High-impermeability cement-based composite material and method for preparing same

A technology of composite materials and permeability, which is applied in the field of high-permeability cement-based composite materials and its preparation, can solve the problems of poor corrosion resistance, slow strength development, and reduced service life, so as to improve impermeability and promote flow good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

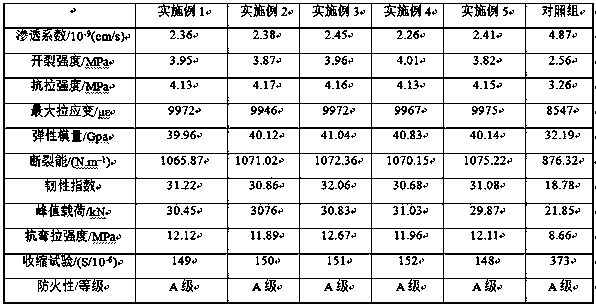

Examples

Embodiment 1

[0027]The whiskers are magnesium hydroxide whiskers, silicon carbide whiskers, and calcium carbonate whiskers mixed in a weight ratio of 1:1:1;

[0028] Take rice straw and crop stalks to dry and crush them, place the crushed crop straws in a carbonization furnace device for carbonization, set the carbonization temperature to 300°C, and carbonization time to 83 minutes, and finally crush the carbonized crop straws into 150 meshes to obtain crop straw powder;

[0029] Preparation of chitosan nanogel: dissolving chitosan with 5% acetic acid aqueous solution to obtain chitosan solution, adding cyclodextrin to 10% aqueous solution of sodium hydroxide and stirring to prepare cyclodextrin Dextrin alkali solution, slowly drop the cyclodextrin alkali solution into the chitosan solution and stir evenly to obtain a mixed solution, adjust the pH of the mixed solution to 9.0 and then react, set the reaction temperature to 50°C, and the reaction time to 12h. The stirring speed is 100r / min...

Embodiment 2

[0034] Whiskers are magnesium hydroxide whiskers, silicon carbide whiskers, and calcium carbonate whiskers mixed in a weight ratio of 1:1:1

[0035] The sugarcane crop stalks are dried in the sun and crushed, and the crushed crop stalks are placed in a carbonization furnace for carbonization. The carbonization temperature is set at 310°C, and the carbonization time is 80 minutes. Finally, the carbonized crop stalks are crushed into 120 meshes to obtain crop straw powder;

[0036] Preparation of chitosan nanogel: Dissolve chitosan with an acidic aqueous solution mixed with 3% acetic acid and hydrochloric acid to obtain a chitosan solution, add cyclodextrin to a 10% aqueous solution of sodium hydroxide and stir to mix Prepare a cyclodextrin alkali solution, slowly drop the cyclodextrin alkali solution into the chitosan solution and stir evenly to obtain a mixed solution, adjust the pH of the mixed solution to 6.0 and then react, set the reaction temperature to 45°C, and the reac...

Embodiment 3

[0041] The whiskers are magnesium hydroxide whiskers, silicon carbide whiskers, and calcium carbonate whiskers mixed in a weight ratio of 1:1:1;

[0042] Take the corn crop stalks and dry them for crushing, place the crushed crop stalks in the carbonization furnace for carbonization, set the carbonization temperature at 350°C, and the carbonization time for 85 minutes, and finally crush the carbonized crop stalks into 140 meshes to obtain crop straw powder;

[0043] Preparation of chitosan nanogel: dissolving chitosan with 3% sulfuric acid acidic aqueous solution to obtain chitosan solution, adding cyclodextrin to 10% sodium hydroxide aqueous solution and stirring to prepare cyclopaste Fine alkali solution, slowly drop the cyclodextrin alkali solution into the chitosan solution and stir evenly to obtain a mixed solution, adjust the pH of the mixed solution to 7.0 and then react, set the reaction temperature to 40°C, and the reaction time to 10.5h. The stirring speed is 120r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com