NaYF4:Ln<3+>/C/TiO2 composite photoanode and preparation method thereof

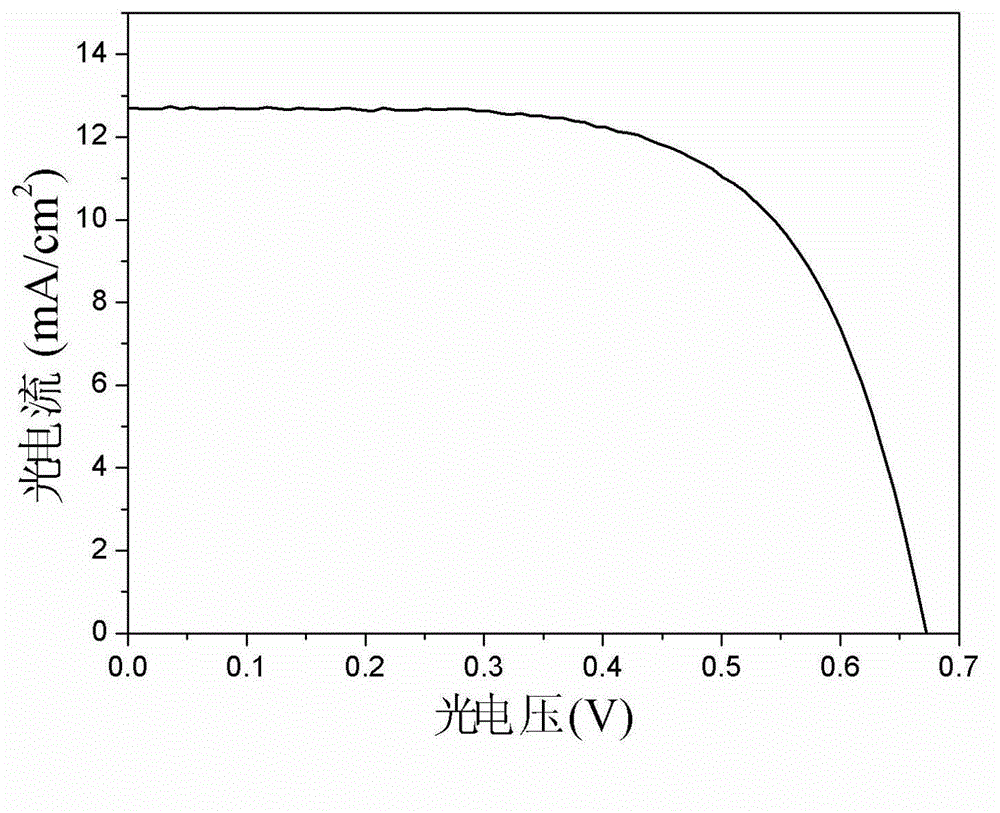

A composite light and anode technology, applied in photosensitive equipment, photovoltaic power generation, final product manufacturing, etc., can solve the problem of low photoelectric conversion efficiency of sensitized solar cells, achieve the effect of improving electron transmission capacity and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

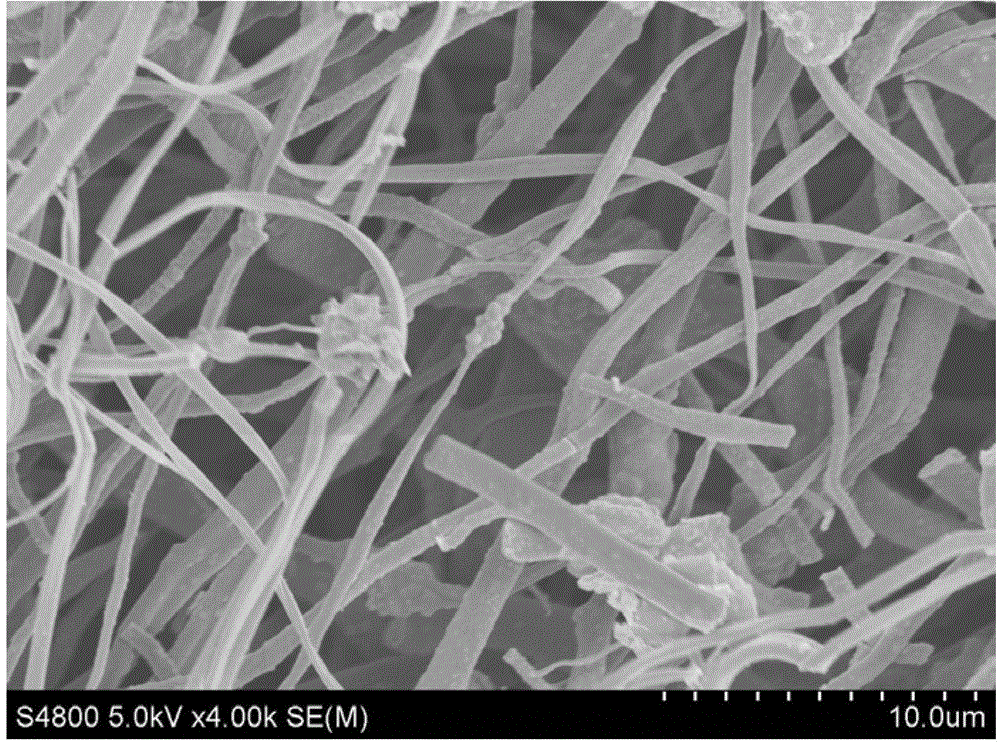

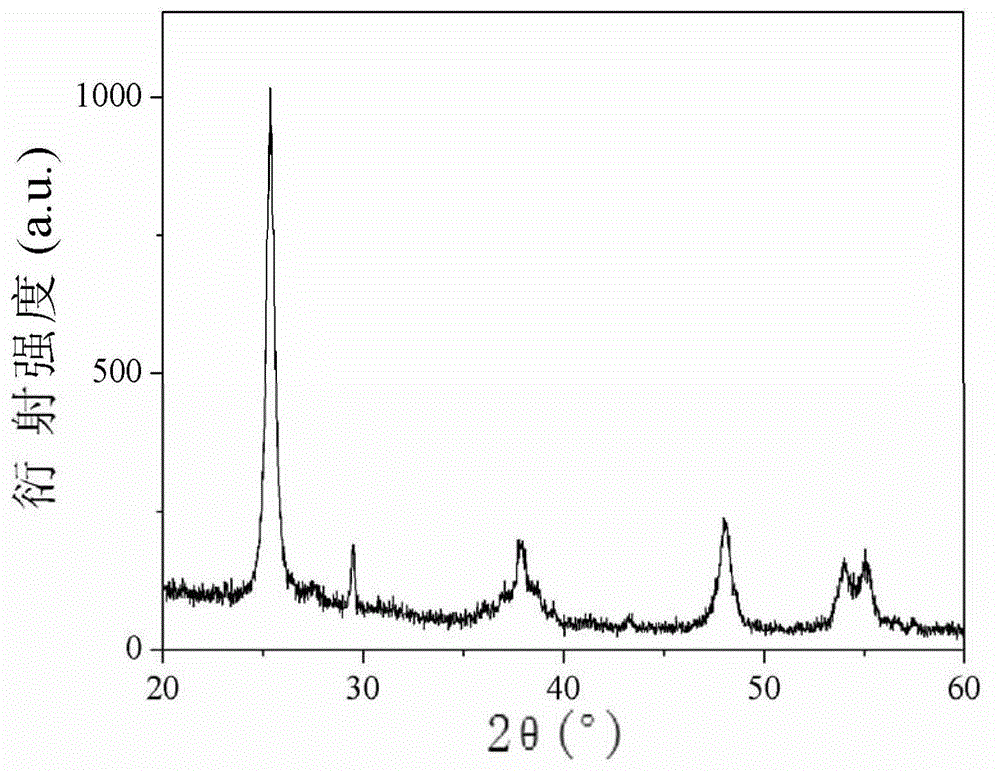

[0020] Specific implementation mode 1: this implementation mode NaYF 4 :Ln 3+ / C / TiO 2 Composite photoanode made of rare earth NaYF 4 :Ln 3+ Nanocrystalline, C quantum dots, TiO 2 and FTO conductive glass; the rare earth NaYF 4 :Ln 3+ Nanocrystalline, C and TiO 2 The mass ratio is 1:1:(10-1000); the FTO conductive glass is F-doped conductive glass, and the rare earth NaYF 4 :Ln 3+ The nano crystal is prepared from a rare earth nitrate solution, a surfactant and a fluorine source solution, wherein the solute in the rare earth nitrate solution is a mixture of yttrium nitrate, erbium nitrate and ytterbium nitrate.

[0021] The rare earth NaYF described in this embodiment 4 :Ln 3+ Nanocrystals are in the cubic crystal phase.

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the surface load of the FTO conductive glass is 0.5-3.0 mg / cm 2 , The thickness of the load layer is 1-5mm.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that TiO 2 For commercial P25 type TiO 2 . Other ingredients are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com