Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Reduce through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Infrared reflection/emission thermal-insulating plastic functional master batch and preparation method thereof

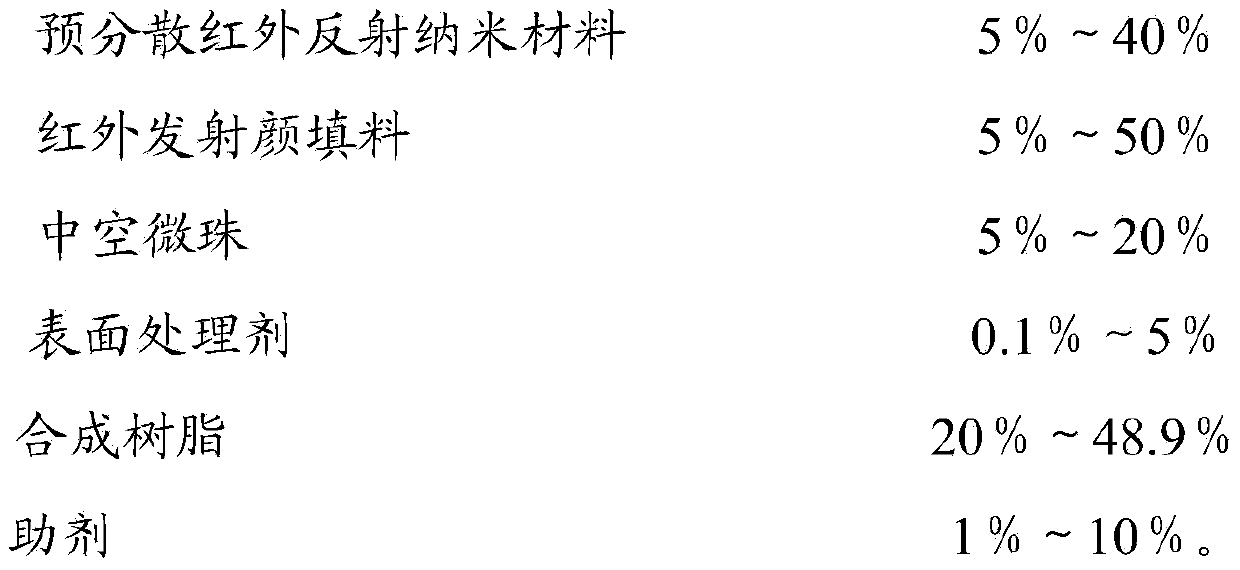

The invention relates to the technical field of plastic, and in particular relates to infrared reflection / emission thermal-insulating plastic functional master batch and a preparation method thereof. The master batch comprises the following components in percentage by weight: 5-40% of pre-dispersed infrared reflection nano material, 5-50% of infrared emission pigment packing, 5-20% of hollow micros beads, 0.1-5% of surface treating agent, 20-48.9% of synthetic resin and 1-10% of additive. Infrared reflection / emission thermal-insulating plastic made of the master batch can replace infrared reflection thermal-insulating coatings in multiple fields, and not only is the time and labor waste in spraying coatings avoided, but also environment pollution caused by organic solvent volatilization is avoided.

Owner:东莞市普凯塑料科技有限公司

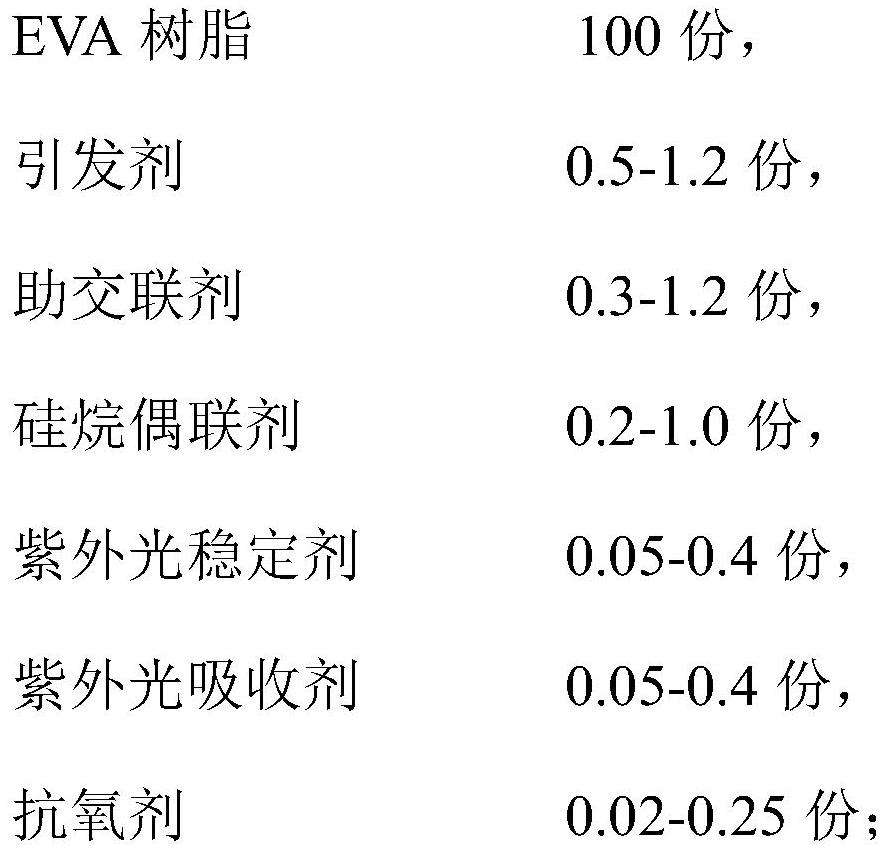

Three-layer co-extrusion composite adhesive film for packaging photovoltaic module and preparation method thereof

PendingCN111793442AGood compatibilitySolve the bubblesNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceTransmittance

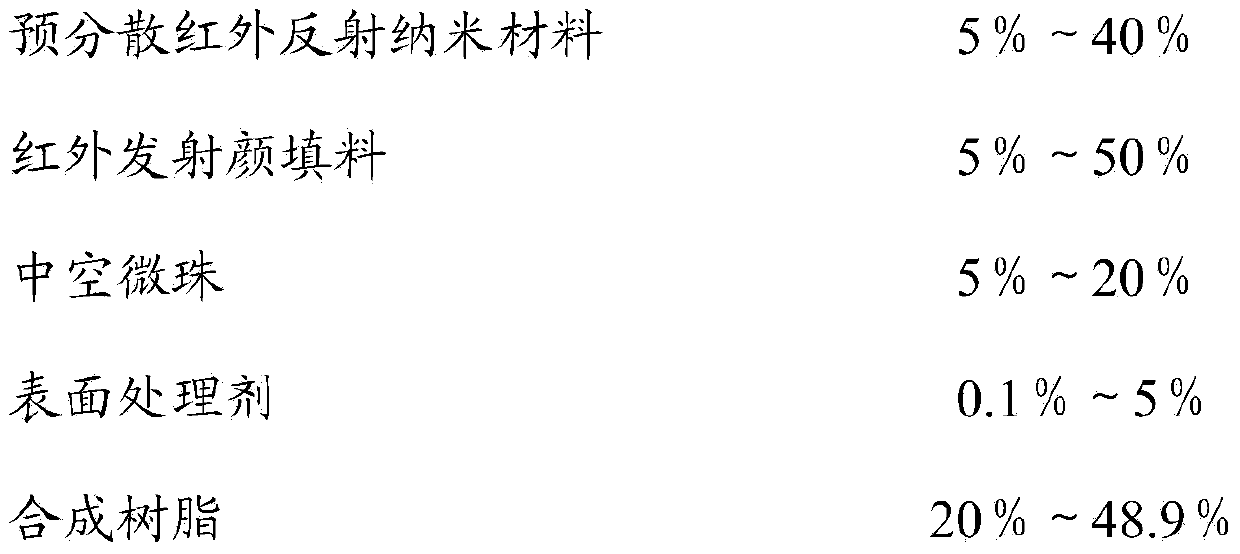

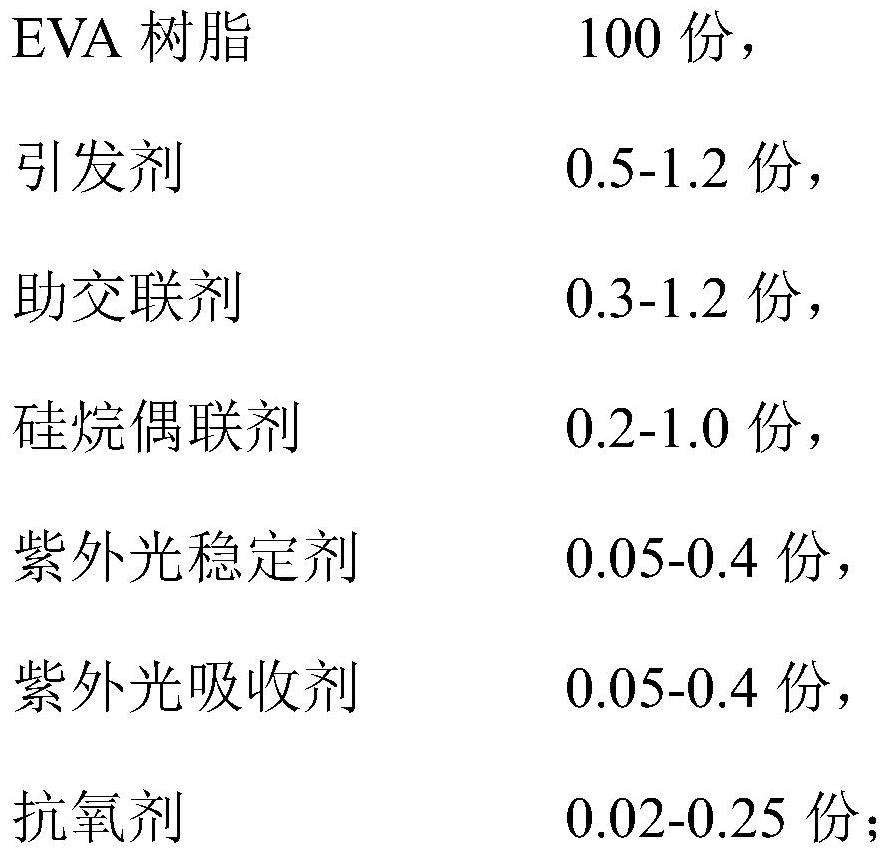

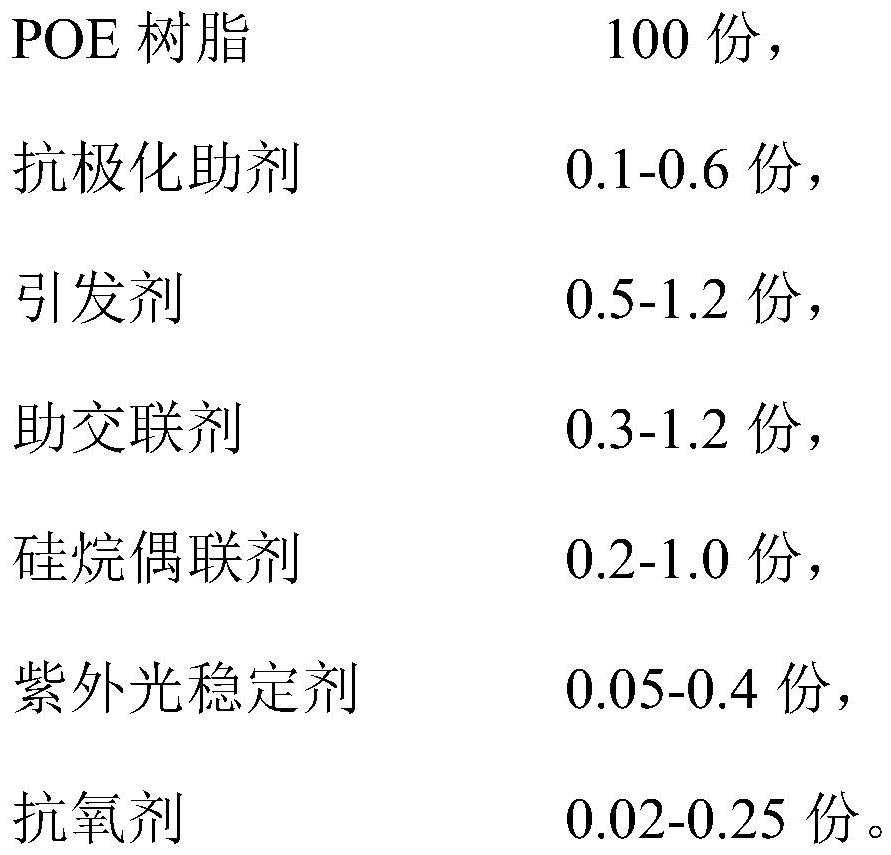

The invention relates to the technical field of photovoltaic module packaging adhesive films, in particular to a three-layer co-extrusion composite adhesive film for packaging a photovoltaic module and a preparation method thereof. The composite adhesive film comprises EVA layers, a POE anti-polarization layer and an EVA layer which are sequentially arranged from top to bottom, wherein EVA resin has a melt flow rate of 5 g / 10 min-30 g / 10 min, light transmittance of larger than 85%, volume resistivity of larger than or equal to 1.0 * 10<14>, melting temperature of 30-80 DEG C, and VA content of5-30%; POE resin has a melt flow rate of 3 g / 10 min-20 g / 10 min, light transmittance of greater than 86%, volume resistivity of greater than or equal to 1.0 * 10<15> and melting temperature of 30-80DEG C. The EVA layers are adopted on the two sides of the composite adhesive film, the compatibility of the EVA layers and polar auxiliaries is good, and the problems of bubbles, slippage and piece combining during assembly laminating can be solved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

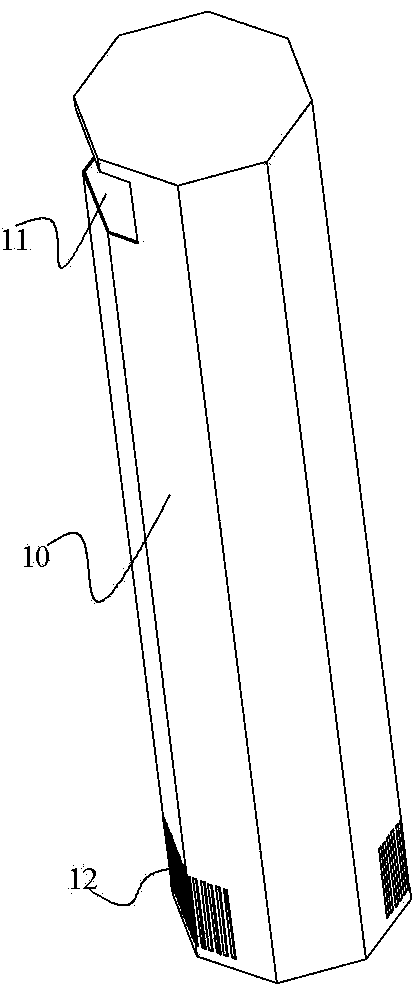

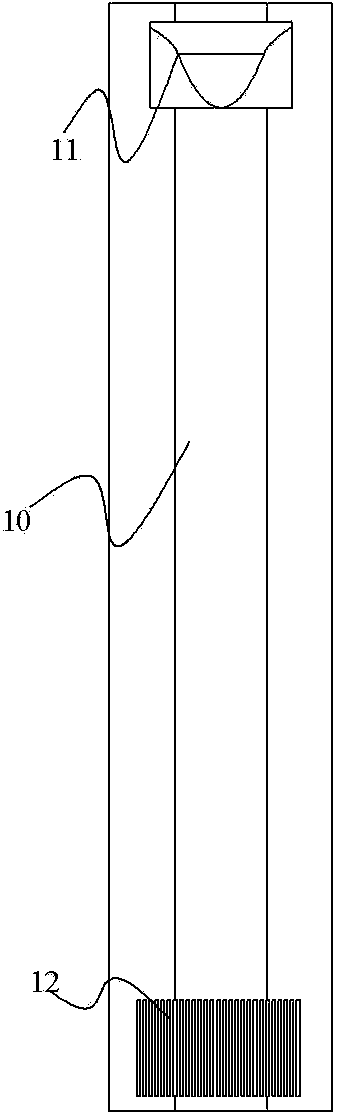

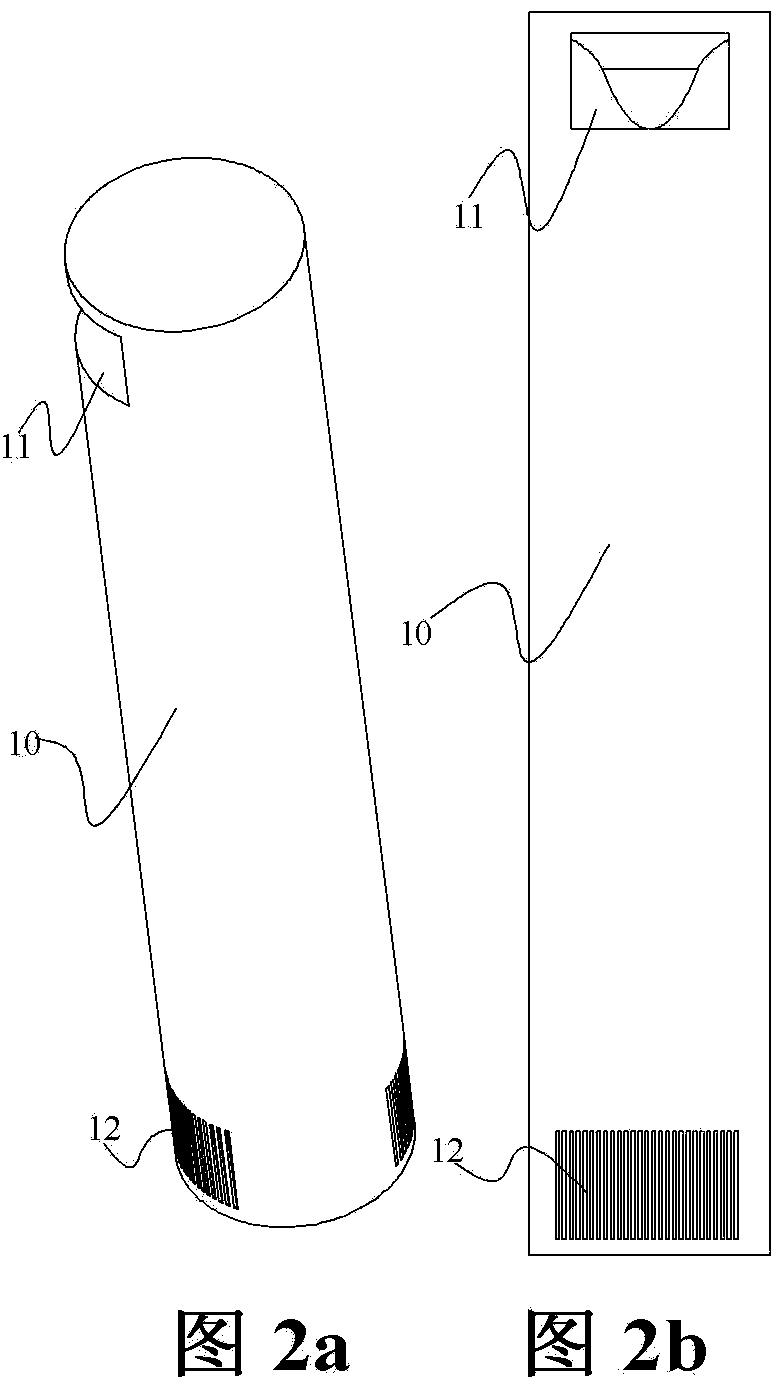

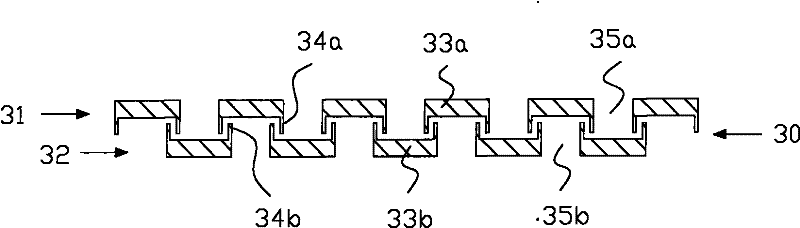

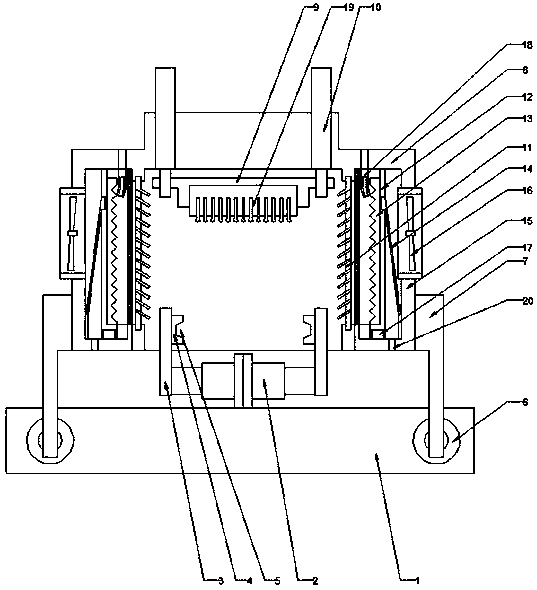

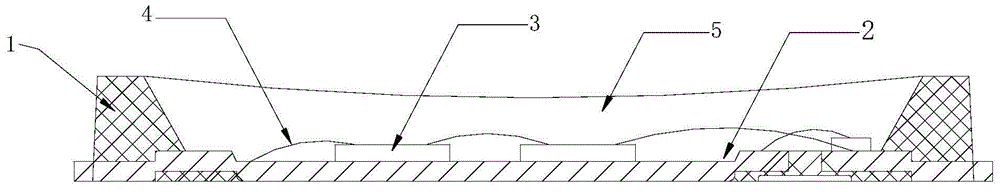

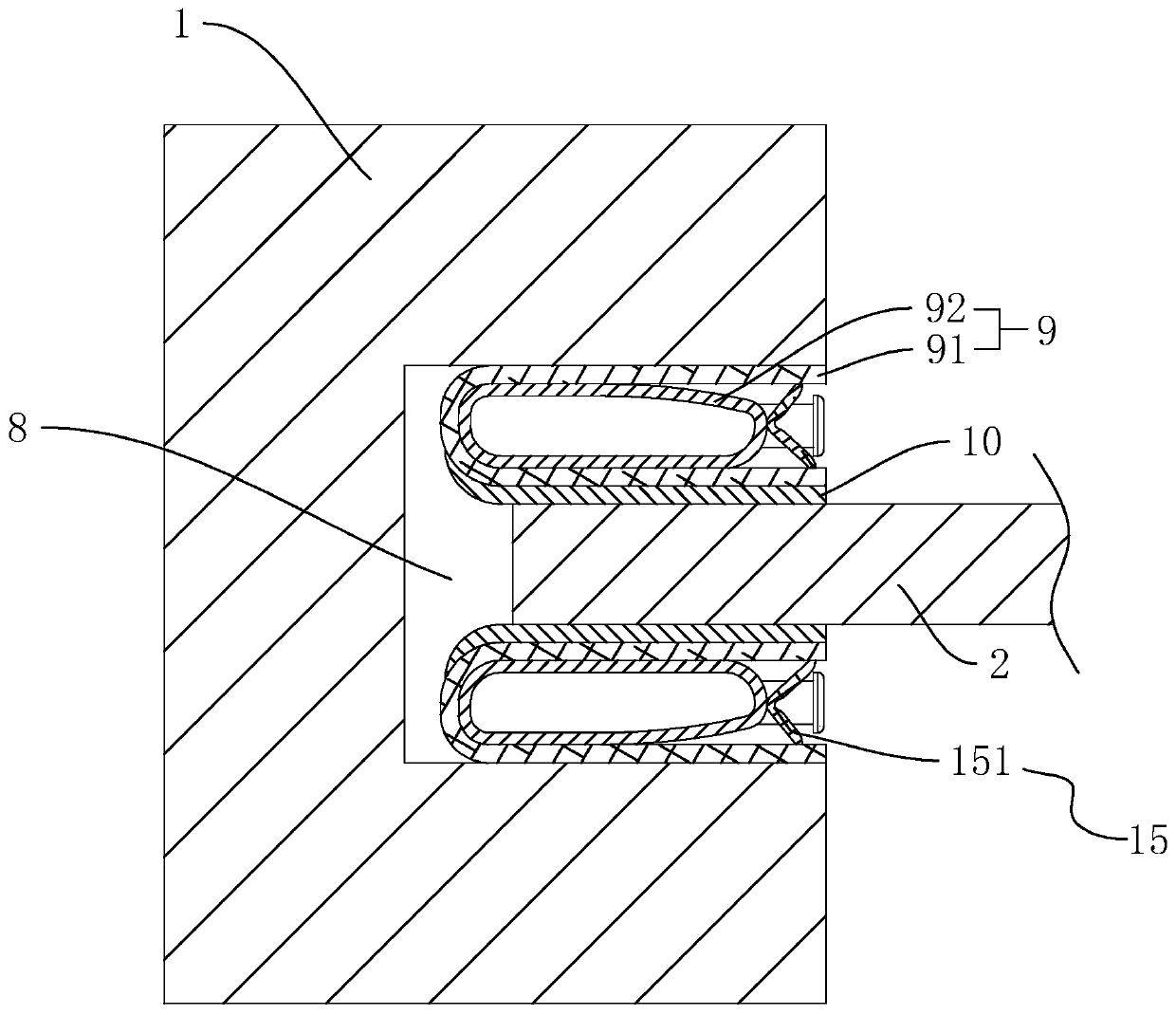

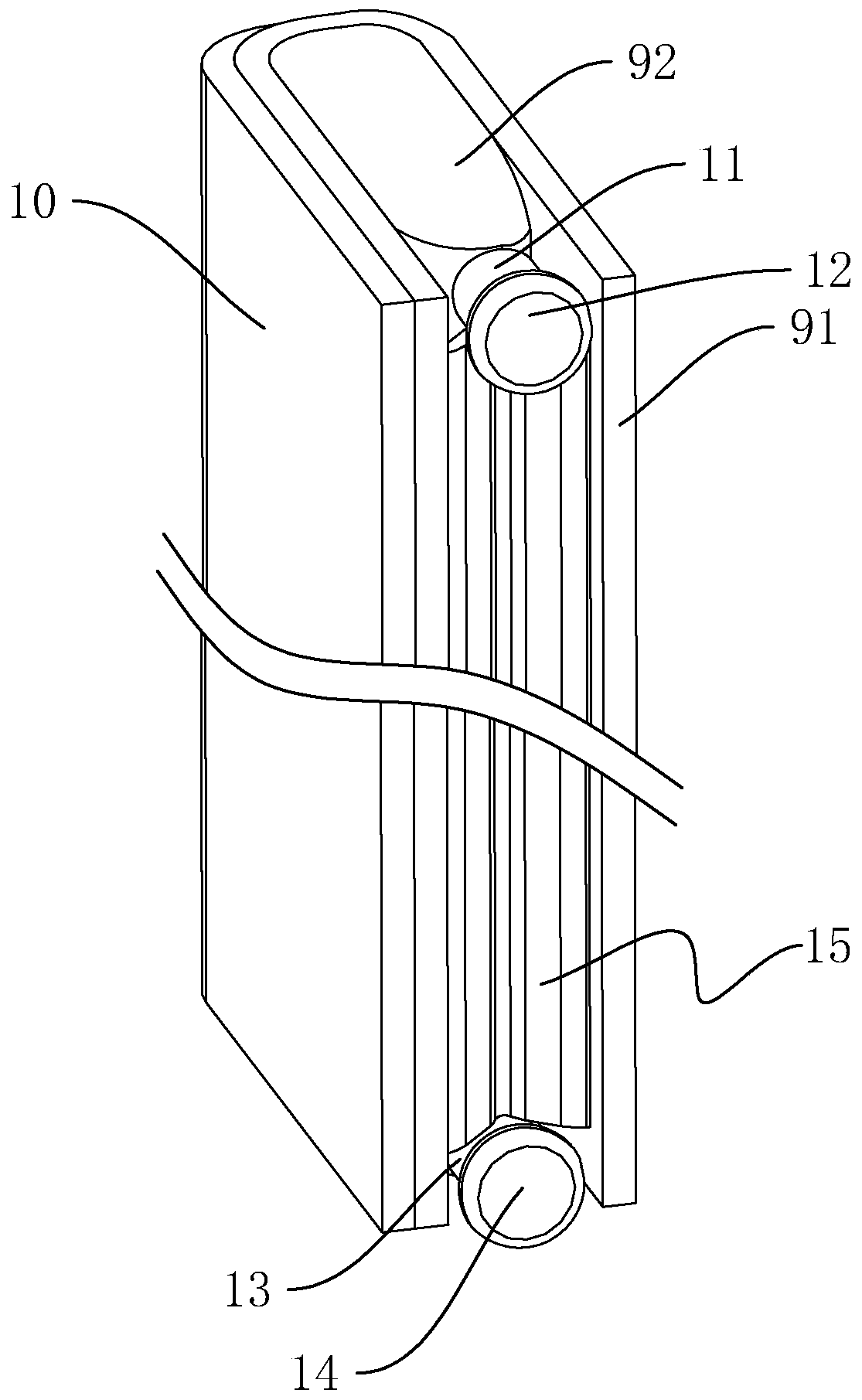

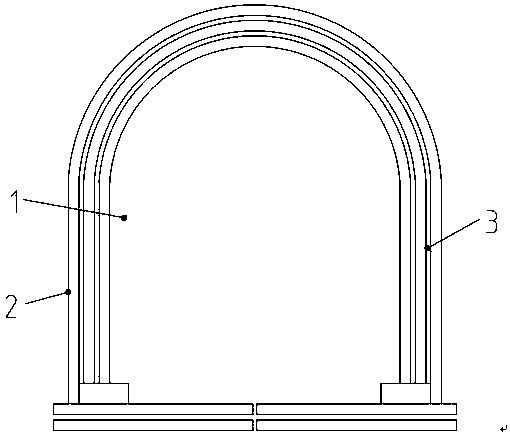

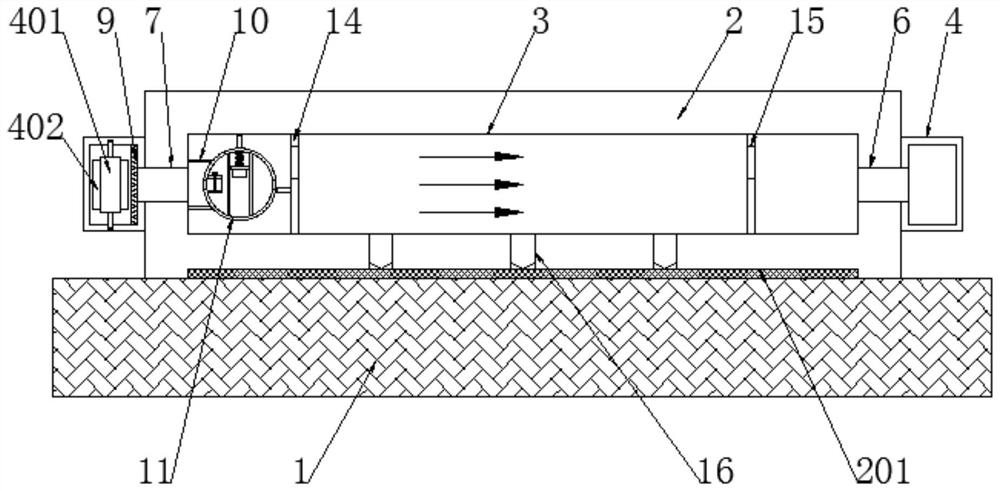

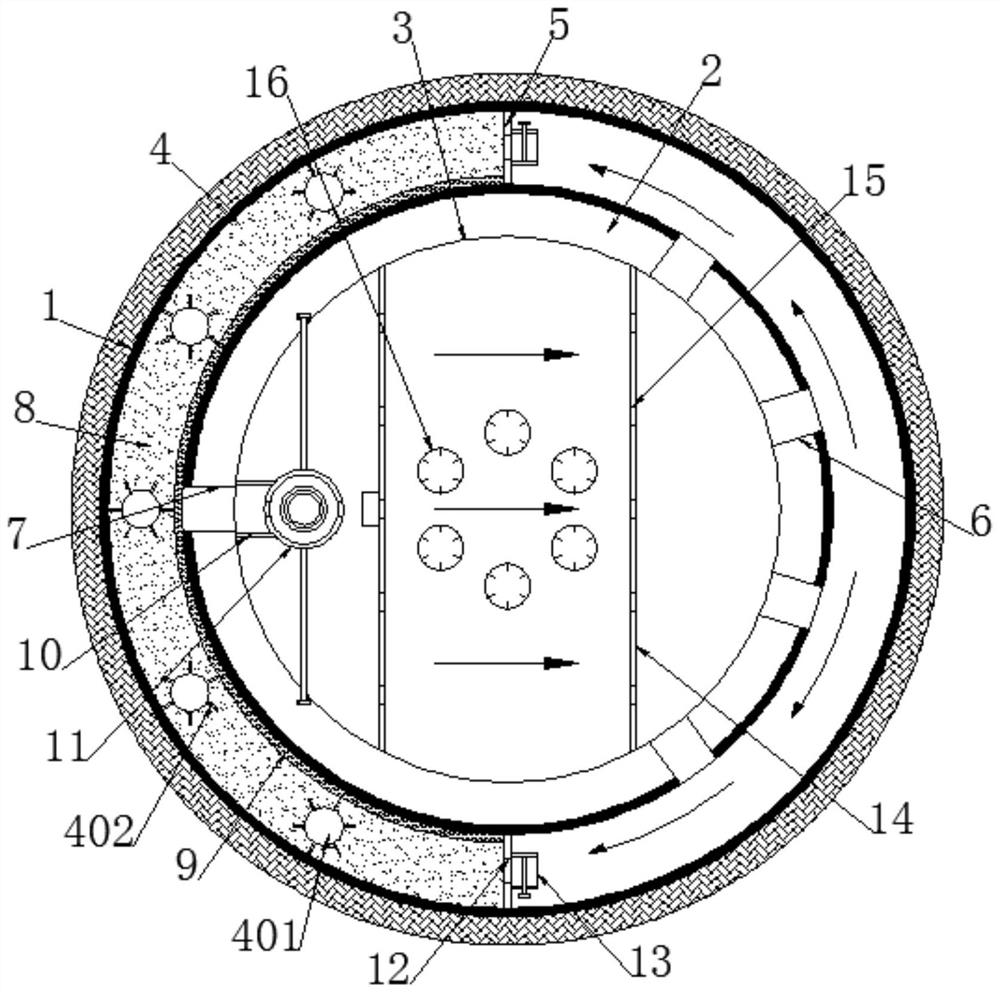

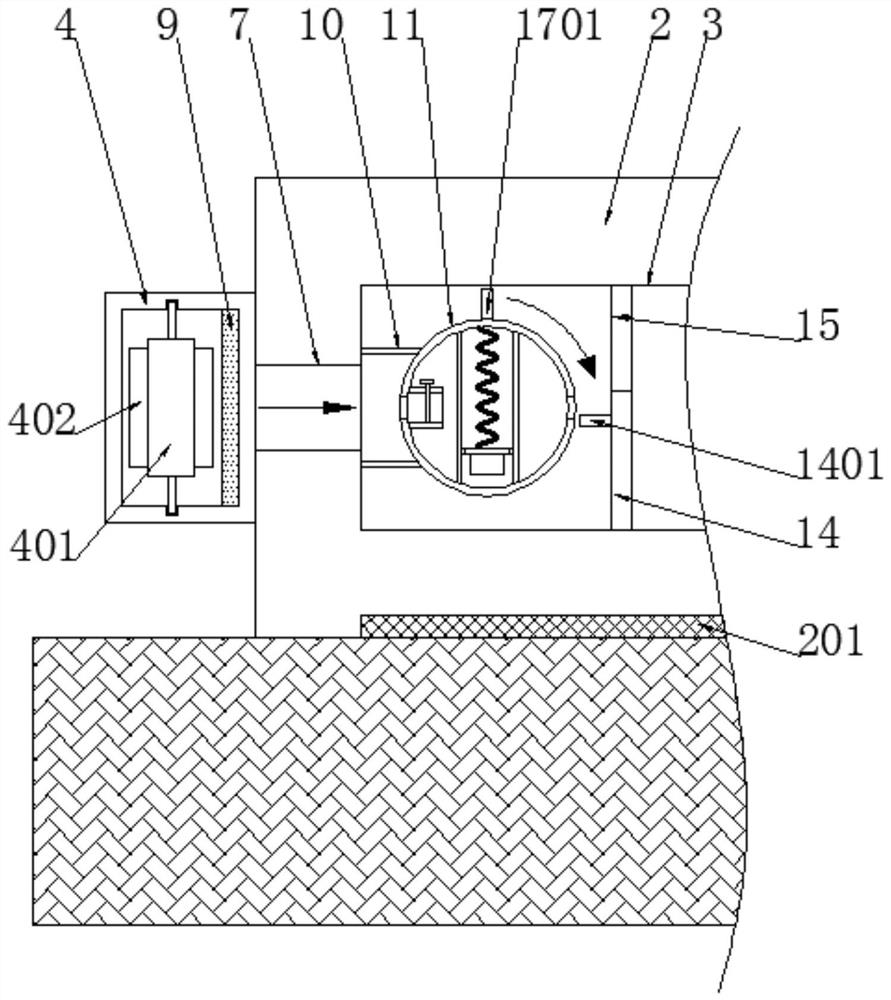

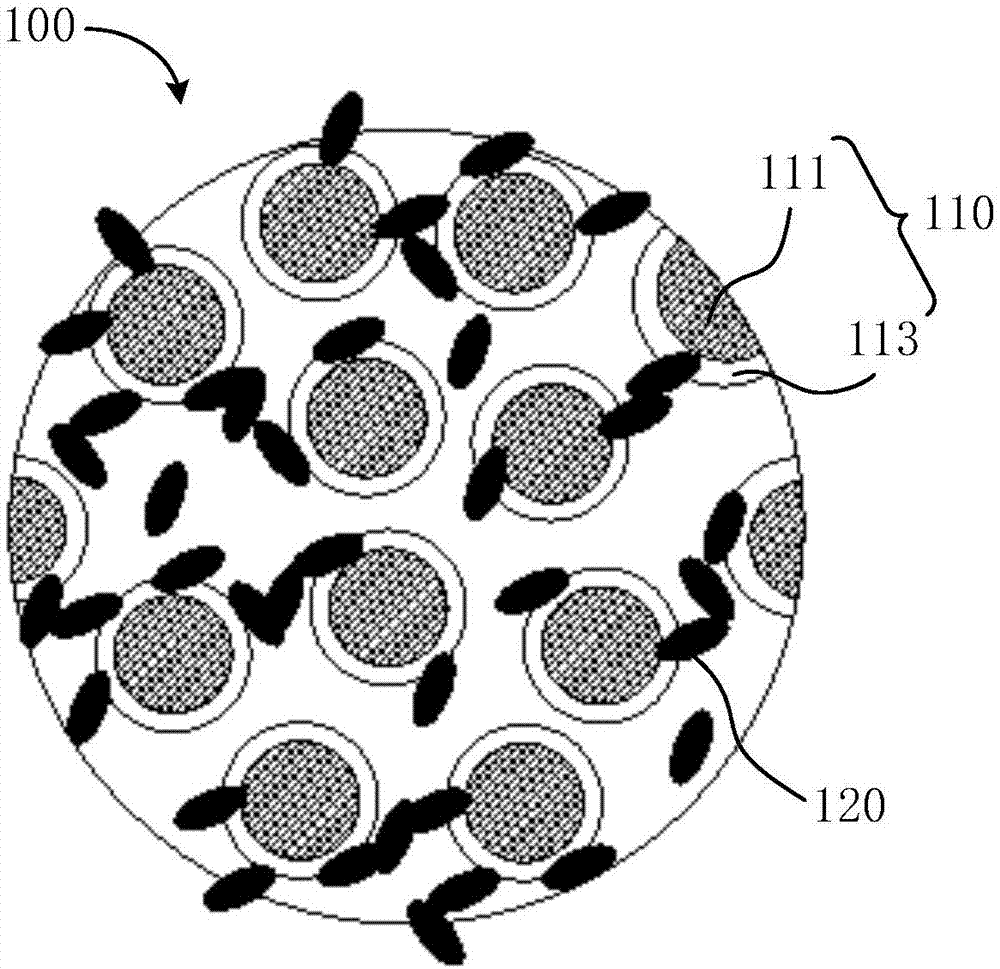

Drum-shaped evaporator and cabinet air conditioner with drum-shaped evaporator

ActiveCN103776203AReduce throughReduced velocity across the evaporatorEvaporators/condensersSpace heating and ventilation detailsEngineeringAirflow

The invention provides a drum-shaped evaporator and a cabinet air conditioner with the drum-shaped evaporator. The drum-shaped evaporator comprises a drum-shaped evaporator body, one of the inner circumference side and the outer circumference side of the evaporator body is the air inlet side, and the other is the air outlet side. The cabinet air conditioner comprises a casing, the upper portion of the casing is provide with an air outlet, the lower portion of the casing is provided with an air inlet, and the drum-shaped evaporator located between the air inlet and the air outlet is further arranged in the casing in the vertical direction. By arranging the evaporator into the drum shape, enabling one of the inner circumference side and the outer circumference side to be the air inlet side and enabling the other to be the air outlet side, even if air flow flows into the drum-shaped evaporator from the periphery of the drum-shaped evaporator or flows out of the drum-shaped evaporator to the periphery of the drum-shaped evaporator, a heat exchange area between the air flow and the evaporator is the whole circumference, the heat exchange area of the evaporator is effectively enlarged, the speed of the air flow penetrating through the evaporator is reduced, the air flow and the evaporator perform heat exchange fully, and the heat exchange effect is improved.

Owner:GREE ELECTRIC APPLIANCES INC

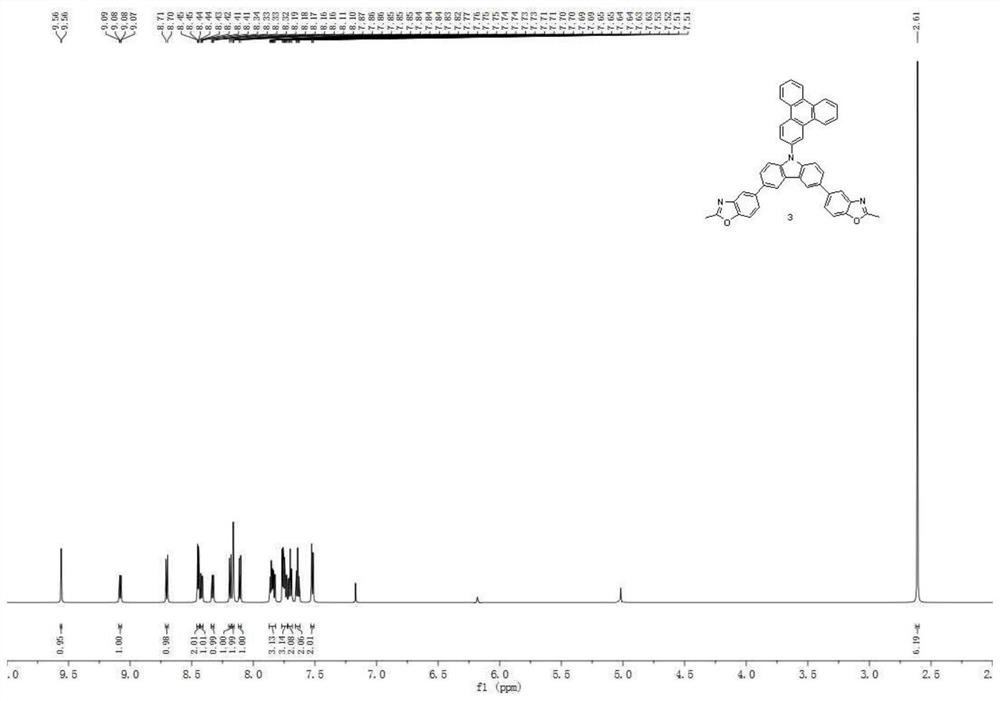

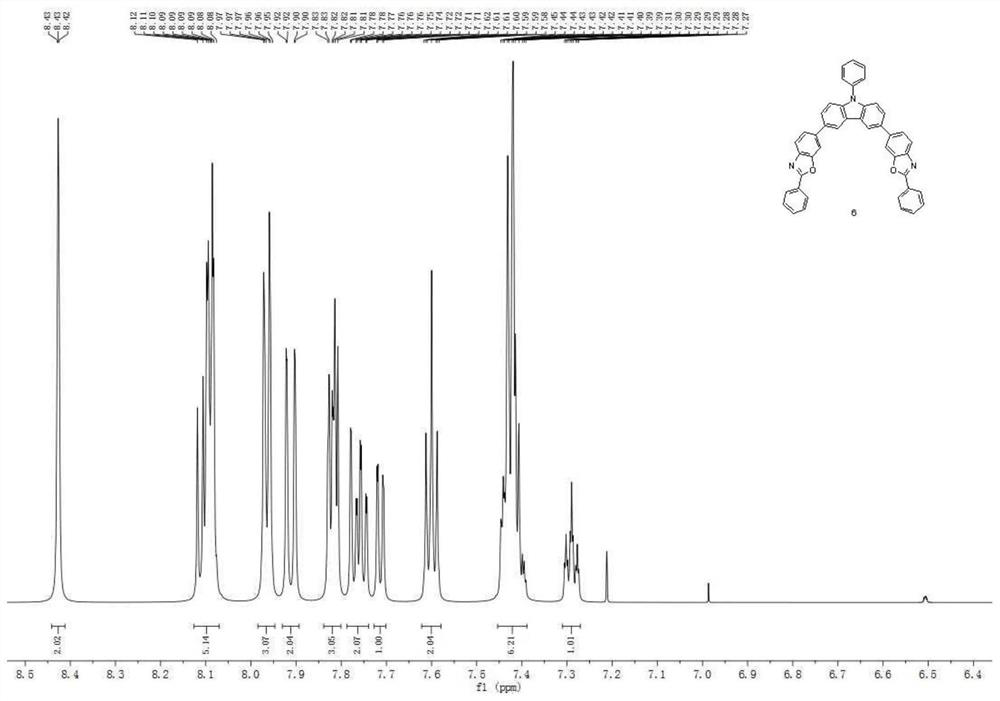

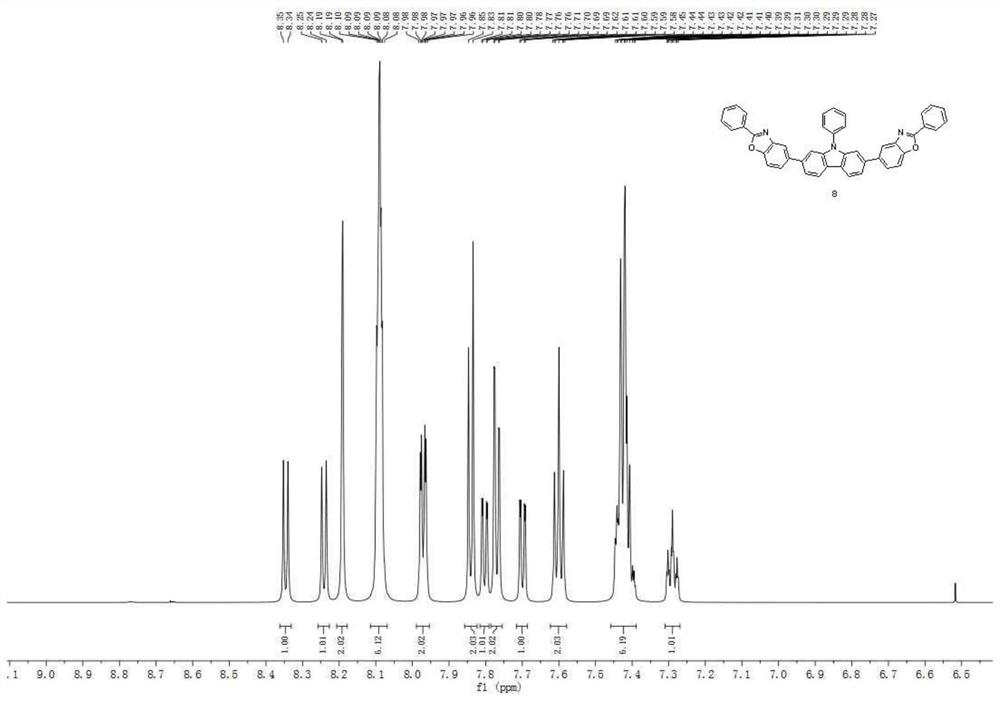

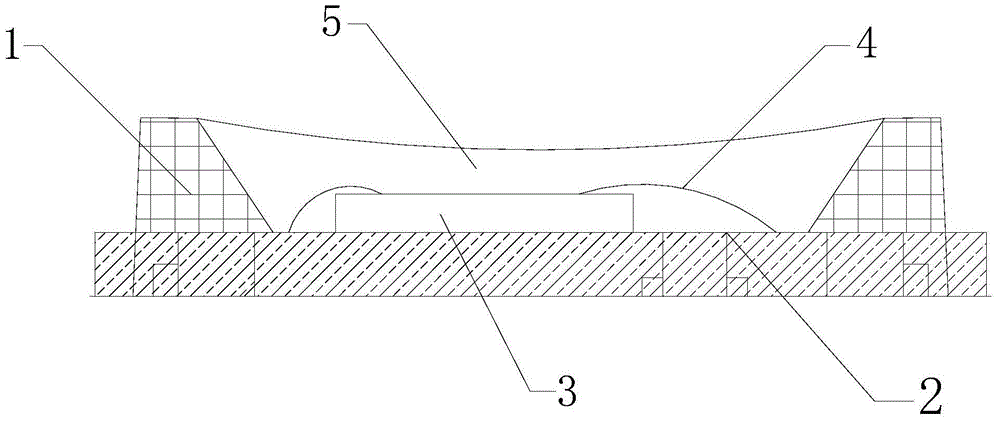

Carbazole-containing compound and organic electroluminescent device thereof

ActiveCN111777602AHigh temperature resistantImprove stabilityOrganic chemistrySolid-state devicesCarbazoleUltraviolet lights

The invention provides a carbazole-containing compound and an organic electroluminescent device thereof, and belongs to the technical field of organic photoelectric materials. In order to improve theluminous efficiency of the device and prolong the service life of the device, the carbazole-containing compound provided by the invention has high temperature resistance and ultraviolet light resistance, has good film stability and durability when being used as a covering layer, can effectively reduce the adverse effect of ultraviolet light in sunlight on organic materials in the device, thereby delaying the aging of the organic material and further prolonging the service life of the device; meanwhile, the carbazole-containing compound has a high refractive index, so that total reflection of light in the device can be reduced, and the luminous efficiency of the device is further improved. Therefore, the carbazole-containing compound provided by the invention is an OLED material with excellent performance.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

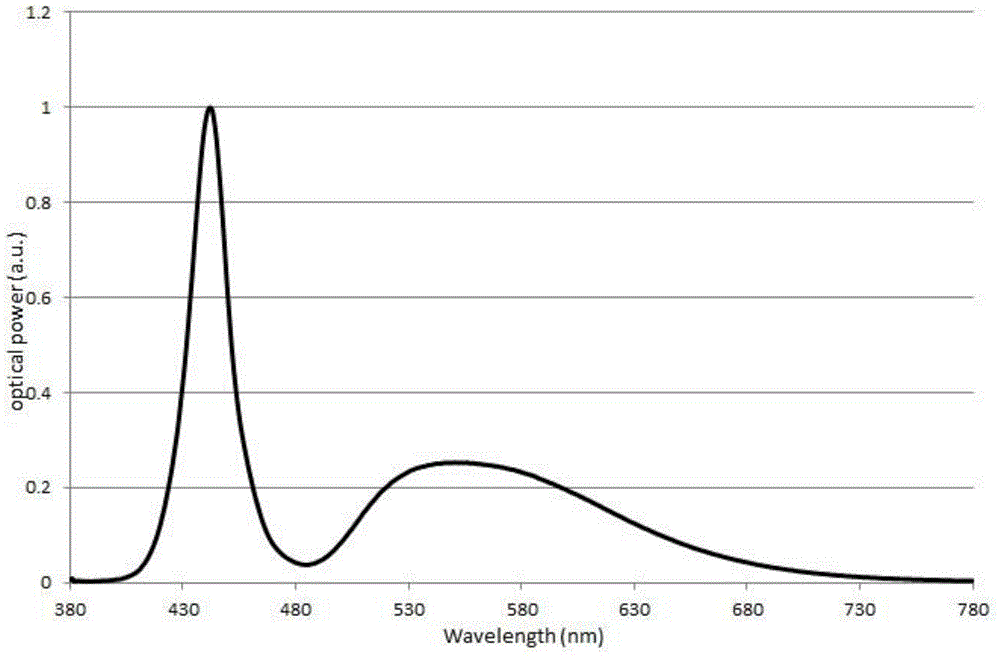

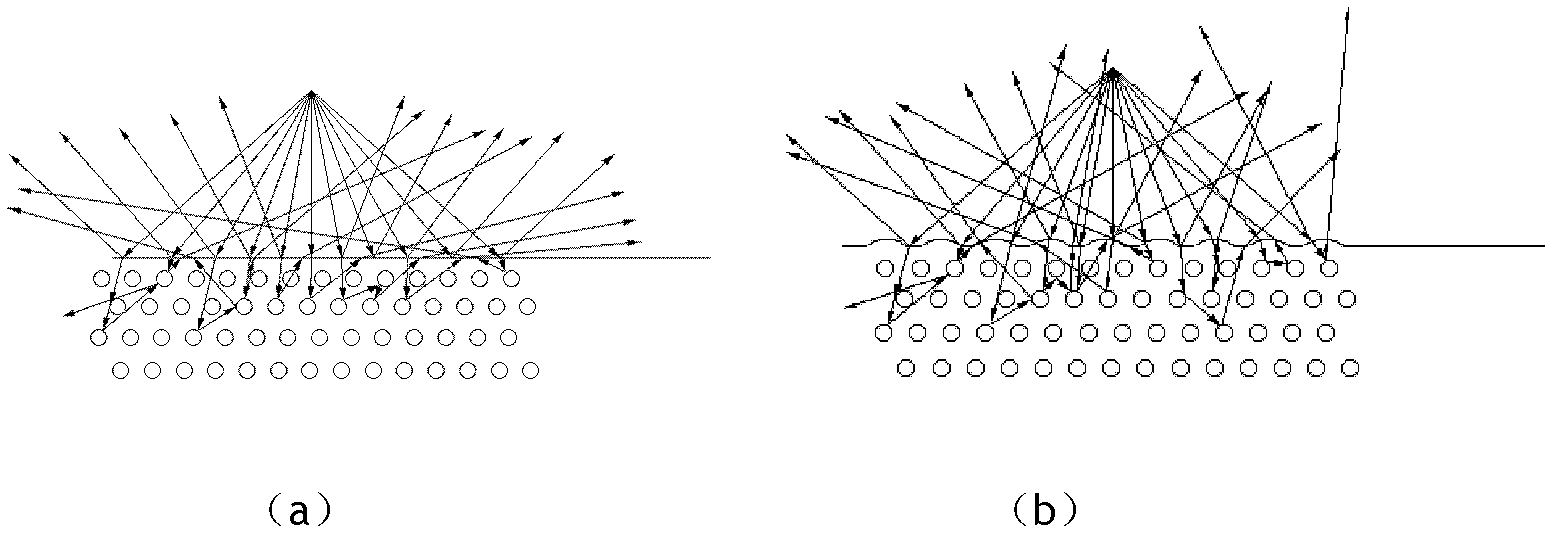

An under-screen optical system and an electronic device

ActiveCN109240021AAchieve hiddenImprove experienceCamera filtersTelephone set constructionsVisibilityOptical Module

The invention is applicable to the field of electronic technology, and provides an under-screen optical system and an electronic device. The under-screen optical system comprises a transparent displayscreen, an optical module and an optical filter. The transparent display screen comprises a plurality of periodically arranged pixel units for display. The optical module is used for receiving lightbeams from the transparent display screen or emitting light beams outward through the transparent display screen. The optical filter is disposed between the transparent display screen and the opticalmodule and configured to reduce transmission of visible light from one side of the transparent display screen. By arranging the filter between the transparent display screen and the optical module which can reduce the transmission of visible light from one side of the transparent display screen, the invention can realize the concealment and visibility of the optical module on the back of the display screen and the filter, and the mechanical structure thereof is not easy to be damaged, thereby realizing the overall screen, improving the display effect and the user experience.

Owner:SHENZHEN ORBBEC CO LTD

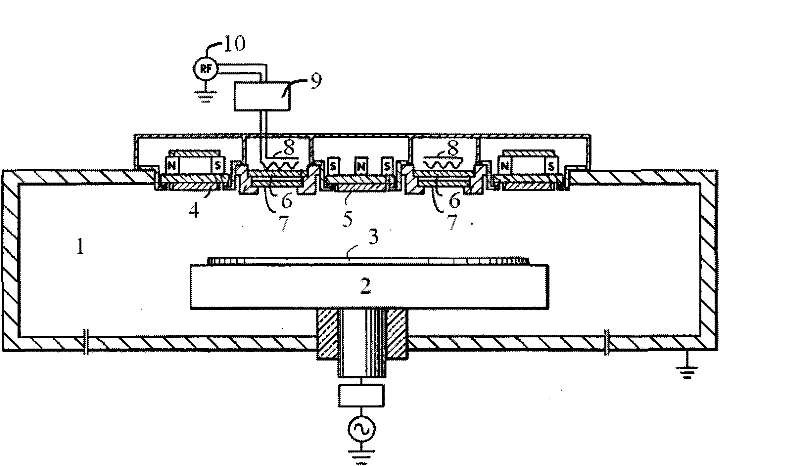

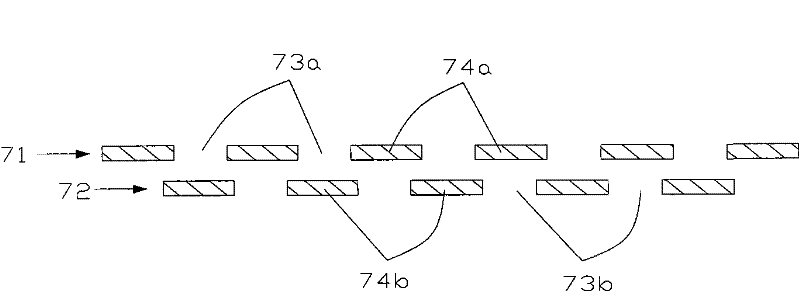

Faraday shield and plasma processing equipment

ActiveCN102543636AIncreased complexityReduced shieldingElectric discharge tubesEngineeringPlasma processing

The invention provides a Faraday shield and plasma processing equipment. The Faraday shield comprises at least two shield units which are arranged side by side, wherein each shield unit comprises a plurality of shield sections which are arranged at intervals, and the shield sections in the two adjacent shield units are arranged in a staggered mode; and the shield sections are provided with blocking parts of which the orientations are opposite and which are arranged in a staggered mode, and a shield channel is formed between the blocking parts of the two shield sections which are arranged in a staggered mode. According to the Faraday shield, plasma can be reduced and even prevented from passing through the Faraday shield by the blocking parts on the shield sections.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

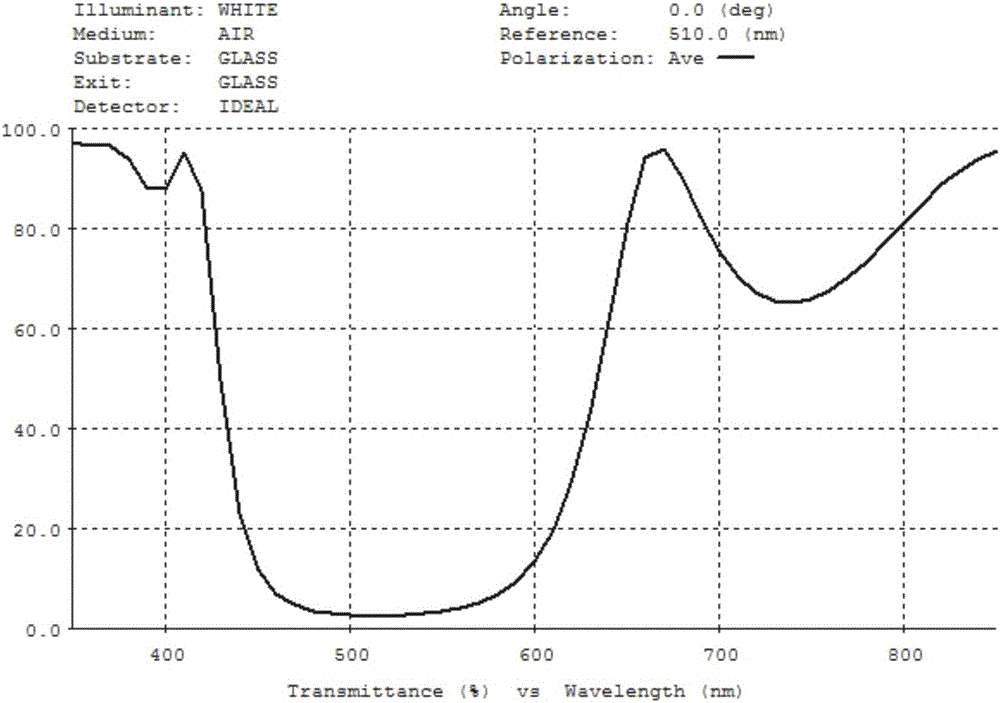

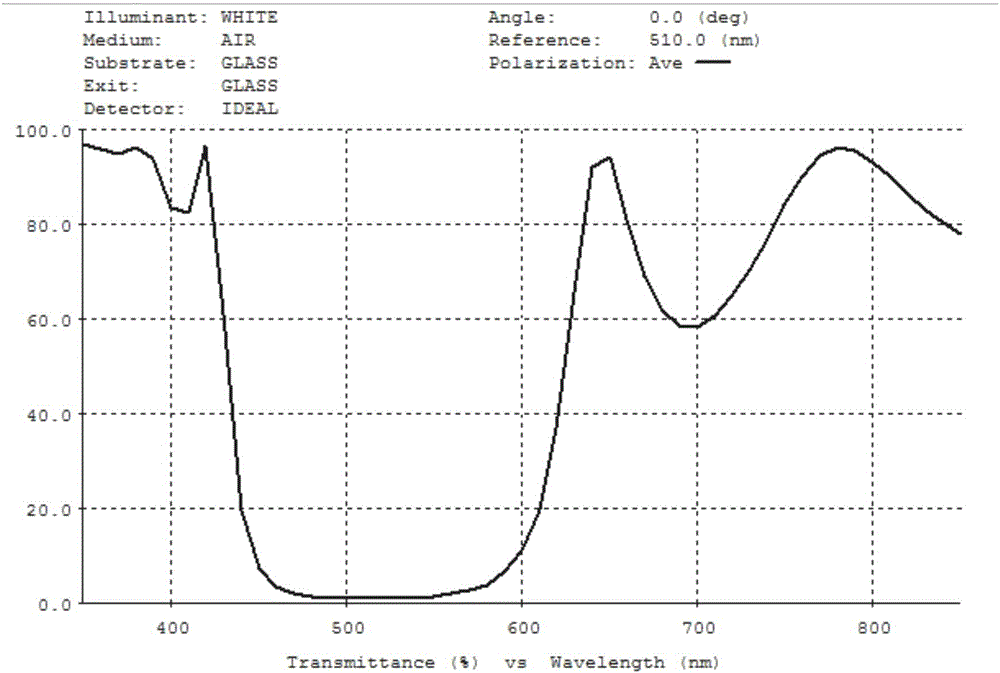

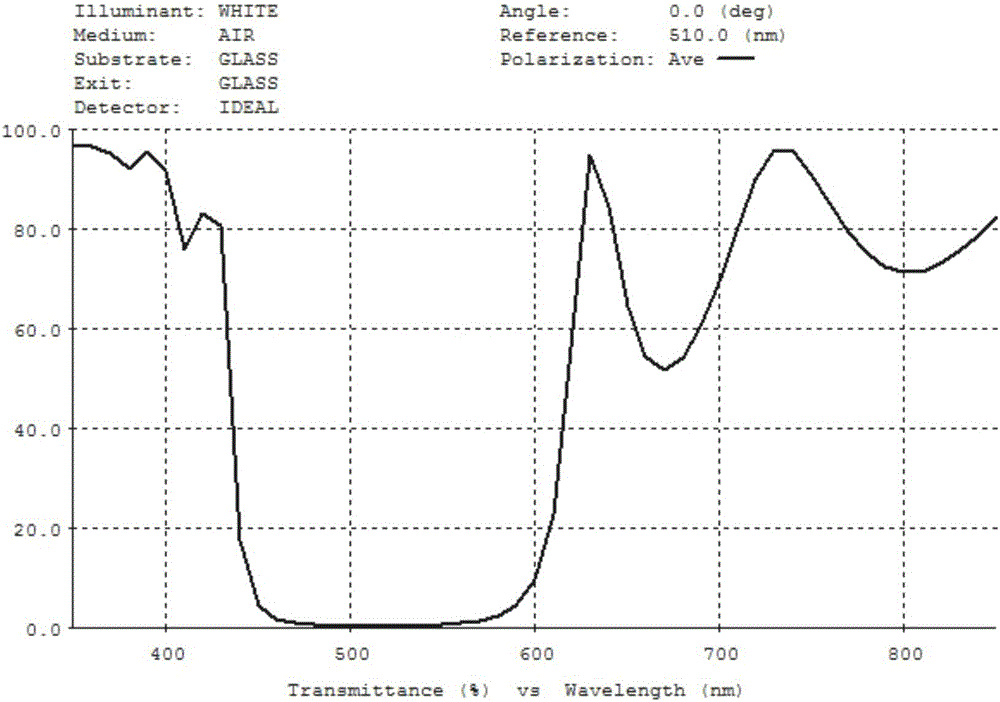

Filter coating and lamp filtering device

InactiveCN105759334AEasy to prepareEasy to adjust colorGlobesSpectral modifiersEngineeringOrganic glass

The present invention discloses a filter coating and a lamp filtering device. The filter coating is made by alternately overlaying a high-refraction material layer and a low-refraction material layer, wherein the optics thickness of each high-refraction material layer and each low-refraction material layer is different, partial wave band light can be filtered, and the light with required special wave band can be transmitted, so that the light with required color may be transmitted through the irradiation of a common light source. The filter coating is applied to a lamp and is formed by direct deposition on glass or organic glass lampshade through a vacuum vapor plating or sputtering mode and a lampshade with the filter coating is formed to allow a common lamp to emit prunosus light, and the filter coating is formed by direct deposition on glass or organic glass lamp frame or lamp ring through a vacuum vapor plating or sputtering mode and the lamp frame or the lamp ring with the filter coating is formed to allow the side wall of the common lamp to emit colorful light; and moreover, the color emitted by the lamp itself cannot be changed, the filter coating and the lamp filtering device are used for people to illuminate and beautifying the lamp.

Owner:张汉新

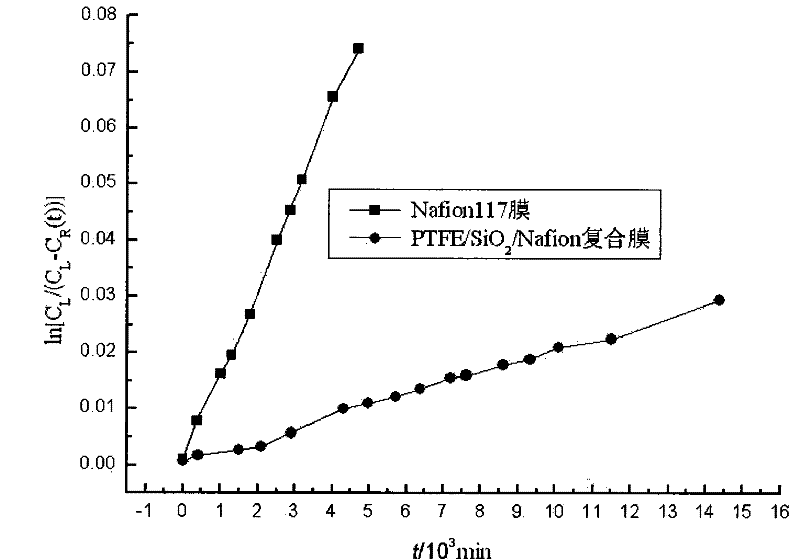

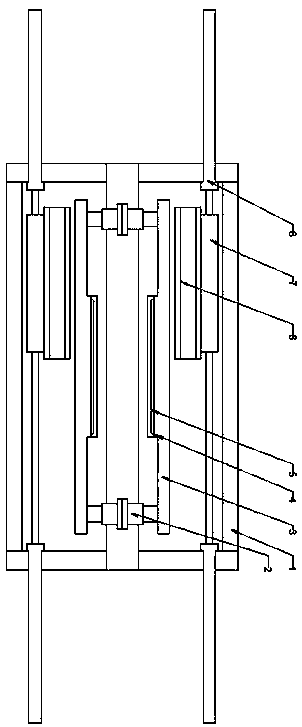

Electrolyte diaphragm for vanadium cell and preparation method thereof

InactiveCN102453262AImprove pore structureImprove mechanical propertiesFinal product manufactureCell component detailsTetrafluoroethyleneConductive polymer

The invention discloses an electrolyte diaphragm for a vanadium cell and a preparation method thereof. The method comprises the following steps of: (1) soaking a porous polyfluortetraethylene film in a mixed liquid consisting of methanol and water to obtain a mixed liquid I; and (2) uniformly mixing the mixed liquid consisting of methanol and ethyl orthosilicate with the mixed liquid I obtained in the step (1), reacting, taking an obtained porous polyfluortetraethylene film out after reacting, drying in vacuum, and soaking into a proton conductive polymer solution to obtain the electrolyte diaphragm for the vanadium cell. In the electrolyte diaphragm for the vanadium cell provided by the invention, the using amount of the proton conductive polymer with high price is reduced on the whole, and the cost of the electrolyte diaphragm is lowered; and nano-silicon dioxide is added, so that the pore diameter structure of an ion film can be effectively controlled, the permeation of vanadium ions is reduced, and the conservation of cell capacity is facilitated.

Owner:CHINA NAT OFFSHORE OIL CORP +2

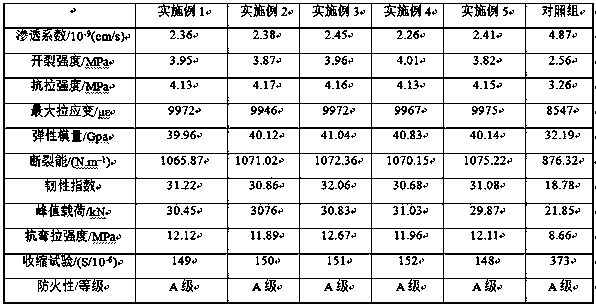

PVA-ECC (Polyvinyl Acetate-Engineered Cementitious Composite) high-toughness fiber cement based composite material and preparation method thereof

InactiveCN108675716AImprove liquidityImprove compactnessClimate change adaptationCelluloseMicrosphere

The invention belongs to the technical field of building materials and in particular relates to a PVA-ECC (Polyvinyl Acetate-Engineered Cementitious Composite) high-toughness fiber cement based composite material and a preparation method thereof. The PVA-ECC high-toughness fiber cement based composite material is prepared from the following components in parts by weight: 25 to 35 parts of 525 white cement, 40 to 60 parts of quartz sand, 18 to 20 parts of titanium white, 1 to 10 parts of pitchstone vitrified microspheres, 0.5 to 2 parts of PVA cellulose, 6 to 8 parts of ionic liquid, 10 to 12 parts of crop straw powder, 3 to 6 parts of clay, 3 to 5 parts of diatomite, 3 to 5 parts of maleic anhydride, 1 to 3 parts of crystal whiskers, 3 to 6 parts of a silane coupling agent, 0.5 to 2 partsof cellulose ether, 0.3 to 2 parts of redispersible latex powder, 0.1 to 3 parts of a high-efficiency water reducing agent, 0.5 to 2 parts of an inorganic pigment and 90 to 100 parts of water. The preparation method comprises the following steps: taking the maleic anhydride, the clay, the diatomite and the PVA cellulose as raw materials to prepare a PVA fiber / clay / diatomite nano composite material, and then mixing and stirring the PVA fiber / clay / diatomite nano composite material with other raw materials.

Owner:吴远怀

Integrated panel cleaning and painting device

ActiveCN110064559AImprove environmental performanceImprove versatilityCombination devicesPretreated surfacesElectrical and Electronics engineeringNozzle

The invention relates to an integrated panel cleaning and painting device. A panel clamping platform comprises two groups panel clamping plates; two groups of linear telescoping mechanisms A are arranged on a rack; a spraying and cleaning mechanism assembly is connected to the upper part of the panel clamping platform through the linear telescoping mechanisms A and comprises two groups of adsorption surface mechanisms; the two groups of adsorption surface mechanisms are located on two side wall surfaces of a support housing and comprise filter cavities located on the side wall surfaces of thesupport housing; air inlet plates arranged on the inner walls of the support housing are arranged on one sides of the filter cavities; division plates are arranged in the middles of the filter cavities; exhaust notches are arranged between the bottom parts of the division plates and the bottom parts of the filter cavities; adsorption plates are arranged on one sides, facing a blind window, of thedivision plates; water spraying pipes are arranged on the top parts of the filter cavities; exhaust outlets are formed in the exhaust wall surfaces, corresponding to the support housing, of the outersides of the filter cavities; and the spraying and cleaning mechanism assembly further comprises a nozzle mechanism which is arranged on a nozzle connecting plate.

Owner:江苏伟森家居有限公司

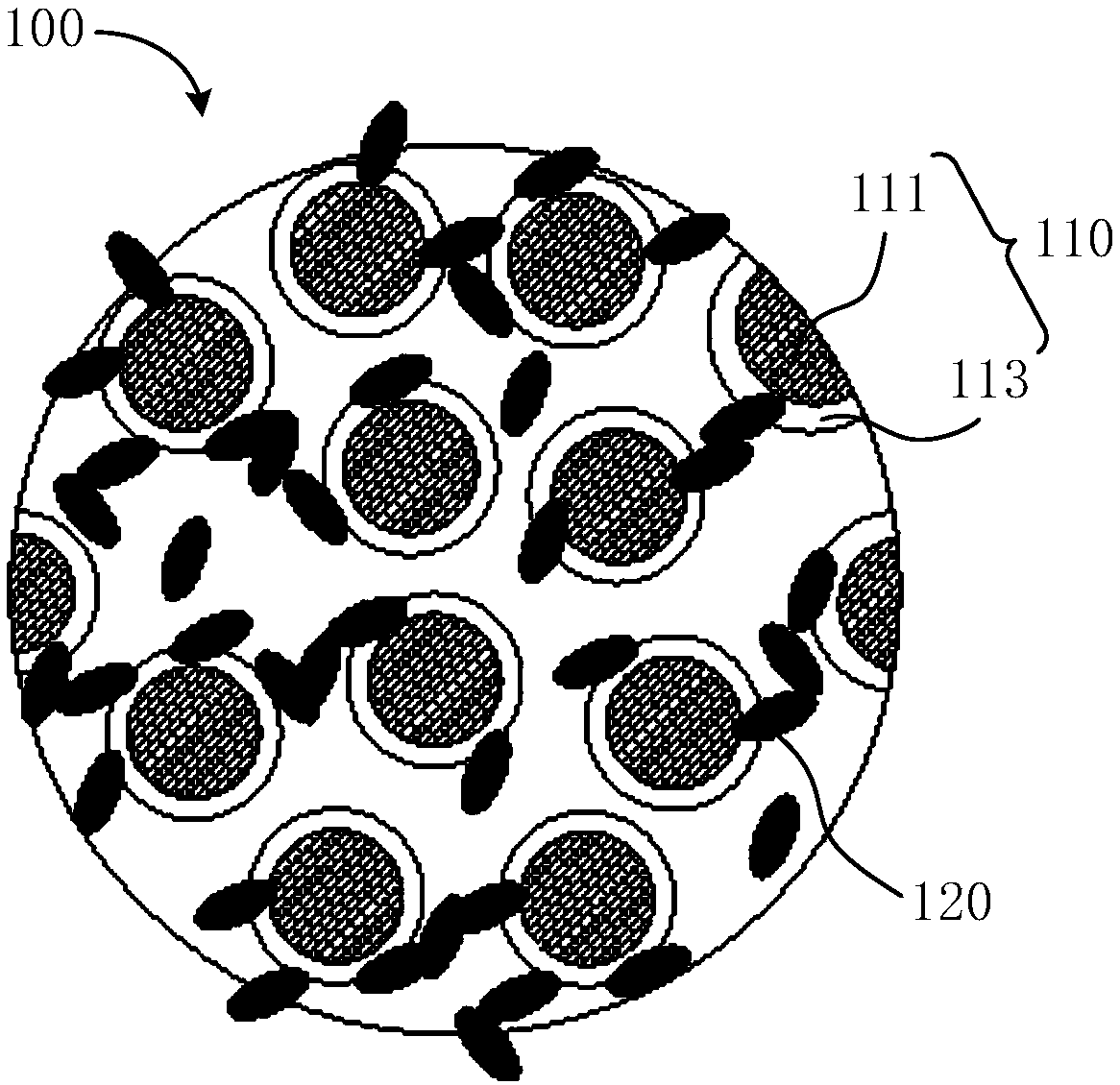

Light emitting diode (LED) device characterized by wide color gamut display

InactiveCN105355760AImprove excitation efficiencyOptimize locationSemiconductor devicesGamutLiquid-crystal display

The invention discloses a light emitting diode (LED) device characterized bywide color gamut display. The LED device comprises a package body, an LED chip module and fluorescent powder adhesive, wherein the package body is provided with a package groove, the LED chip module is arranged at the bottom of the package groove, a chip of the LED chip module is a blue-light chip, and the fluorescent powder adhesive is arranged in the package groove and formed by mixing fluoride K<2>SiF<6>.Mn<4+> multi-peak red fluorescent powder, green fluorescent powder and silica gel. Through substituting the traditional fluorescent powder by the fluoride K<2>SiF<6>.Mn<4+> multi-peak red fluorescent powder, the red-light excitation efficiency, chromaticity coordinate position and half-peak width of the LED device are effectively improved, the color gamut coverage rate of a liquid crystal display product is increased, and compared with nitride red fluorescent powder, the LED device has the advantages that the luminous efficiency is obviously improved.

Owner:SHINEON BEIJING TECH

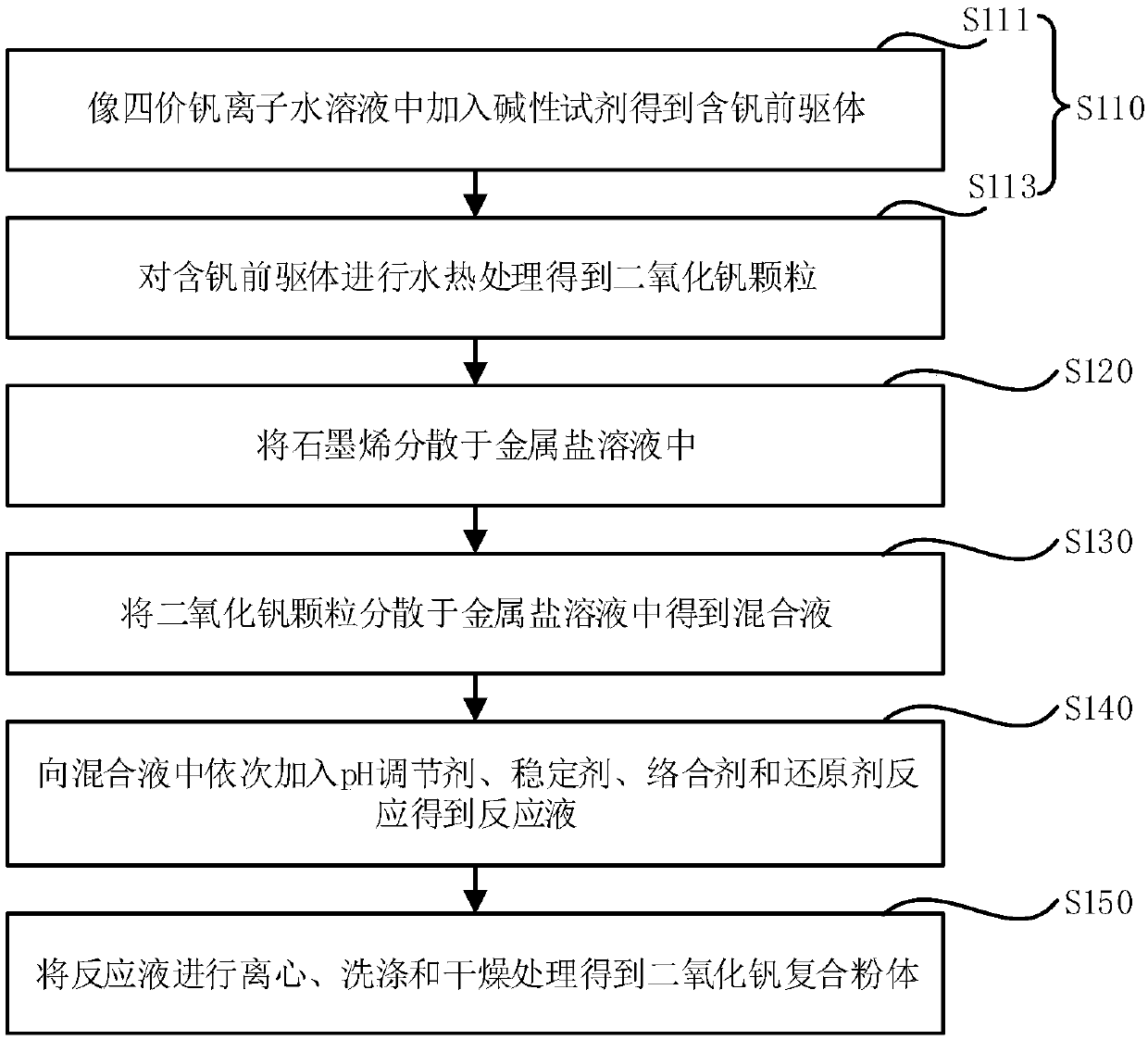

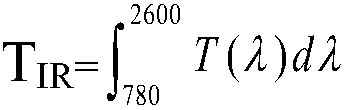

Graphene-containing vanadium dioxide composite powder and preparation method and application thereof

InactiveCN107916066AEnhanced electron transport capabilitiesImprove conductivityPolyurea/polyurethane coatingsEpoxy resin coatingsPlasma resonanceCore shell

The invention relates to a graphene-containing vanadium dioxide composite powder and a preparation method and application thereof. The graphene-containing vanadium dioxide composite powder consists ofcore-shell particles and graphene dispersed between the core-shell particles, each core-shell particle consists of a vanadium dioxide particle and metal, the metal wraps the surface of the vanadium dioxide to form a metal shell, and the mass ratio of the vanadium dioxide particles, the metal and the graphene is (70 to 98) to (1 to 20) to (1 to 10). Through the synergistic effect of the metal shells and the graphene of the graphene-containing vanadium dioxide composite powder, the high conductivity of the graphene-containing vanadium dioxide composite powder can be achieved, and the electron transfer capability and infrared transmission and reflection capability of the graphene-containing vanadium dioxide composite powder are increased. When temperature increases, plasma resonance is generated inside the vanadium dioxide particles, a conductive network formed by the vanadium dioxide particles, the metal shells and the graphene carries out the total reflection of infrared light, at themoment, the transmission and absorption of infrared rays can be greatly reduced, consequently, temperature rise is decreased, and the objective of energy saving is achieved.

Owner:广东华材实业股份有限公司

Smearing type intradermal injection capable of directly reaching dermis layer and preparation method thereof

ActiveCN105616187AKeep healthyRepair damageCosmetic preparationsToilet preparationsMedicineUltraviolet

The invention discloses smearing type intradermal injection capable of directly reaching the dermis layer and a preparation method thereof. The smearing type intradermal injection comprises, by weight, 10-30 parts of hyaluronic acid and 10-30 parts of collagen. The smearing type intradermal injection has the advantages that the smearing type intradermal injection is high in activity, appropriate in component and reasonable in combination, the smearing type intradermal injection can permeate the epidermis to reach the dermis layer when the smearing type intradermal injection is applied to the face or smeared to the epidermis of the skin, the hyaluronic acid and collagen lost due to aging are injected to allow the skin to absorb and store moisture with the weight being 1000 times of the weight of the skin, the regenerative function of cells is awakened, the withered and fractured cells of the skin are repaired again, the compact, smooth and elastic skin can be achieved again in a short time, effects of removing yellowness and whitening and resisting wrinkles and tightening the skin are achieved, the skin can restore elasticity, be transparent, bright and compact and form a moisture shield, different mechanisms are coordinated to bring an anti-ultraviolet effect into play, ultraviolet permeation can be reduced, the skin damage caused by the ultraviolet can be repaired, dual-protection and a good effect are achieved, and the smearing type intradermal injection has a quite good anti-allergic function.

Owner:티안지우안

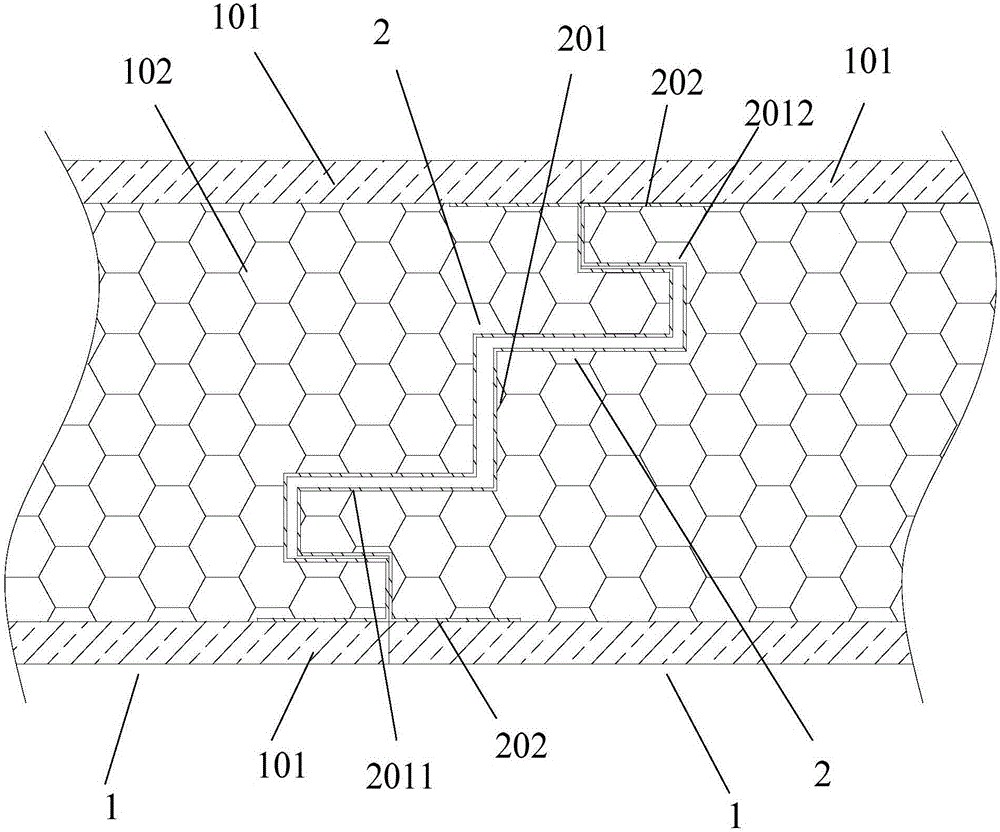

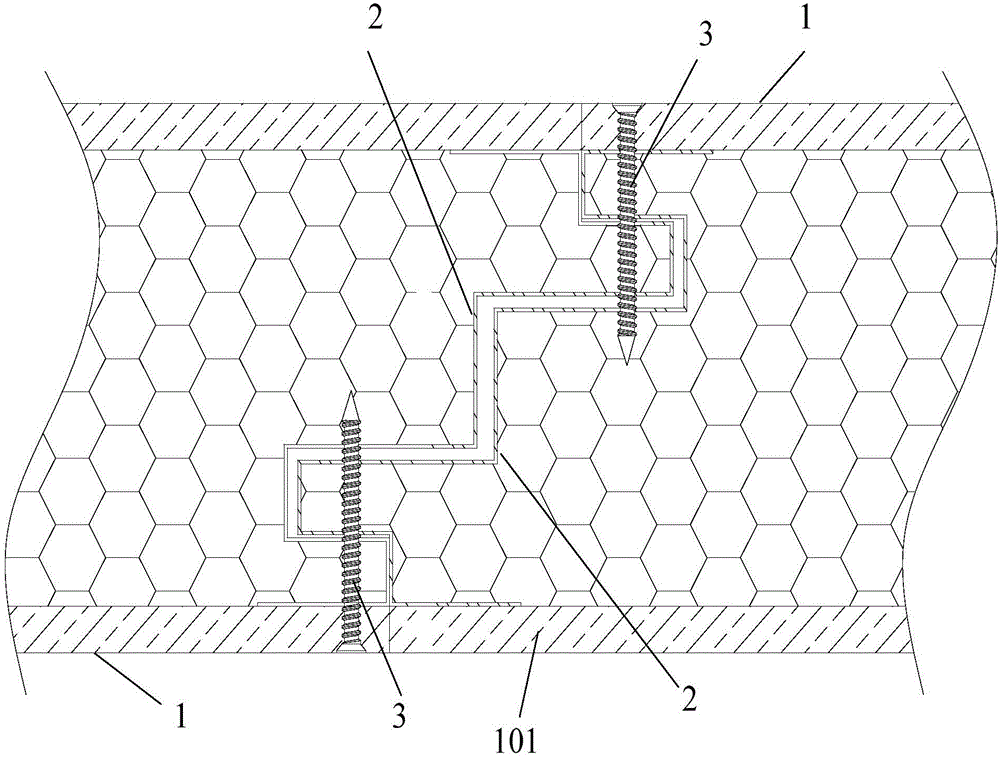

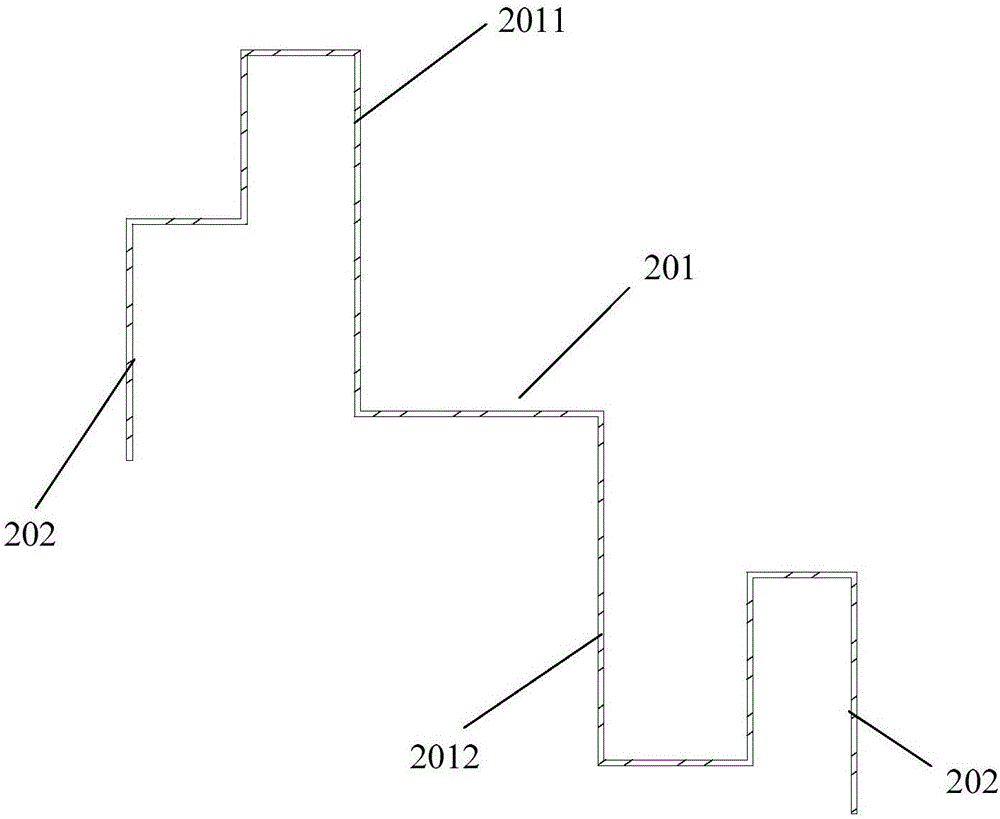

Structure and method of self-fit splicing for assembled walls

The invention discloses a structure of self-fit splicing for assembled walls. The structure comprises self-fit keels which are strip profiles; the self-fit keel comprises a base board and two wing boards installed at two sides of the base board; the base board, in the length direction, is provided with a projection trip protruding from the base board and a groove recessing in the base board; the self-fit splicing structure is provided with two identical self-fit keels which are vertically arranged between adjacent wall units, wherein one self-fit keel is embedded in one wall unit and the other one is horizontally rotated for 180 DEG and embedded in adjacent wall unit; the projection strip and groove of each self-fit keel are spliced with the groove and projection strip of another self-fit keel to form a self-fit splicing structure. The invention also discloses a method for splicing the above structure. The method comprises following steps: the self-fit keels are embedded and spliced. The invention relates to the field of buildings and provides a self-fit connecting structure for assembled walls, aiming at achieving better sealing performance and convenient splicing among assembled walls.

Owner:BEIJING NEW BUILDING MATERIALS PLC

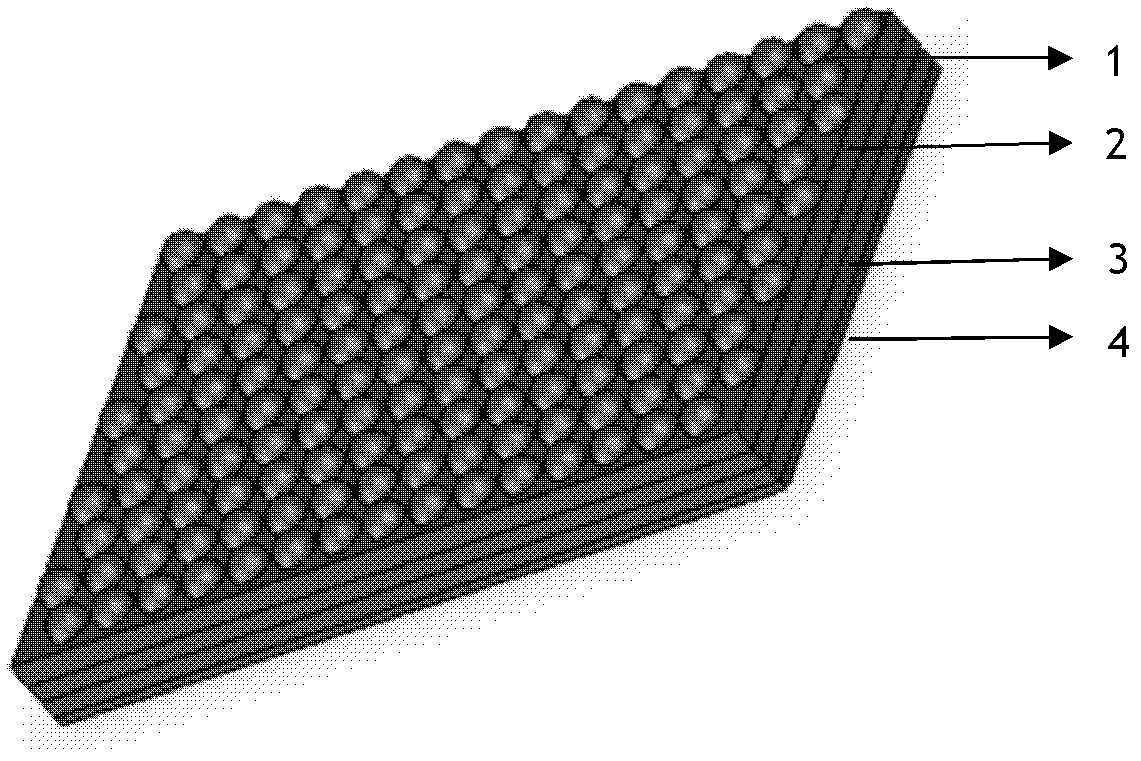

Polymer-based composite structure diffuse reflection material

InactiveCN102590906ATo achieve the purpose of graphic copy transferImprove reflectivityDiffusing elementsSurface layerDiffuse reflection

The invention relates to a polymer-based composite structure diffuse reflection material. The material is characterized in that: the diffuse reflection material, which is formed by multi-layer structures, comprises a microstructure surface layer material, a single layer or multi-layer intermediate material and a reflecting layer material. Specifically, the surface microstructure is a microlens array having a linear or non-linear geometrical characteristic; and the surface microstructure is in a microgroove type, a ball type, an ellipsoid type, a polygonal type, a paraboloidal type, a hyperboloidal type or a combined type. According to the invention, the prepared diffuse reflection high polymer material with the composite structure has advantages of high reflectivity and good diffuse reflection effect.

Owner:BEIJING UNIV OF CHEM TECH

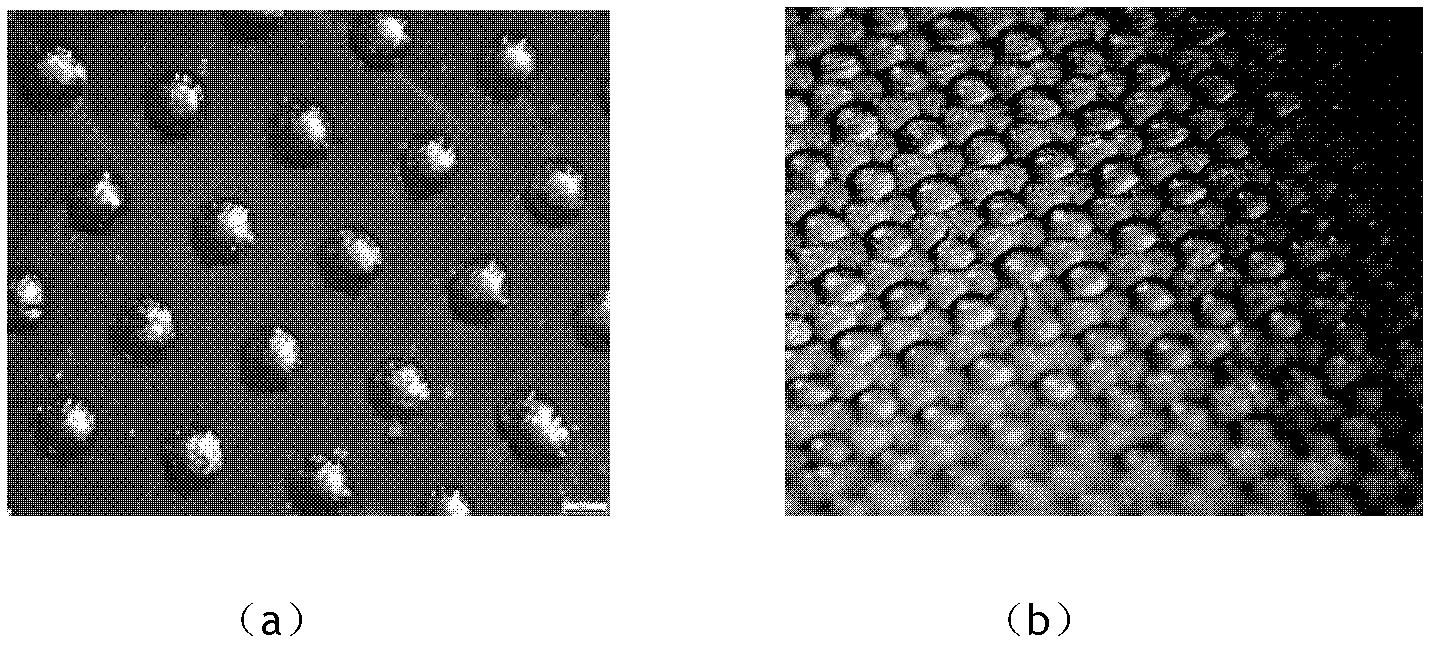

High-impermeability cement-based composite material and method for preparing same

The invention relates to a high-impermeability cement-based composite material and a method for preparing the same. The high-impermeability cement-based composite material comprises, by weight, 20-30parts of 525 white cement, 40-60 parts of quartz sand, 18-20 parts of titanium dioxide powder, 10-12 parts of fly ash, 5-15 parts of chitosan nanogel, 3-5 parts of polyacrylate emulsion, 1-10 parts ofpitchstone vitrified micro-spheres, 0.5-2 parts of PVA (polyvinyl alcohol) celluloses, 6-8 parts of ionic liquid, 10-12 parts of crop straw powder, 3-6 parts of clay, 3-5 parts of diatomaceous earth,3-5 parts of maleic anhydride, 1-3 parts of whiskers, 3-6 parts of silane coupling agents, 0.5-2 parts of cellulose ether, 0.3-2 parts of redispersible latex powder, 0.1-3 parts of superplasticizers,0.5-2 parts of inorganic pigment and 60-70 parts of water. The method includes preparing composite materials from the maleic anhydride, the clay, the diatomaceous earth and the PVA celluloses; mixingand stirring the composite materials and other raw materials with one another to obtain the high-impermeability cement-based composite material which is a product.

Owner:吴远怀

Method for synthetizing carbon-doped monoclinic phase mesoporous bismuth vanadate

InactiveCN103170325AImprove adsorption performanceExcellent photocatalytic performanceMetal/metal-oxides/metal-hydroxide catalystsCarbon dopedTube furnace

The invention relates to a method for synthetizing carbon-doped monoclinic phase mesoporous bismuth vanadate. The method comprises the steps of mixing silica aerogel microspheres, glucose and water according to the mass fraction ratio of 1 to (0.02-0.2) to (20-200), drying to obtain a compound as a template; taking nitric acid, ethanol and bismuth nitrate according to the mass fraction ratio of 1 to 15 to 0.5, and carrying out ultrasonic treatment to obtain bismuth nitrate solution; taking nitric acid, ethanol and ammonium metavanadate according to the mass fraction ratio of 1 to 15 to 0.125, and carrying out ultrasonic treatment to obtain ammonium metavanadate solution; slowly dripping the ammonium metavanadate solution into the bismuth nitrate solution to obtain a mixed solution; adding the template to the mixed solution, vacuuming to fully inject the mixed solution into the template, and reacting for 6-24 hours at 60-110 DEG C to obtain a solid product; heating the solid product to 200-600 DEG C at the heating speed of 0.5-10 DEG C.min<-1> in a tube furnace under the protection of nitrogen, and keeping constant temperature for 0.5-5 hours; and naturally cooling to room temperature and then removing the silica aerogel microspheres by sodium hydroxide solution to obtain carbon-doped monoclinic phase mesoporous bismuth vanadate. Carbon-doped monoclinic phase mesoporous bismuth vanadate disclosed by the invention has good photocatalytic performance within the range of a visible light.

Owner:TONGJI UNIV

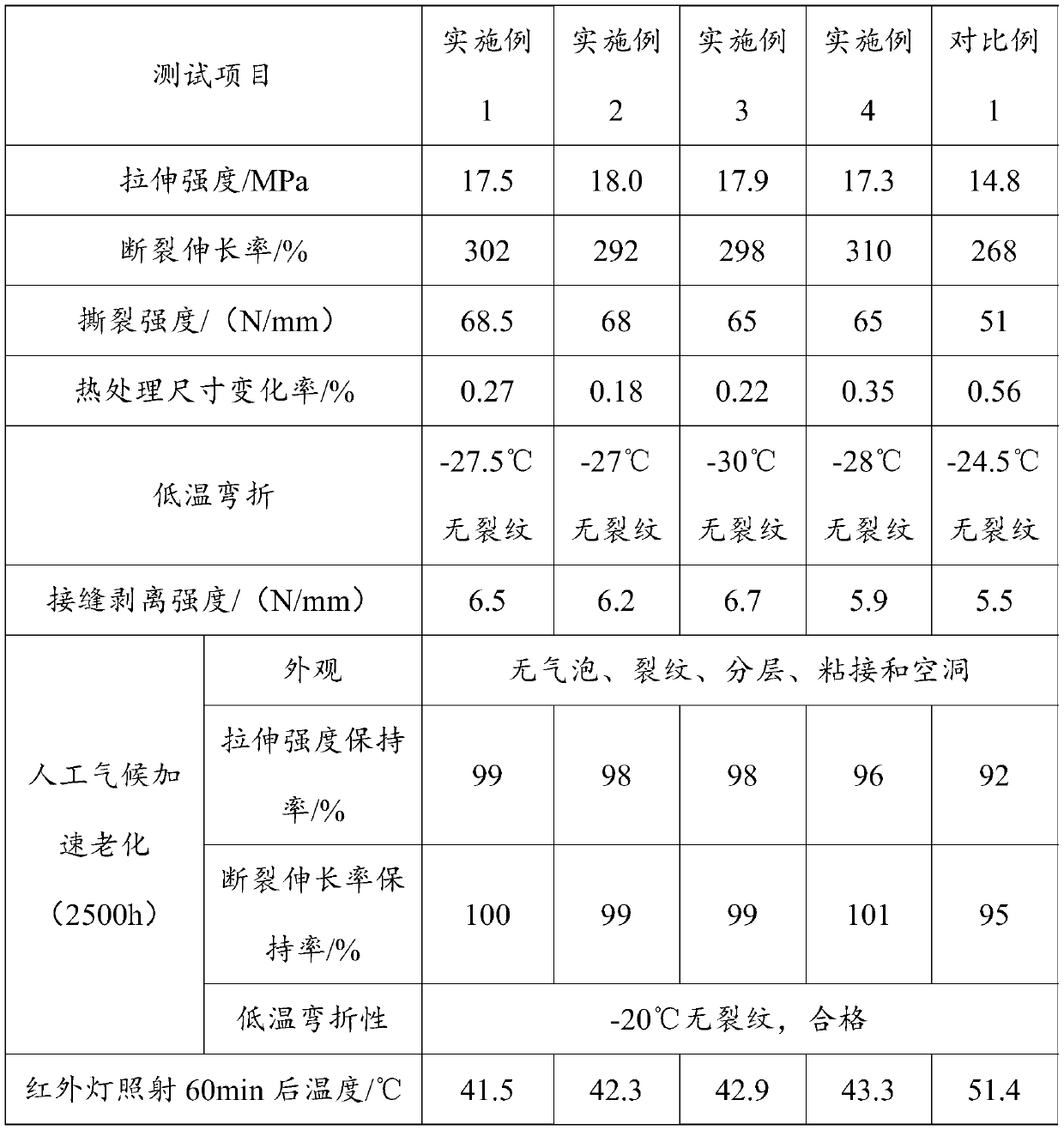

Reflective heat-insulation polyvinyl chloride (PVC) waterproof coiled material and preparation method thereof

ActiveCN110423416AHigh infrared reflectivityLow thermal conductivityRoof covering using flexible materialsPressure sensitive film/foil adhesivesPolyvinyl chloridePotassium

The invention discloses a reflective heat-insulation polyvinyl chloride (PVC) waterproof coiled material and a preparation method thereof. The PVC waterproof coiled material comprises the following components in parts by weight: 100 parts of PVC resin powder, 20-60 parts of a plasticizer, 10-30 parts of a toughening agent, 4-6 parts of epoxidized soybean oil, 2-5 parts of a heat stabilizer, 3-12 parts of potassium hexatitanate and / or sodium hexatitanate, 3-5 parts of titanium dioxide, 0.2-0.5 part of stearic acid, 0.1-0.4 part of calcium stearate, 0.2-2 parts of an antioxidant, 0.2-2 parts ofa light stabilizer, 20-40 parts of calcium carbonate and 0.1-0.5 part of a coupling agent. The coiled material has excellent dimensional stability, reflection heat insulation performance, good mechanical property, good low-temperature toughness, good aging resistance, long service life of the product, energy conservation and environment friendliness, and is particularly suitable for being used onexposed roofs.

Owner:HUNAN SHENYU NEW MATERIAL CO LTD

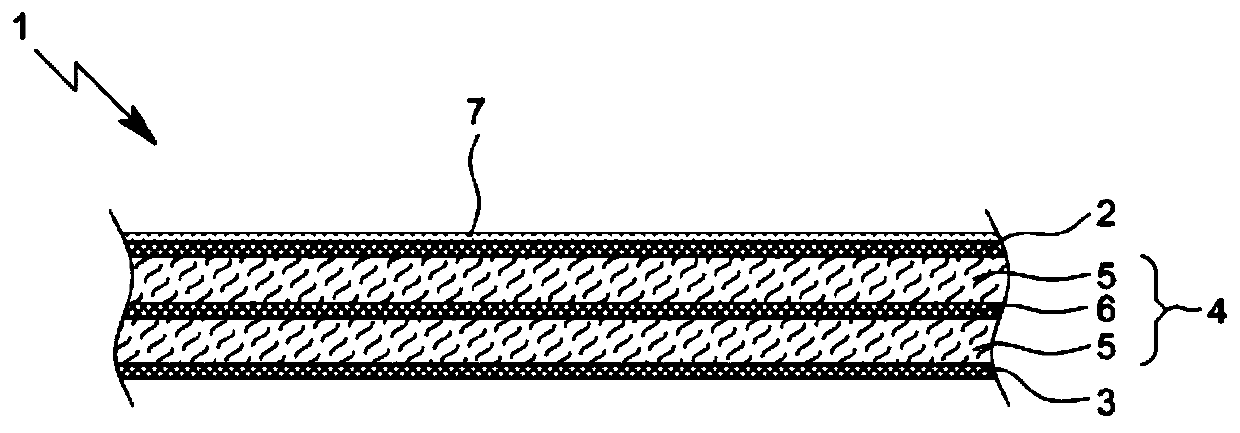

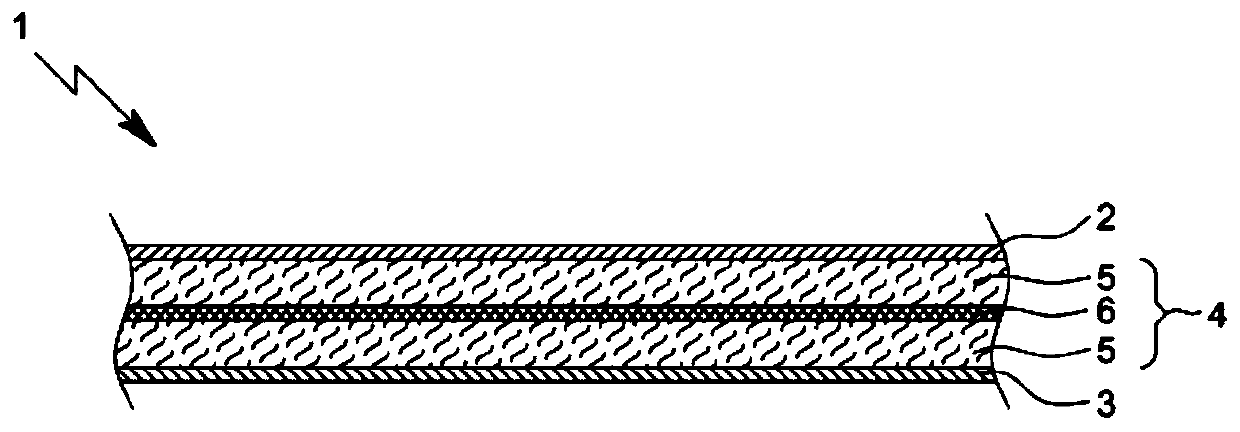

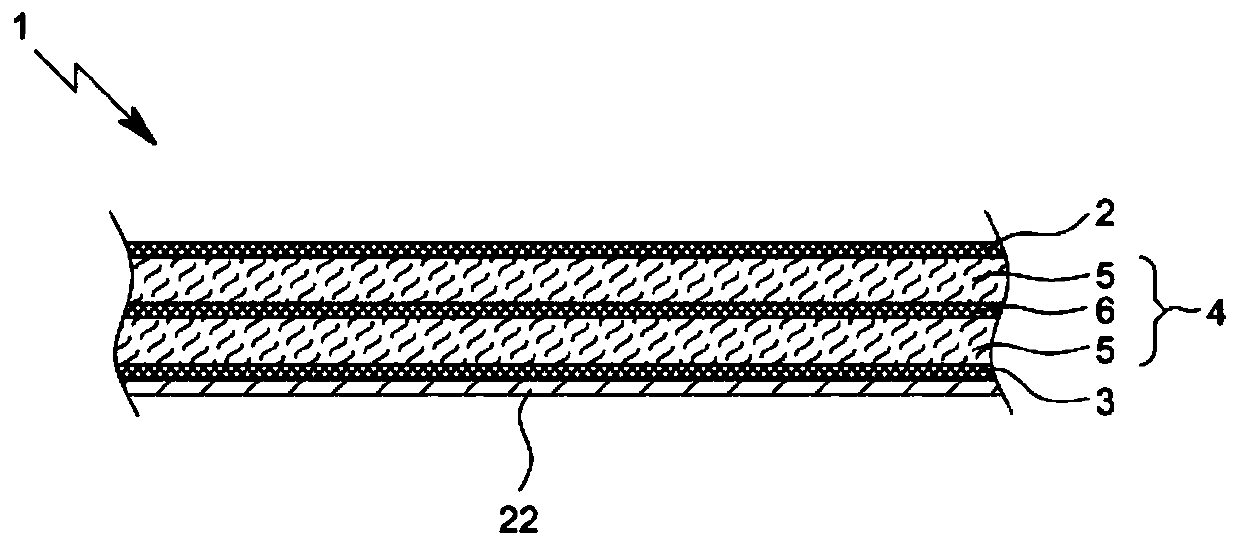

Multi-layer thermal insulation element for batteries

PendingCN111512464AReduce weight per unit areaReduce throughThermal insulationBattery isolationThermal insulationNonwoven fabric

The invention relates to a multi-layer thermal insulation element for thermally insulating a battery, comprising a first cover layer, a second cover layer and a compressible and / or flexible intermediate layer arranged between the cover layers, said intermediate layer having at least one heat-resistant fiber layer, wherein the fiber layer is formed from a needled nonwoven fabric and / or wherein thecover layers are flexurally weak and the thermal insulation element is overall compressible and flexible.

Owner:H K O 绝缘 纺织技术股份有限公司

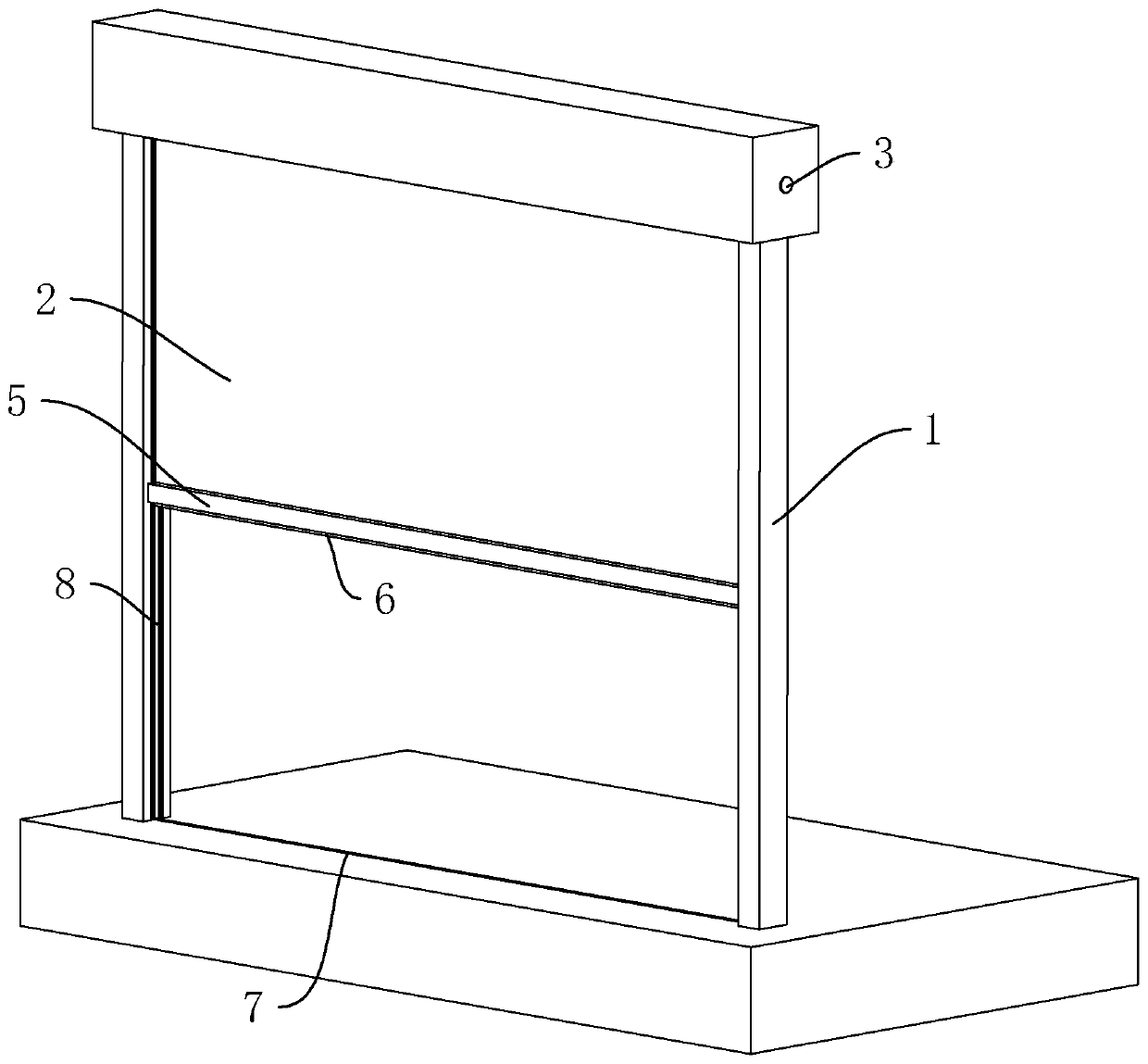

Composite steel fireproof roller shutter door

ActiveCN110700746AImprove sealingGood smoke isolation effectShutters/ movable grillesFireproof doorsSodium bicarbonateStructural engineering

The invention discloses a composite steel fireproof roller shutter door, and relates to the technical field of fireproof roller shutter doors. According to the technical scheme, the composite steel fireproof roller shutter door is characterized by comprising a door frame and a shutter plate, wherein a reel is rotatably connected to the upper end of the door frame; the upper end of the shutter plate is fixedly connected to the reel; guide grooves allowing the two ends of the shutter plate in the horizontal direction to be embedded and move are formed in the opposite inner sides of the door frame in the vertical direction; fireproof sealing pieces are arranged on the inner side walls of the guide grooves; each fireproof sealing piece comprises a fireproof sealing strip and a fireproof air bag; the fireproof sealing strip is arranged on the inner side wall of the corresponding guide groove in the vertical direction; the section of the fireproof sealing strip is in a U shape; the fireproofair bag is arranged in a U-shaped cavity of the fireproof sealing strip; and sodium bicarbonate is arranged in the fireproof air bag. The fireproof sealing pieces are arranged, when fire is close tothe fireproof roller shutter door, the fireproof air bags are heated to expand, so that the fireproof sealing strips are tightly attached to the end face of the shutter plate, the sealing performanceof the shutter plate and the guide grooves is enhanced, thus smoke penetrating from the two sides of the roller shutter door is reduced, and the smoke isolation effect is enhanced.

Owner:山东安舜消防设备有限公司

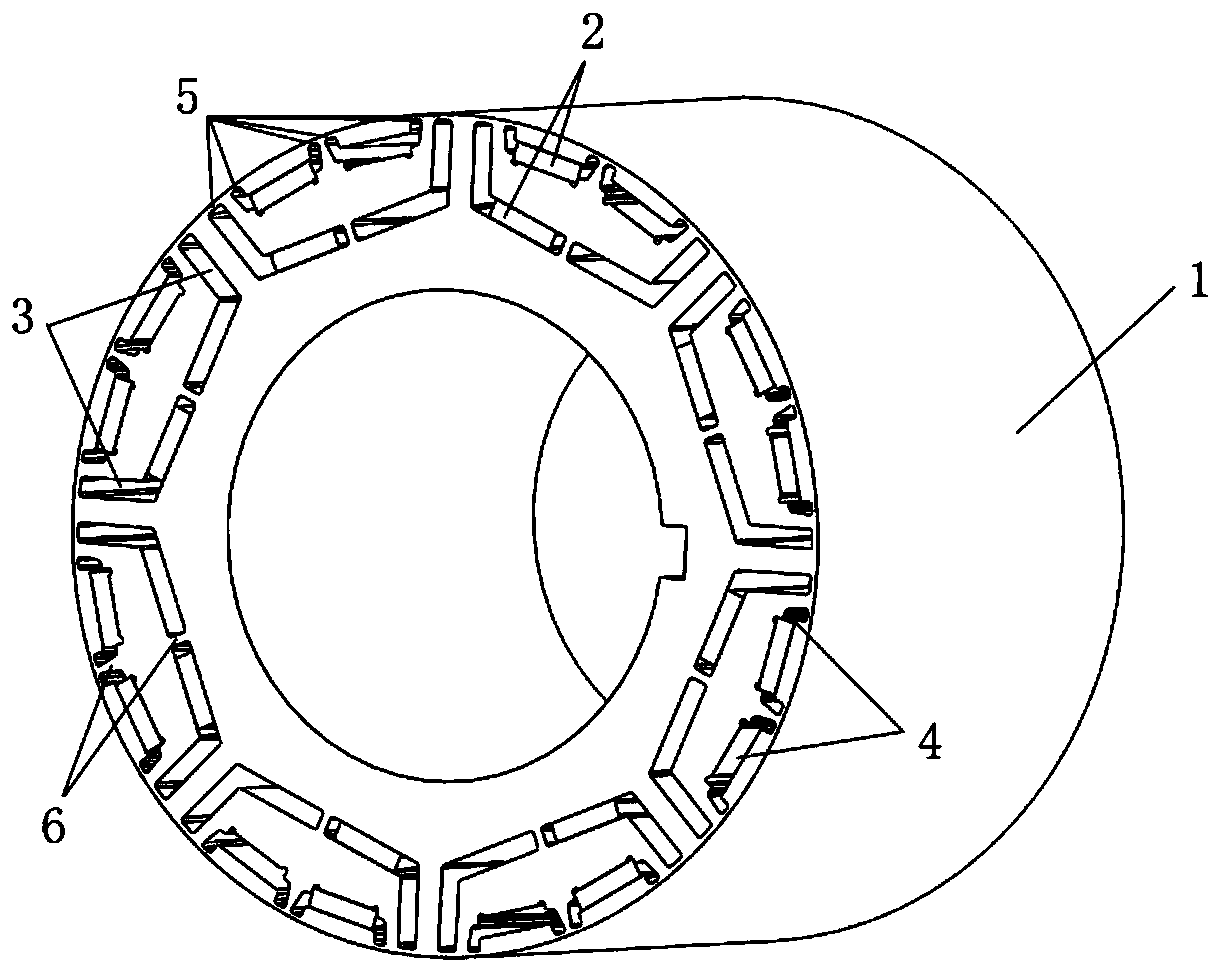

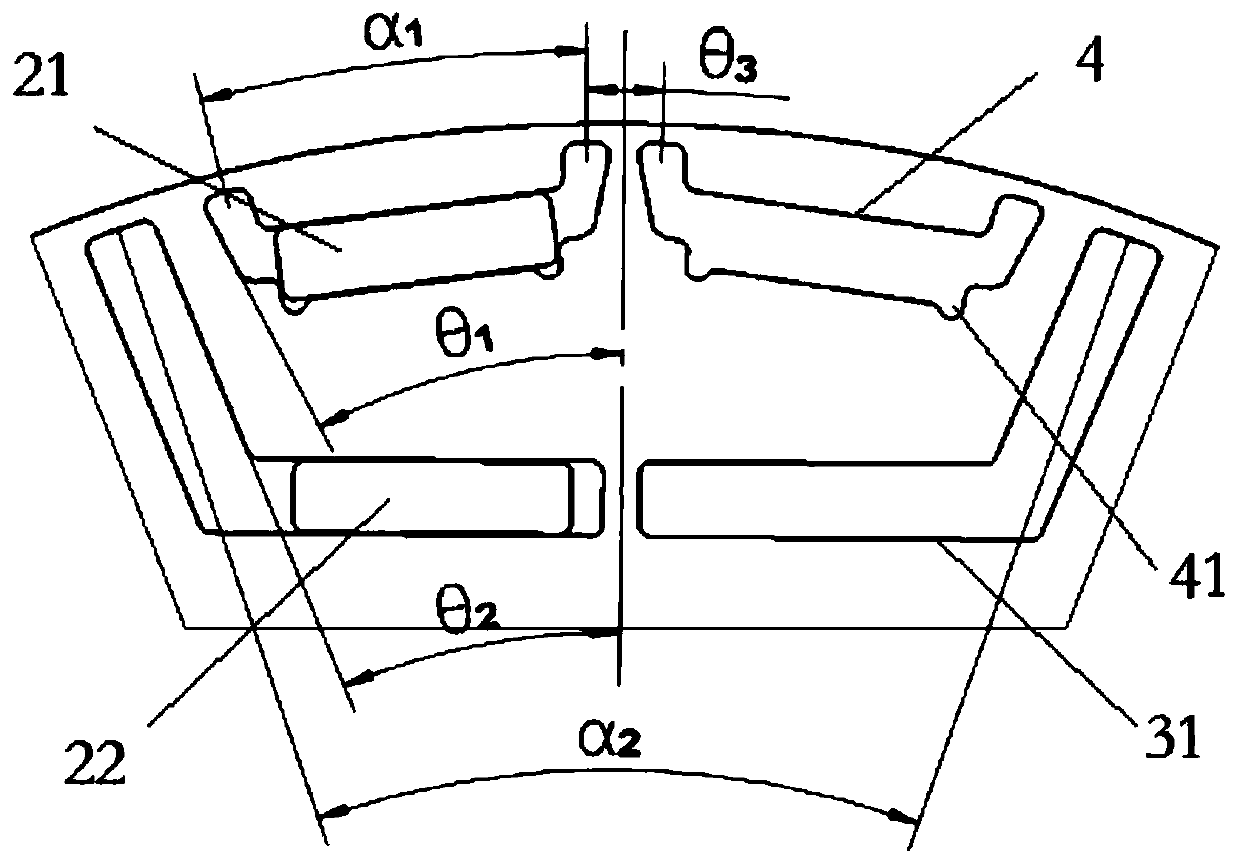

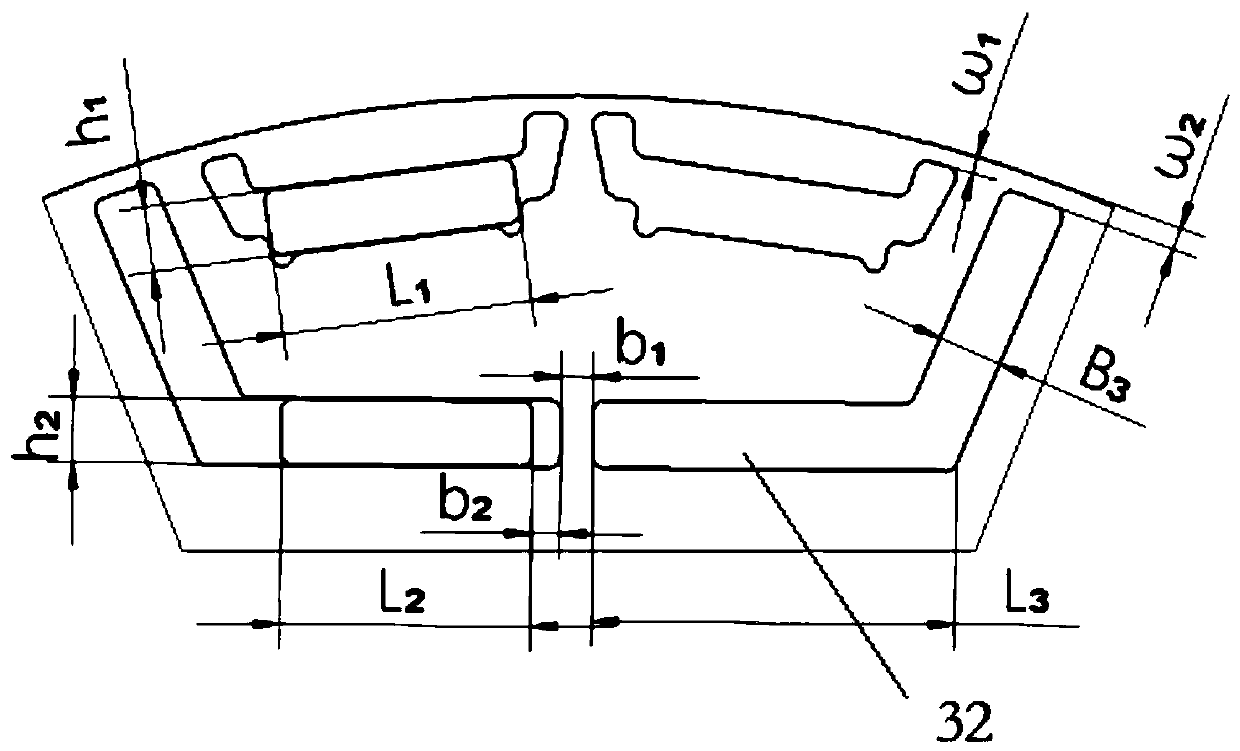

Permanent magnet auxiliary synchronous reluctance type motor rotor structure

PendingCN110535267AIncrease output torqueBoost permanent magnet torqueMagnetic circuit rotating partsEngineeringRotor flux

The invention relates to a permanent magnet auxiliary synchronous reluctance type motor rotor structure. A rotor core is provided with a plurality of U-shaped grooves, wherein the inner layer and theouter layer of each U-shaped groove are correspondingly arranged; each inner-layer U-shaped groove is divided into two L-shaped grooves through a reinforcing rib; every two outer-layer U-shaped grooves form a group and are arranged corresponding to one inner-layer U-shaped groove to form a magnetic space; and the inner U-shaped groove and the outer U-shaped groove are respectively provided with asecond permanent magnet and a first permanent magnet which are biased leftwards, so that the flux linkage of the rotor deviates, and the second permanent magnet of the inner U-shaped groove plays a role in magnetic conduction and corrects the deviation angle of the magnetic line of force passing through the first permanent magnet. The torque of the permanent magnet is improved, and the lengths andthe widths of the first permanent magnet and the second permanent magnet are the same, so that the utilization rate of the permanent magnets is increased, magnetic lines of force are gathered to theleft side, the offset of a rotor flux linkage is achieved, the reluctance torque is increased, and the material cost of the motor can be greatly reduced under the same torque requirement.

Owner:苏州英磁新能源科技有限公司

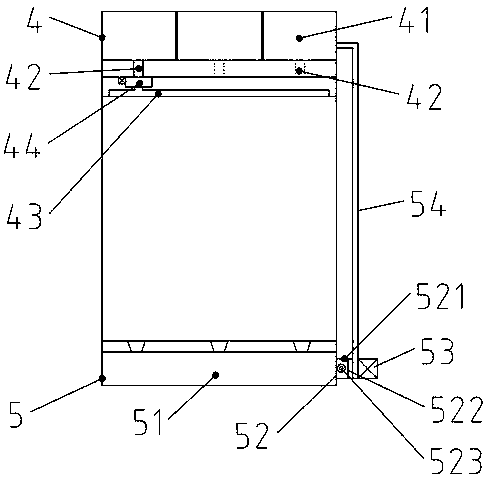

Light transmittance adjustable sightseeing elevator

The invention provides a light transmittance adjustable sightseeing elevator. The side wall of an elevator car of the elevator is formed through a transparent material in a connecting and defining manner. The side wall is of a multi-layer structure. Interlayer space is formed between every two adjacent layers of the side walls and is up-down through. The interlayer space is filled with light shading liquid. A liquid injection structure is fixed to the top of the side wall, a liquid recycling structure is fixed to the bottom of the side wall, and the light shading liquid circulates among the liquid injection structure, the interlayer space and the liquid recycling structure. The car wall itself of the elevator is made of the transparent material, the light transmittance is the highest whenno substances are added, the light shading liquid plays a light shading role, the light shading liquid is injected into the interlayer space of the car wall to form a light shading face in combinationwith an original car wall, and the number of light rays entering the elevator is reduced; meanwhile, to achieve multi-level adjustment, the set interlayer space is of a multi-layer structure, the multiple layers of light shading liquid can be selected to be injected according to needs, and the larger the number of the injected layers is, the fewer light rays can be transmitted.

Owner:DELFAR ELEVATOR

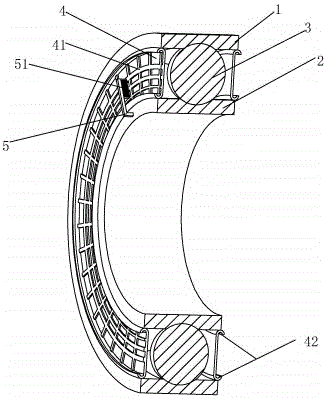

Bearing structure

InactiveCN105972097AReduce the chance of passing throughGood dustproof effectBearing componentsElectrostatic dischargeEngineering

The invention relates to a bearing structure. It is characterized in that the dust-proof cover is insulated from the outer ring, and an electrostatic dust-absorbing device is provided on the dust-proof cover, and the electrostatic dust-absorbing device includes an electrostatic brush and an electrostatic dust-absorbing net. There are bristles in contact with the electrostatic dust collection net, and the electrostatic brush is connected with the inner ring. In the present invention, by adopting the above technical scheme, the dust cover has no contact with the inner ring or outer ring of the bearing, and has no influence on the normal operation of the bearing. The bearing and the dust cover are insulated and matched, so static electricity can be generated by friction on the dust cover. When the electrostatic device works through the bearing, the inner ring rotates. The brushes fixed on the inner ring and the electrostatic dust collection net on the dust cover rub each other to generate static electricity. The friction between the bristles and the electrostatic dust collection net is very small and can be ignored. Regardless, the generated static electricity absorbs nearby dust, reducing the probability of dust passing through the gap between the dust cover and the bearing, and the dustproof effect is good.

Owner:新昌县梅渚镇富大轴承厂

Drying-pyrolysis integrated vertical furnace

ActiveCN107227165AImprove heat utilizationBroaden the effective particle size rangeSpecial form destructive distillationHeat carrierBiomass

The invention discloses a drying-pyrolysis integrated vertical furnace. According to the vertical furnace, a 3-30 section three-dimensional space inner baffled (in the shape of continuous S) operation conveyor belt is used as a material conveying device, high-temperature gas (or high temperature flue gas) is used as a gas heat carrier for multiple-step staggered countercurrent-type heat exchange with material coal or biomass, and drying, low temperature pyrolysis and medium-high temperature pyrolysis of the material coal or biomass are realized from top to bottom step by step through bottom-to-top temperature gradient of the gas heat carrier. The vertical furnace has a wide material particle size application range, realizes drying-pyrolysis integration of the material coal or biomass in the same furnace, effectively uses flue gas produced by material coal or biomass pyrolysis to cool hot semicoke at the outlet of the vertical furnace or to adjust and control the temperature of the gas heat carrier, improves a thermal energy utilization rate of the vertical furnace, has a simple design, can be flexibly and simply operated, realizes a low investment cost and is easy to industrialize.

Owner:NORTHWEST UNIV

Novel stainless steel surface polishing technology

ActiveCN111805406APromote escapeAchieve circular flowSievingPolishing machinesPolishingSS - Stainless steel

The invention discloses a novel stainless steel surface polishing technology, and belongs to the technical field of stainless steel processing. According to the scheme, fine polishing is performed ona stainless steel plate through a negative-pressure type cloth wheel, heat produced by friction during polishing is transmitted into a solution chamber, meanwhile, a redirection rotating ball rotatesanticlockwise to communicate with an epitaxial duct, carbon dioxide contained in a carbon dioxide aqueous solution is prompted to escape, sequentially penetrates through a gas-permeable membrane, a gas outlet hole, the epitaxial duct, the redirection rotating ball, a shunting hole and a gas inlet hole and then enters an air chamber, with continuous flowing of the carbon dioxide, the carbon dioxidecan be forced to flow back to the solution chamber, thus circulating flowing of the carbon dioxide is realized; the pressure during flowing is relatively low, so that the negative pressure is formedon the upper side of the cloth wheel; and under the action of the atmospheric pressure, metal chippings produced during fine polishing are sucked into the cloth wheel upwards, the probability of harmcaused by the metal chippings produced during polishing to the human body is reduced, and meanwhile, the reuse rate of the metal chippings is increased.

Owner:佛山市中力金属制品有限公司

Multilayer coextruded anti-polarization composite adhesive film and preparation method thereof

InactiveCN110041835AGood compatibilitySolve the bubblesNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveVapor barrierOptical transmittance

The invention relates to the technical field of photovoltaic module packaging adhesive films, in particular to a multilayer coextruded anti-polarization composite adhesive film. The composite adhesivefilm comprises a POE layer, an anti-polarization layer and an EVA layer arranged from top to bottom sequentially. After adoption of the structure, the composite adhesive film has the benefits as follows: 1, the EVA layer making contact with a battery surface has better compatibility with a polarity aid, and bubble, non-melting and piece combining problems during module lamination can be solved; 2, ethylene segments contained in copolymer resin in the anti-polarization layer have better compatibility with POE and EVA, and higher surface bonding can be formed; besides, acrylate has higher polarization performance, and negative voltage values produced by modules through outer frames can be reduced, so that the anti-PID performance of modules is improved; 3, the POE layer making contact witha back plate and glass has better vapor barrier performance, the light transmittance and volume resistivity of the adhesive film can be increased, thus, electric potential on battery pieces can be increased, the power generation efficiency of the modules can be improved, and the service life of the modules can be prolonged.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

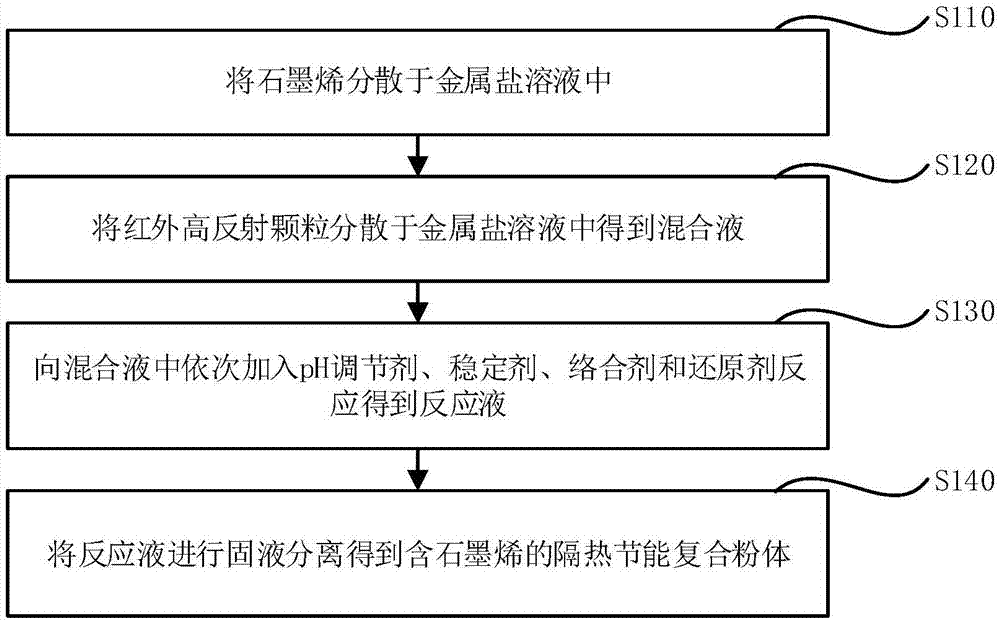

Graphene-containing heat-insulating energy-saving composite powder, and preparation method and application thereof

InactiveCN107398556AImprove conductivityEnhanced electron transport capabilitiesMaterial nanotechnologyTransportation and packagingInfraredElectricity

The invention relates to graphene-containing heat-insulating energy-saving composite powder, and a preparation method and application thereof. The graphene-containing heat-insulating energy-saving composite powder comprises nuclear shell particles and graphene dispersing among the nuclear shell particles. The nuclear shell particles comprise infrared high-reflectivity particles and metal. The metal covers the infrared high-reflectivity particles to form metal shells. The mass ratio of the infrared high-reflectivity particles, the metal to the graphene is (70-98):(1-20):(1-10). The graphene-containing heat-insulating energy-saving composite powder has the advantages that high electric conductivity of the graphene-containing heat-insulating energy-saving composite powder can be realized, and electric transmission ability and infrared-ray reflection ability of the composite powder can be improved; total reflection, not normal diffuse reflection, of an electricity-conducting network, formed by the infrared high-reflectivity particles, the metal shell and the graphene, to infrared rays can be realized, absorption and transmission of base materials to the infrared rays can be reduced remarkably, and accordingly, the objectives of temperature rise reduction and energy conservation are achieved.

Owner:广东华材实业股份有限公司

Purple rice and albizzia julibrissin depression relieving walnut kernel and preparation method thereof

InactiveCN104872734ARich tasteRich in nutritional valueFood preparationCodonopsis pilosulaAdditive ingredient

The invention discloses a purple rice and albizzia julibrissin depression relieving walnut kernel which is prepared from the following raw materials in parts by weight: 50-60 parts of walnut kernels, 9-14 parts of dried persimmon, 6-8 parts of dried ballonflower, 7-10 parts of purple rice, 3-4 parts of pickles, 1-2 parts of rice wine, 21-22 parts of honey, 1-1.5 parts of albizia flowers, 1.4-2 parts of codonopsis pilosula, 1-1.5 parts of butterflybush flowers, and appropriate amounts of emulsifying agents and zein. The purple rice and albizzia julibrissin depression relieving walnut kernel is subjected to film coating treatment by employing the zein, and moisture and oxygen from outside are isolated, so that an oxidative rancidity process of the depression relieving walnut kernel is inhibited, and the quality guarantee period of the Chinese walnut kernel is prolonged; and the added traditional Chinese medicine components such as the albizia flowers and codonopsis pilosula enable the depression relieving walnut kernel to have the health-care efficacies of relieving depression, calming nerves, nourishing yin, tonifying yang, clearing heat and nourishing a liver.

Owner:石台县横渡镇香口二郎家庭农场

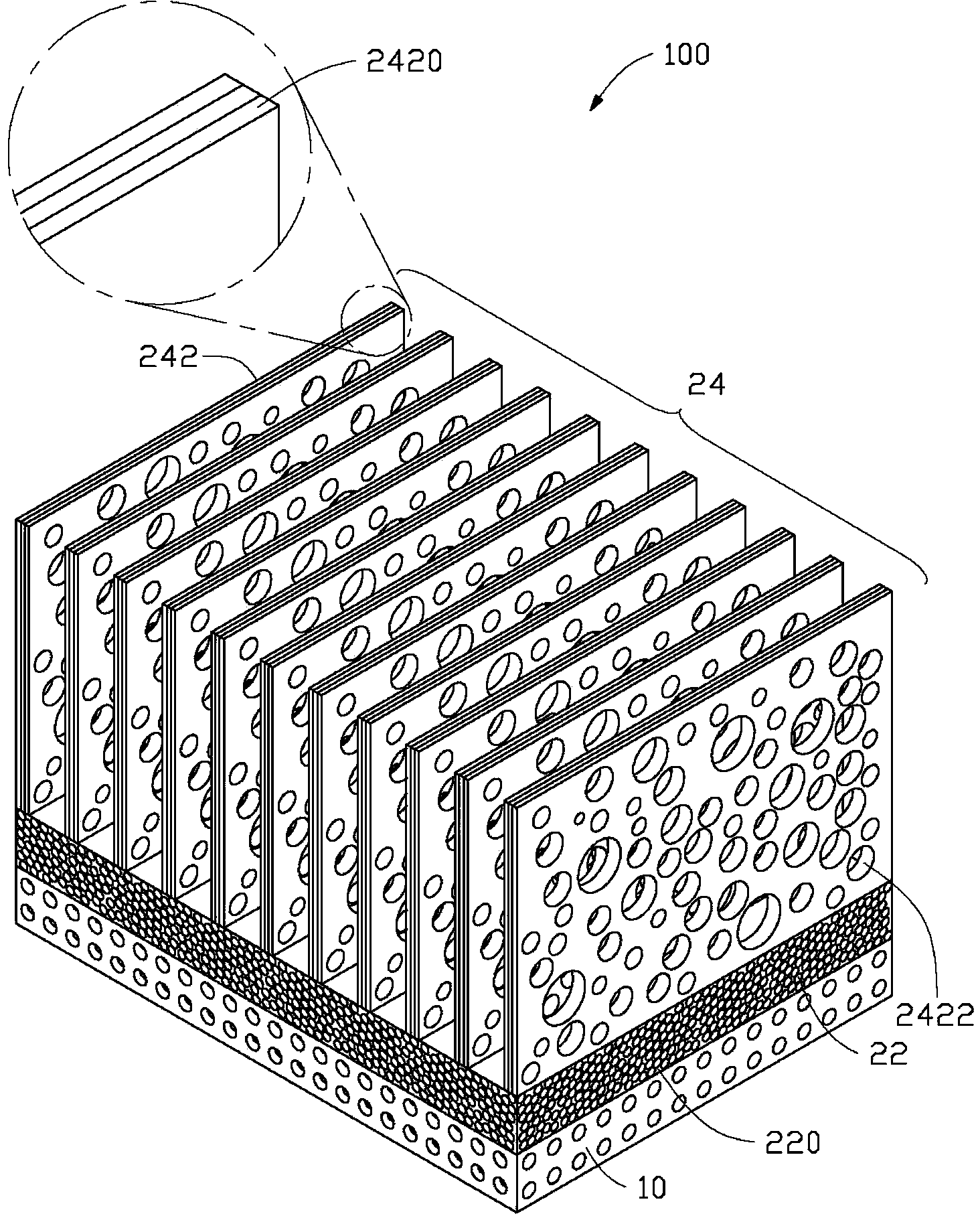

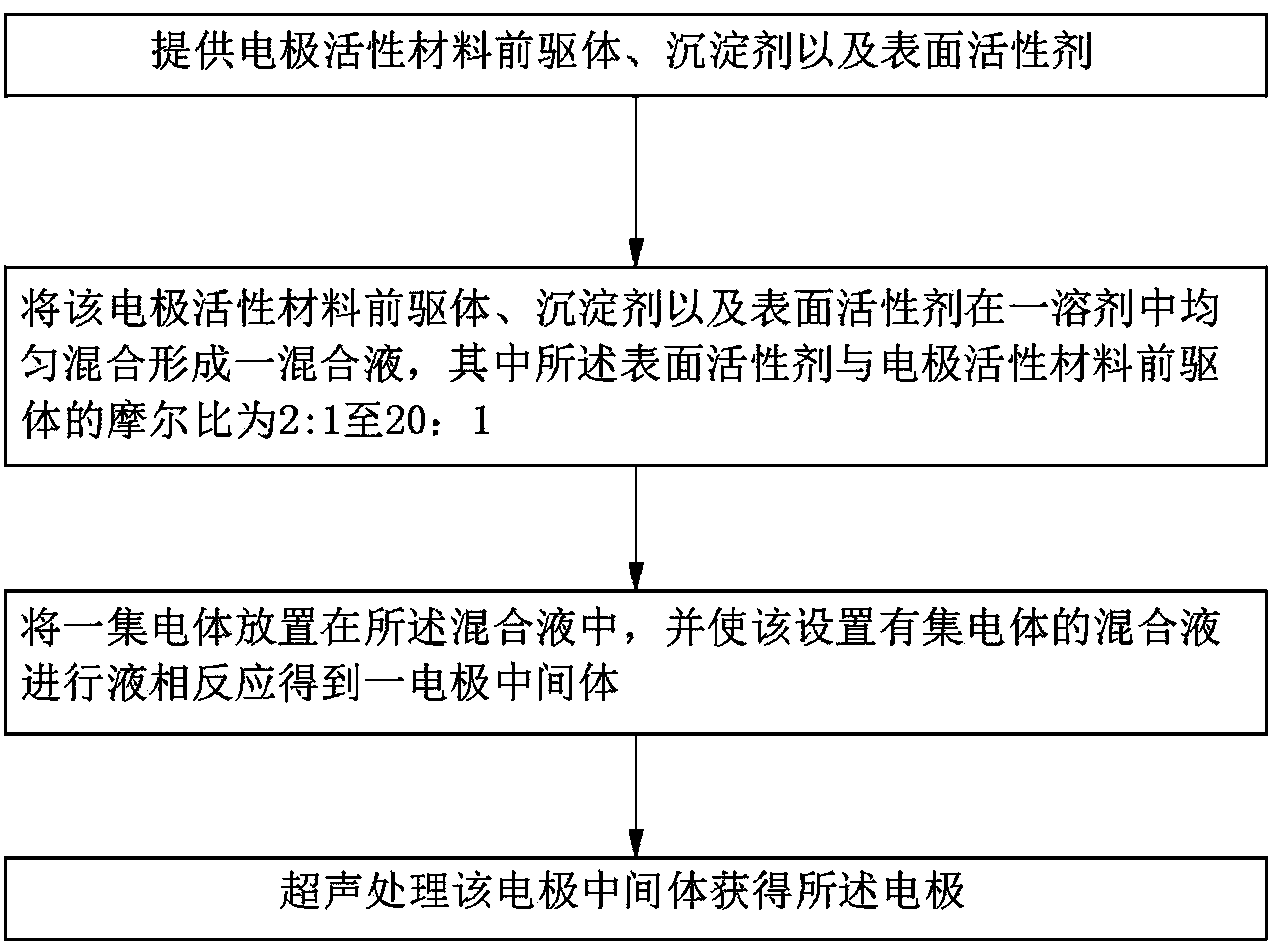

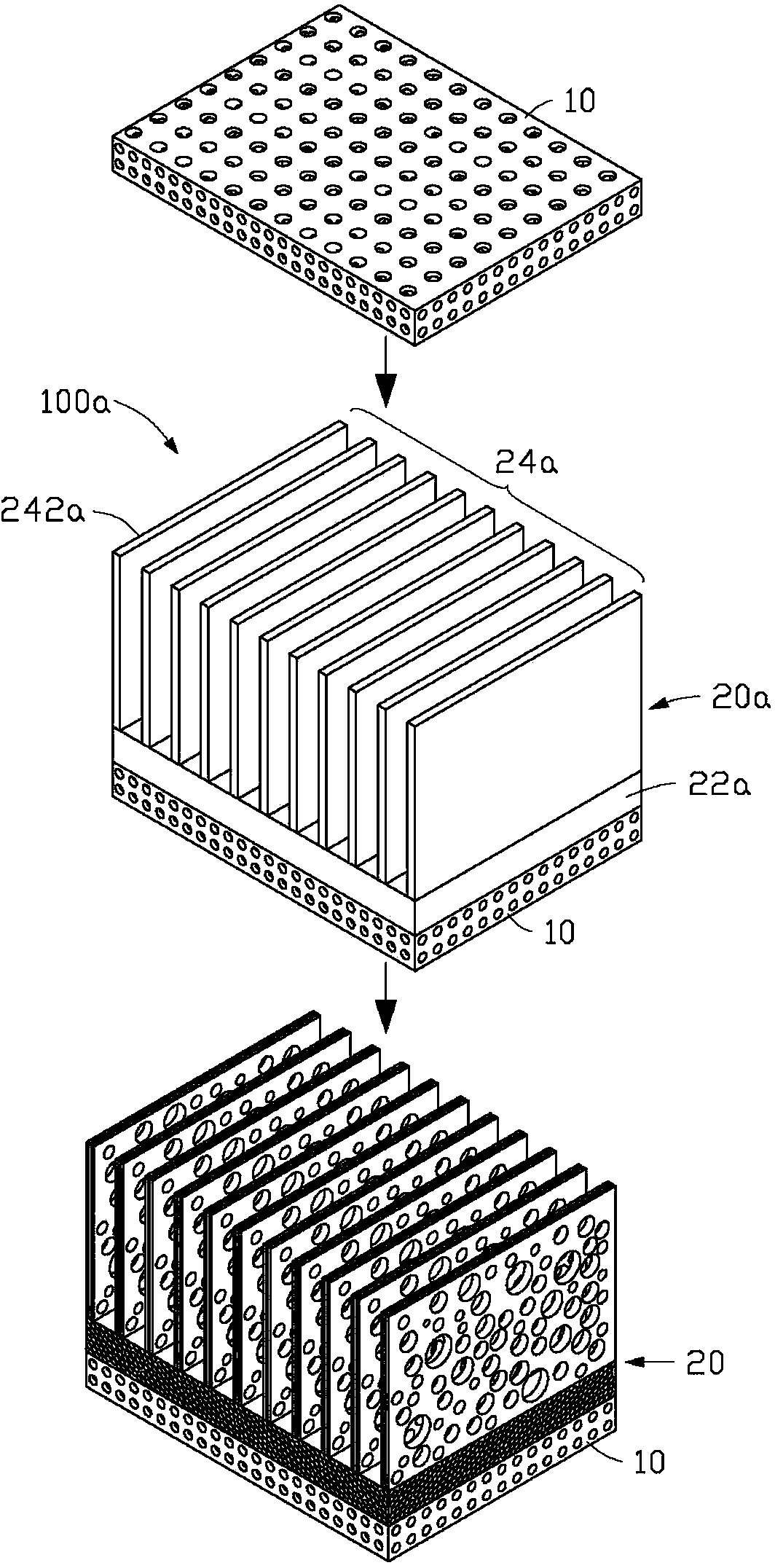

Electrode applied to electrochemical energy storage device and preparation method of electrode

ActiveCN104241637AIncrease capacityExcellent rate performanceHybrid capacitor electrodesCell electrodesElectrochemistryElectrochemical energy storage

The invention relates to an electrode applied to an electrochemical energy storage device. The electrode comprises a current collector and an electrode active material structural body arranged on the current collector, wherein the electrode active material structural body comprises a porous buffering layer and a nano-sheet array; the porous buffering layer is arranged on the surface of the current collector; the nano-sheet array is vertically arranged on the surface of the porous buffering layer and comprises multiple nano sheets; each nano sheet is of a porous structure, and at least one nano sheet comprises multiple single nano layers.

Owner:HUBEI UNIV OF ARTS & SCI

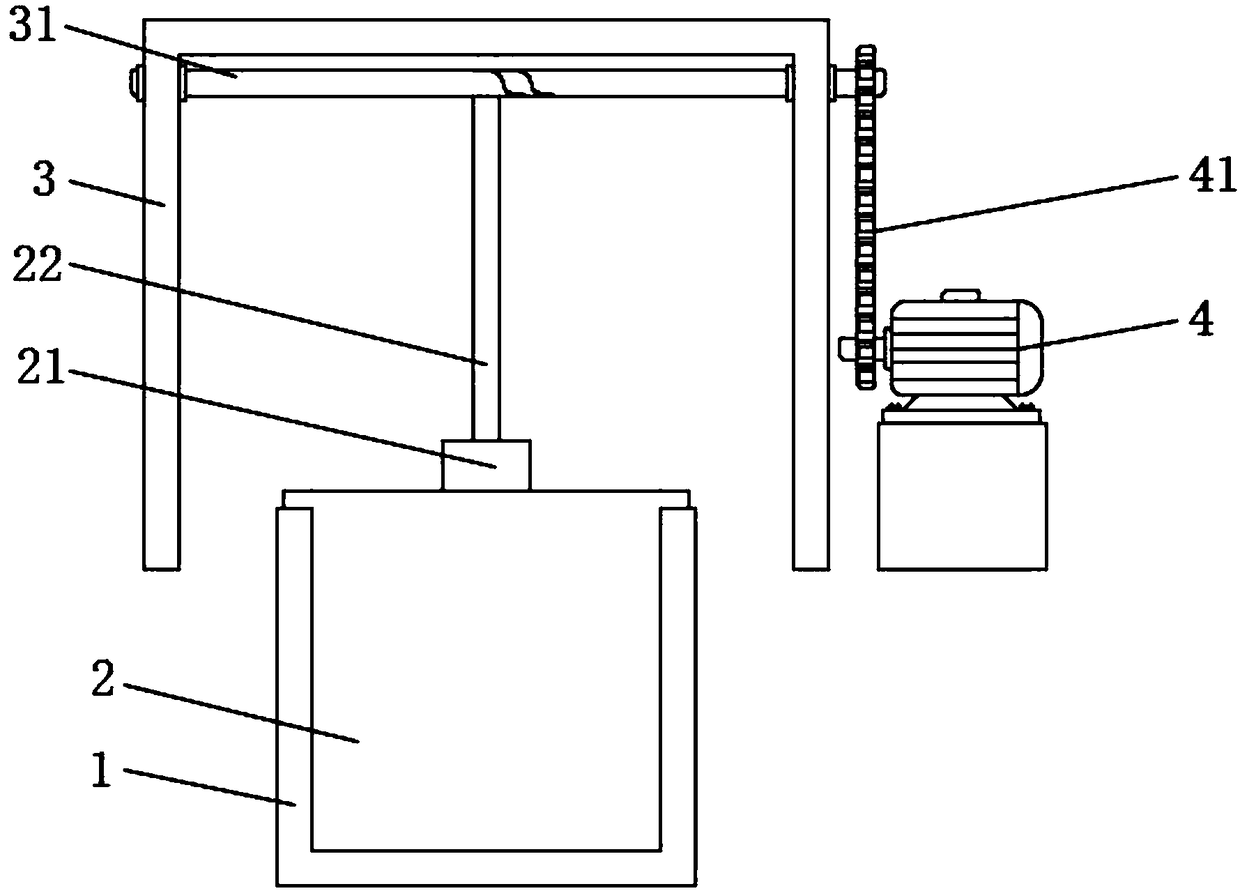

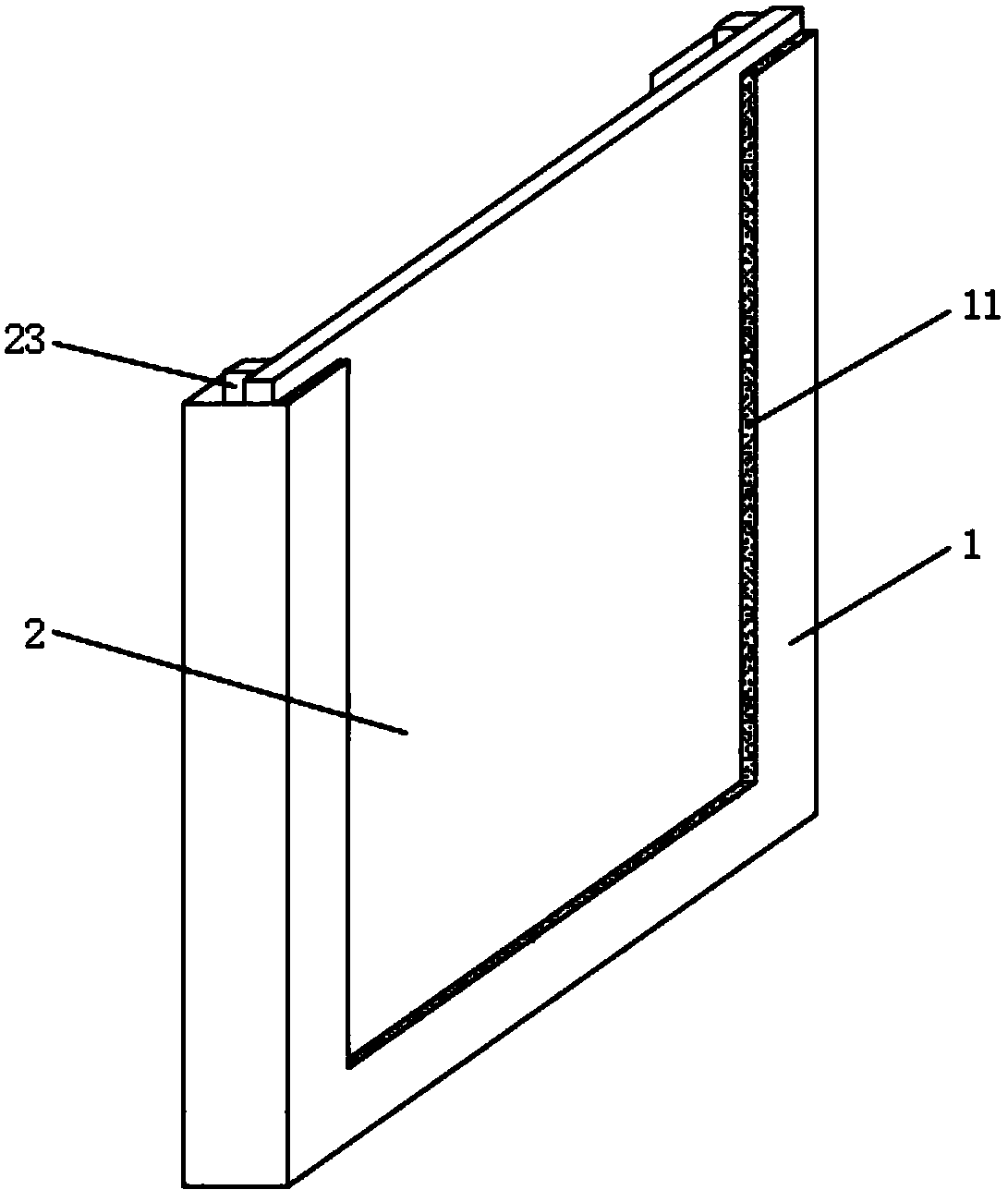

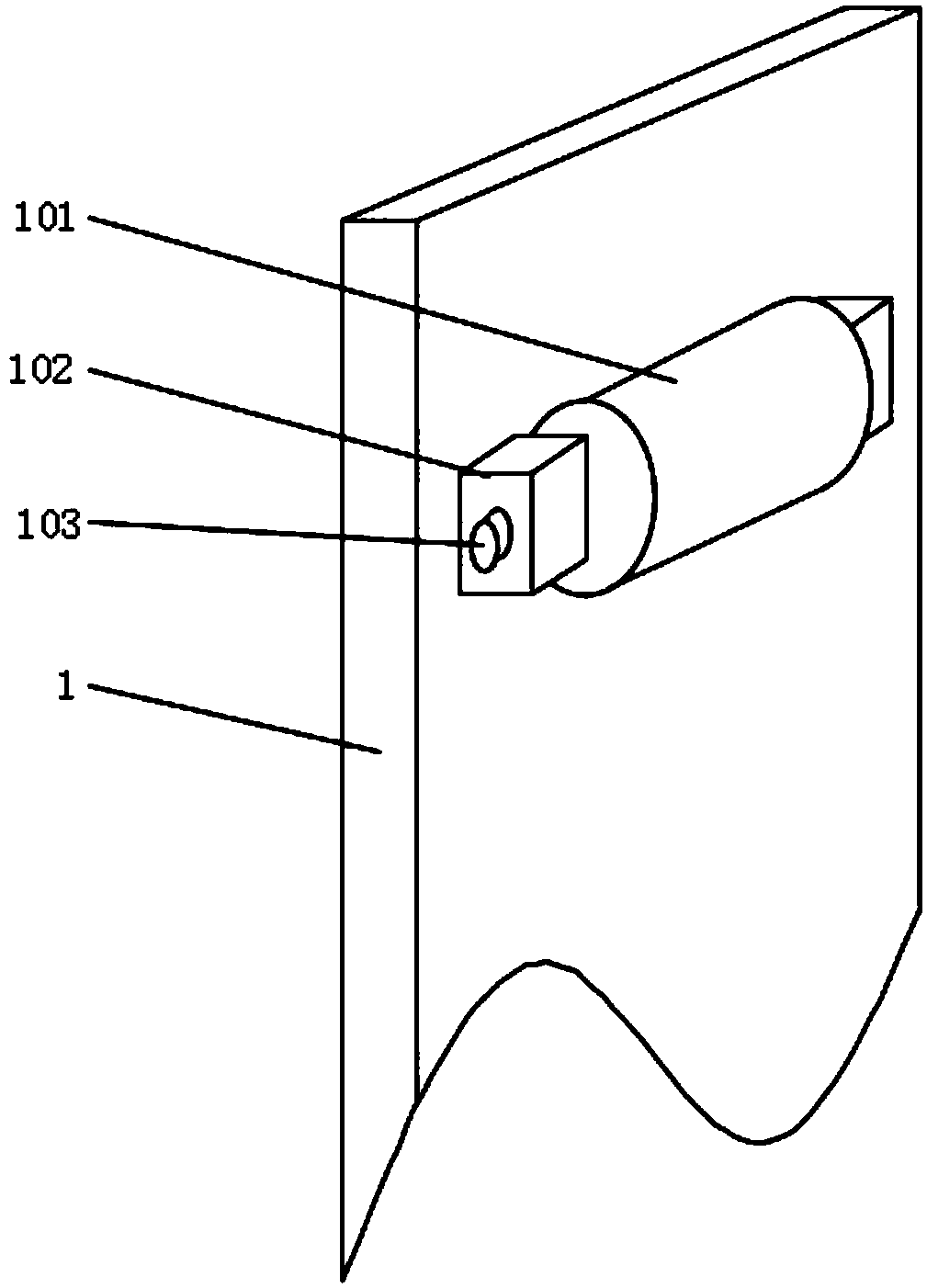

Special gate lifting device for water conservancy and hydropower

The invention discloses a special gate lifting device for water conservancy and hydropower. The device comprises an edge frame and a gate; the gate is arranged in the edge frame; a lifting frame is arranged above the gate; a motor is arranged on one side of the lifting frame; a wedge structure is arranged on one side of the gate; the wedge is narrow in lower end and wide in upper end; in the gatedescending process, due to the effect of the wedge, the gate slowly moves to the side with a rubber pad; when the gate is descended to the bottom, the wedge is totally fed in the edge frame to fully fill the edge frame, so that the gate tightly presses the rubber pad to reduce a gap therebetween, the tightness of the gate is effectively improved, and penetration of water currents is reduced; a roller structure is arranged in the edge frame; when the gate is ascended or ascended, the wedge is contacted with a pulley; and due to the effect of the roller, the gate is hoisted and placed more smoothly and easily, so that the burden of the motor is relieved, and the service life of the motor is prolonged.

Owner:ANHUI CAREMIC CONSULTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com