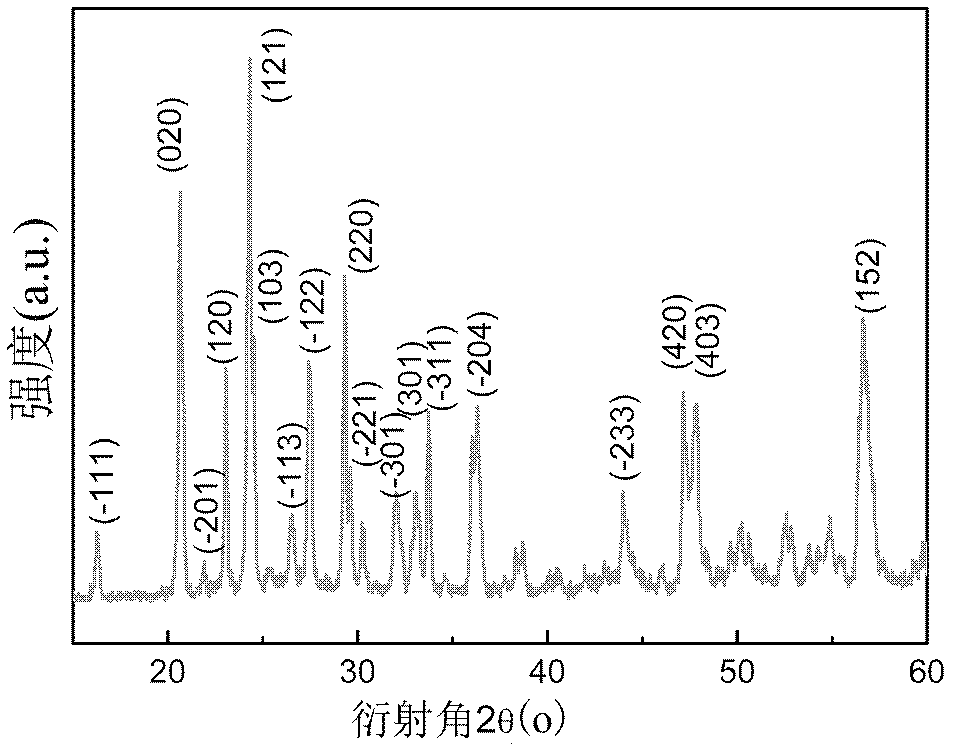

Lithium ion battery anode Li3V2(PO4)3/C composite material and preparation method thereof

A technology for lithium ion batteries and composite materials, which is applied in the field of lithium ion battery cathode Li3V23/C composite materials and their preparation, and can solve problems such as affecting rate performance and poor electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

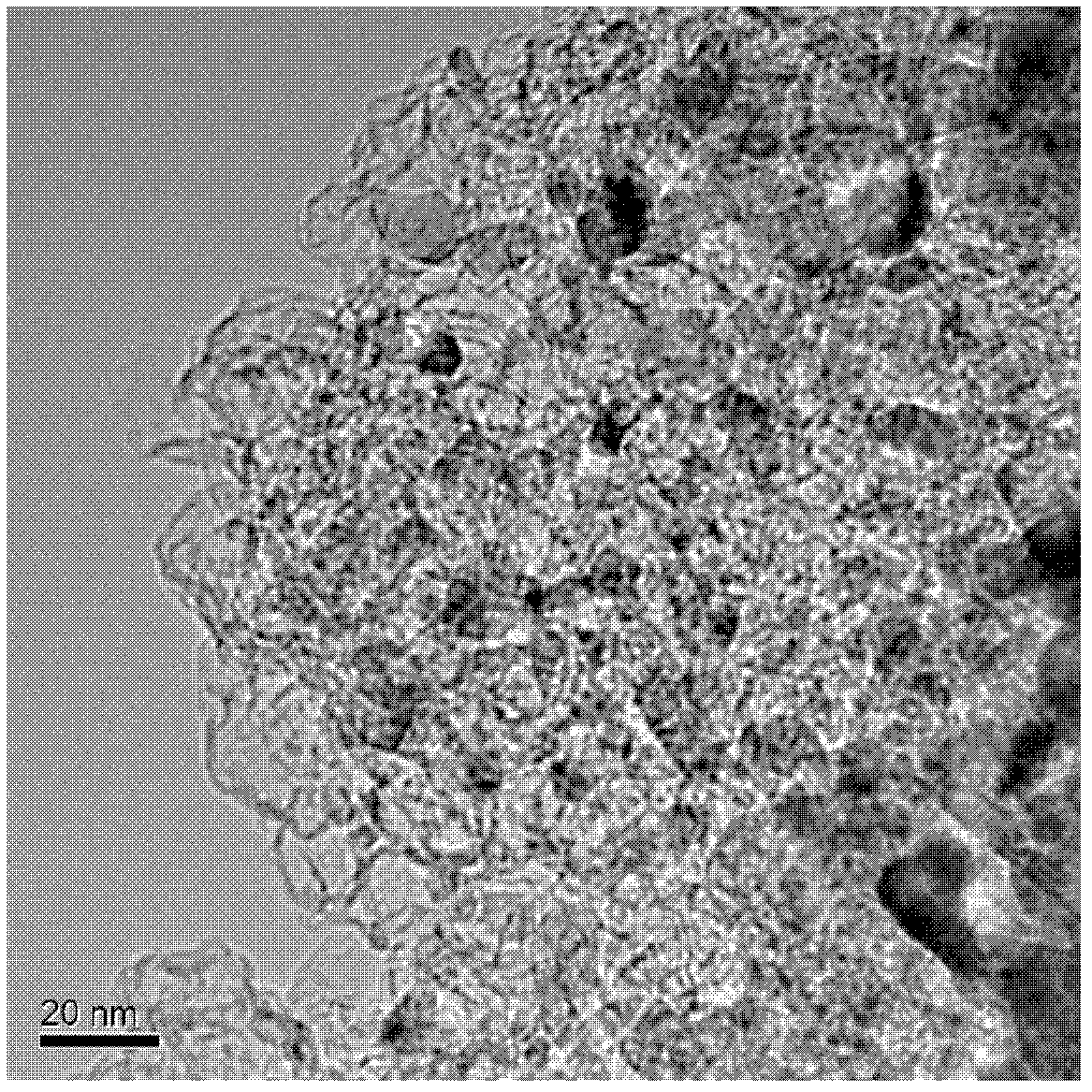

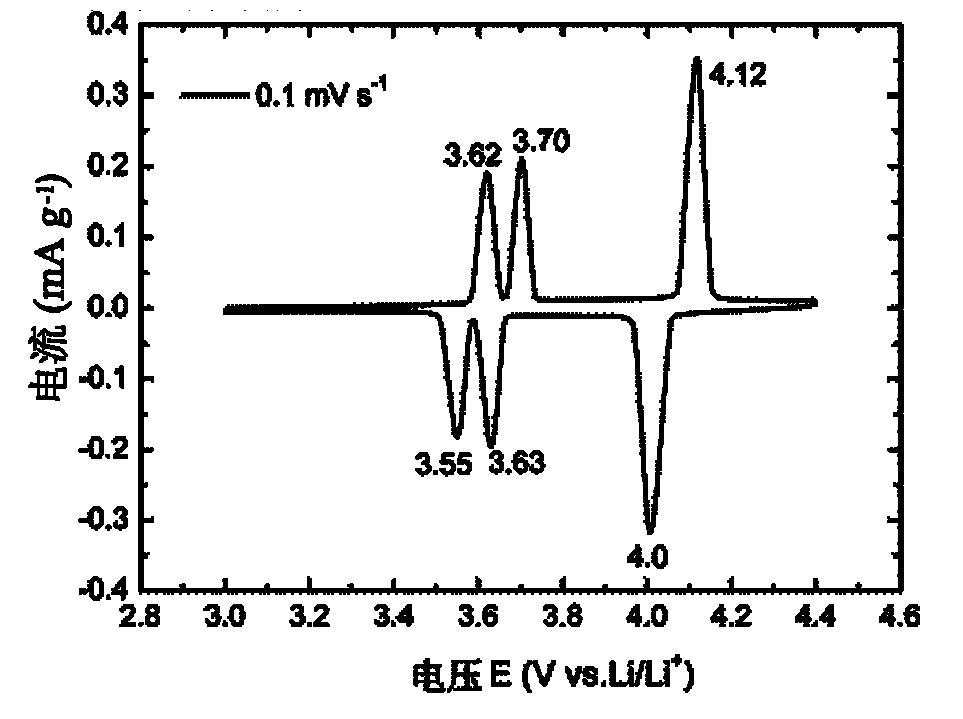

Embodiment 1

[0020] VOC 2 o 4 Added to deionized water, stirred magnetically until a blue solution was formed; then, NH 4 h 2 PO 4 , Li 2 CO 3 Added to the above solution and stirred for one hour, the molar ratio of Li / V / P was 3:2:3; then KB carbon was added to the above mixed solution. Heat and stir at 80°C until a slurry-like mixture forms, then dry overnight at 80°C to give a dry solid. KB carbon was added according to its proportion of 20% in the final composite. The obtained granules were milled, tabletted, and heated in 96% Ar, 4% H 2 Calcined at 350°C for 4 hours under the protection of mixed gas. Afterwards, the obtained sample was re-milled and pressed into tablets, calcined at 800°C for 8 hours in the same atmosphere, cooled and then ground (ground until no obvious lumpy particles were seen) to obtain the final Li 3 V 2 (PO 4 ) 3 / C Composite. Li 3 V 2 (PO 4 ) 3 / C composite material and PVDF adhesive were mixed together in a weight ratio of 90:10, and then dispe...

Embodiment 2

[0025] Lithium source Li in embodiment 1 2 CO 3 use CH 3 COOLi was replaced, and other conditions remained unchanged, and the performance of the prepared composite material was still very good.

Embodiment 3

[0027] The protective atmosphere in Example 1 was replaced by pure Ar, and other conditions remained unchanged, and the performance of the prepared composite material was still very good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com