Multi-index high-speed dynamic detection and material dividing method and device of annular sliding bearing

An annular sliding bearing and sliding bearing technology, applied in the field of mechanical parts testing, can solve the problems of inability to achieve multi-index simultaneous detection and material distribution, poor automation, insufficient reliability, etc. Mass production requirements to ensure the effect of fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

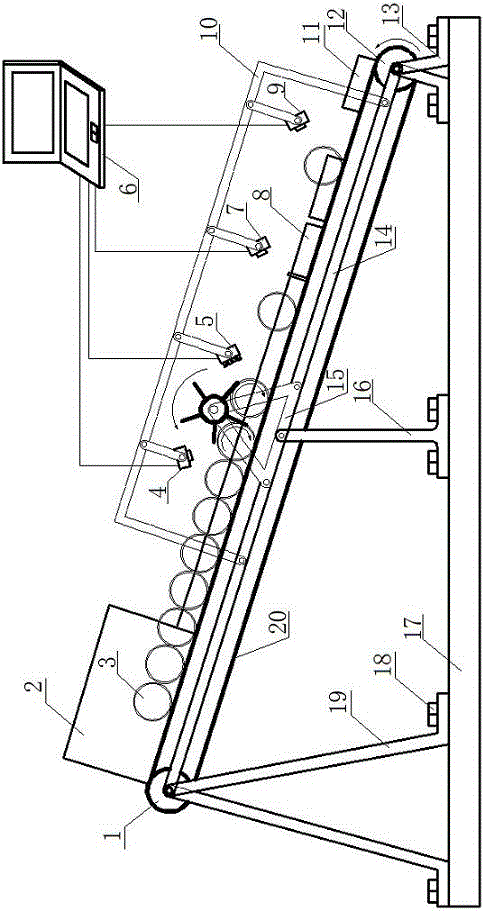

[0045] Such as Figure 1-3 shown.

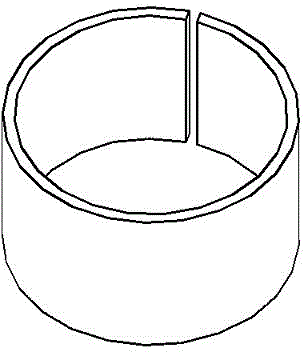

[0046] Taking the aspect ratio of INA-K06 type sliding bearing = 0.6 and satisfying the condition of no more than 2 as an example, the product testing method for outer surface diameter, height and inner surface coating peeling is explained in detail. The number of testing is 50,000 pieces.

[0047] A method for multi-index high-speed dynamic detection and material distribution of an annular sliding bearing, comprising the following steps:

[0048] First, make the driving roller 12 rotate counterclockwise, so that the sliding bearing or bushing will roll clockwise to a low position under the action of gravity and the friction of the conveyor belt. When the sliding bearing is in the detection position, it will stop moving down under the action of the tooth surface of the gear 26. And make a fixed axis rotation;

[0049] Secondly, the camera I4 is used to collect images on the outer surface of the sliding bearing or the bushing, and the camer...

Embodiment 2

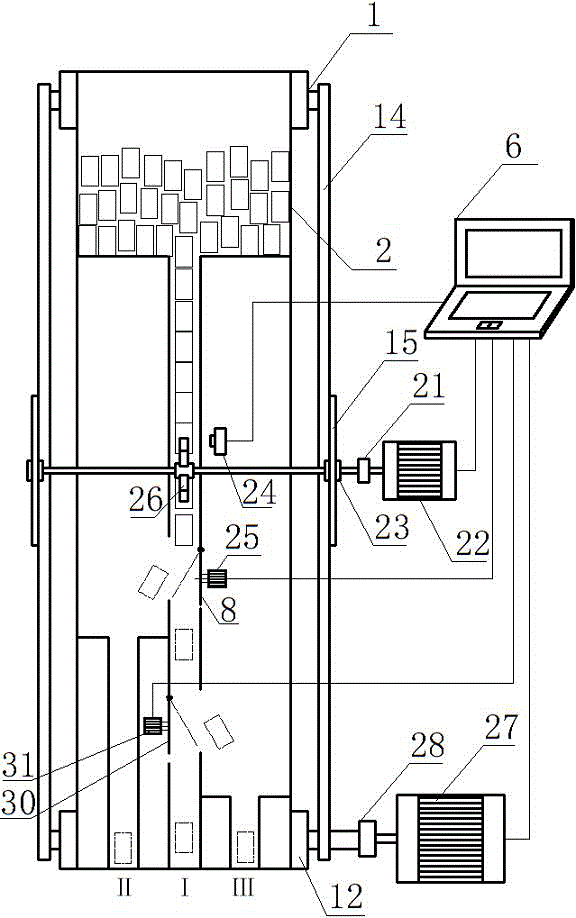

[0057] Such as Figure 1-3 shown.

[0058] A device for multi-index high-speed dynamic detection and material distribution of annular sliding bearings. The main and driven rollers 12, 1 are installed on the base 17 through high, middle and low brackets 19, 16, 13, and the brackets 19, 16, 13 are connected to the base They are connected by studs 18, and the central shafts of the main and driven rollers 1, 12 and the high and low brackets 19, 13 are respectively fixed by deep groove ball bearings, such as figure 1 Shown; The right side of driving drum 12 is connected with motor II27 by shaft coupling 28, as figure 2 As shown; the main and driven rollers 12 and 1 are kept at a certain distance through the crossbeam 14, and the conveyor belt 20 is set in the middle, and the inclination angle of the conveyor belt can be set between 30-50 degrees; the feeding device 2 and the raceway I II III 11 are fixed on the On the beam 14, and keep a distance of 5~8 mm from the upper surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com