Vanadium oxide thin film and preparation method thereof

A vanadium oxide thin film and thin film technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of low sensitivity and low phase transition range of vanadium oxide thin film, and achieve simple preparation process, shorten Preparation time, effect of improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Cleaning of Al2O3 substrate

[0036] Put the Al2O3 substrate (1cm×1cm) in the R direction into acetone and absolute ethanol for 15min and ultrasonically vibrate for 15min, then take out the substrate and dry it for later use.

[0037] 2) Preparation of thin films of metal vanadium by magnetron sputtering

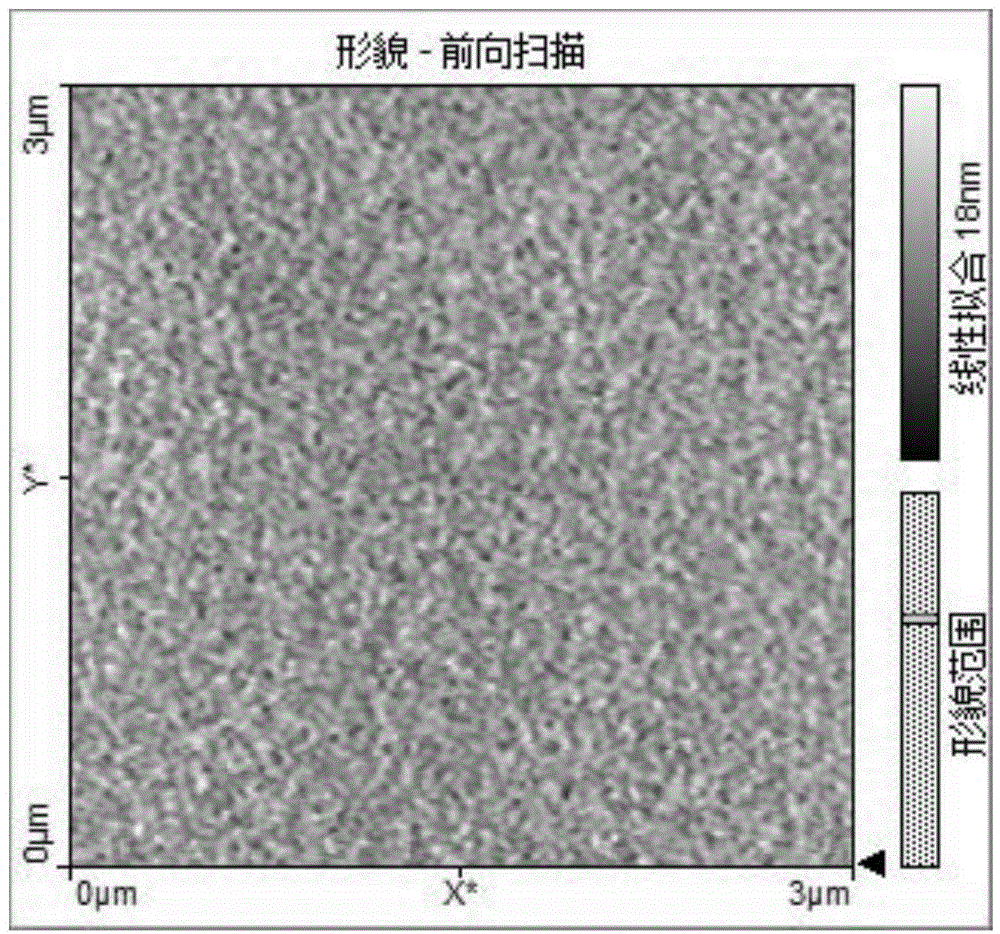

[0038] Pure metal vanadium film was deposited on Al2O3 substrate by DPS-Ⅲ type ultra-high vacuum direct-current counter-target magnetron sputtering. For the deposition target, a metal vanadium target with a purity of 99.999% was selected, and the aluminum oxide substrate cleaned in step (1) was placed in a vacuum chamber, and the body was vacuumed to 4.0×10 -4 Pa; use argon with a mass purity of 99.999% as the working gas, control the flow of argon to 48sccm, the working pressure of sputtering to 2.0pa, the sputtering power to 172.5W, the sputtering time to 10min, and the substrate temperature during sputtering for room temperature. The atomic force microscope p...

Embodiment 2

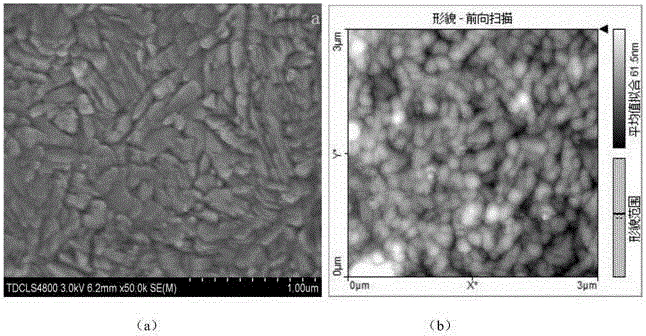

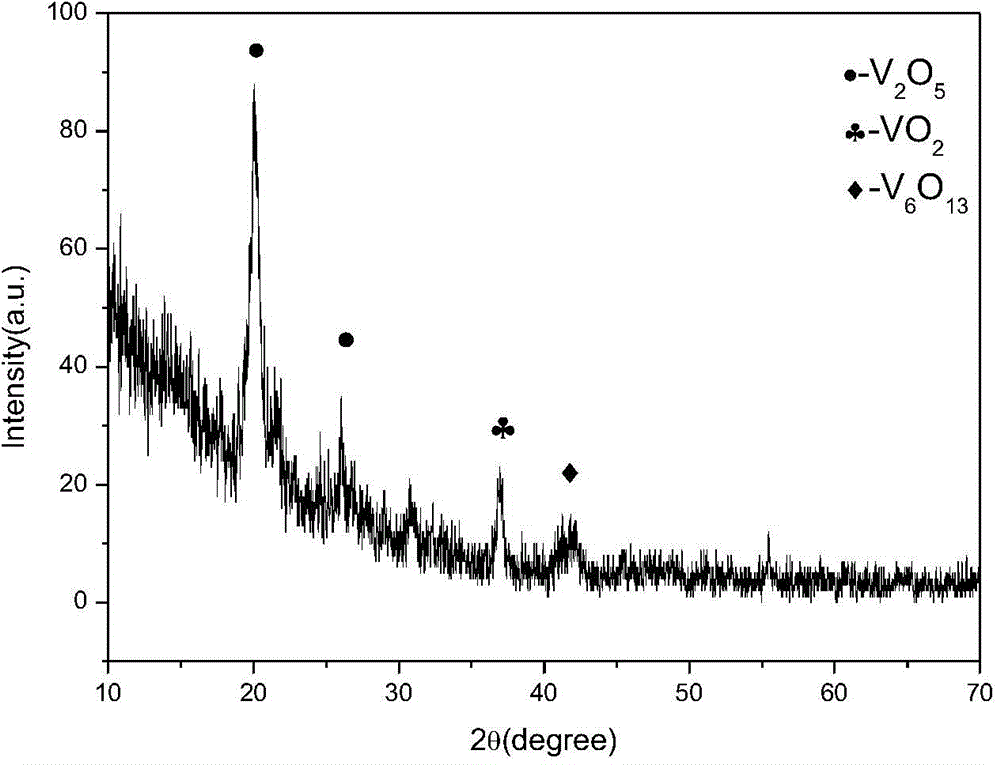

[0045] This embodiment is similar to Embodiment 1, except that: the oxygen flow rate during the annealing process in step 3) is 3 slpm when heating up and keeping warm. The surface morphology of thin films was measured by scanning electron microscopy and atomic force microscopy, such as Figure 5 shown. The phase transition characteristics of the vanadium oxide film were measured by using four probes, and the measured temperature range was 27-90°C. During the heating process, when the surface temperature of the sample is 30.5, 50, 68, and 90°C, the sheet resistance of the corresponding film is 7.89, 5.58, 2.04, and 1.58KΩ / □, and the sheet resistance increases with the increase of temperature. The change factor is about 5; during the cooling process, when the temperature is 90, 68, 50.5, and 30°C, the corresponding sheet resistance is 1.6, 2.4, 2.8, 8.04KΩ / □, and the resistance change factor is 5. The magnitude of the phase transition is nearly an order of magnitude. The curve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com