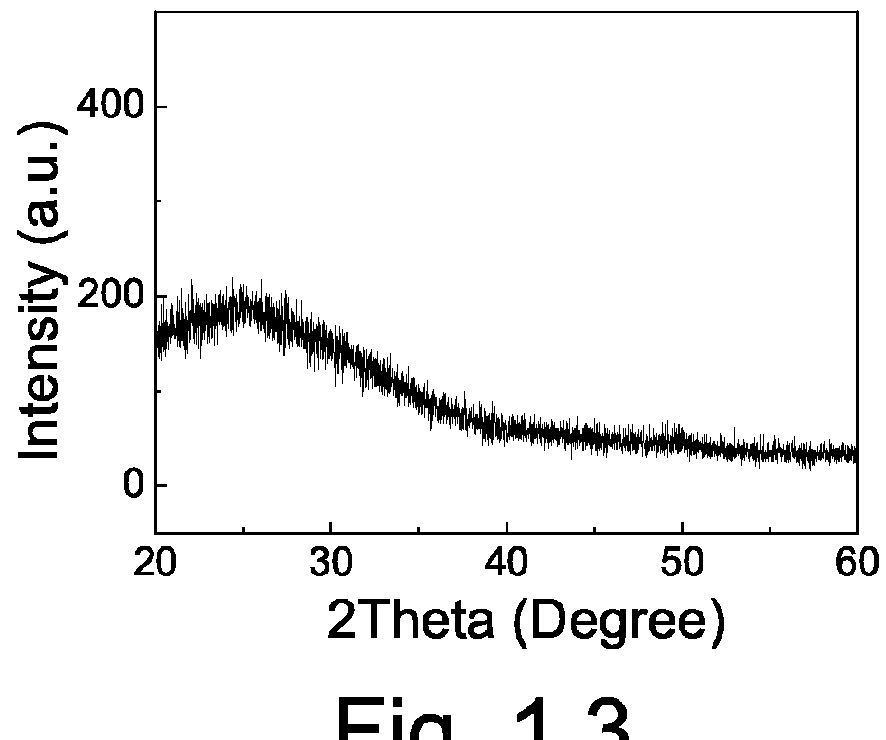

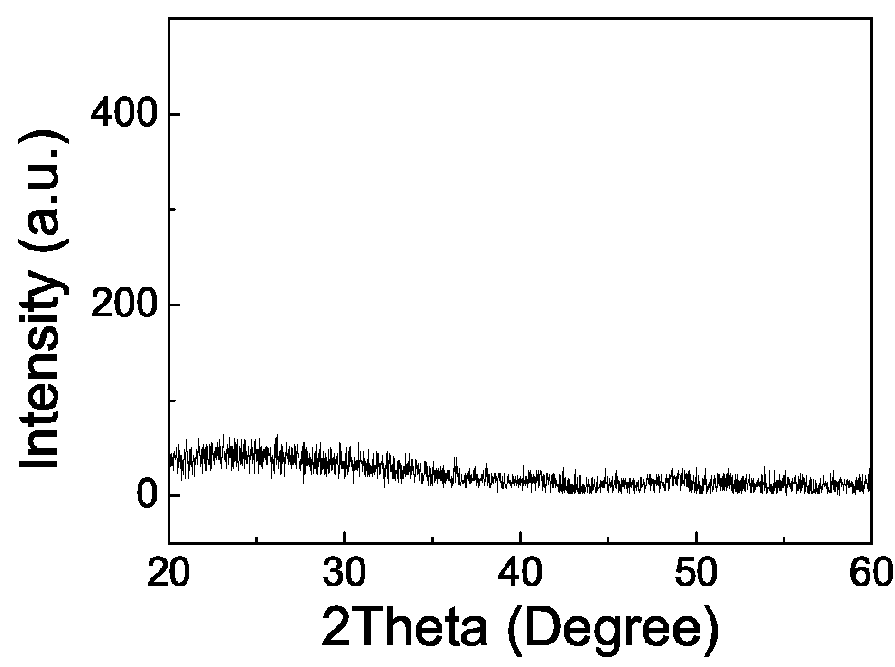

ActiveUS20160032443A1Accurate modificationHigh TCRConductive materialVacuum evaporation coatingHigh concentrationRare-earth element

A vanadium oxide thermo-sensitive film material with a high temperature coefficient of resistance (TCR) contains a rare earth element of Yttrium serving as a dopant in a preparation process. The vanadium oxide thermo-sensitive film material includes a substrate and a yttrium-doped vanadium oxide film layer. The yttrium-doped vanadium oxide film layer includes three elements of vanadium, oxygen and yttrium, wherein the atomic concentration of yttrium is at a range of 1%-8%, the atomic concentration of vanadium is at a range of 20-40% and the residue is oxygen. The method for preparing the vanadium oxide thermo-sensitive film material with high TCR includes a reactive magnetron sputtering method using a low-concentration yttrium-vanadium alloy target as a sputtering source or a reactive magnetron co-sputtering method using dual targets including a high-concentration yttrium-vanadium alloy target and a pure vanadium target as a co-sputtering source.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Phase-change vanadium dioxide thin film and preparation method thereof

InactiveCN104975262ATemperature controlAutomatic temperature adjustmentMaterial nanotechnologyVacuum evaporation coatingVanadium dioxideSputtering

The invention discloses a phase-change vanadium dioxide thin film. The phase-change vanadium dioxide thin film comprises a base layer, wherein a vanadium dioxide nano-thin-film layer is arranged on the base layer; an infrared light-transmittance film layer is arranged on the vanadium dioxide nano-thin-film layer; the vanadium dioxide nano-thin-film layer is a vanadium dioxide thin film layer deposited by virtue of an ion beam reactive sputtering method; the infrared light-transmittance film layer is prepared by virtue of evaporation or sputtering plating of a high-refraction-rate film and a low-refraction-rate film and is prepared by virtue of alternative evaporation of six small layers including TiO2 thin films and SiO2 thin films. The phase-change vanadium dioxide thin film is capable of reflecting infrared light at high temperature and transmitting infrared light at low temperature, so that the purpose of automatically regulating the temperature is achieved; meanwhile, the performance is table.

Owner:周少波

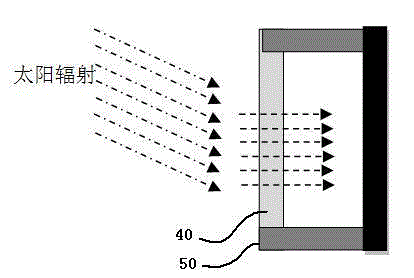

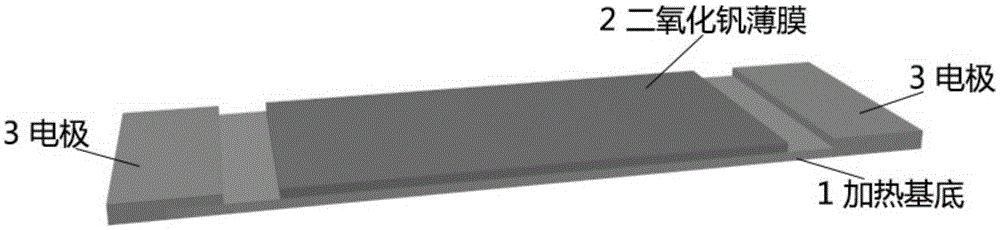

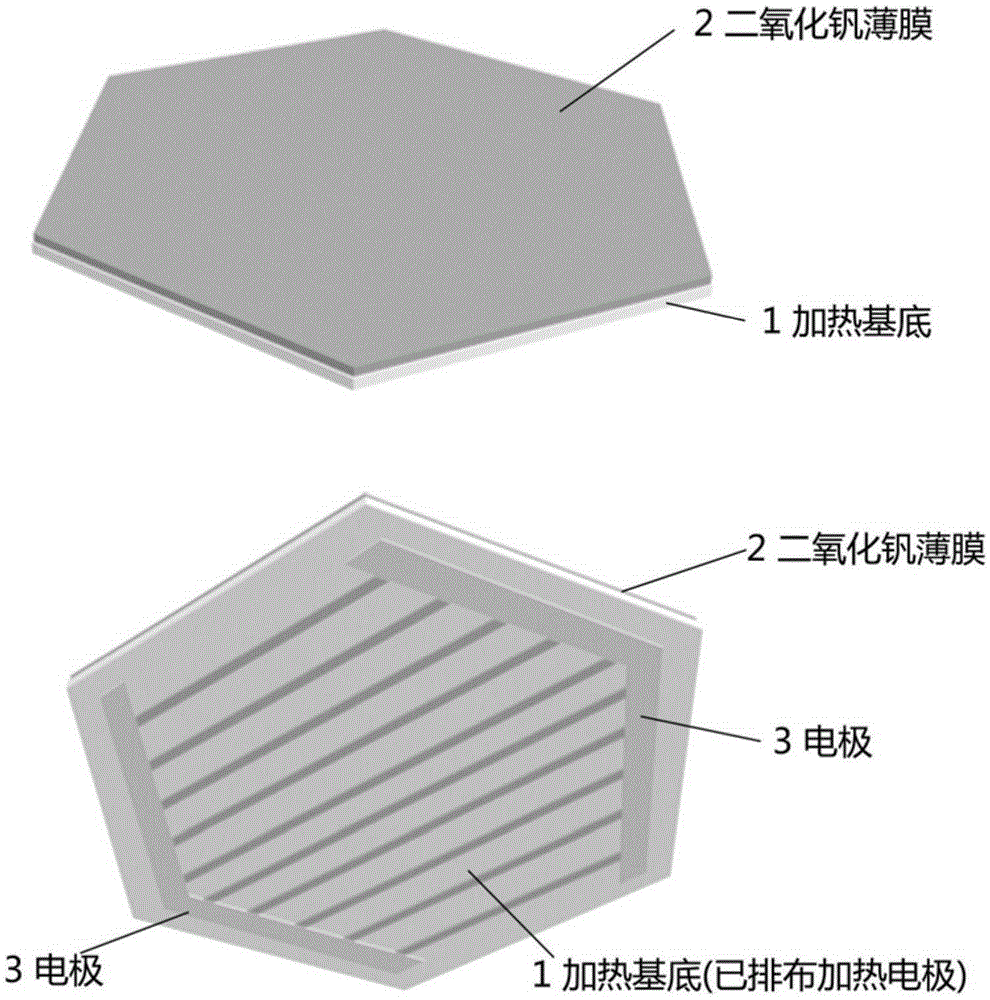

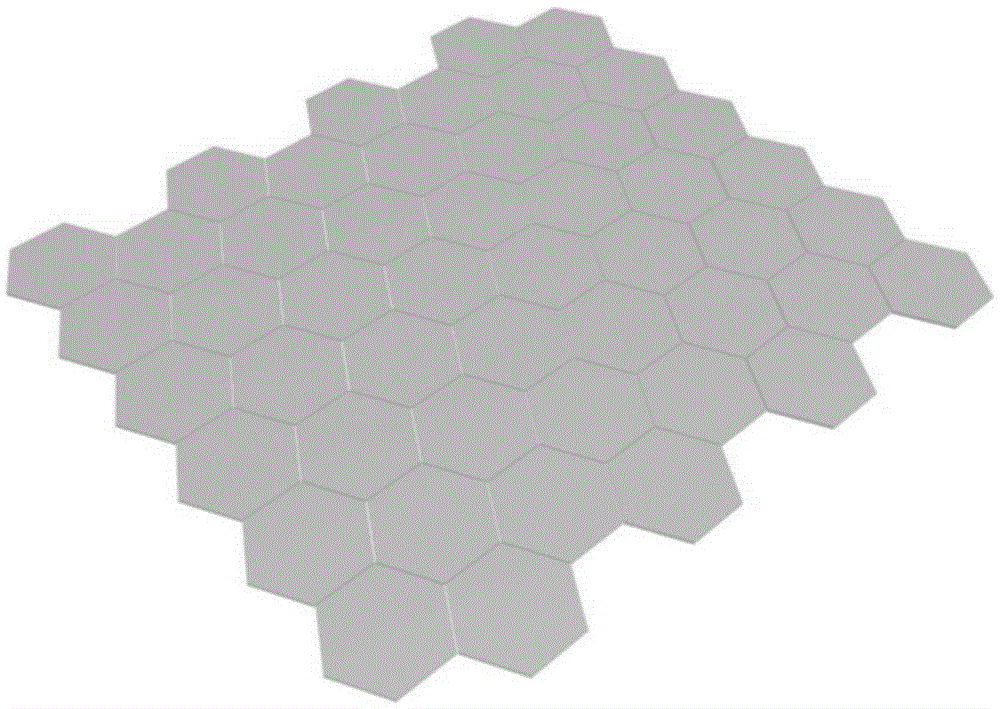

Active-type infrared camouflage structure based on vanadium dioxide

ActiveCN105428516AReduce power consumptionUnaffected by the surrounding environmentCamouflage devicesThermoelectric device detailsVanadium dioxideEmissivity

The invention discloses an active-type infrared camouflage structure based on vanadium dioxide, and the structure comprises a heating substrate, a vanadium dioxide film, and an electrode pair. The vanadium dioxide film is disposed on the upper surface of the heating substrate in a manner of coating or vapor plating The heating substrate changes the temperature of the vanadium dioxide film through current heating while providing support for the vanadium dioxide film. The electrode pair is located at two ends of the heating substrate, and is connected with an external power supply and the heating substrate. The electrode pair is used for changing the temperature of the heating substrate, so as to adjust the change of the emissivity of vanadium dioxide. The structure can achieve low-power-consumption and quick adjustment infrared camouflage.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

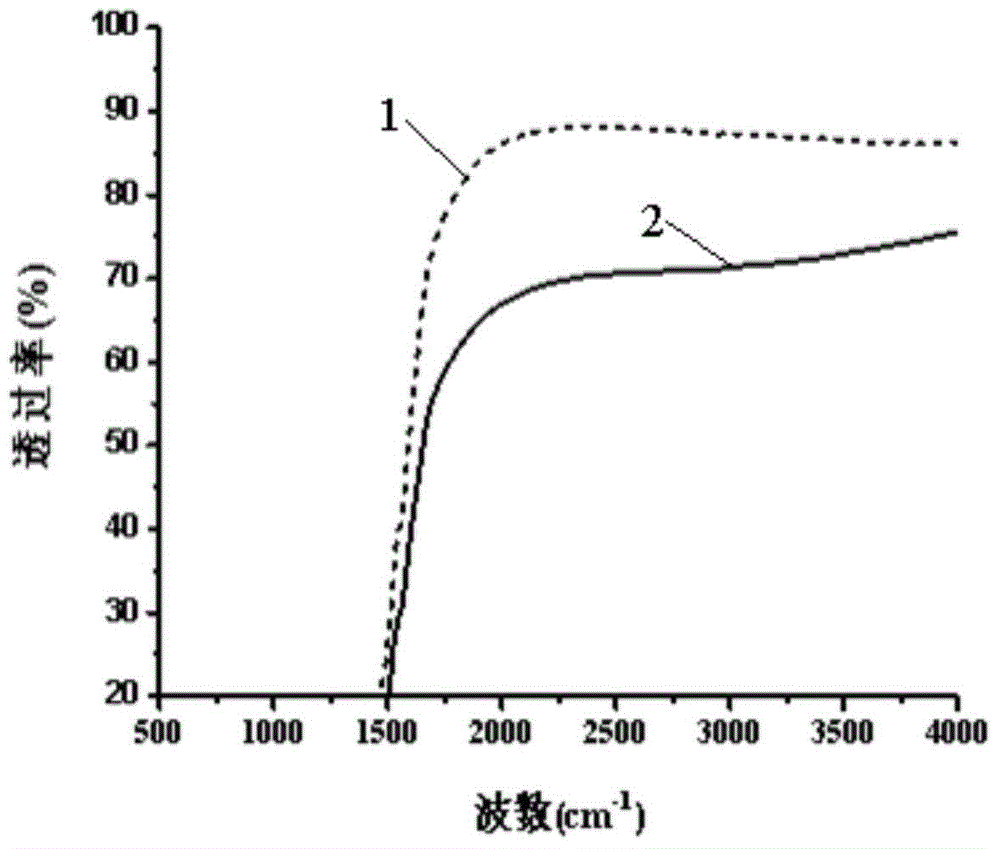

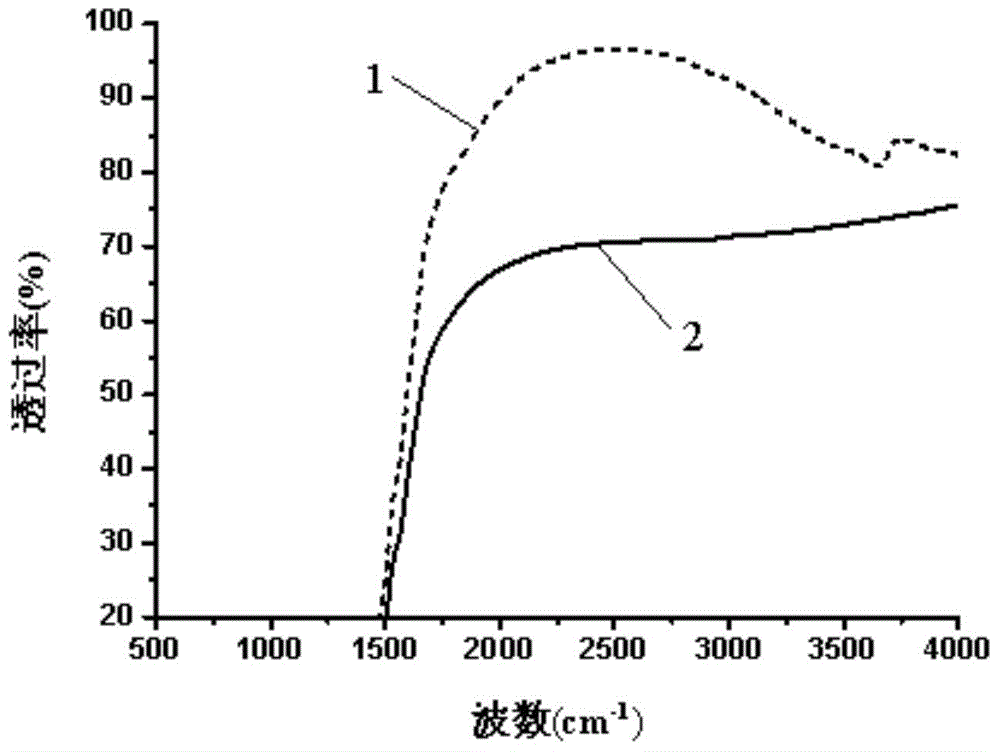

Method for preparing monox infrared permeability increasing vanadium oxide film

ActiveCN104928641AReduce throughHigh purityVacuum evaporation coatingSputtering coatingWeather resistanceTransmittance

The invention relates to a method for preparing a monox infrared permeability increasing vanadium oxide film, and aims at solving the problems that the infrared transmittance of an existing VO2 film is low, and weather resistance is poor. The method comprises the first step of cleaning, the second step of preparing before film plating, the third step of VO2 film plating, the fourth step of annealing, the fifth step of SiO2 film plating and the sixth step of shutdown, and accordingly the method for preparing the monox infrared permeability increasing vanadium oxide film is finished. The method is used for preparing the monox infrared permeability increasing vanadium oxide film.

Owner:HARBIN INST OF TECH

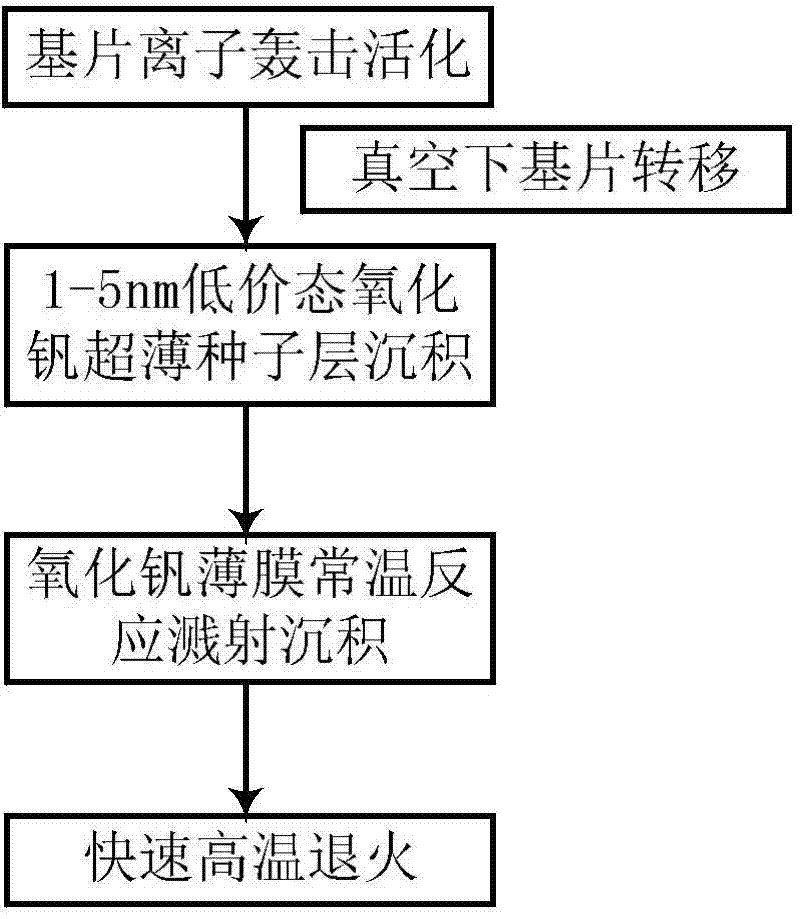

High-resistance temperature coefficient vanadium oxide film preparation method

ActiveCN103882389AGood manufacturing process compatibilityImprove compatibilityVacuum evaporation coatingSputtering coatingHigh resistanceIntegrated circuit manufacturing

The invention discloses a high-resistance temperature coefficient vanadium oxide film preparation method which comprises the following steps: (1) performing ion bombardment activation treatment on a substrate in an oxygen-enriched atmosphere; (2) performing vanadium oxide film deposition in two steps at normal temperature: depositing a 1-5nm low-valence ultrathin vanadium oxide seed layer on the treated substrate, and then depositing a vanadium oxide film through reactive sputtering; and (3) rapidly annealing the film at a high temperature in the same atmosphere as reactive sputtering. By adopting the preparation method disclosed by the invention, vanadium oxide film deposition with the resistance temperature coefficient of -3-5% / K is achieved, and meanwhile the preparation method disclosed by the invention has good compatibility with a micro-electromechanical systems (MEMS) process and an integrated circuit manufacturing process, and is applicable to large-scale manufacturing of devices based on the vanadium oxide thermosensitive film.

Owner:WUXI ALEADER INTELLIGENT TECH

Preparation method and application of porous vanadium dioxide thin film

InactiveCN104775101AThermochromicOxidation annealing process is simpleVacuum evaporation coatingSputtering coatingVanadium dioxideTransmittance

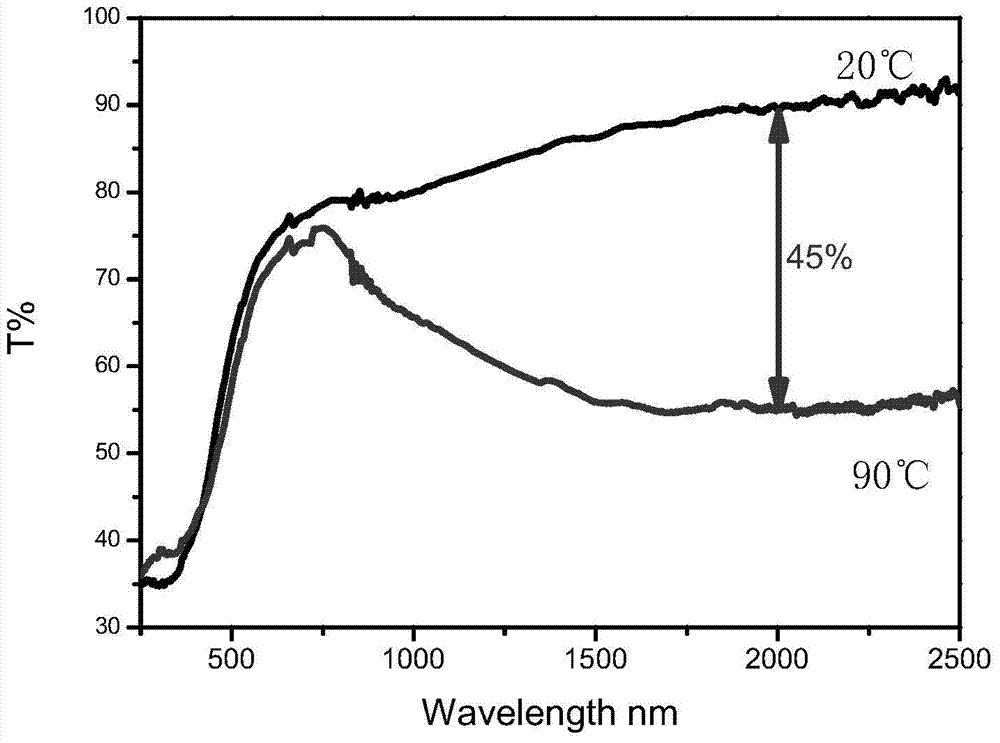

The invention discloses a preparation method and an application of a porous vanadium dioxide thin film. The preparation method comprises the following steps: by virtue of a magnetron sputtering method, preparing a C-doped metallic vanadium film from a graphite target and a metallic vanadium target; and then adding the C-doped metallic vanadium film in an annealing furnace and annealing in an atmospheric condition so as to obtain the porous vanadium dioxide thin film having a phase change effect. C doping content can be regulated by controlling the sputtering power of the two target materials, and the optimum annealing temperature and annealing time can be selected according to the C doping content and the thickness of the metallic vanadium film, so that the obtained vanadium dioxide thin film is excellent in performance; an infrared transmittance regulating amplitude can reach 45% and visible light transmittance can reach 70%. Normal glass, quartz glass or transparent conductive oxide glass can be used as a substrate of the thin film; and the thin film has a broad application prospect in the fields of smart windows, light storage devices, optoelectronic switches and the like.

Owner:WUHAN UNIV OF TECH

Low-temperature deposition method for vanadium dioxide thin film

ActiveCN105132877AGood phase change performanceReduce manufacturing costVacuum evaporation coatingSputtering coatingVanadium dioxideLow temperature deposition

The invention discloses a low-temperature deposition method for a vanadium dioxide thin film. A magnetron sputtering technique is adopted; vanadium metal or vanadium alloy is taken as a target; oxygen is taken as a reactant gas; argon is taken as a sputtering gas. A vacuum chamber is vacuumized until the air pressure is below the background vacuum of 1*10<-3> Pa before the thin film is prepared; then a mixed gas of the oxygen and the argon is pumped in, and oxygen partial pressure is held to be 0.01-0.06 Pa; in the process of deposition of the thin film, the deposition temperature is controlled to be 240-260 DEG C and negative bias is added to a base, the sputtering power density of the target surface is 2-3 W / cm<2> and the high-property VO2 thin film is obtained on the surface of the base. According to the low-temperature deposition method for the vanadium dioxide thin film, the deposition temperature of the VO2 thin film is low and is matched with appropriate negative bias and other technological parameters to prepare the high-property VO2 thin film which is even and compact, low in phase transition temperature of the vanadium dioxide and good in phase transition property; the production cost is greatly reduced.

Owner:SHENZHEN UNIV

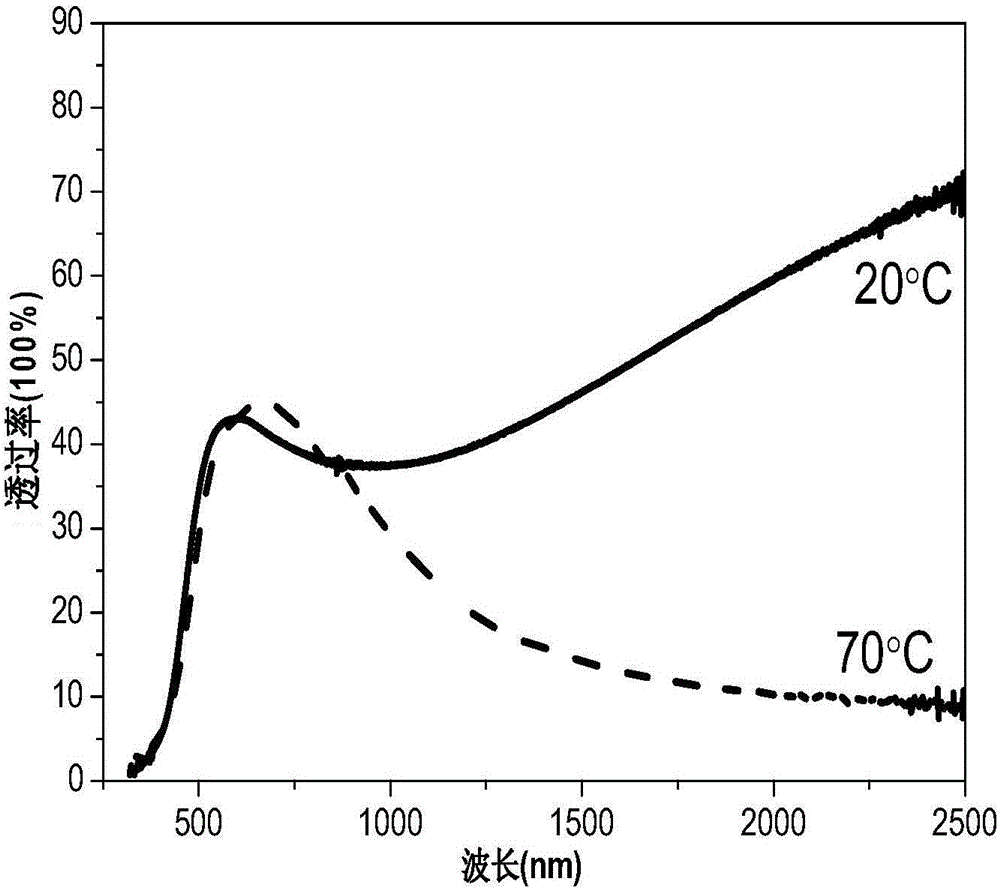

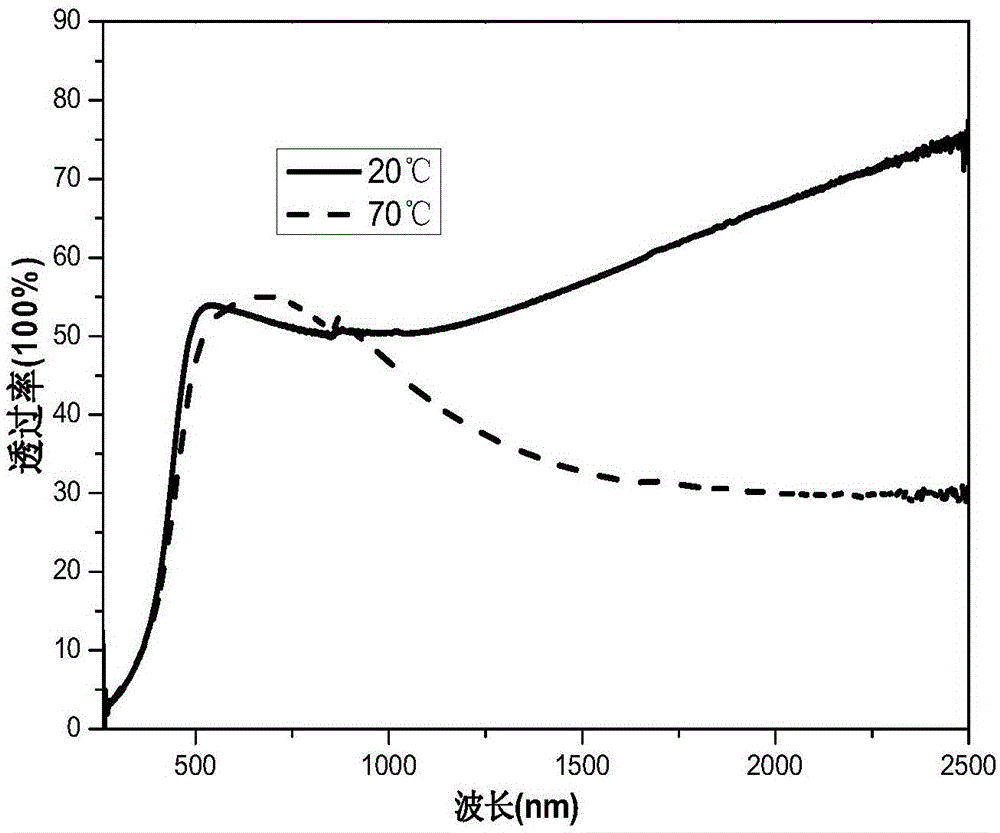

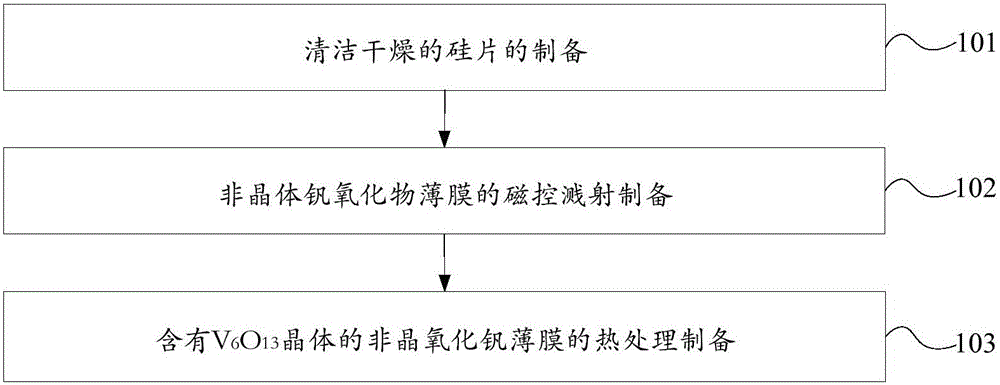

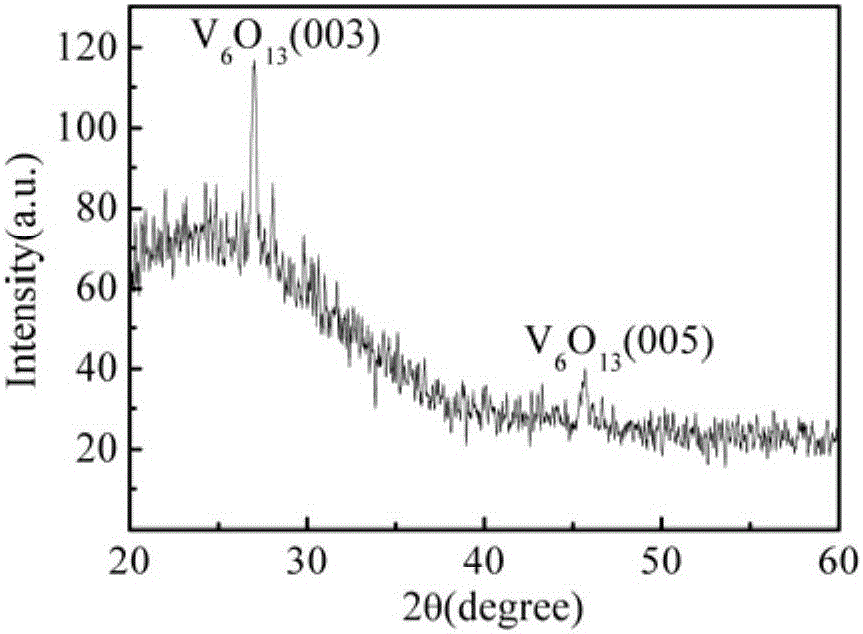

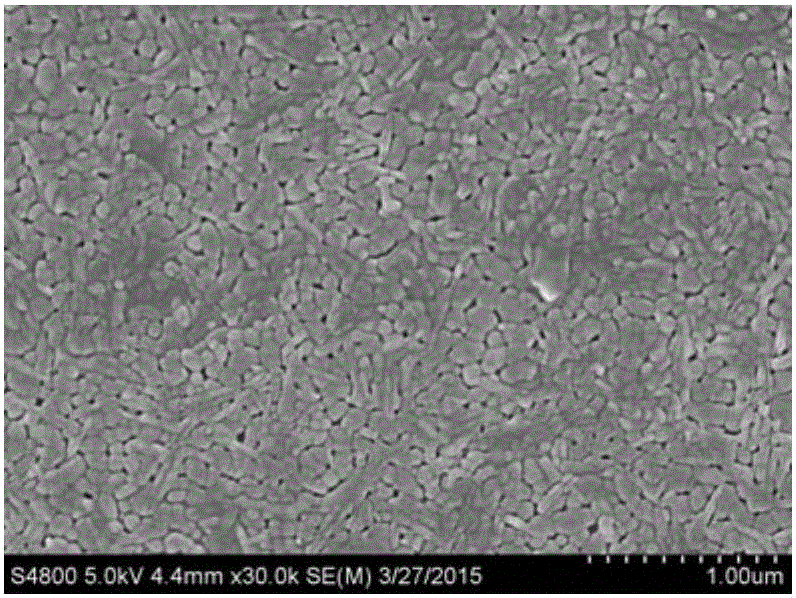

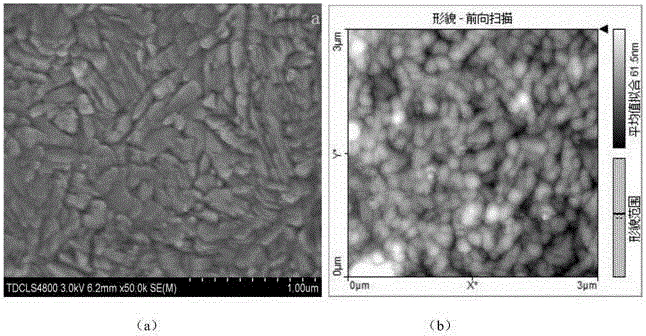

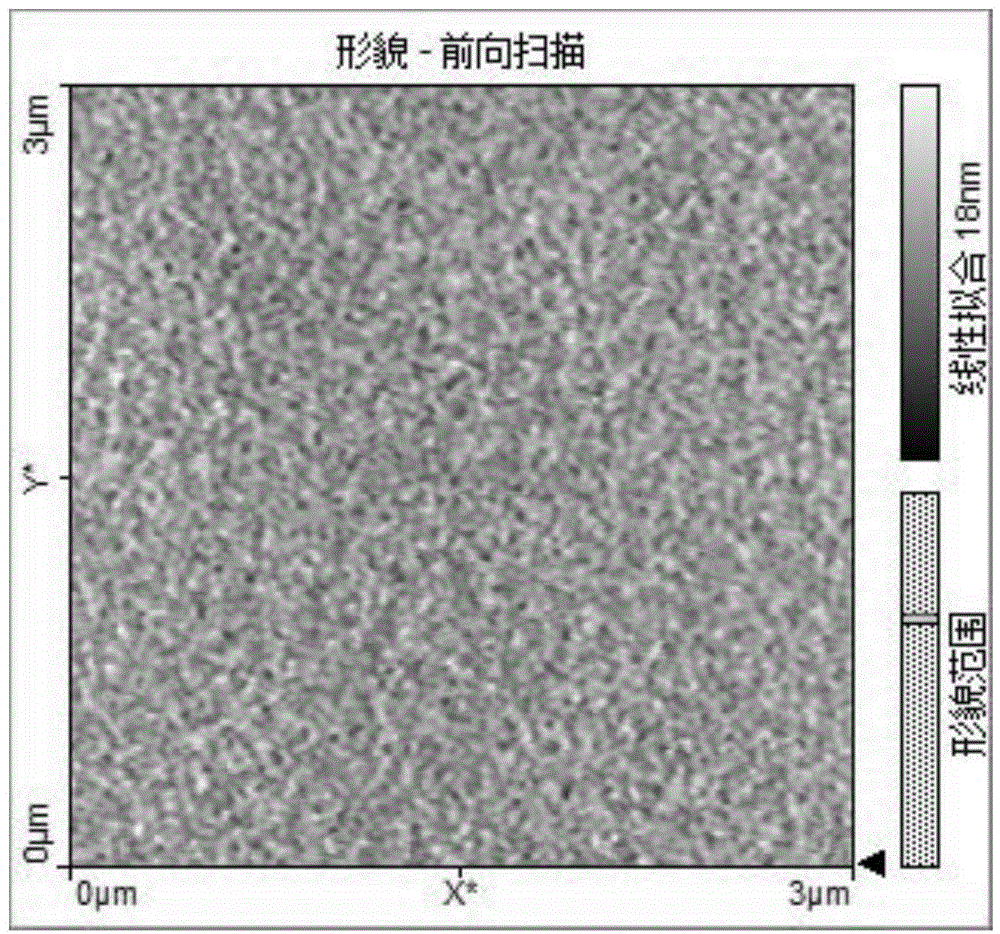

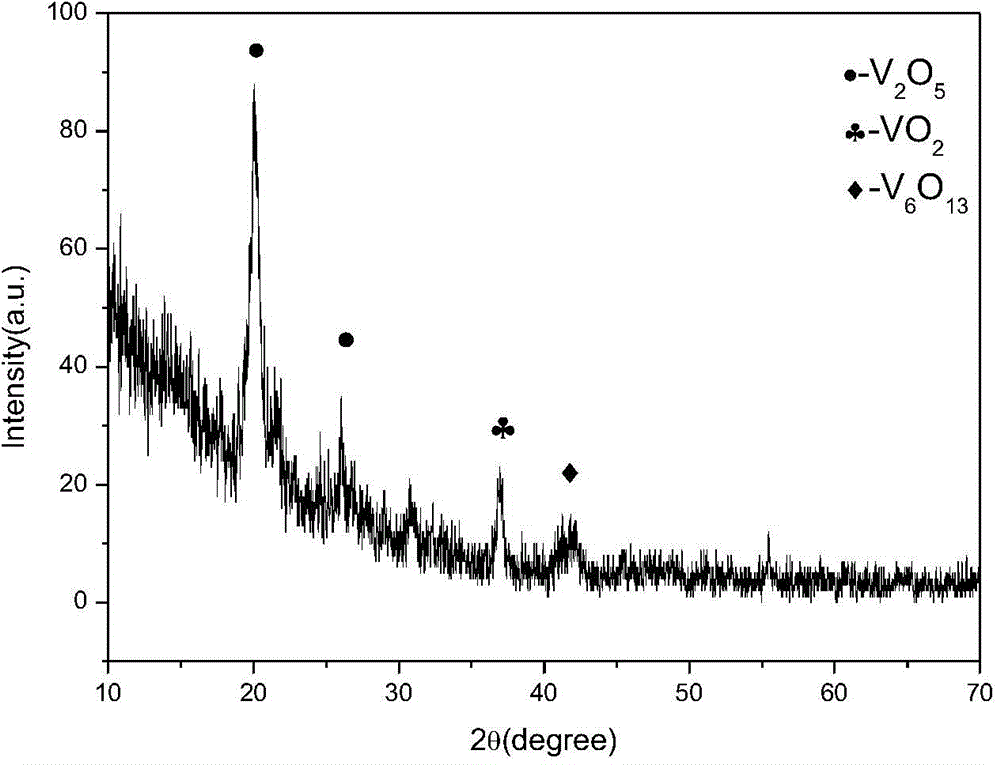

Amorphous vanadium oxide film material containing V6O13 crystals and preparing method thereof

ActiveCN105018881AFlat and dense surfaceUniform particlesVacuum evaporation coatingSputtering coatingOxygenVanadium oxide

The invention provides an amorphous vanadium oxide film material containing V6O13 crystals and a preparing method thereof. The method comprises the following steps: preparing a clean and dry silicon wafer; in a sputtering process, simultaneously introducing a metallic vanadium target used as a target material, the clean and dry silicon wafer used as a substrate, argon used as sputtering gas and oxygen used as reaction gas into a magnetically-controlled sputtering chamber, and depositing an amorphous vanadium oxide film on the silicon substrate; and placing the prepared amorphous vanadium oxide film into a vacuum annealing furnace so as to carry out thermal treatment, and after thermal treatment, obtaining the amorphous vanadium oxide film material containing the V6O13 crystals. According to the preparing method provided by the invention, the prepared film material has neat and compact surfaces and relatively uniform material particles. Meanwhile, the resistance of the produced film material is moderate and sensitive with temperature variation, the temperature coefficient of the resistance is larger than 2% / K, and the variation of the resistance is stable in heating and cooling processes. The amorphous vanadium oxide film material can be used for manufacturing a micro-bolometer.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Vanadium oxide thin film and preparation method thereof

InactiveCN104593738ASimple preparation processFew parametersVacuum evaporation coatingSputtering coatingPhase changeRepeatability

The invention discloses a vanadium oxide thin film and a preparation method thereof. According to the preparation process, the oxygen flow rate during annealing is improved, so that the surface of the prepared vanadium oxide thin film is loose and porous, and the phase change amplitude of the vanadium oxide thin film is improved. According to the method, the defects that the vanadium oxide thin film is long in preparation time and low in phase change amplitude are overcome, the process parameters can be strictly controlled, and the process repeatability and the phase change amplitude of the vanadium oxide thin film are improved, so that the sensitivity of the device is improved. Meanwhile, according to the loose and porous morphology, the specific surface area of the film is enlarged, and the film plays an important role in improving the gas-sensitive property of the sensor and can be well applied to actual operation.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com