Preparation method and application of photocuring temperature-induced phase change ionic gel electrolyte

An ion gel, light curing technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, hybrid capacitor electrolyte, etc., can solve the problems of single function, difficult sealing, environmental pollution, etc., to avoid environmental pollution, avoid air bubbles, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In order to solve the above technical problems, the first aspect of the present invention provides a method for preparing a photocurable temperature-induced phase change ion gel electrolyte, comprising the following steps:

[0040] (1) Synthesis of polymer monomer: mix polymer and diisocyanate, add catalyst, heat to 70-90°C in nitrogen atmosphere for 1-2.5h, then drop to 40-60°C and add acrylic acid monomer, react After 1-2 hours, the reaction is terminated, and the polymer monomer is obtained;

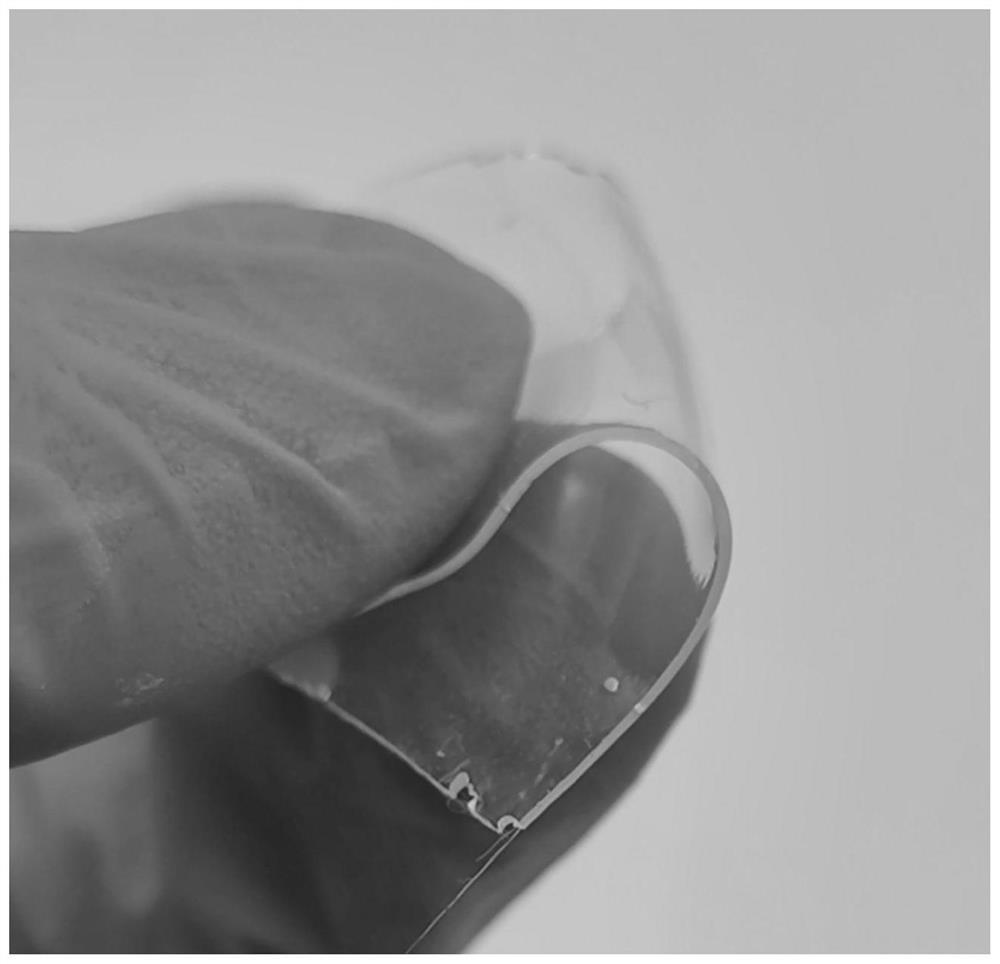

[0041] (2) Preparation of photocurable temperature-induced phase change ionic gel electrolyte: mix polymer monomer with bistrifluoromethanesulfonimide salt, add photoinitiator, mix well, inject into mold, and irradiate with ultraviolet light for 30s ~10min to prepare photocurable temperature-induced phase change ion gel electrolyte.

[0042] In one embodiment, the molar ratio of the polymer to the diisocyanate is 1:(1-2).

[0043] In one embodiment, the molar ratio of the pol...

Embodiment 1

[0075]Synthesis of Polymer Monomer-1: Mix PPG-4000 (CAS No.: 25322-69-4) with a molecular weight of 4000 and isophorone diisocyanate (CAS No.: 4098-71-9), add dilauric acid Dibutyltin (CAS No.: 77-58-7) was heated to 80°C for 1.5 hours in a nitrogen atmosphere and then lowered to 50°C. Add hydroxyethyl methacrylate (CAS No.: 868-77-9) and react for 1 hour to terminate Reaction to obtain polymer monomer-1; the molar ratio of PPG-4000 to isophorone diisocyanate is 1:1.3; the molar ratio of PPG-4000 to hydroxyethyl methacrylate is 1:1.3; dilauric acid The weight of dibutyltin is 1% of the total weight of PPG-4000 and isophorone diisocyanate;

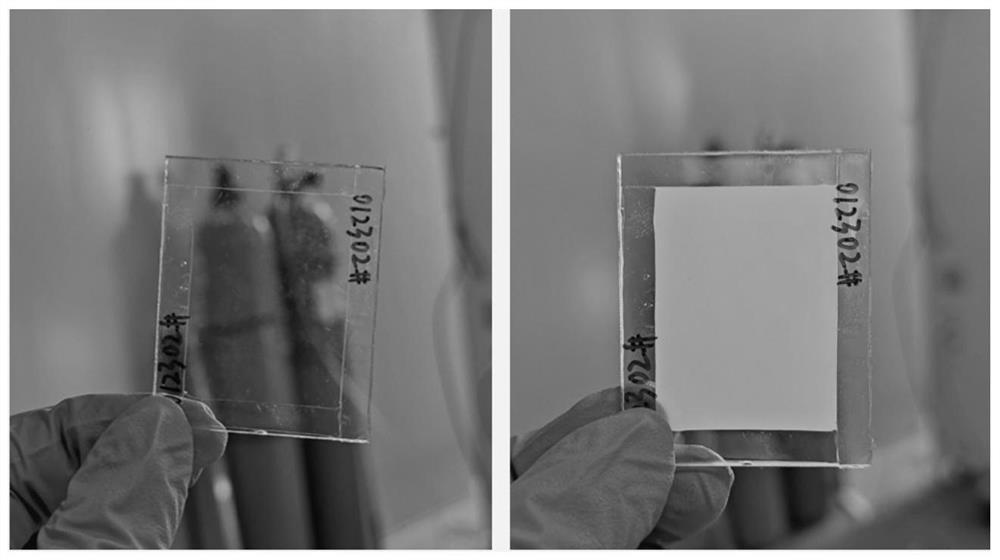

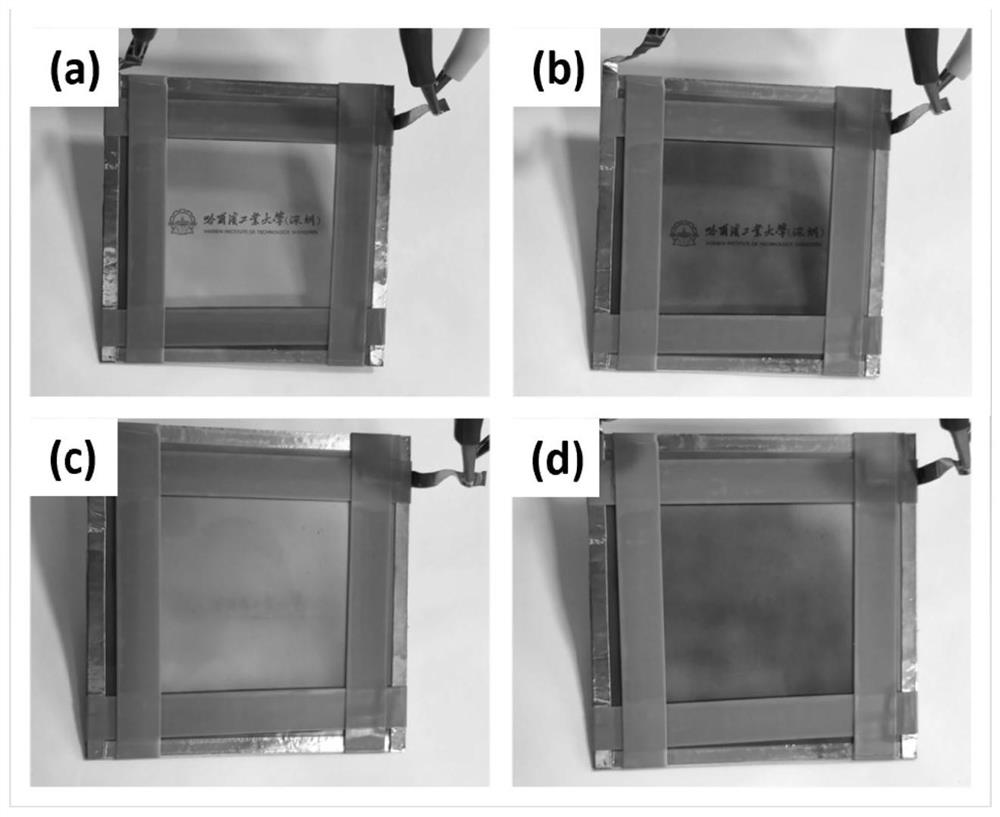

[0076] Preparation of photocurable temperature-induced phase change ion gel electrolyte-1: polymer monomer-1 and 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt (CAS number: 174899-82- 2) After mixing, add 2-hydroxy-2-methylpropiophenone (CAS No.: 7473-98-5) and mix well, then pour into the double-layer transparent glass, irr...

Embodiment 2

[0080] Synthesis of Polymer Monomer-2: Mix PPG-4000 with a molecular weight of 4000 and isophorone diisocyanate, add dibutyltin dilaurate, heat to 80°C for 1.5h in a nitrogen atmosphere, then drop to 50°C and add After reacting hydroxyethyl methacrylate for 1 hour, the reaction was terminated, and the polymer monomer-2 was obtained; the molar ratio of PPG-4000 and isophorone diisocyanate was 1:1.8; the molar ratio of PPG-4000 and hydroxyethyl methacrylate The molar ratio is 1:1.8; the weight of dibutyltin laurate is 1% of the total weight of PPG-4000 and isophorone diisocyanate;

[0081] Preparation of photocurable temperature-induced phase change ionic gel electrolyte-2: mix polymer monomer-2 with 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt and add 2-hydroxyl-2 - Methylpropiophenone is mixed evenly and poured into double-layer transparent glass, and after being irradiated by ultraviolet light for 5 minutes, the double-layer transparent glass is disassembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com