Vanadium dioxide thin film and preparation method thereof

A technology of vanadium dioxide and vanadium pentoxide, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., to achieve the effect of good crystallinity, easy post-processing, and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 0.3 g of vanadium pentoxide and 0.6 g of oxalic acid into 300 mL of deionized water, stir and react in a water bath at 80 °C for 24 hours to obtain a blue vanadium precursor solution; transfer 30 mL of it to an autoclave, and clean the FTO glass was vertically inserted into the precursor solution, and after reacting at 200 °C for 12 hours, the long VO 2 Thin-film FTO glass;

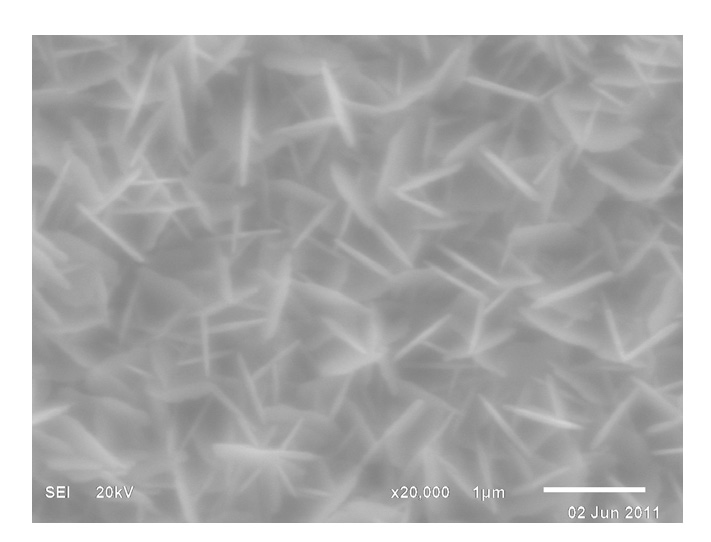

[0037] figure 1 VO prepared for this embodiment 2 The scanning electron microscope photo of the thin film shows that it is flake VO 2 Textured film with specific surface morphology;

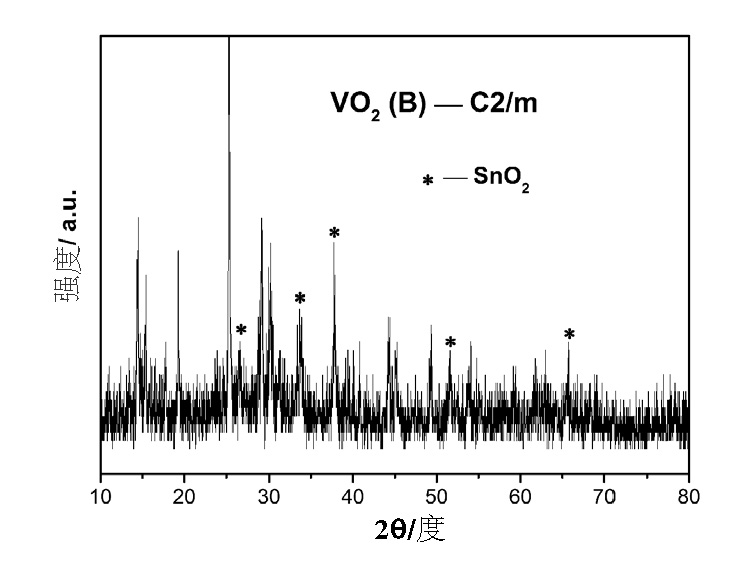

[0038] figure 2 VO prepared for this embodiment 2 The X-ray diffraction pattern of the film, it can be seen from the figure that the obtained VO 2 For the B phase, the space group is C2 / m.

Embodiment 2

[0040] Add 0.3 g of vanadium pentoxide and 0.6 g of oxalic acid into 300 mL of deionized water, stir and react in a water bath at 80 °C for 12 hours to obtain a blue vanadium precursor solution; transfer 30 mL of it to an autoclave, and put the cleaned SnO 2 The film substrate was vertically inserted into the precursor solution, and after reacting at 250 °C for 96 hours, the SnO 2 VO 2 film;

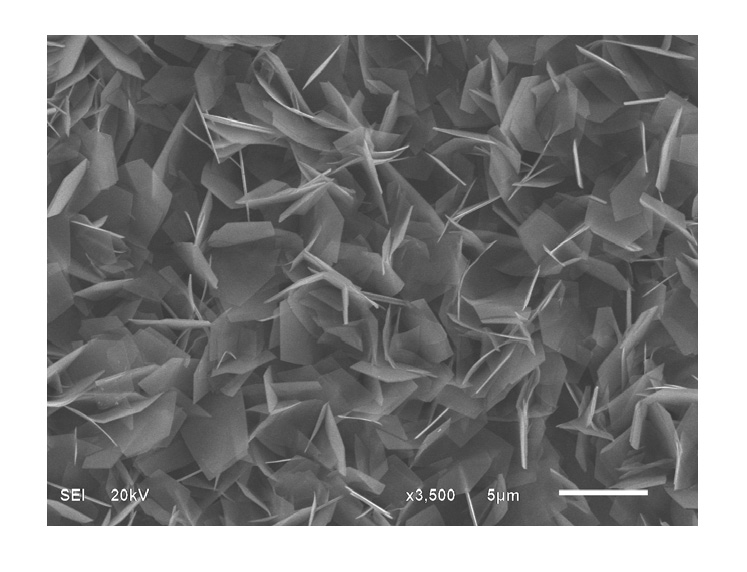

[0041] image 3 VO prepared for this example 2 The scanning electron micrograph of the thin film shows that it is an obvious morphology composed of interwoven sheet-like units.

Embodiment 3

[0043] Add 0.3 g of vanadium pentoxide and 0.6 g of oxalic acid into 300 mL of deionized water, stir and react in a water bath at 80 °C for 24 hours to obtain a blue vanadium precursor solution; transfer 30 mL of it to an autoclave, and clean the TiO 2 The film substrate was vertically inserted into the precursor solution, and after reacting at 200 °C for 23.5 hours, the TiO 2 VO 2 film;

[0044] Figure 4 VO prepared for this example 2 The scanning electron micrograph of the thin film shows that it also has a morphology composed of a specific sheet structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com