Quick thermal treatment method for preparing vanadium dioxide film

A technology of rapid heat treatment and vanadium oxide thin film, applied in ion implantation plating, metal material coating process, coating, etc., to achieve high repeatability, efficient heat treatment method, and optimization of rapid heat treatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Cut the silicon wafer into a square substrate with a size of 2cm×2cm, soak it in absolute ethanol, clean it ultrasonically for 10 minutes, rinse it with deionized water, and dry it;

[0029] (2) Place the silicon substrate cleaned in step 1) in a vacuum chamber, and evacuate the body to 2.5×10 -4 Pa. Introduce argon and oxygen, the flow rates of argon and oxygen are 30sccm and 0.8sccm respectively; start sputtering when the working pressure is adjusted to 1.0Pa, and the sputtering time is 15 minutes;

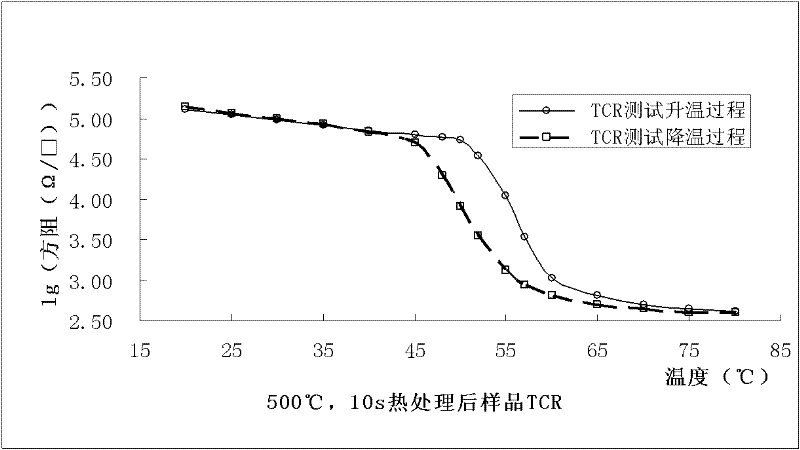

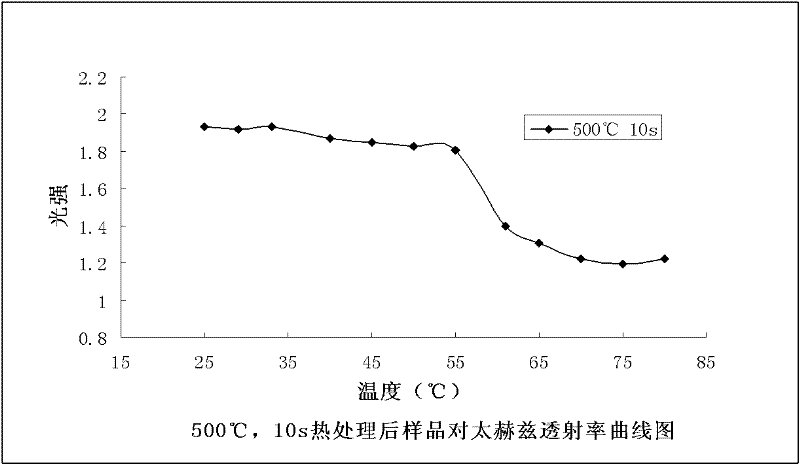

[0030] (3) Put the sample in step 2) into a rapid annealing furnace, set the annealing temperature to 500°C; the heating rate to 50°C / s; and the holding time to 10s. The protective gas nitrogen (mass purity is 99.999%) flow rate is 10 slpm when the temperature is lowered, and the nitrogen flow rate is 3 slpm when the temperature is raised and kept warm;

[0031] (4) Measure the temperature coefficient of resistance (TCR) and terahertz transmittance of the sample, su...

Embodiment 2

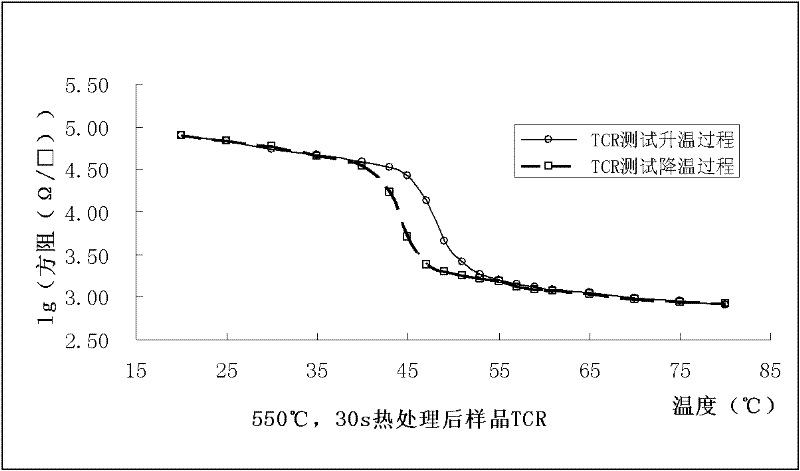

[0033] The operation steps are the same as in Example 1, and the process conditions are correspondingly changed as follows: the flow rates of argon and oxygen are 55 sccm and 1.3 sccm respectively; the working pressure is 2.0 Pa; the sputtering time is 30 minutes; the annealing temperature is 550° C., and the holding time is 30 s.

[0034] Measure the temperature coefficient of resistance (TCR) and terahertz transmittance curve of the sample, such as image 3 and Figure 4 . It can be seen from the figure that the phase transition point obviously moves to a lower temperature, which is 47°C, which is closer to room temperature. Generally, the reduction of the phase transition point can be achieved by doping vanadium dioxide, but now it can be achieved by changing the conditions of rapid heat treatment.

[0035] Implementation 3

[0036] The operation steps are the same as in Example 1, and the process conditions are correspondingly changed as follows: the flow rates of argon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com