Preparation method and application of porous vanadium dioxide thin film

A vanadium dioxide, porous structure technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem that the film uniformity and thickness are not well controlled, the vanadium dioxide thin film process is difficult to control, not suitable for Large-scale production and other issues, to achieve high visible light transmittance, improve visible light transmittance, and ensure the effect of infrared regulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

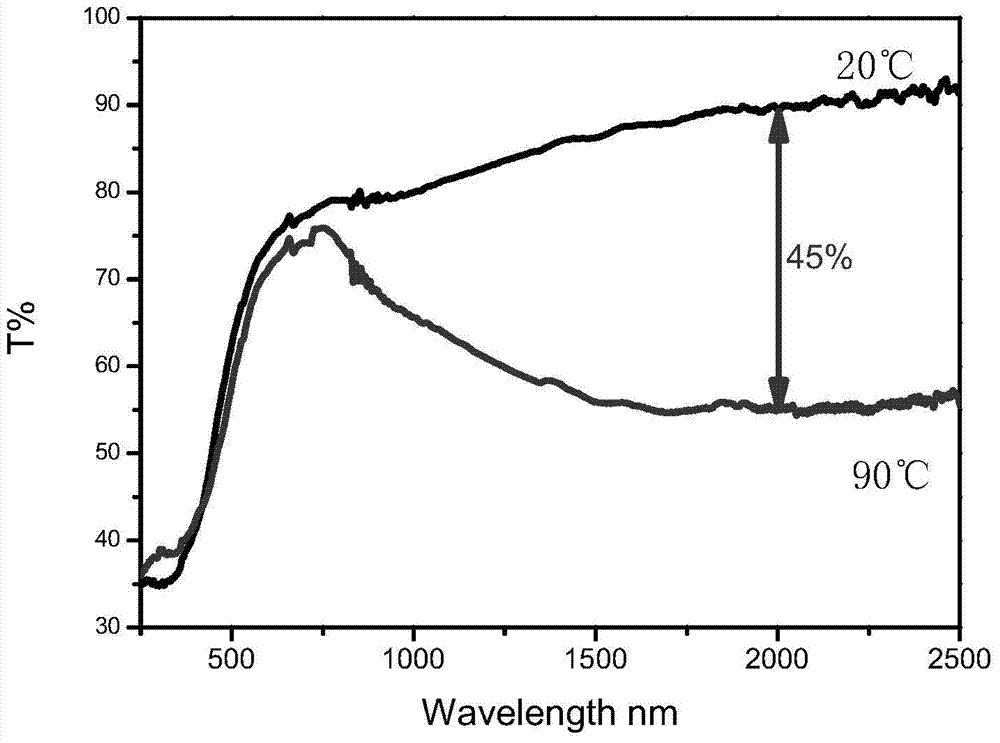

Embodiment 1

[0030] Prepare a porous vanadium dioxide film on a quartz glass substrate, the specific steps are as follows:

[0031] 1) Clean the glass substrate, the process is as follows: first clean the glass surface with a detergent, then rinse and dry with distilled water, then ultrasonically clean with acetone for 30 minutes, and finally put it in absolute ethanol for 30 minutes, and dry for later use.

[0032] 2) Using the magnetron sputtering method, prepare a V / C composite film on the above-mentioned glass substrate, fix the quartz glass substrate on the substrate stage, put a metal vanadium target (purity 99.99%) and a graphite target (purity 99.9%) ), first draw a low vacuum, and then turn on the molecular pump to fine pump to 3.0×10 -3 Pa. Argon gas (purity 99.999%) was introduced to the pressure in the chamber to 1 Pa, and it was kept stable. The metal vanadium target adopts DC sputtering, and the graphite target adopts radio frequency sputtering. Set the DC target sputterin...

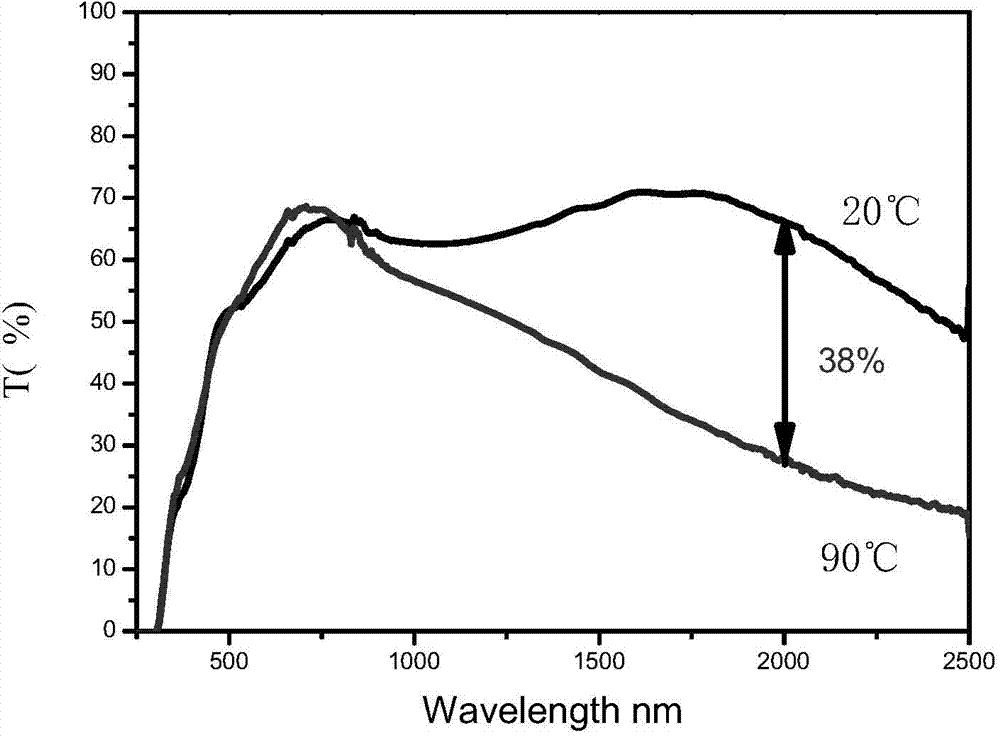

Embodiment 2

[0036] Prepare porous structure vanadium dioxide thin film on ITO glass substrate, concrete steps are as follows:

[0037] 1) Clean the substrate, the process is as follows: first clean the surface of the substrate with a detergent, then rinse and dry with distilled water, then ultrasonically clean with acetone for 30 minutes, and finally put it into absolute ethanol for 30 minutes, and dry it for later use.

[0038] 2) Using the magnetron sputtering method to prepare a V / C composite film on the above-mentioned substrate, the ITO substrate is fixed on the substrate platform, and a metal vanadium target (purity 99.99%) and a graphite target (purity 99.9%) are put in, First draw a low vacuum, and then turn on the molecular pump to fine pump to 3.0×10 -3 Pa. Argon gas (purity 99.999%) was introduced to the pressure in the chamber to 1 Pa, and it was kept stable. Set the DC target sputtering power to 77W, and the RF target sputtering power to 300W. Sputtering time is 3min. Aft...

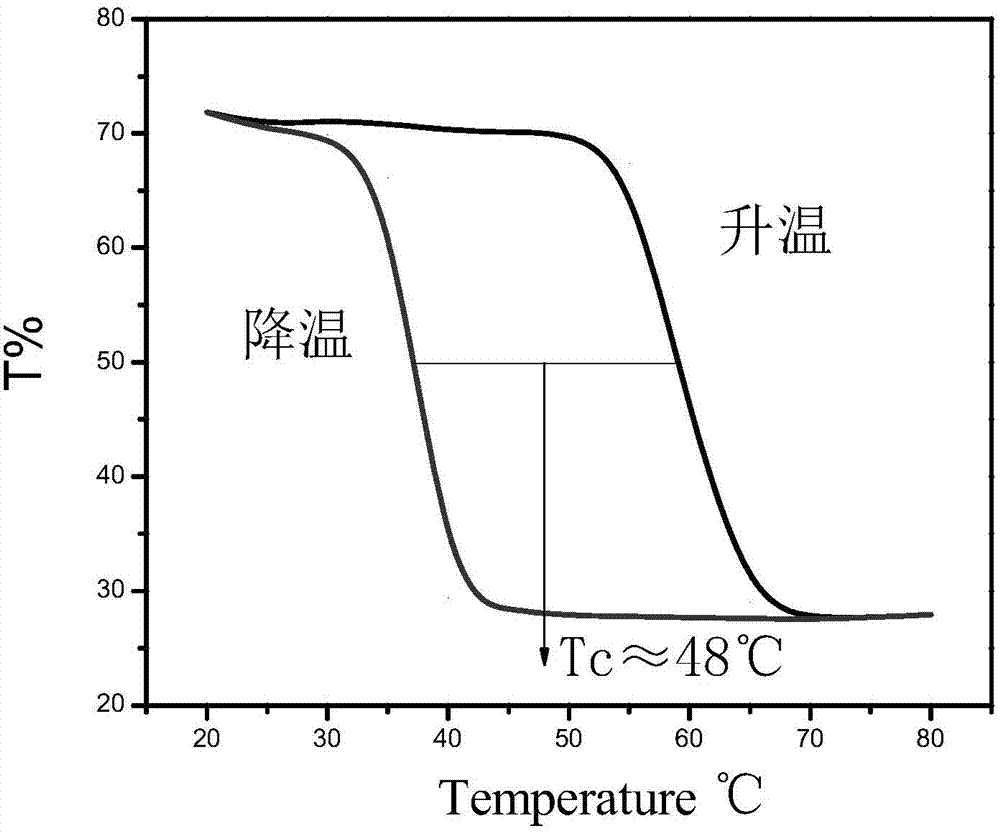

Embodiment 3

[0042] Prepare vanadium dioxide thin film on quartz glass substrate, difference with embodiment 1 is the sputtering power of vanadium target and carbon target, concrete steps are as follows:

[0043]1) Clean the glass substrate, the process is as follows: first clean the glass surface with a detergent, then rinse and dry with distilled water, then ultrasonically clean with acetone for 30 minutes, and finally put it in absolute ethanol for 30 minutes, and dry for later use.

[0044] 2) Using the magnetron sputtering method, prepare a V / C composite thin film on the above-mentioned glass substrate, fix the quartz substrate on the substrate stage, put the metal vanadium target (purity 99.99%) and graphite target (purity 99.9%) , first draw a low vacuum, and then turn on the molecular pump to fine pump to 3.0×10 -3 Pa. Argon gas (purity 99.999%) was introduced to the pressure in the chamber to 1 Pa, and it was kept stable. Set the DC target sputtering power to 77W, and the RF tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com