Method for preparing vanadium dioxide thin film with high temperature coefficient of resistance

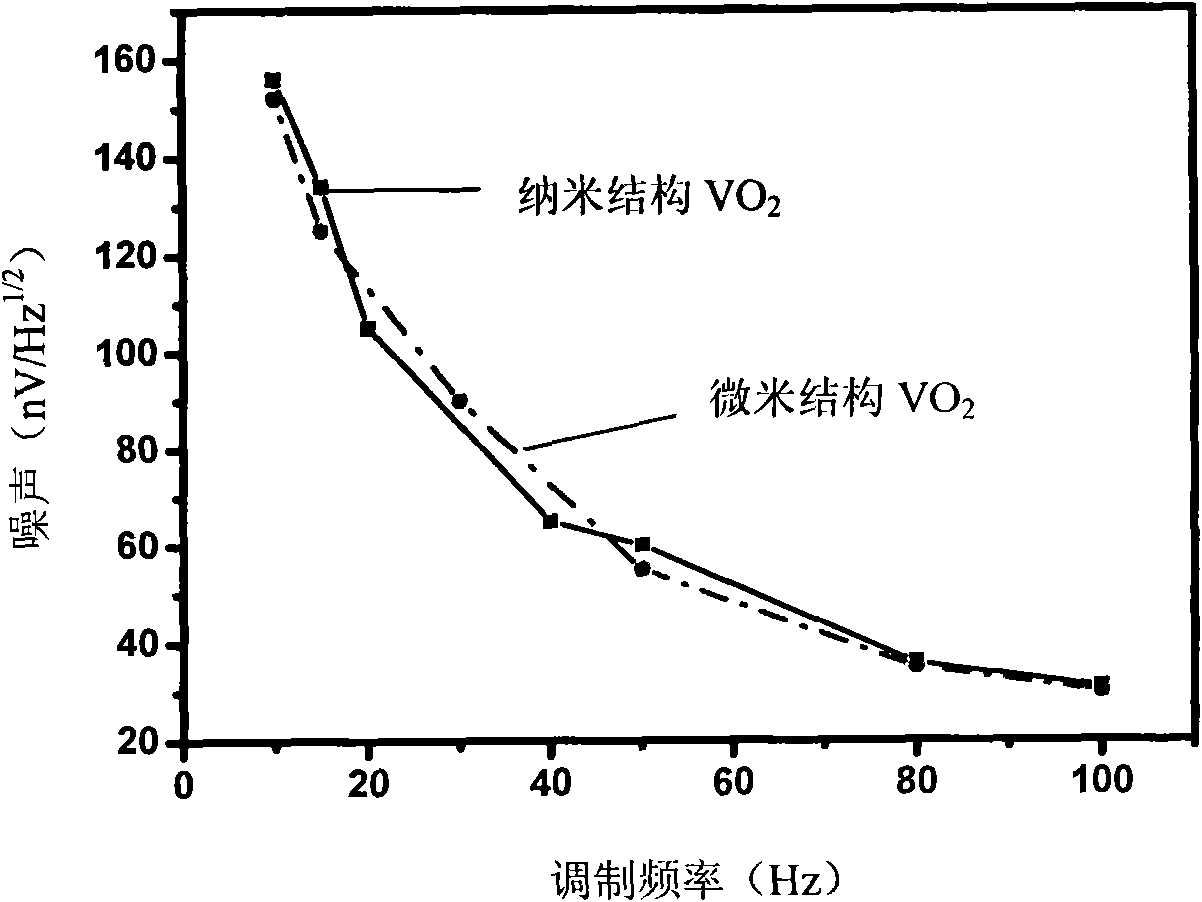

A technology of vanadium dioxide and temperature coefficient, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of high material noise, unfavorable device integration process, and limited detector performance, and achieve a firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment the present invention will be further described:

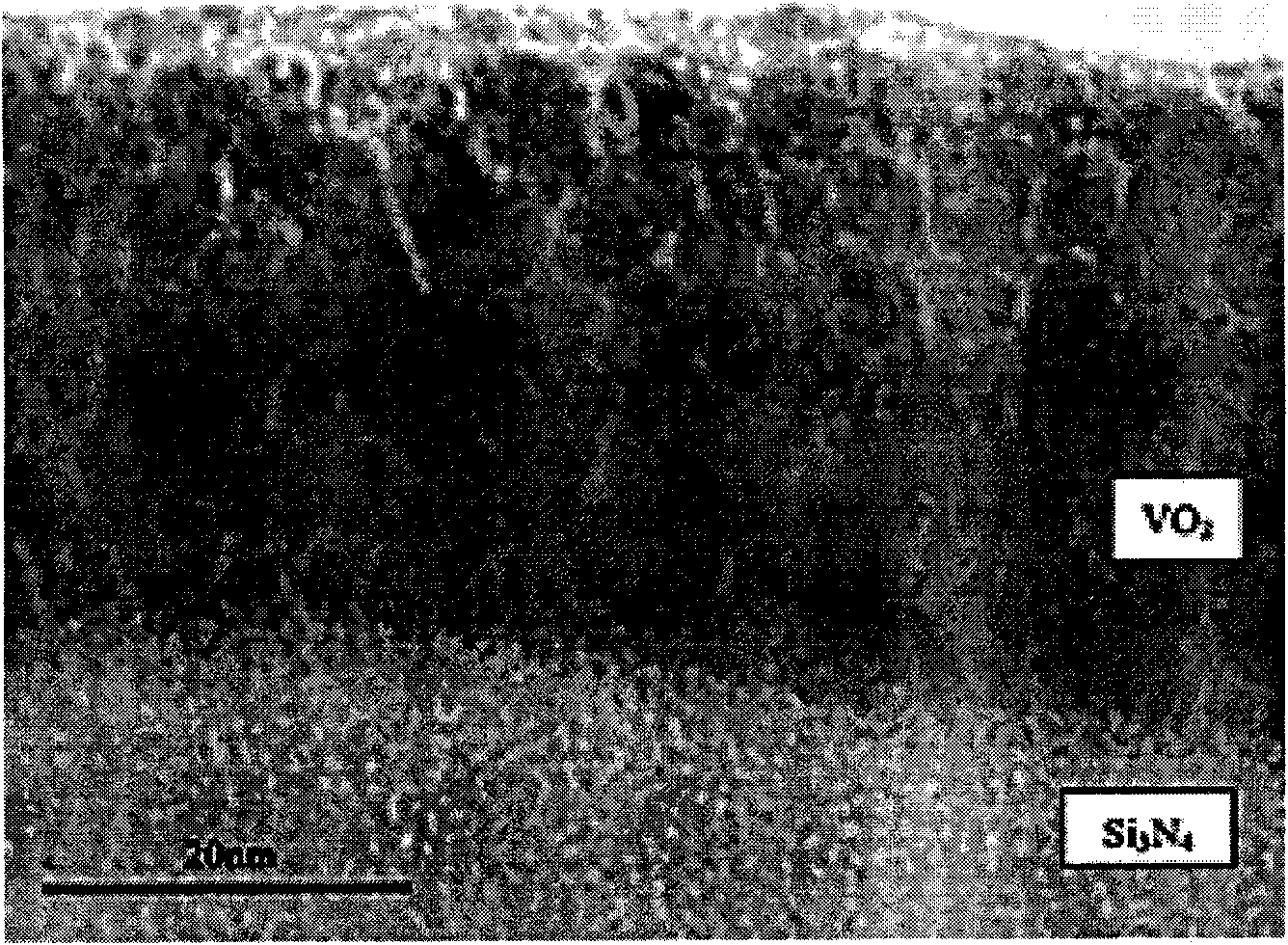

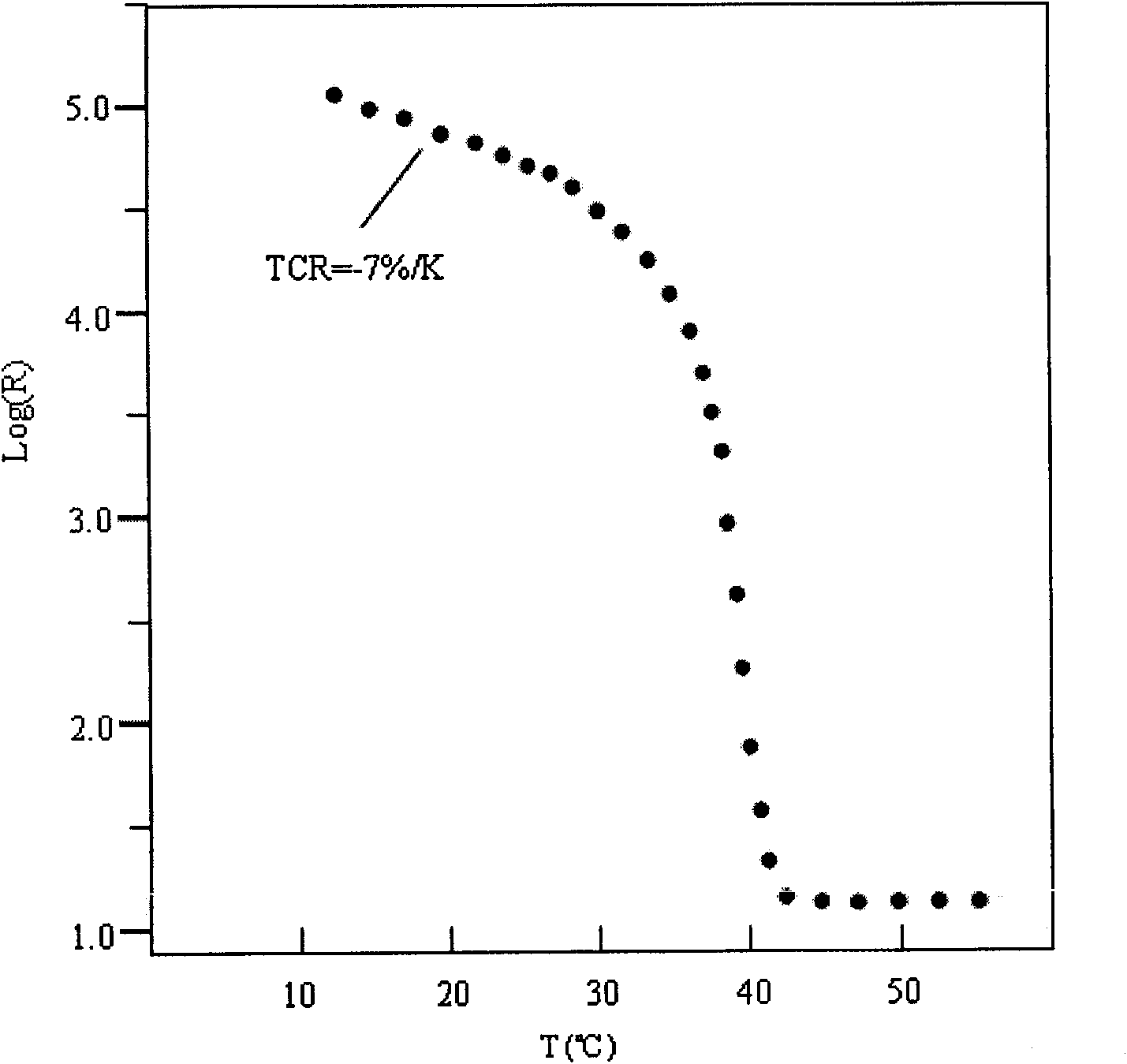

[0021] 1. VO with a temperature coefficient of resistance of -7% / K 2 Film Preparation Process

[0022] (1) Clean the substrate of the high-resistance silicon with (100) crystal orientation according to the standard RCA process, and then dry it with nitrogen.

[0023] (2) Put the silicon wafer into the reactive ion sputtering system, turn on the heating device, and keep the substrate temperature at 280°C; after the vacuum degree reaches the required substrate temperature and stabilizes, clean the surface of the silicon wafer by parallel ion beam sputtering. The sputtering uses a vanadium target with a purity of 4N, the purity of the sputtering reaction gas is 4N, and the deposition rate is 2-3nm / min. The process parameters are as follows:

[0024]

[0025] (3) Use the focused ion source to clean the surface of the sputtering target for 3 minutes, and then open the baffle to sputter the buffer la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com