Structure and method of self-fit splicing for assembled walls

A prefabricated and self-configured technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor sound insulation and heat insulation effect of walls, poor sealing, and difficulty in meeting the requirements of sound insulation and heat preservation of the whole wall, and achieves a high level of improvement. Sound insulation and fire resistance, the effect of reducing production varieties and inventory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

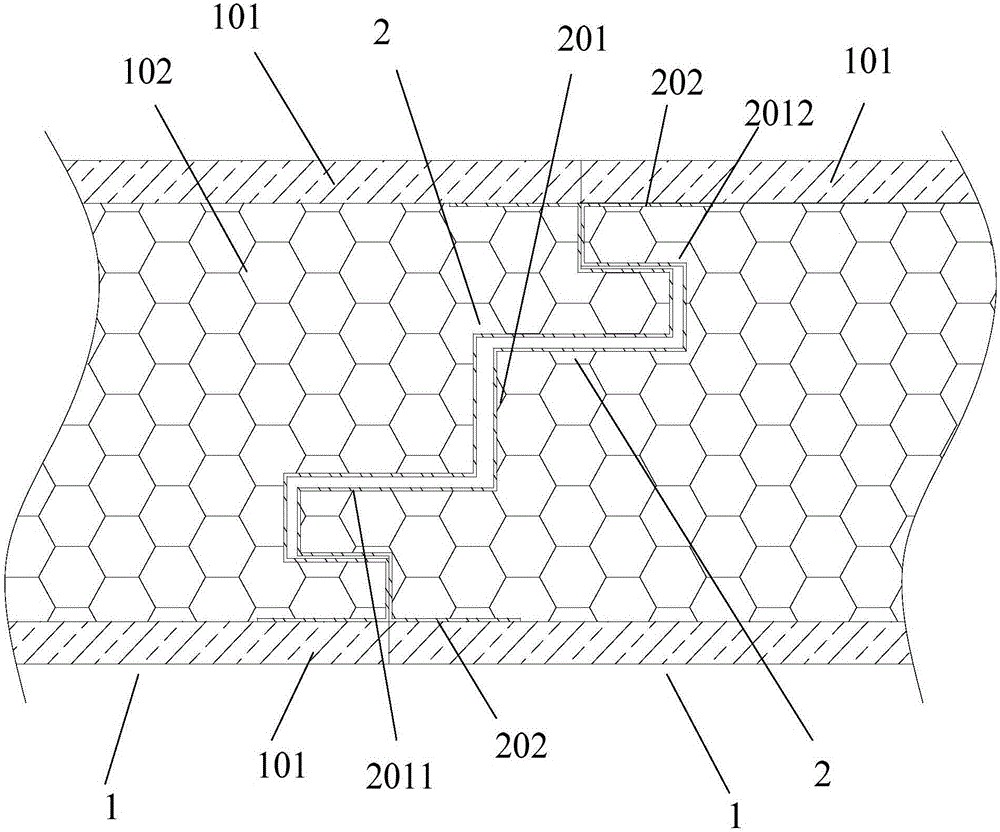

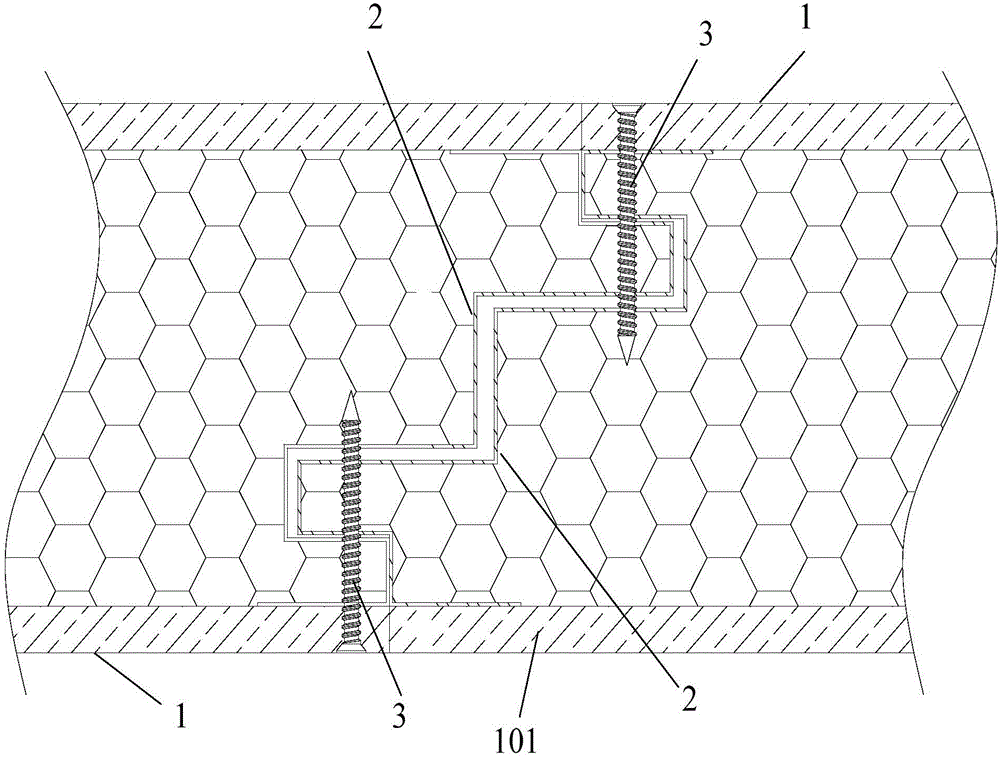

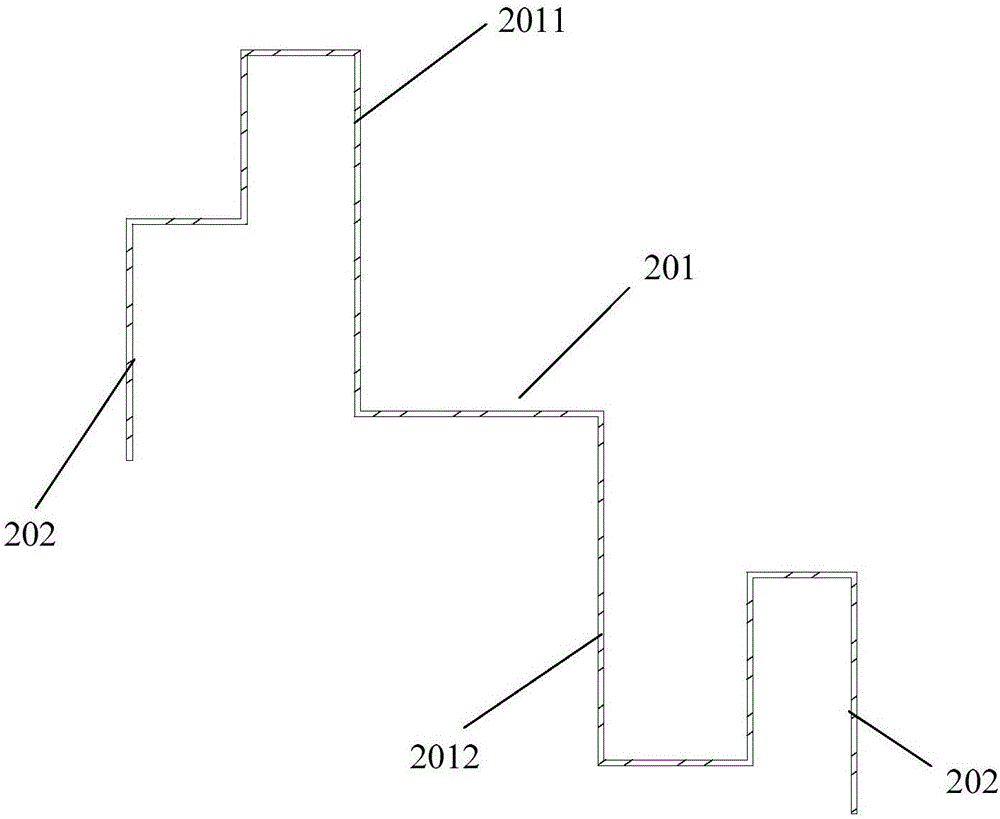

[0041] figure 1 and figure 2 It is a self-fit splicing structure of a prefabricated wall, figure 1 It is a schematic diagram of the self-fit splicing structure, such as figure 1 As shown, the self-fit splicing structure is assembled by a wall unit 1, and the wall unit 1 includes a wallboard 101, a thermal insulation material 102 and a horizontal keel, and the thermal insulation material 102 is arranged between two wallboards 101 and combined into one; Two transverse keels are respectively arranged on the top and bottom of the wall unit, and the transverse keels are C-shaped, U-shaped, rectangular, parallel to each other, and embedded and fixed between the wall panels 101; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com