Preparation method of vanadium oxide film with high resistance temperature coefficient

A technology of vanadium oxide film and temperature coefficient, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of increasing intrinsic noise of devices and affecting the uniformity of microstructure in vanadium oxide film, achieving The effect of guaranteeing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

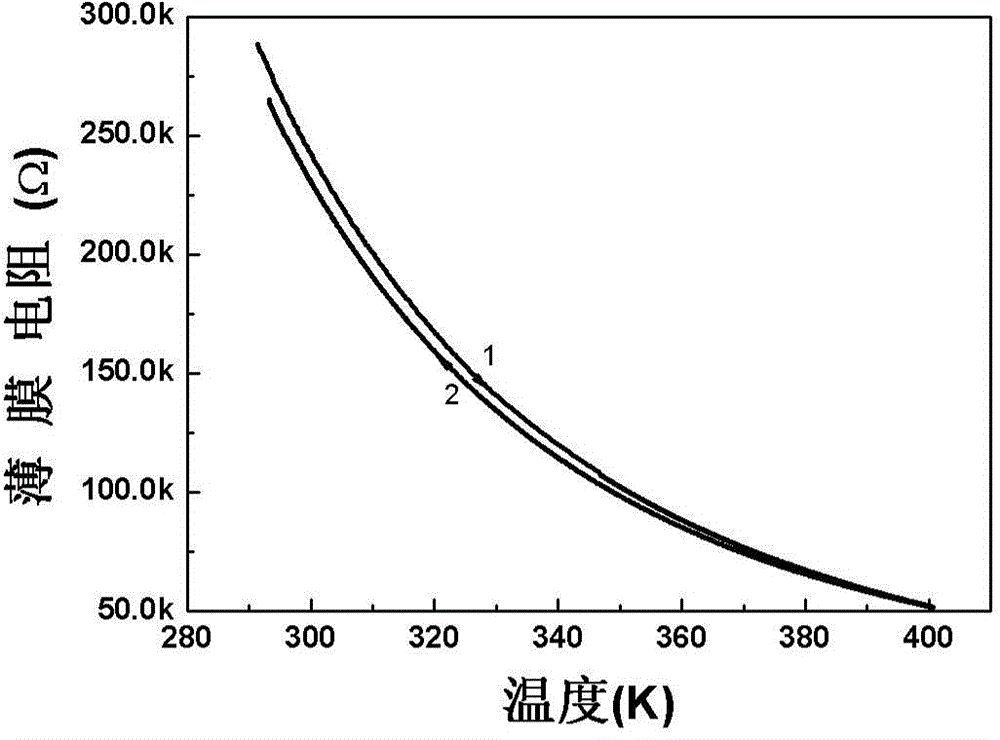

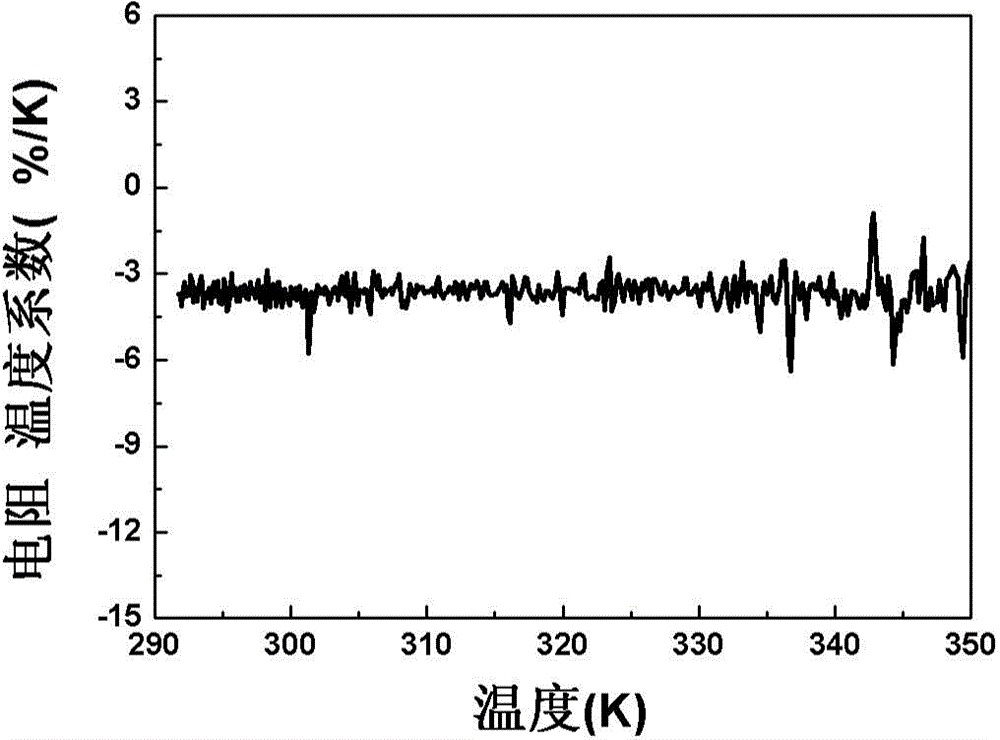

[0034] The present invention prepares VO by magnetron sputtering x / ZnS / VO x Thin film structure, and through low temperature annealing treatment to improve VO x The temperature coefficient of resistance of the thin film material, and obtain a suitable thin film resistivity. The present invention uses ZnS thin film as the reducing agent of vanadium oxide material for the first time. The main mechanism is to diffuse oxygen atoms into the ZnS thin film through low-temperature annealing treatment, and at the same time reduce the vanadium in a high-valence state to a low-valence state, and finally obtain VO 2 and V 2 o 3 Dominated mixed-phase vanadium oxide films.

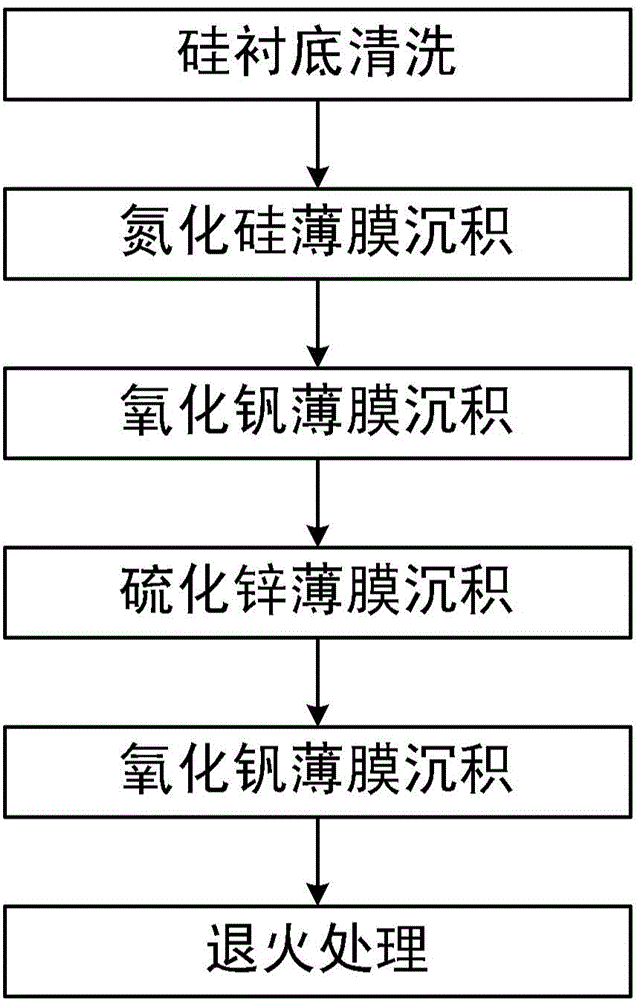

[0035] like figure 1 as shown, figure 1 A flow chart ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com