Graphene-containing vanadium dioxide composite powder and preparation method and application thereof

A vanadium dioxide, composite powder technology, applied in epoxy resin coatings, coatings, reflection/signal coatings, etc., can solve problems such as poor absorption or reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

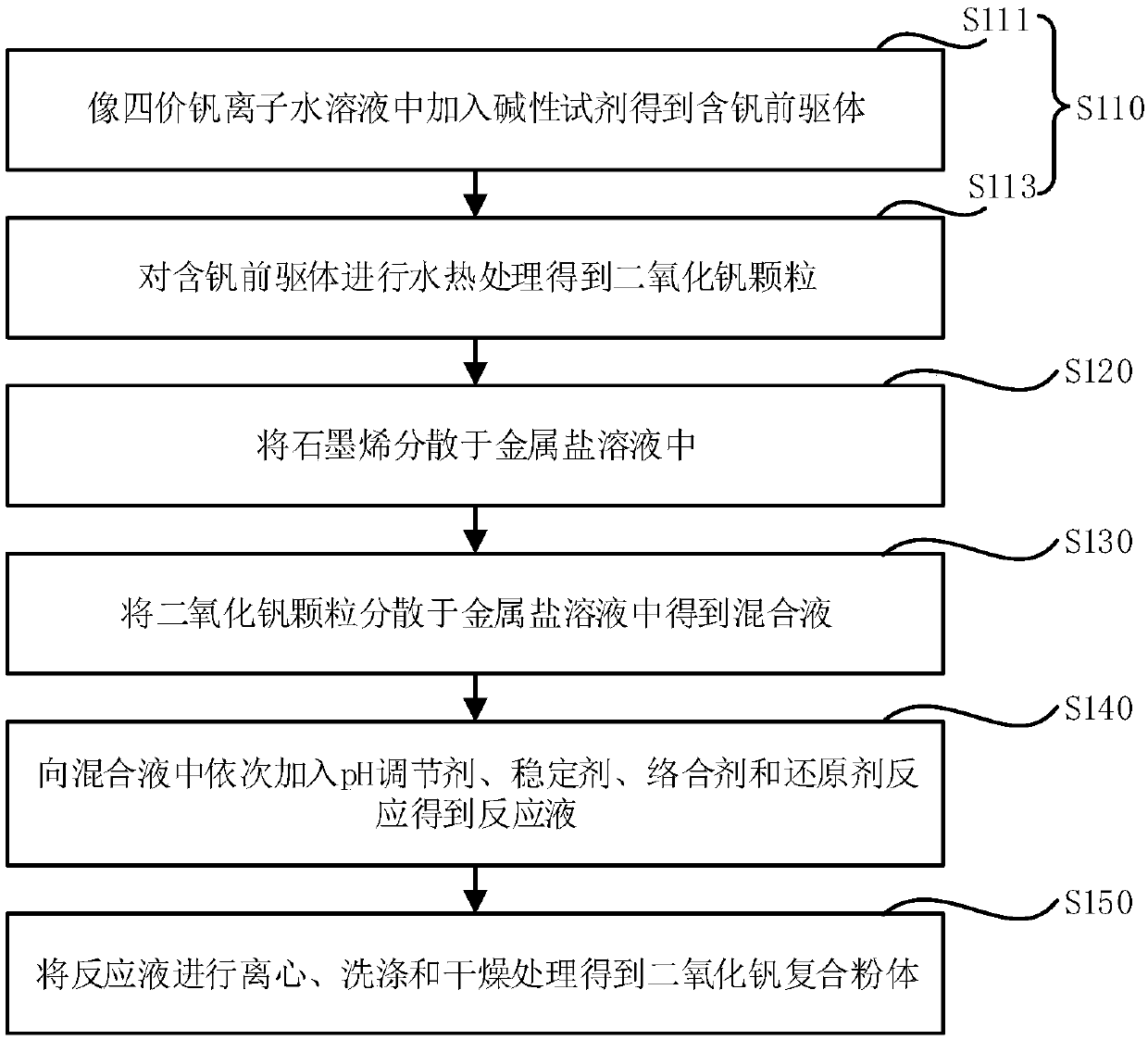

[0056] see figure 2 , the preparation method of the vanadium dioxide composite powder containing graphene of one embodiment, comprises the following steps:

[0057] S110, preparing vanadium dioxide particles.

[0058] In one of the embodiments, the step of preparing vanadium dioxide particles specifically includes:

[0059] S111, adding an alkaline reagent to the tetravalent vanadium ion aqueous solution to obtain a vanadium-containing precursor.

[0060] In one of the embodiments, the anion in the tetravalent vanadium ion aqueous solution is SO 4 2- , Cl - and C 2 o 4 2- at least one of the

[0061] In one of the embodiments, the alkaline reagent is selected from at least one of ammonia water, sodium hydroxide and potassium hydroxide. Preferably, the alkaline reagent is formulated into an aqueous solution and then added to the tetravalent vanadium ion aqueous solution.

[0062] In one embodiment, the concentration of tetravalent vanadium ions in the aqueous solutio...

Embodiment 1

[0090] (1) take by weighing the tetravalent vanadium ion aqueous solution of 10g, wherein the concentration of tetravalent vanadium ion is 0.8mol / L; Then add the basic reagent containing 10g sodium hydroxide to it and mix uniformly to obtain the vanadium-containing precursor; The vanadium precursor is placed in a high-pressure reactor, and reacted for 20 hours at 150° C. and a pressure of 1 MPa; then the product is filtered, washed and dried to obtain vanadium dioxide particles. The particle size of the prepared vanadium dioxide particles is 100nm.

[0091] (2) Weigh 4L of AuCl 3 solution, where AuCl 3 The concentration of the solution is 0.01mol / L; 5g of graphene is added thereto, and the graphene is dispersed uniformly by ultrasonic and stirring. Among them, the surface size of graphene is 1μm, the thickness of graphene is 0.5nm, and the specific surface area of graphene is 10m 2 / g. The power of ultrasonic dispersion is 50Hz, the rotation speed of stirring is 200r / min...

Embodiment 2

[0096] (1) Take by weighing 100g of tetravalent vanadium ion aqueous solution, wherein the concentration of tetravalent vanadium ion is 0.02mol / L; then add alkaline reagent containing 10g ammonia water and mix uniformly to obtain vanadium-containing precursor; the above-mentioned vanadium-containing precursor The body was placed in a high-pressure reactor, and reacted at 300° C. and a pressure of 10 MPa for 4 hours; then the product was filtered, washed and dried to obtain vanadium dioxide particles. The particle size of the prepared vanadium dioxide particles is 200nm.

[0097] (2) Weigh 3L of AgNO 3 solution, where AgNO 3 The concentration of the solution is 0.05mol / L; 10g of graphene is added thereto, and the graphene is uniformly dispersed by ultrasonic and stirring. Among them, the surface size of graphene is 100μm, the thickness of graphene is 50nm, and the specific surface area of graphene is 1000m 2 / g. The power of ultrasonic dispersion is 20Hz, the rotational s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com