Vanadium oxide film for infrared detector and manufacturing method thereof

A technology of vanadium oxide film and infrared detector, which is applied in the direction of electric radiation detectors, etc., can solve the problems of poor product repeatability and stability, high temperature, complex valence state of V element in vanadium oxide film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

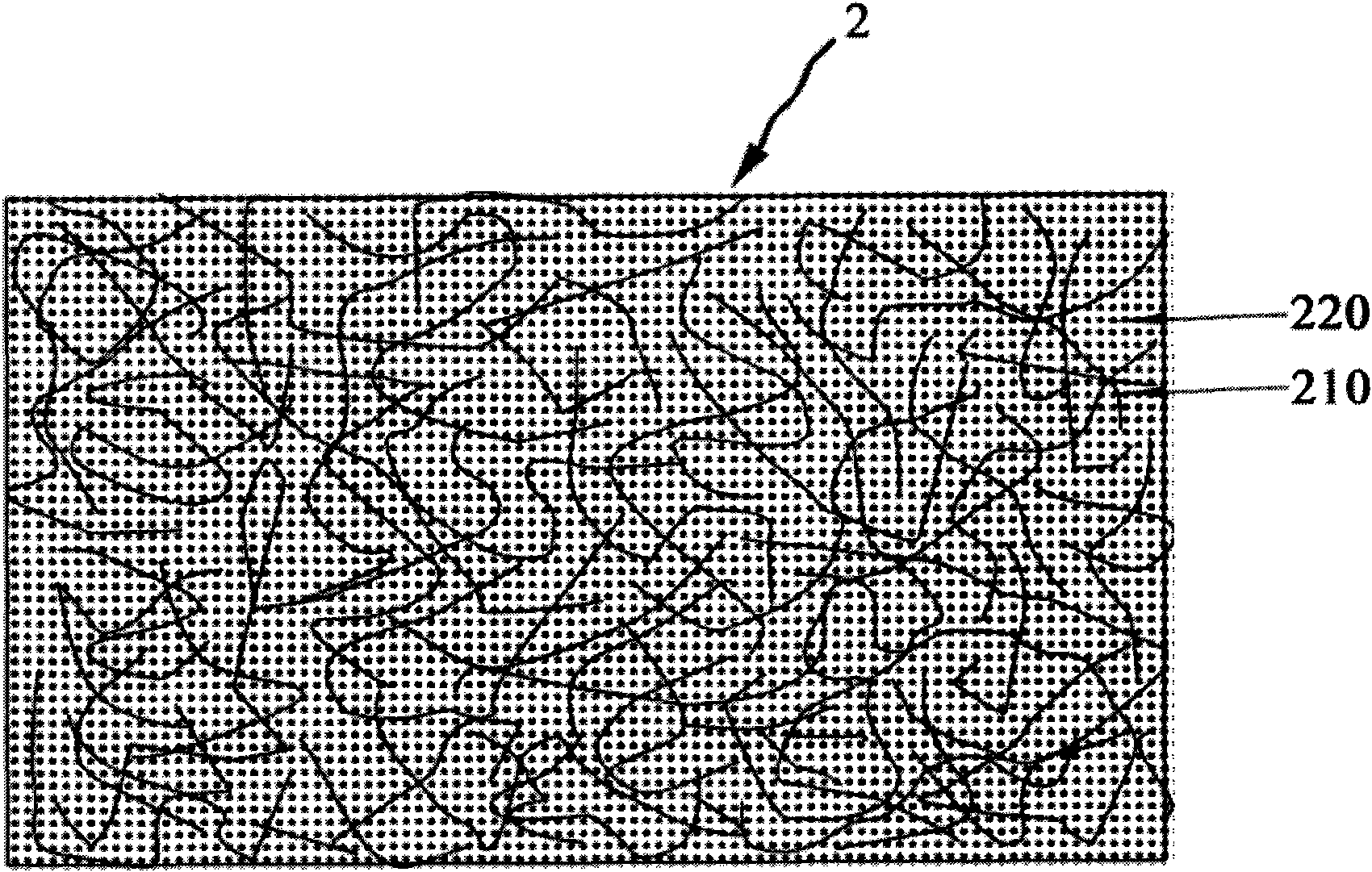

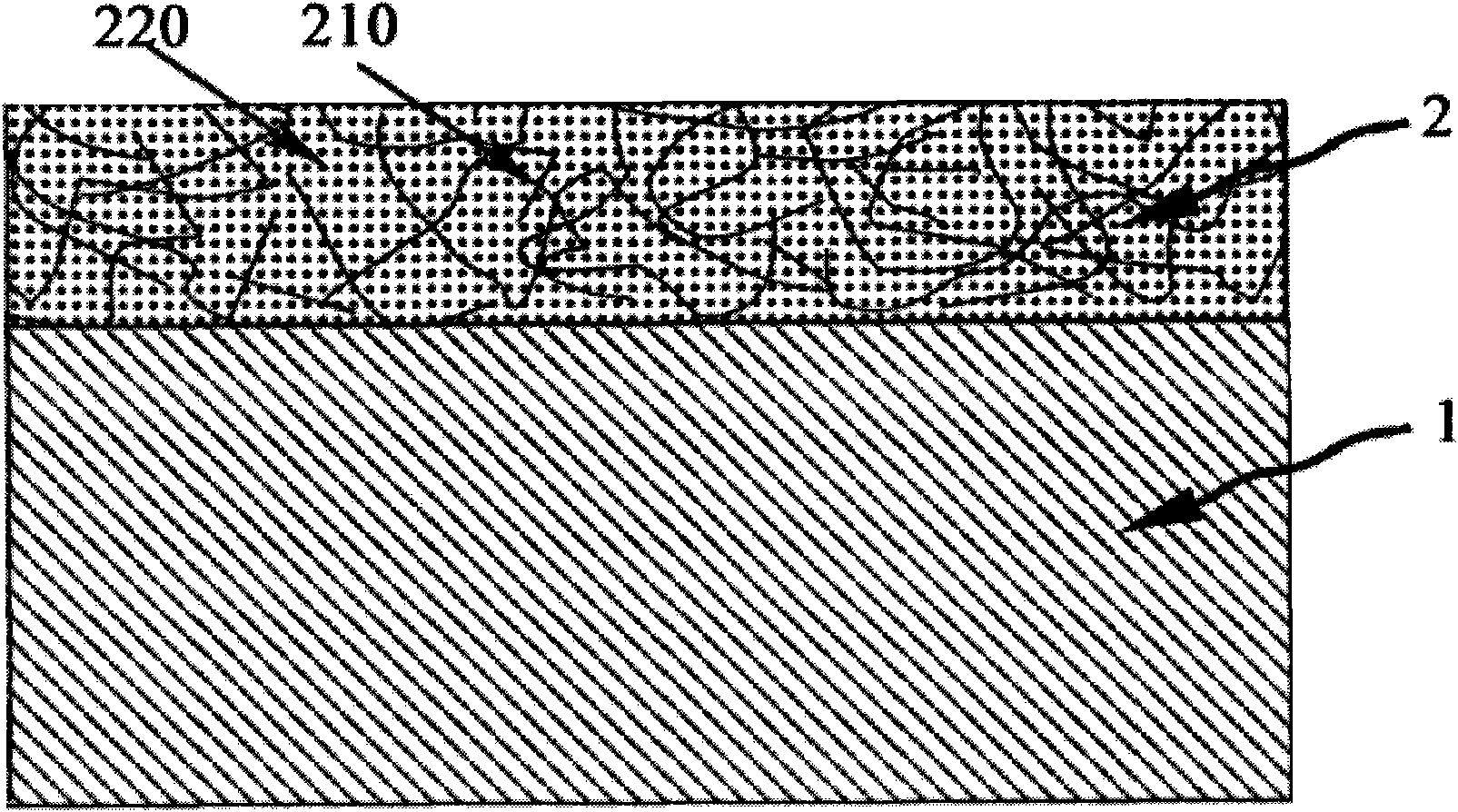

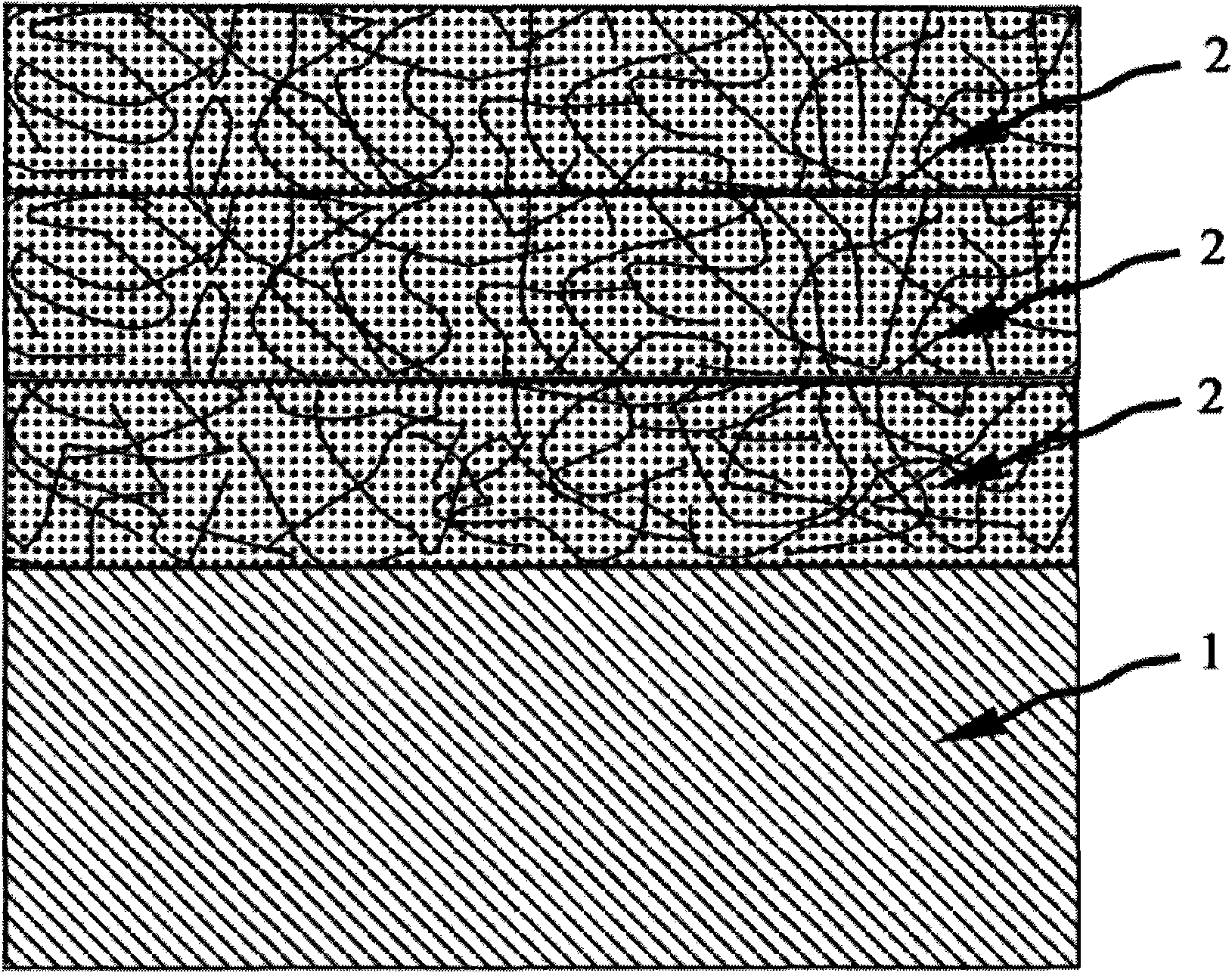

[0036] The guiding ideology of the present invention is in vanadium oxide-carbon nanotube composite membrane structure, utilizes carbon nanotube and vanadium oxide respectively good electrical and optical property, prepares the composite thin film (as figure 1 Shown), used as thermistor material of infrared detector microbolometer, and infrared absorbing material, improve the performance of infrared detector (such as Figure 4-7 shown). The preparation of vanadium oxide-carbon nanotube composite film embodiment of the present invention is as follows: 1. clean the substrate 1 of thin film growth, then blow dry with nitrogen, standby; The method introduces some special functional groups on the surface of carbon nanotubes, and then undergoes steps such as filtration, washing, and drying. Obtaining functionalized carbon nanotubes for later use; ③ mixing a certain amount of va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com