Faraday shield and plasma processing equipment

A Faraday shielding and molecular technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of reducing the production efficiency of plasma processing equipment, polluting the annular dielectric window, increasing the labor intensity of workers, etc., to reduce the time to interrupt the process, The effect of increasing complexity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the Faraday shield and plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

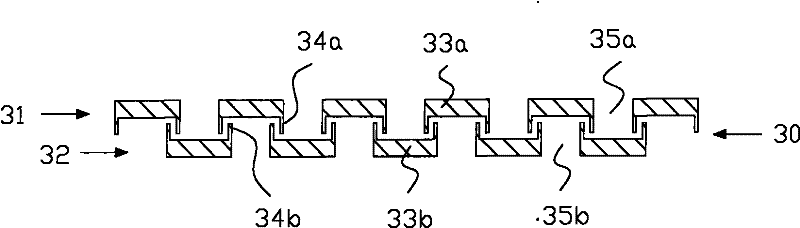

[0024] image 3 A cross-sectional view of a Faraday shield provided by an embodiment of the present invention, Figure 4 Partial enlarged view of the Faraday shield provided for the present invention. Please also refer to image 3 and Figure 4 In this embodiment, the Faraday shielding is a double-layer structure, including a first Faraday shielding unit 31 and a second Faraday shielding unit 32 arranged side by side, and the first Faraday shielding unit 31 and the second Faraday shielding unit 32 are separated by a certain distance to form a gap 30. Both the first Faraday shielding unit 31 and the second Faraday shielding unit 32 include a plurality of shielding segments arranged at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com