Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Tetraethylammonium bromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetraethylammonium bromide (TEAB) is a quaternary ammonium compound with the chemical formula C₈H₂₀N⁺Br⁻, often written as "Et₄N⁺Br⁻" in the chemical literature. It has been used as the source of tetraethylammonium ions in pharmacological and physiological studies, but is also used in organic chemical synthesis.

Synthetic method of high silica ZSM-5 zeolite

InactiveCN101898767AReduce dosageShape is easy to controlPentasil aluminosilicate zeoliteTetramethylammonium bromideAdhesive

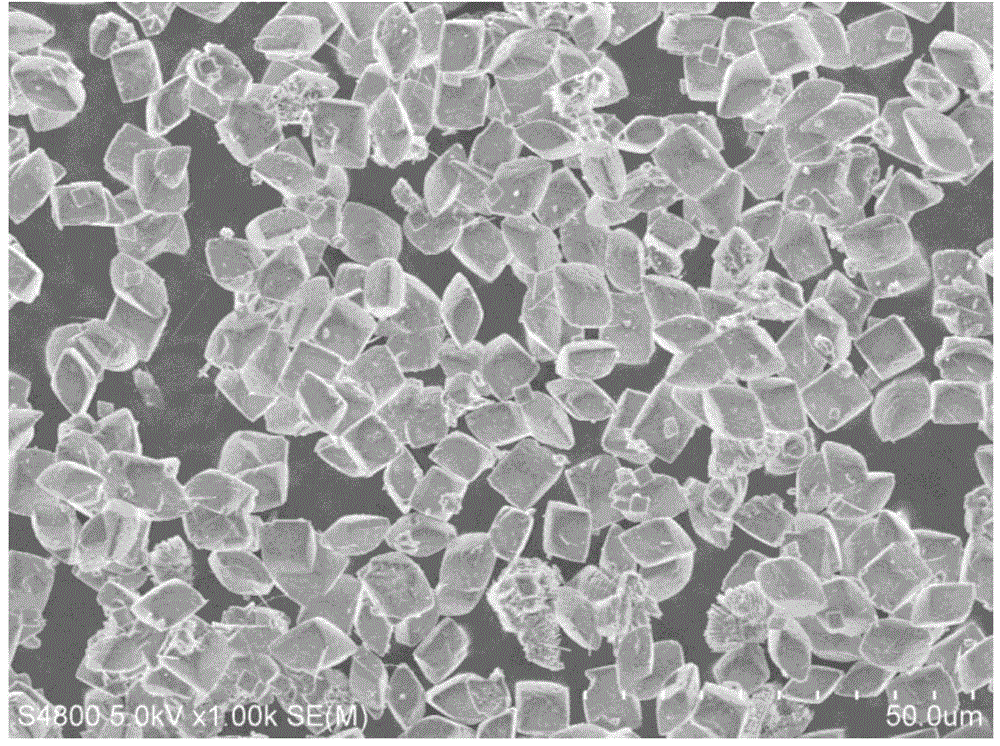

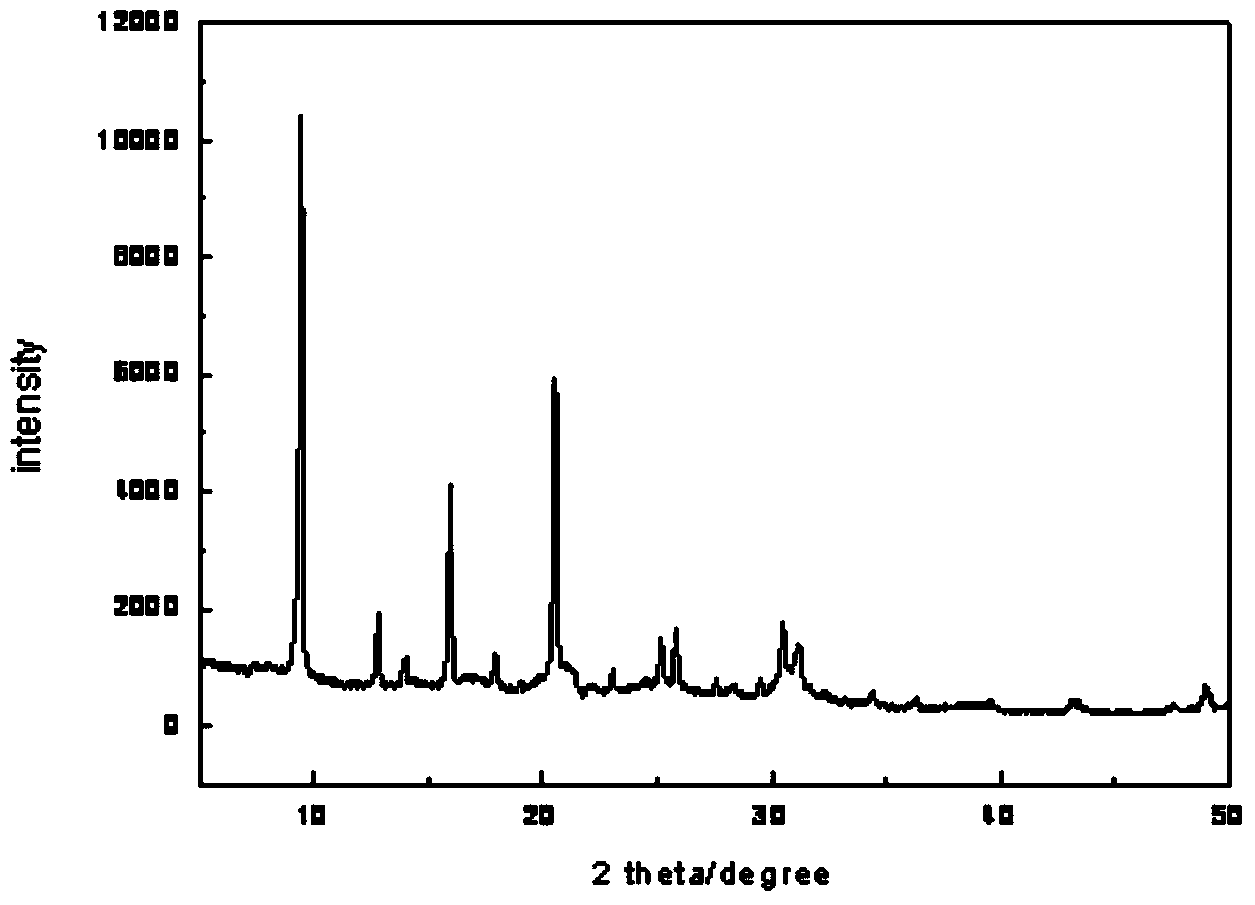

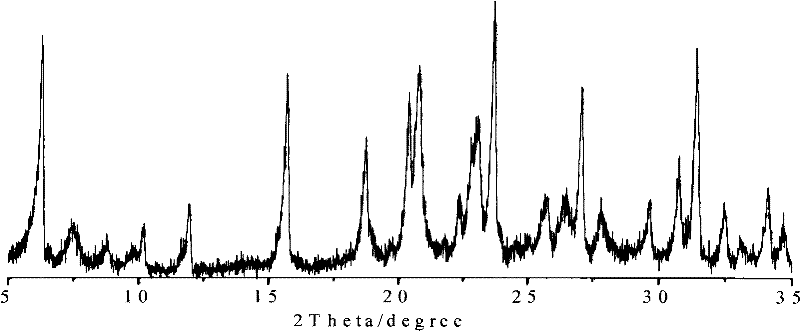

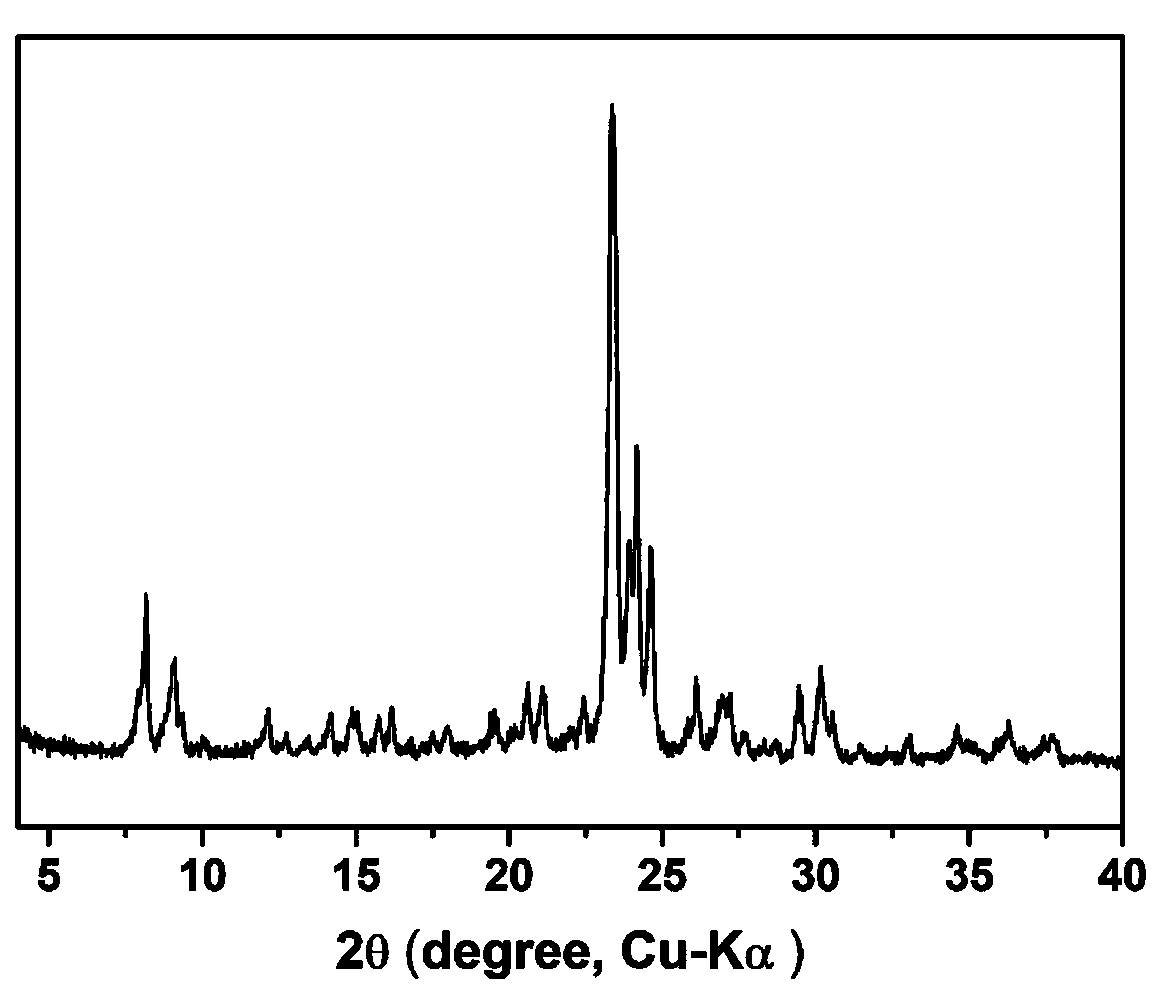

The invention discloses a synthetic method of high-silica ZSM-5 zeolite, the method comprises the steps of adopting water glass as a silica source, adopting aluminum salts of aluminum sulfate, aluminum nitrate, aluminum chloride and the like, as well as organic aluminum compounds of sodium metaaluminate, isopropanol and the like as aluminum sources, using sulfuric acid or hydrochloric acid to regulate alkalinity, adding an organic template, simultaneously adding a guide adhesive, carrying out high-temperature crystallization at 120-200 DEG C, and then synthesizing the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100; and the molar ratio of raw materials is as follows: SiO2 / Al2O3 is equal to 100-infinity, Na2O / SiO2 is equal to 0.05-0.20, and H2O / SiO2 is equal to 10-100. The organic template comprises tetrapropylammonium bromide, tetrapropylammonium hydroxide, tetraethylammonium bromide, tetraethylammonium hydroxide, n-butylamine, ethylamine, hexamethylene diamine and any other organic matters which can synthesize the ZSM-5 zeolite or the mixture thereof, wherein the using amount of the organic template is that R / SiO2 is equal to 0.005-0.50; and the amount of silicon dioxide in the guide adhesive is 0-5% of the total weight of the silicon dioxide in a synthetic system. The synthetic method can synthesize the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100 and has the advantages of cheap raw materials, a small using amount of the organic template, and capability of realizing the control of product appearance and particle size by changing the relative using amount of the template and the guide adhesive.

Owner:EAST CHINA NORMAL UNIV

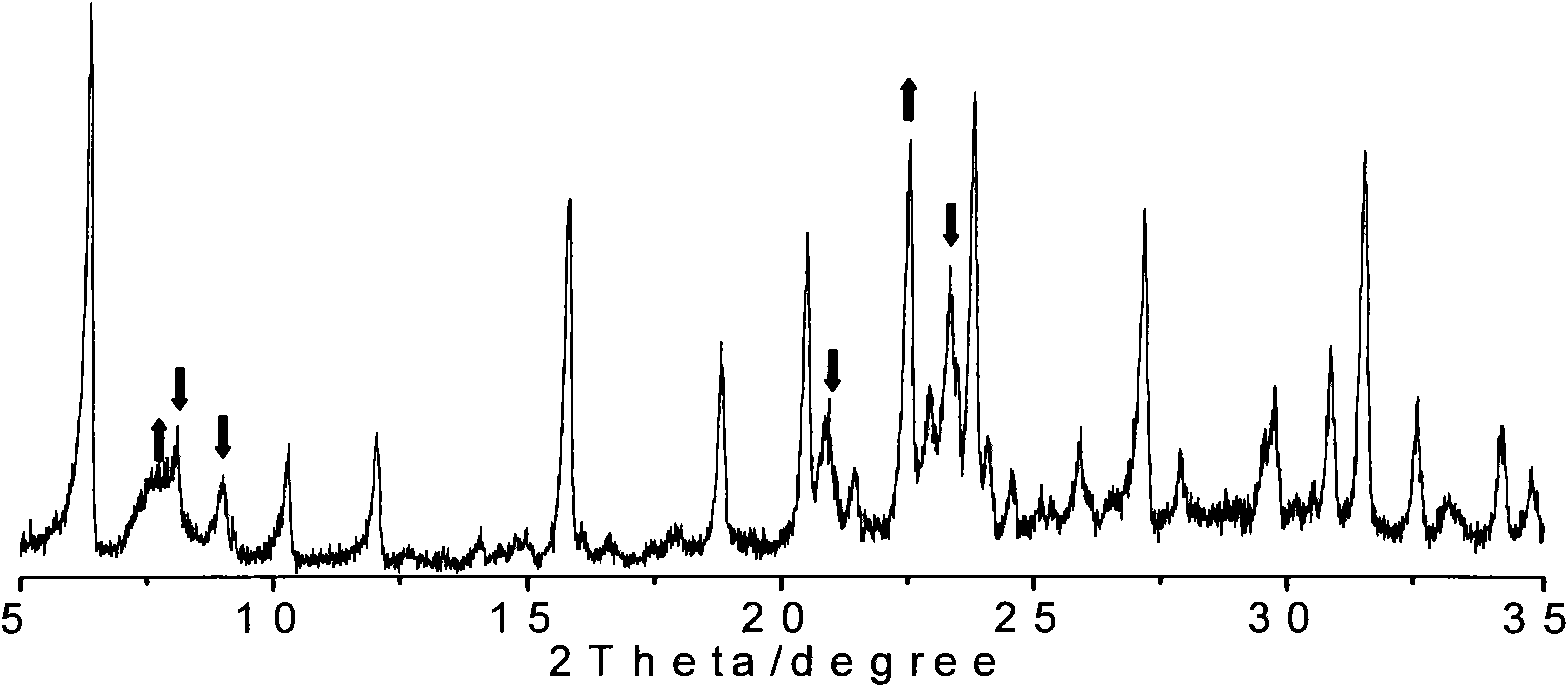

Three-crystalline phase composite molecular sieve and preparation method thereof

ActiveCN101898151AEasy to useMolecular sieve catalystsBulk chemical productionSal ammoniacTetramethylammonium bromide

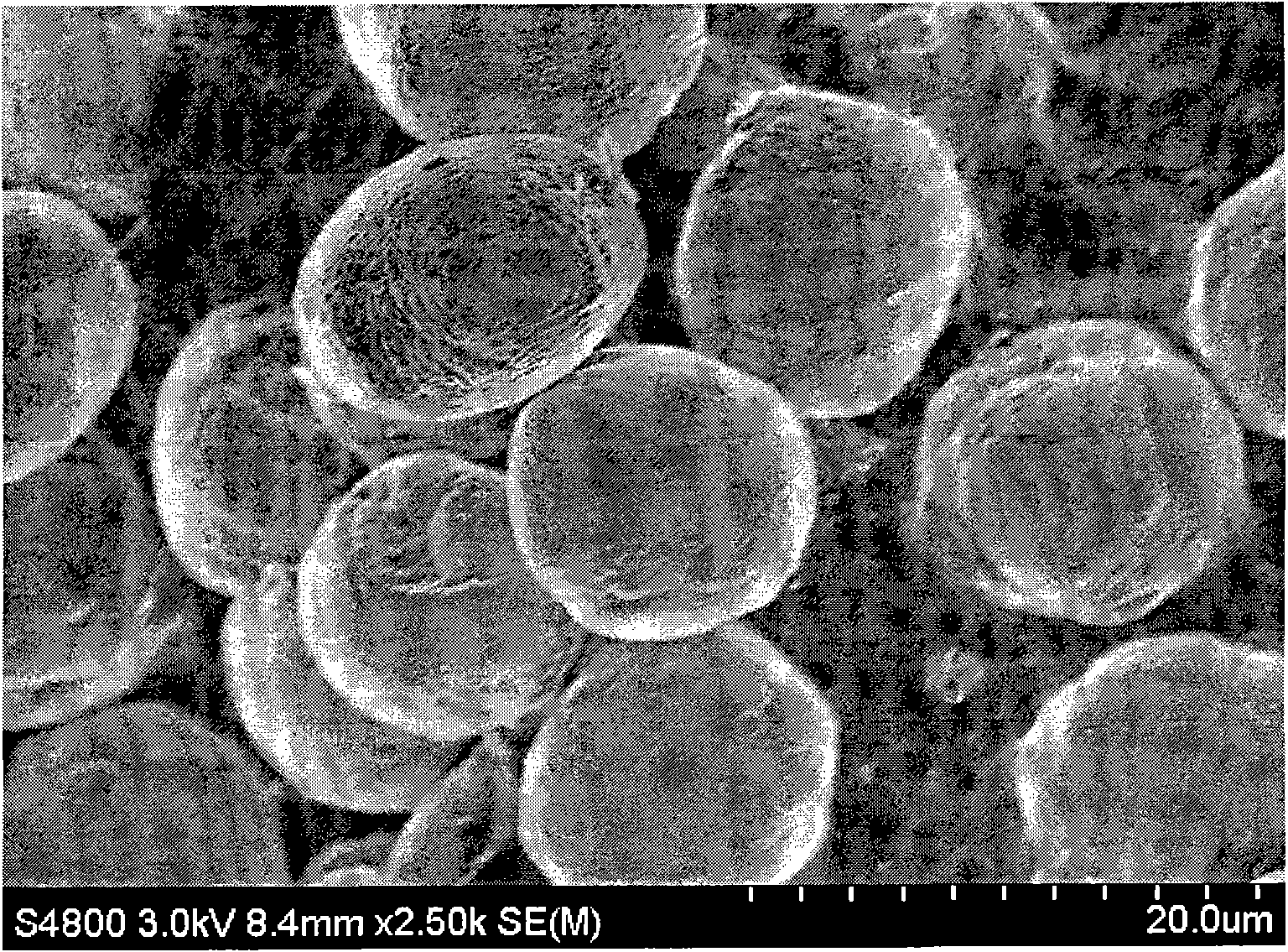

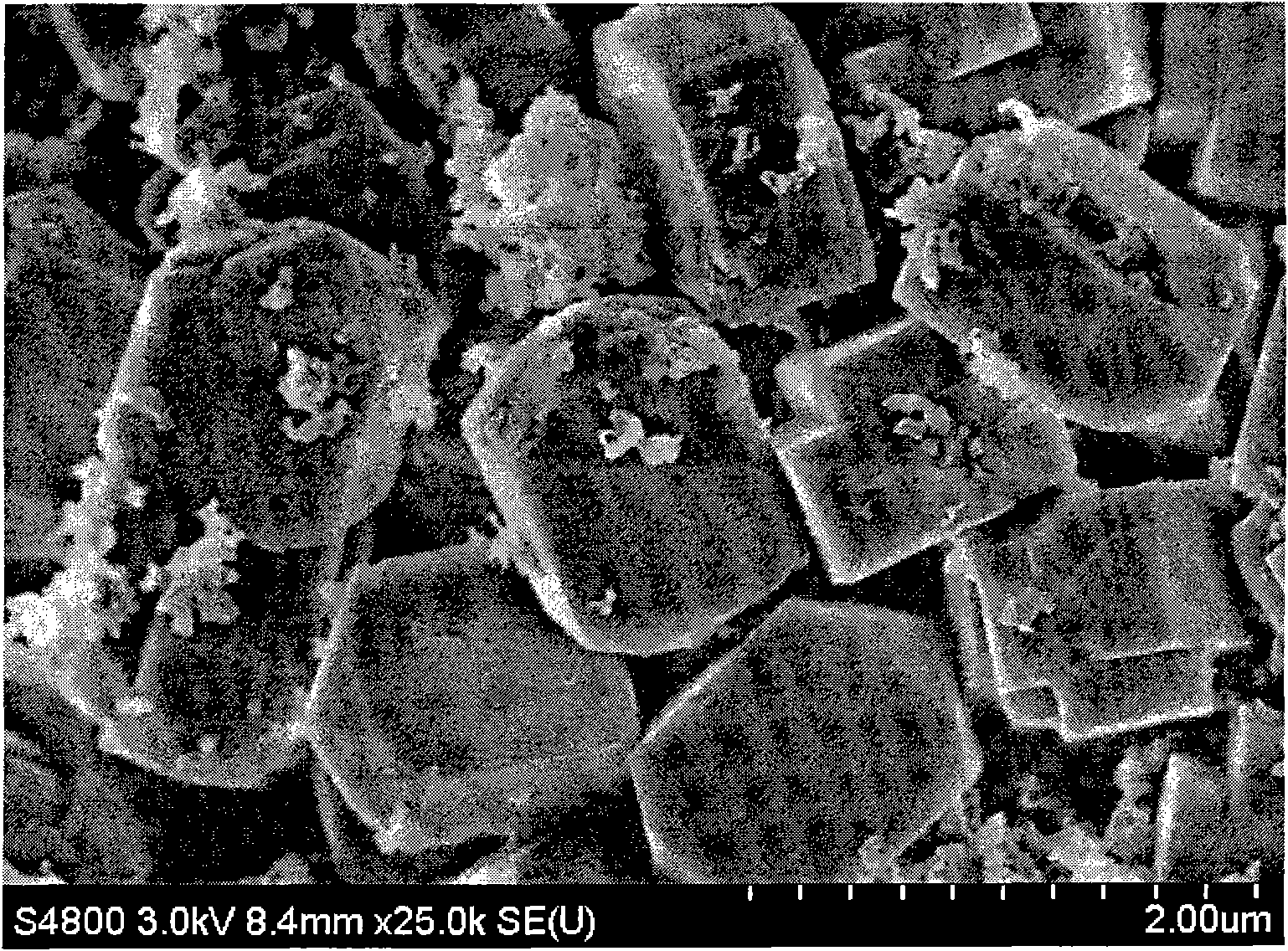

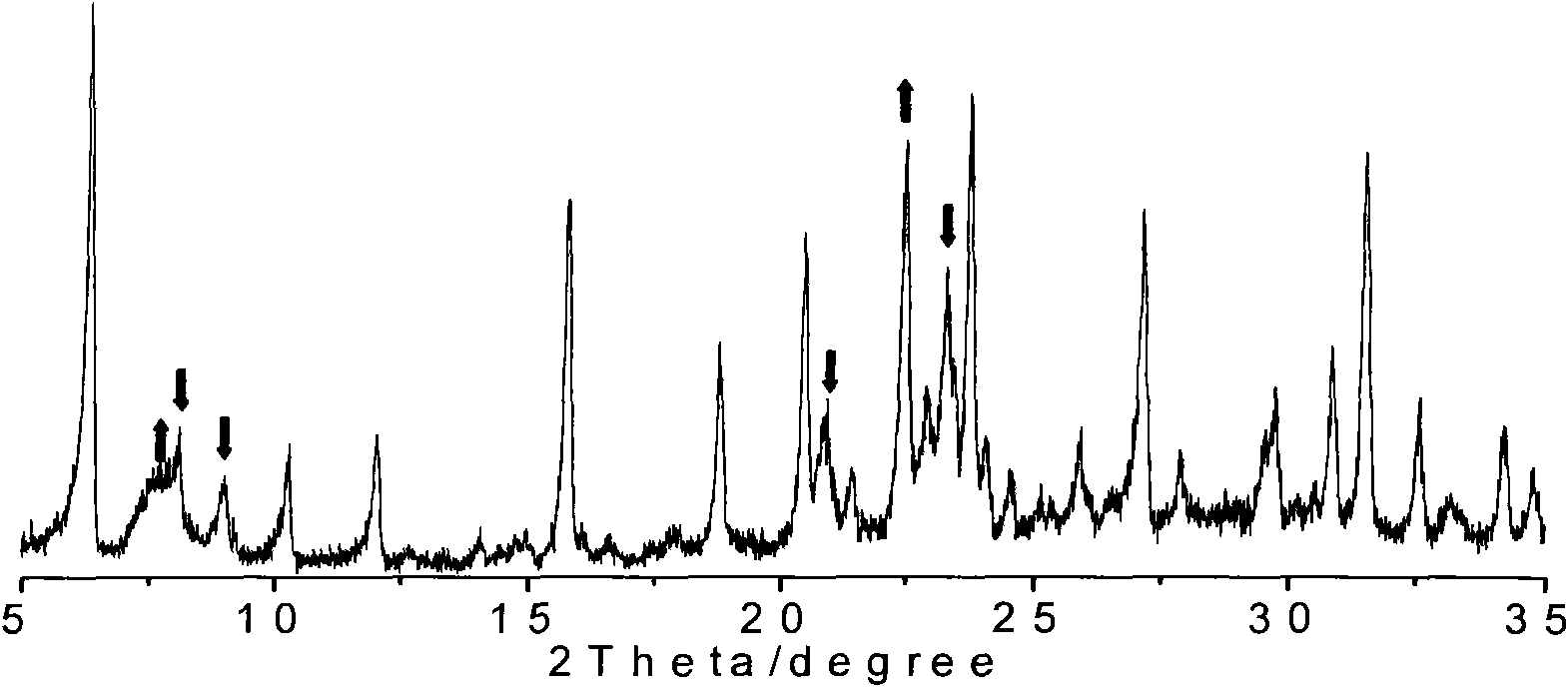

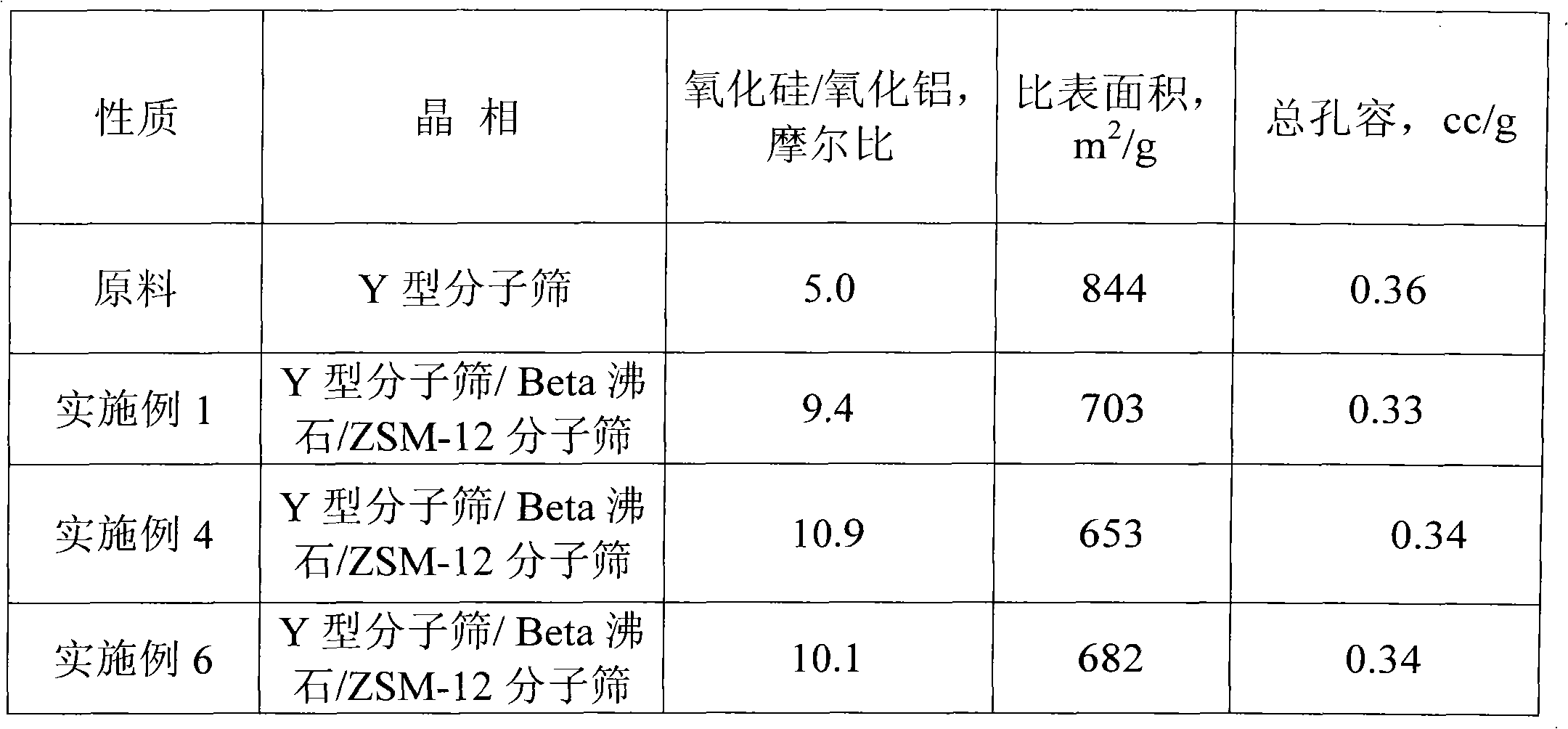

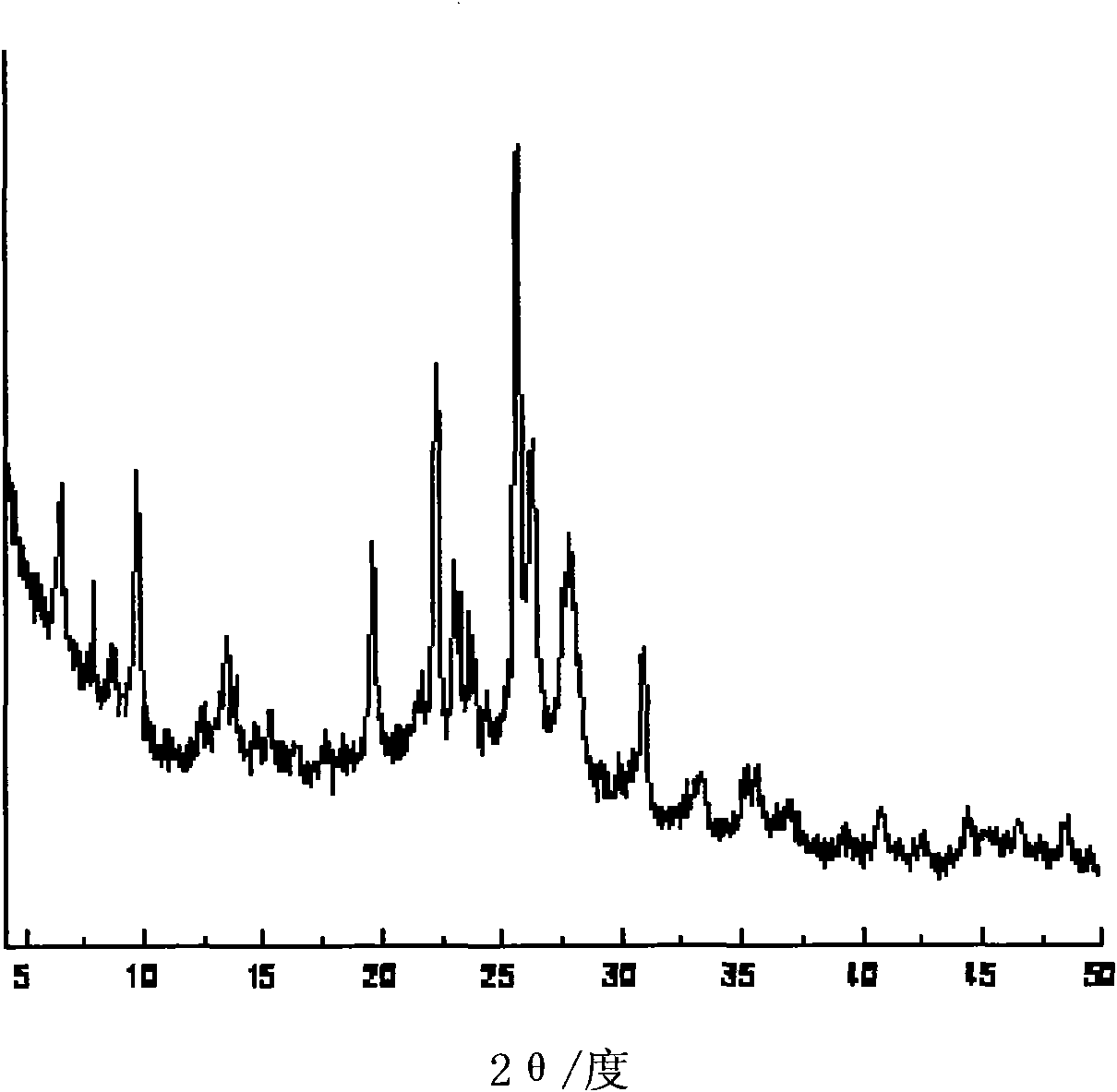

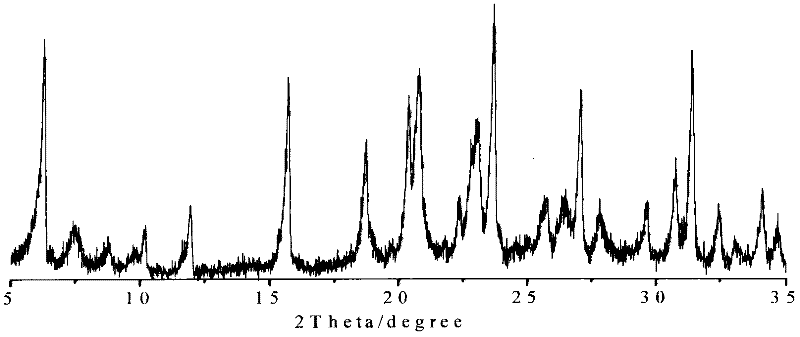

The invention relates to a three-crystalline phase composite molecular sieve. The composite molecular sieve has a Y molecular sieve crystalline phase, a Beta zeolite crystalline phase and a ZSM-12 molecular sieve crystalline phase. A preparation method for the three-crystalline phase composite molecular sieve comprises the following steps of: adding Y molecular sieve powder into solution containing sodium hydroxide and tetraethylammonium bromide; selectively adding ammonia water, adding a silicon source, and stirring uniformly to obtain a reaction mixture gel system, wherein the molar ratio in the reaction mixture gel system is: 0.90-1.15 Na2O:8.0-15.0 SiO2:0.8-2.0TEABr:0-8.0 NH4OH:AL2O3:80-102 H2O; crystallizing the reaction mixture under the closed condition at 130 to 160 DEG C for 5 to 10 days to obtain a Y-Beta-ZSM-12 composite molecular sieve. The composite molecular sieve is a new product and can be used for various catalytic processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

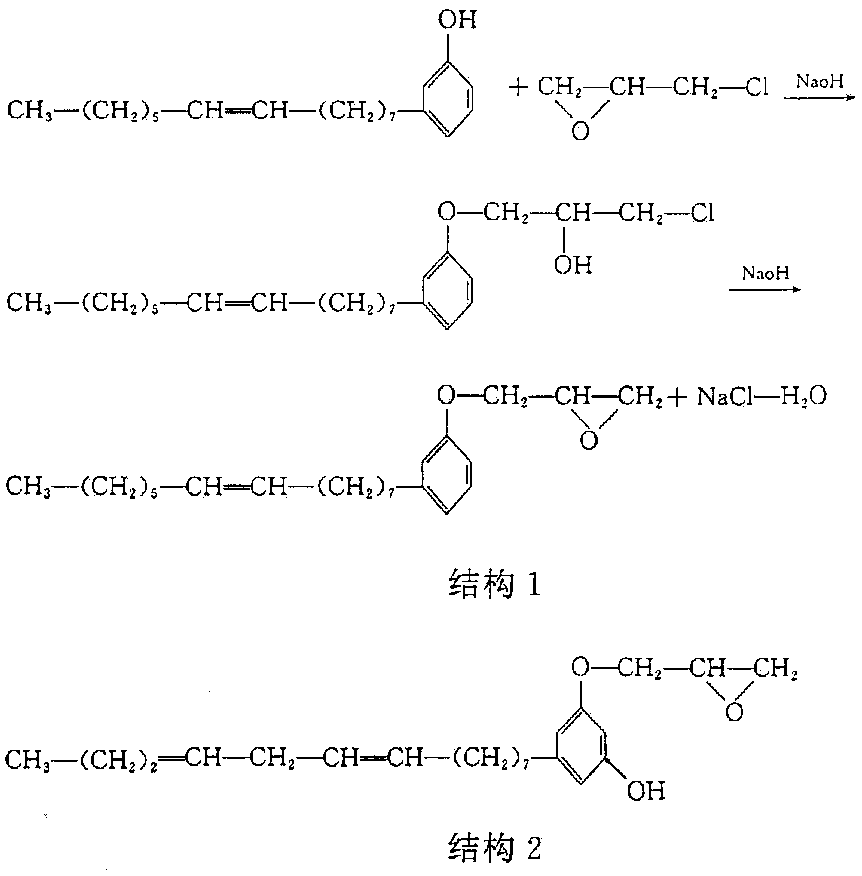

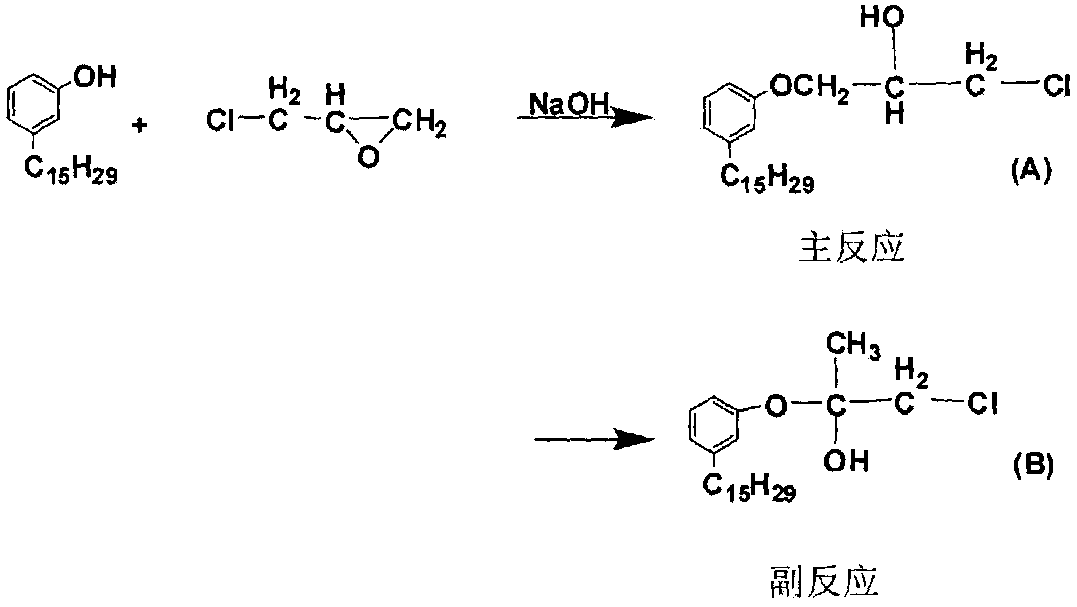

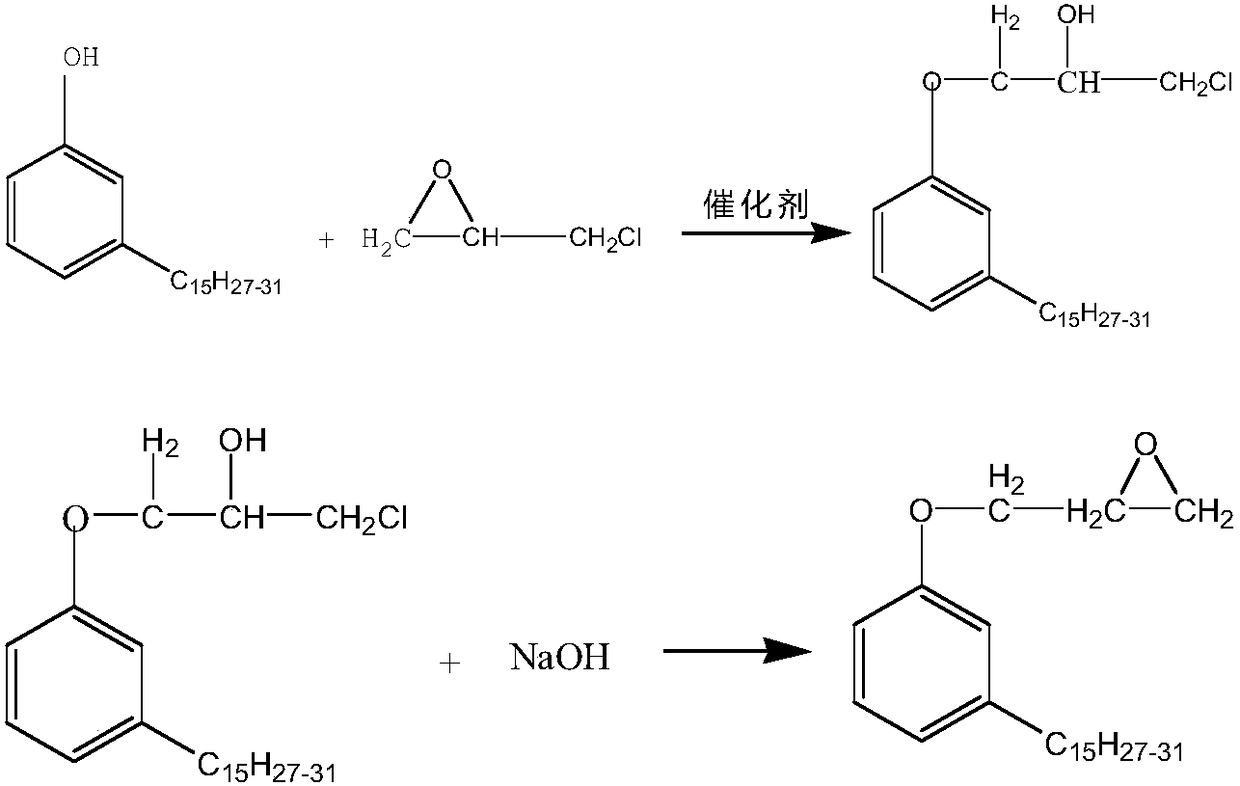

Preparation method of anacardol glycidyl ether

InactiveCN108299165AViolent reactionLow epoxy equivalentEther preparation from oxiranesTetramethylammonium bromideDistillation

The invention relates to a preparation method of anacardol glycidyl ether. According to the preparation method, raw materials include anacardol, epoxy chloropropane, sodium hydroxide and a catalyst are used. The catalyst is a mixture of tetraethylammonium bromide and tetramethyl ammonium bromide; meanwhile, reduced pressure distillation is used for recovering the epoxy chloropropane for many timesin the method. The epoxide equivalent of the anacardol glycidyl ether prepared by the preparation method provided by the invention is lower and stable; the content of free anacardol is greatly reduced.

Owner:江苏万盛大伟化学有限公司

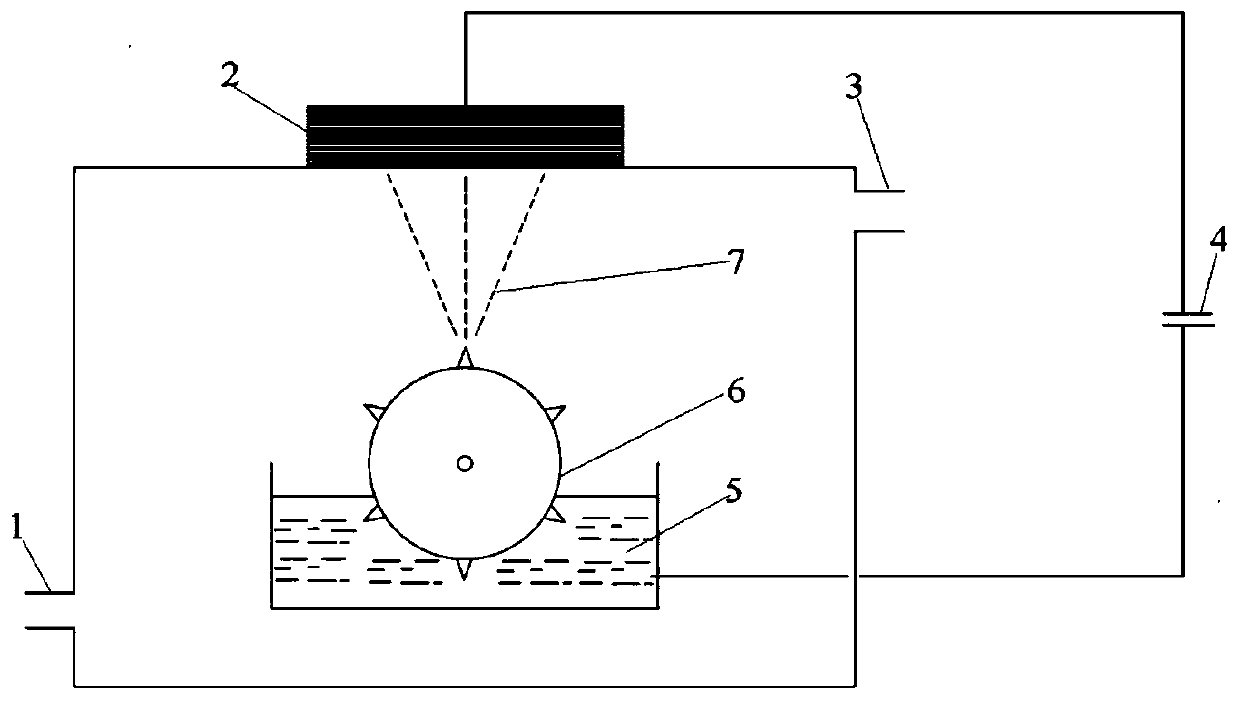

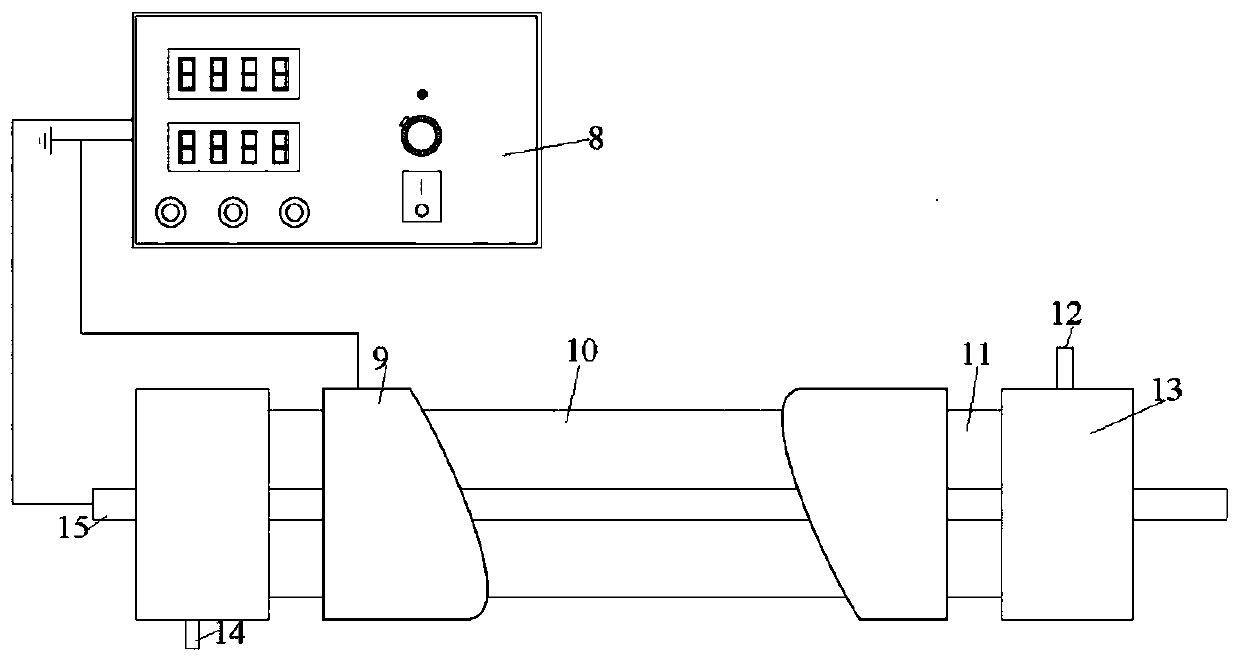

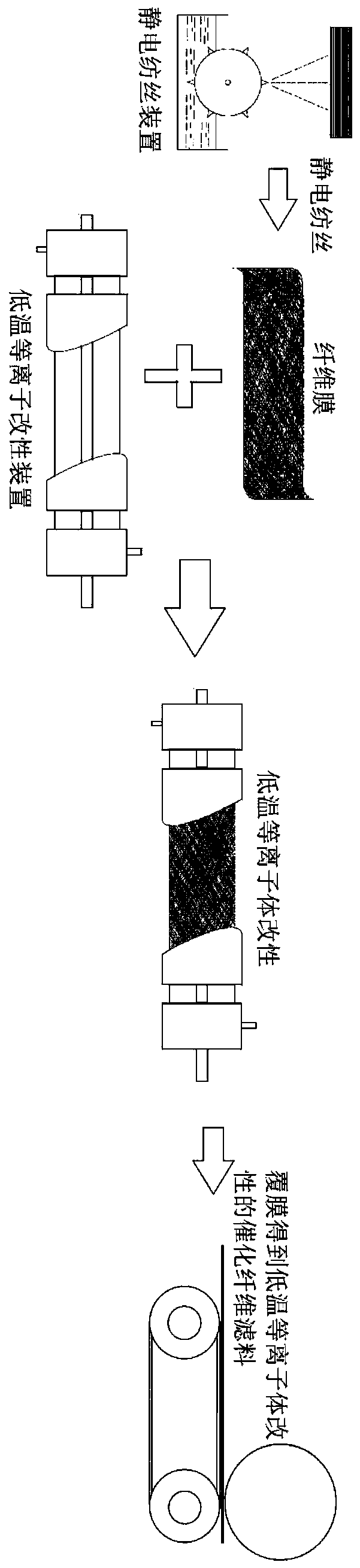

Preparation method of low-temperature plasma modified catalytic fiber filter material

ActiveCN110639362AFully contactedImprove denitrification effectGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsTetramethylammonium bromideFiber

The invention discloses a preparation method of a low-temperature plasma modified catalytic fiber filter material. The method comprises the following steps: 1) weighing polyurethane as a solute, and preparing a solution by using a dimethylformamide solution as a solvent; 2) adding a tetraethylammonium bromide powder into the obtained solution to obtain a mixed solution; 3) adding a catalyst precursor into the mixed solution, and performing stirring to obtain an electrostatic spinning solution; 4) carrying out electrostatic spinning on the electrostatic spinning solution, and collecting spun yarns to obtain a nanofiber film; 5) putting the nanofiber film in a low-temperature plasma modification device, introducing argon, carrying out plasma modification, and cooling the obtained film to room temperature to obtain a low-temperature plasma modified catalytic fiber film; and 6) coating and packaging the low-temperature plasma modified catalytic fiber film to obtain the low-temperature plasma modified catalytic fiber filter material. The method which adopts preparation of the fiber filtration material by combining the electrostatic spinning with the low-temperature plasma modification process as the innovation point has the advantages of wide material sources, easiness in process operation, good product processability, good market competitiveness and good promotion values.

Owner:SOUTHEAST UNIV

Method for preparing mordenite/ Zeolite Socony Mobil (ZSM)-5 composite molecular sieve

ActiveCN102464334AMordenite aluminosilicate zeolitePentasil aluminosilicate zeoliteTetramethylammonium bromideMicrosphere

The invention relates to a method for preparing a mordenite / Zeolite Socony Mobil (ZSM)-5 composite molecular sieve, which comprises the following steps: evenly mixing sodium hydroxide, tetraethylammonium bromide and deionized water; adding mordenite or ZSM-5 seed crystal, wherein the seed crystal addition volume is 5wt% of total feeding material SiO2; carrying out ultrasonic vibration for 30min to evenly disperse the seed crystal; then, adding kaolin microspheres and white carbon black; stirring for half an hour, and transferring gel into a polytetrafluoroethylene reaction kettle; and then transferring the gel into an oven after ageing at the room temperature for 10-40h and crystallizing at the temperature of 110-170DEG C for 14-70h. A reaction system is formed at the following molar ratio: SiO2 / Al2O3 is equal to 10-60, Na2O / SiO2 is equal to 0.029-0.31, tetraethylammonium (TEA)+ / SiO2 is more than or equal to 0.02, and H2O / SiO2 is equal to 5.0-30.0. In the method, only the single seedcrystal needs to be added to obtain a product which can be directly used for fluid catalytic cracking (FCC) reaction after being slightly modified.

Owner:PETROCHINA CO LTD +1

Preparation method of H beta/HMCM-49 compound molecular sieve

ActiveCN102464328AWell mixedLarge average pore sizeCrystalline aluminosilicate zeolitesAluminateTetramethylammonium bromide

The invention relates to a preparation method of an H beta / HMCM-49 compound molecular sieve, which comprises the steps of: mixing and dissolving sodium aluminate, sodium hydroxide and potassium hydroxide into distilled water; dissolving tetraethylammonium bromide and ammonia water to prepare hexamethonium ammonia water; at normal temperature, reacting sodium and potassium meta-aluminate alkali liquor and the hexamethonium ammonia water with silicon sol, adding Na beta molecular sieve raw powder for crystallizing; dissolving the sodium aluminate into the distilled water, adding hexamethyleneimine; at normal temperature, dropping the silicon sol; adding NaMCM-49 molecular sieve compound molecular sieve raw powder, mixing and introducing O3 or H2O2 for oxidizing to prepare modified H beta / HMCM-49 compound molecular sieve raw powder; exchanging with an ammonium nitrate solution to prepare H beta / HMCM-49 compound molecular sieve raw powder. A compound molecular sieve has efficacy of an MCM-49 molecular sieve and a beta molecular sieve, and has the characteristics of uniform mixing, large average pore diameter, many through holes and strong total acidity.

Owner:PETROCHINA CO LTD

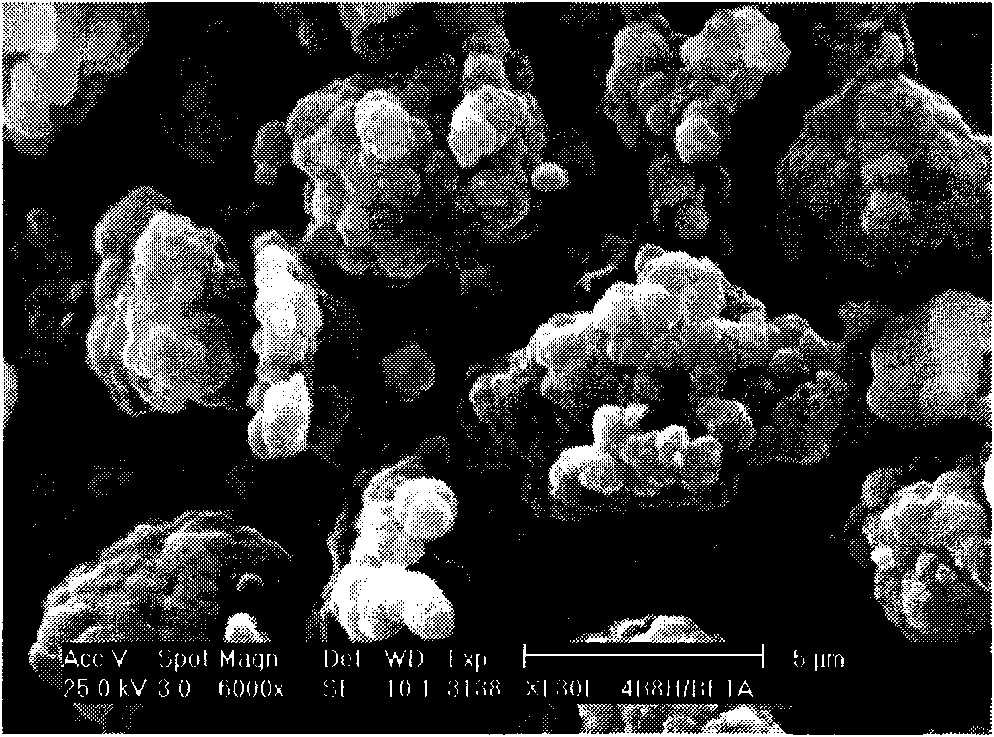

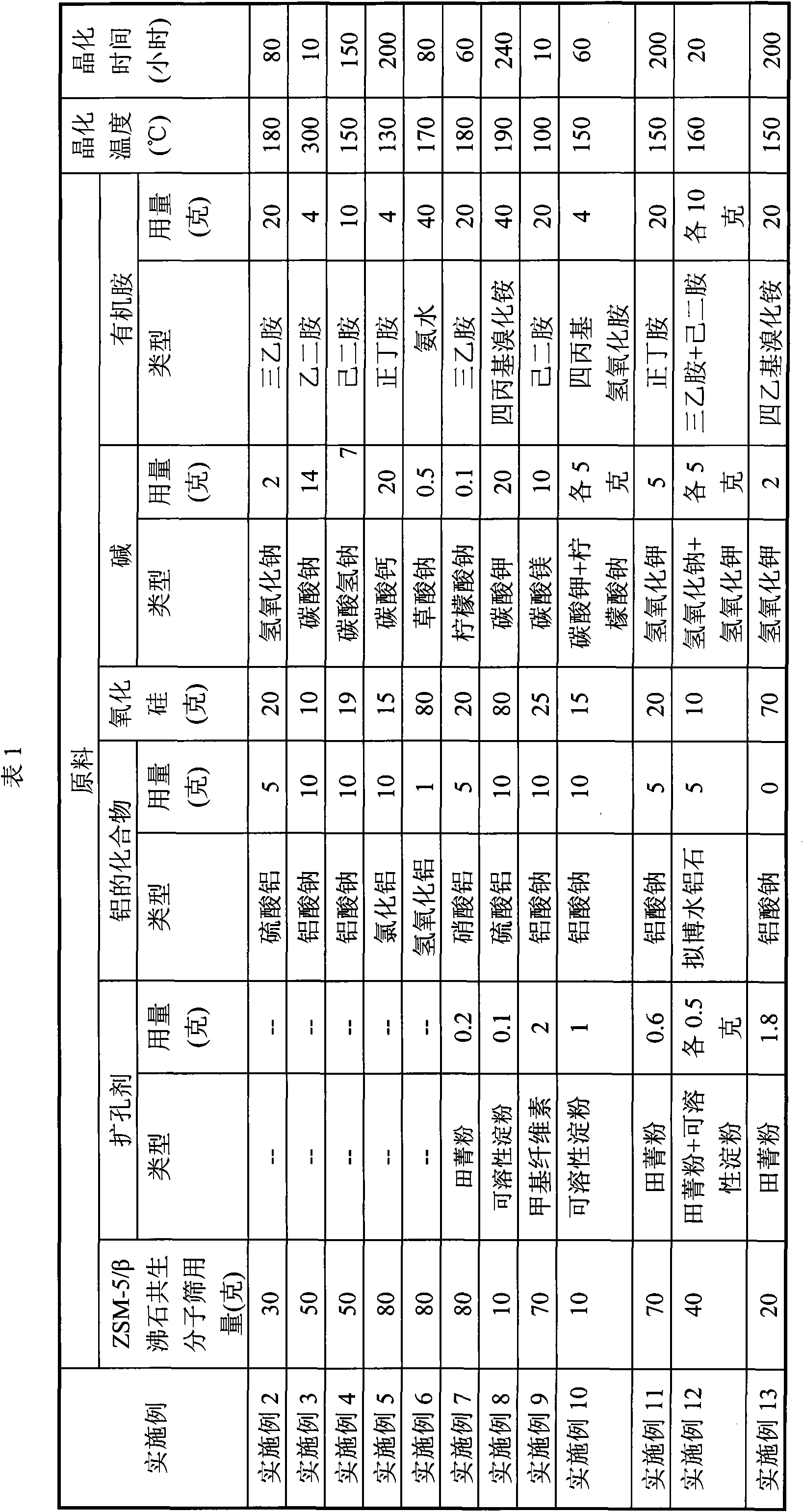

Preparation method of non-binder ZSM-5/zeolite beta coexisting molecular sieve catalyst

ActiveCN102039171BIncrease contentHigh activityMolecular sieve catalystsCatalyst activation/preparationEthylenediamineTetramethylammonium bromide

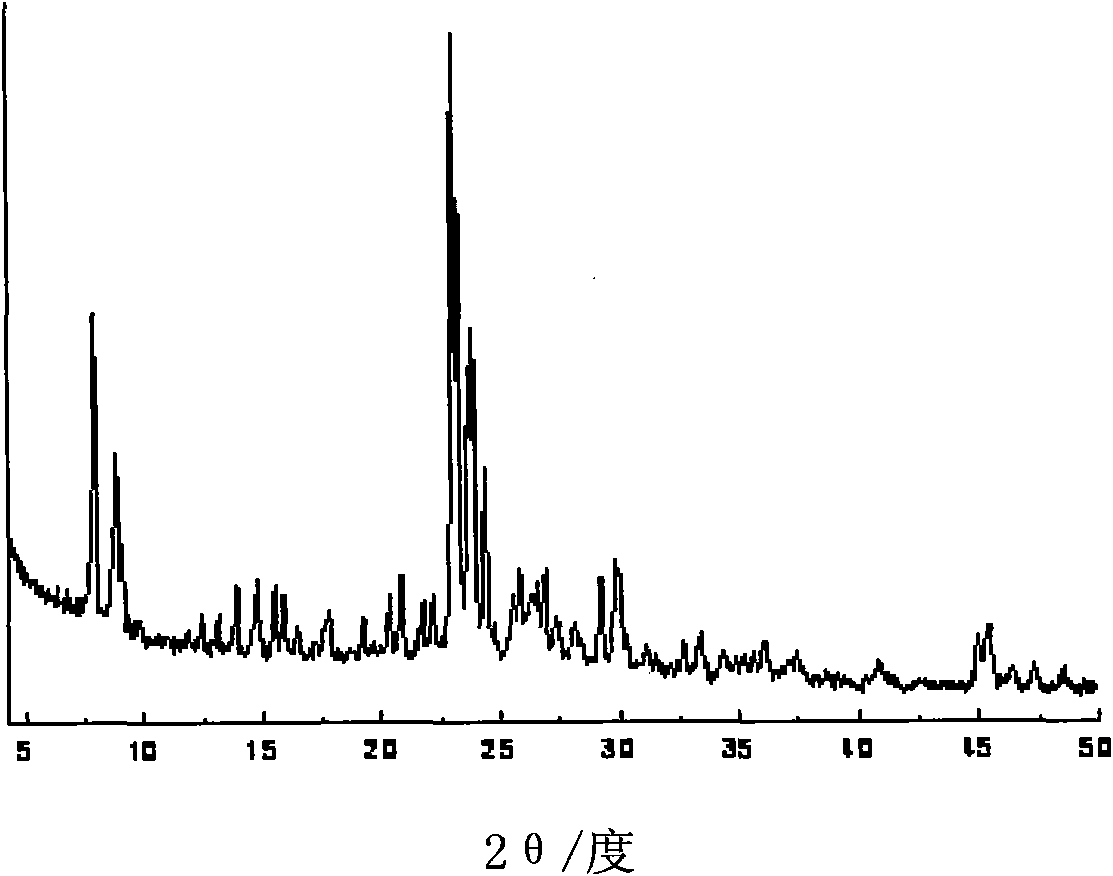

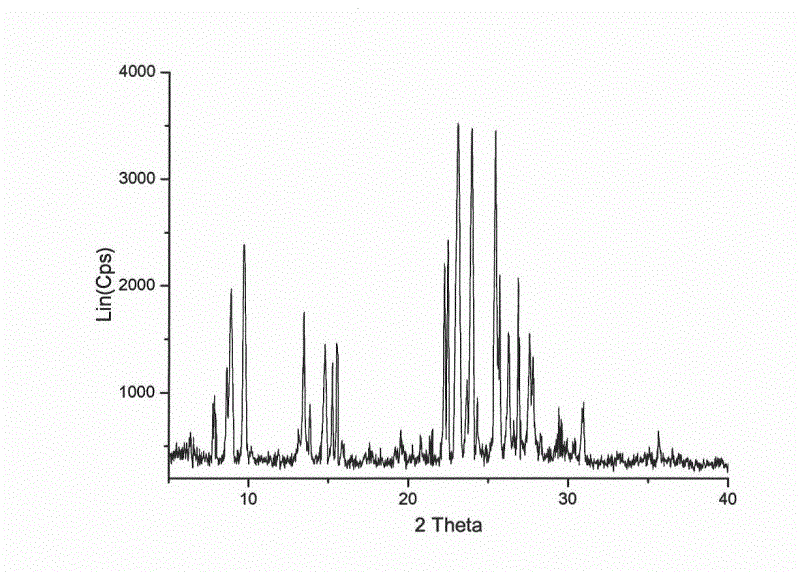

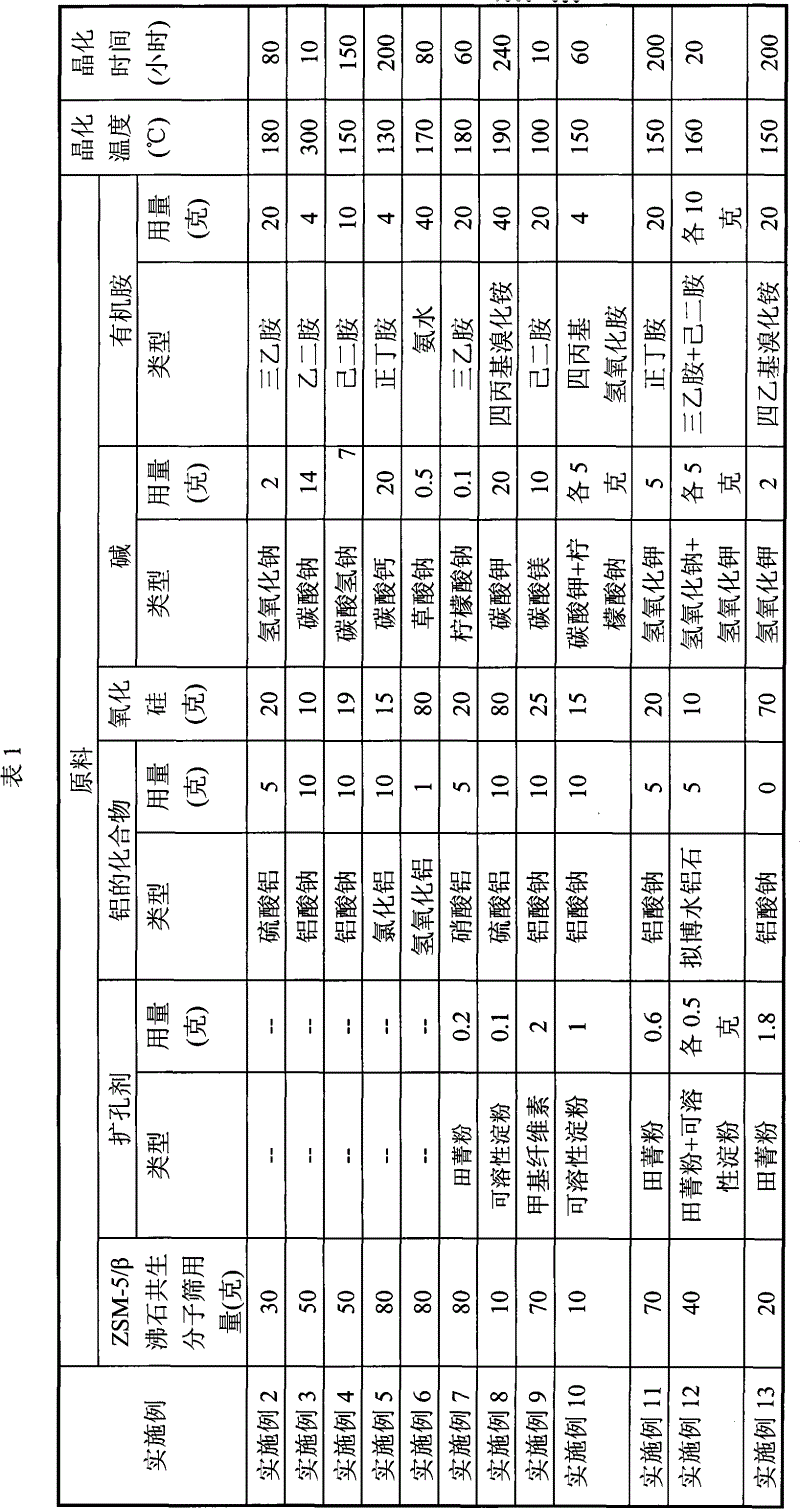

The invention relates to a preparation method of a non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst. In the invention, the problems that when a hydrothermal synthesis method is adopted to prepare the existing ZSM-5 / zeolite beta coexisting molecular sieve, the preparation process is complicated, the cost is higher, the ZSM-5 / zeolite beta coexisting molecular sieve catalyst with the binder has lower activity, the non-binder ZSM-5 / zeolite beta coexisting molecular sieve has lower strength and the mechanical mixture of ZSM-5 with the binder and zeolite beta has lower activity, are mainly solved. The technical scheme in the invention comprises the following steps: mixing ZSM-5 / zeolite beta coexisting molecular sieve, alkaline substance, aluminum compound and silicon oxide, forming, drying, placing the dried mixture in template agent vapor containing at least one of ammonia water, ethylenediamine, triethylamine, n-butylamine, hexanediamine, tetrapropylammonium bromide or tetrapropylammonium hydroxide, and tetraethylammonium hydroxide or tetraethylammonium bromide to perform crystallization treatment at 100-200 DEG C for 10-300 hours and obtain the non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst, wherein the weight contents of ZSM-5 / Magadiite coexisting molecular sieve, alkaline substance, aluminum compound and silicon oxide calculated according to the weight of the formed and roasted catalyst are 10-80%, 0.1-10%, 0.5-20%, and 20-80% respectively. The problems can be better solved and the prepared non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst can be used in the naphtha catalytic cracking reaction for preparing propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method for Silicalite-1

ActiveCN105858672ADie intactSilicaMolecular-sieve and base-exchange compoundsTetramethylammonium iodideTetramethylammonium bromide

The invention discloses a synthesis method for a Silicalite-1 molecular sieve, wherein the method comprises the following steps: (1) mixing evenly a silicon source, a structure directing agent, a mineralizer and water, to obtain a reaction mixture with the molar ratio of OH<->:SiO2:R:F:H2O=(0.05-5):1:(0.05-0.39):(0.05-5):(2-100), wherein R represents the mole number of the structure directing agent, F represents the mole number of the mineralizer, and the structure directing agent is at least one selected from the group consisting of tetraethylammonium hydroxide, tetraethylammonium bromide, tetraethylammonium chloride, tetraethylammonium fluoride, tetraethylammonium iodide and triethylamine; (2) transferring the reaction mixture obtained in the step (1) to a pressureproof airtight container, crystallizing for 0.5-60 days at the temperature of 80-200 DEG C and at the self-generated pressure, to obtain a crystallized product; and (3) recycling the crystallized product obtained in the step (2). By the synthesis method, the Silicalite-1 molecular sieve with uniform and perfect crystal grains can be synthesized under the action of the novel structure directing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of silicoaluminophosphate molecular sieve with hierarchical pore structure

ActiveCN103979569ALow costEasy to industrializeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesTetramethylammonium bromidePhosphoric acid

The invention provides a preparation method of a silicoaluminophosphate molecular sieve with a hierarchical pore structure. The method comprises the steps: firstly, by adopting tetraethyl orthosilicate or silica sol as a silicon source, pseudo-boehmite or aluminum isopropoxide as an aluminum source, orthophosphoric acid as a phosphorus source, and triethylamine, tetraethylammonium bromide or tetraethylammonium hydroxide as a template agent, uniformly stirring the silicon source, the aluminum source, the phosphorus source, the template agent and deionized water, performing hydrothermal crystallization treatment, and then centrifuging to obtain supernatant liquor; secondly, uniformly stirring the silicon source, the aluminum source, the phosphorus source, the template agent and the supernatant liquor, performing hydrothermal crystallization treatment, and filtering to obtain a filter cake and filtrate; thirdly, sequentially washing, drying and roasting the filter cake, and naturally cooling to obtain the silicoaluminophosphate molecular sieve with the hierarchical pore structure. The prepared silicoaluminophosphate molecular sieve provided by the invention has an obvious hierarchical pore structure, greatly shortens the diffusion path, improves the acid site accessibility, significantly prolongs the service life, and has very important practical values in reaction of preparing olefin from methanol.

Owner:陕西省煤化工工程技术研究中心

Y/ZSM-12 composite molecular sieve and preparation method thereof

InactiveCN102441424AEasy to useMolecular sieve catalystsCatalyst activation/preparationTetramethylammonium bromideMolecular sieve

The invention relates to a Y / ZSM-12 composite molecular sieve and a preparation method thereof. The composite molecular sieve is provided with a Y molecular sieve crystal phase and a ZSM-12 molecular sieve crystal phase. The preparation method for the composite molecular sieve includes the following steps: Y-type molecular sieve powder is added into solution containing sodium hydroxide and tetraethylammonium bromide, a silicon source is added, a reaction mixture gel system is obtained after uniform stirring, the molar ratio of the mixture of the reaction mixture gel system is (1.16 to 1.21) Na2O:(9.0 to 11.0) SiO2:(2.20 to 2.30) TEABr:Al2O3:(135 to 150) H2O, the reaction mixture is crystallized under a hermetic condition and at the temperature of 130 DEG C to 150 DEG C for 4 to 7 days, and thereby the Y / ZSM-12 composite molecular sieve is obtained. The composite molecular sieve provided by the invention is a new product, and can be used in a variety of catalytic processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly metal oil/rust-removing anti-rust solution

The invention discloses an environment-friendly metal oil / rust-removing anti-rust solution. The environment-friendly metal oil / rust-removing anti-rust solution is prepared from the following raw materials in parts by weight: 4-5 parts of benzoic acid, 3-5 parts of polypropylene, 1-2 parts of fatty alcohol-polyoxyethylene ether, 3-5 parts of cocamidopropyl betaine, 1-3 parts of coconut fatty acid diethanolamide, 2-3 parts of cetyl trimethyl ammonium bromide, 3-5 parts of tetraethylammonium bromide, 2-3 parts of tert-butyldiphenylsilane, 1-3 parts of di-o-tolyl-thiourea, 1-2 parts of ethylene diamine tetraacetic acid, 1-2 parts of xylenol orange, 2-3 parts of aluminum dihydrogen phosphate, 3-4 parts of sodium hexametaphosphate, 2-3 parts of acetic acid, 50-55 parts of phosphoric acid, 3-5 parts of sodium lignin sulfonate, 2-3 parts of disodium methylene dinaphthalenesulfonate and 50-70 parts of purified water. The environment-friendly metal oil / rust-removing anti-rust solution is multifunctional, and is not only applicable to line production to perform oil removal, rust removal, phosphatization, passivation and rust prevention on metal surfaces at one time, and is harmless to the human body and free from pollution to the environment.

Owner:司徒建辉

Preparation method of hierarchical-pore CoAlPO-5 molecular sieve

InactiveCN103818926AFast crystallization rateChange the spatial structureMolecular-sieve and base-exchange phosphatesTetramethylammonium bromidePhosphoric acid

The invention relates to a preparation method of a hierarchical-pore CoAlPO-5 molecular sieve. The preparation method comprises the following steps: (1) uniformly mixing a succinic acid-choline chloride-tetraethylammonium bromide ternary eutectic mixture EM, aluminium isopropoxide and cobalt acetate tetrahydrate, then adding a proper amount of phosphoric acid and hydrofluoric acid so as to obtain a mixed system of a:Co2O3.Al2O3.b:P2O5.c:HF.d:EM, wherein coefficients are accounted in molar ratio that a is equal to 0.2-0.6, b is equal to 1.1-2.2, c is equal to 0.45-1.35 and d is equal to 62.0-124.0, and heating to 120 DEG C, so as to be mixed uniformly to obtain the mixture; (2) heating the mixture to 175 DEG C, carrying out crystallization for 15 minutes at an ordinary pressure or a self-generated pressure; (3) cooling the crystallization product to a room temperature, carrying out centrifugal washing repeatedly with water and acetone, and drying for 2 h at 90 DEG C so as to obtain a powder product of the hierarchical-pore CoAlPO-5 molecular sieve.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Arylmethyl phosphonate preparation method

ActiveCN105237567AReduce pollutionHigh yieldGroup 5/15 element organic compoundsTetramethylammonium bromideTriethylphosphite

The invention provides an arylmethyl phosphonate preparation method. The method includes the following steps that arylmethyl ester, triethyl phosphate and a catalyst are sequentially added into a reactor and reacted for 5-8 h at the temperature of 100-200 DEG C after full stirring, and after excessive triethyl phosphate is distilled off through decompression, the mixture continues to be reacted for 3-7 h at the temperature of 100-200 DEG C; then, the mixture is cooled to the room temperature, a product is extracted through a mixed solvent, and arylmethyl phosphonate is obtained after the mixed solvent is removed. The catalyst is one or more of tetramethyl ammonium bromide, tetraethylammonium bromide, tetrabutyl ammonium bromide, benzyltrimethyl ammonium bromide, cetyl trimethyl ammonium bromide, cetyltrimethyl ammonium chloride, ammonium chloride, sodium iodide and potassium iodide. Arylmethyl phosphonate is synthesized through a one-step method, other solvents are not added, operation is easy, and the product yield is high and can be 85.3% at maximum.

Owner:HEBEI UNIV OF TECH

Terpene isopropyl carbonate gasoline antiknock

ActiveCN102229823ABoost octaneImprove explosion-proof performanceProductsReagentsTetramethylammonium bromideEnvironmental engineering

The invention relates to the technical field of antiknock, and specifically relates to a terpene isopropyl carbonate gasoline antiknock. The gasoline antiknock of the invention has unique performance and purpose, and can be used as a novel functional compound. A octane number of gasoline can be raised with a small amount of the antiknock, so as to raise gasoline explosion-proof effect. The gasoline antiknock of the invention comprises raw materials of, by weight, 0.1-3.0 parts of tetraethylammonium bromide, 60-100 parts of alpha-pinene and 20-40 parts of isopropanol.

Owner:XIAN WONDER SCI & TECH

Preparation method of weather-resistant aluminum alloy wood grain transfer printing sections

InactiveCN108047900AGood flexibilityImprove hydrophobicity and oleophobicityAntifouling/underwater paintsNatural patternsTetramethylammonium bromideEpoxy

The invention discloses a preparation method of weather-resistant aluminum alloy wood grain transfer printing sections. The method comprises the steps of surface treatment on aluminum alloy base materials, electrostatic spraying and solidification of wood grain transfer printing paint and wood grain transfer printing; in the electrostatic spraying process of the wood grain transfer printing paint,the wood grain transfer printing paint is prepared from polyester resin, epoxy resin, acrylic resin, nano cellulose, precipitated barium sulfate, montmorillonite, nano titanium dioxide, fumed silica,calcium carbonate, nano-alumina, glycerin, tetraethylammonium bromide, triglycidyl isocyanurate, a leveling agent, benzoin, polyethylene wax, pigment and an ultraviolet absorber UV-0. The preparationmethod of the weather-resistant aluminum alloy wood grain transfer printing sections is simple in process and mild in condition, and the obtained aluminum alloy wood grain transfer printing sectionsare good in weather resistance and excellent in heat resistance.

Owner:ANHUI XIN FA ALUMINUM PROD

Catalyst for synthesizing ethylbenzene through ethylene and benzene liquid phase method and preparation and application of catalyst

ActiveCN103831129AHigh catalytic activityHigh catalytic efficiencyMolecular sieve catalystsHydrocarbonsTetramethylammonium bromidePolymer science

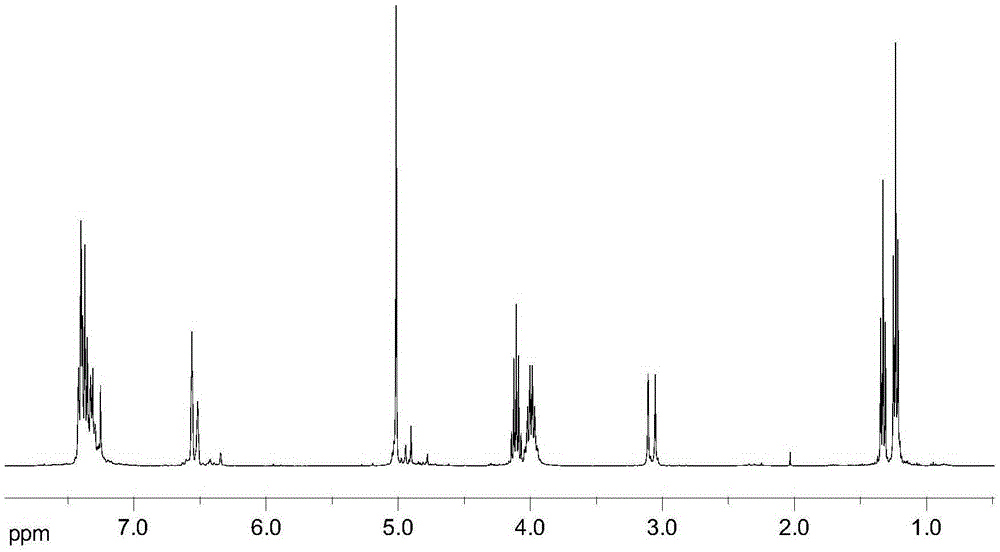

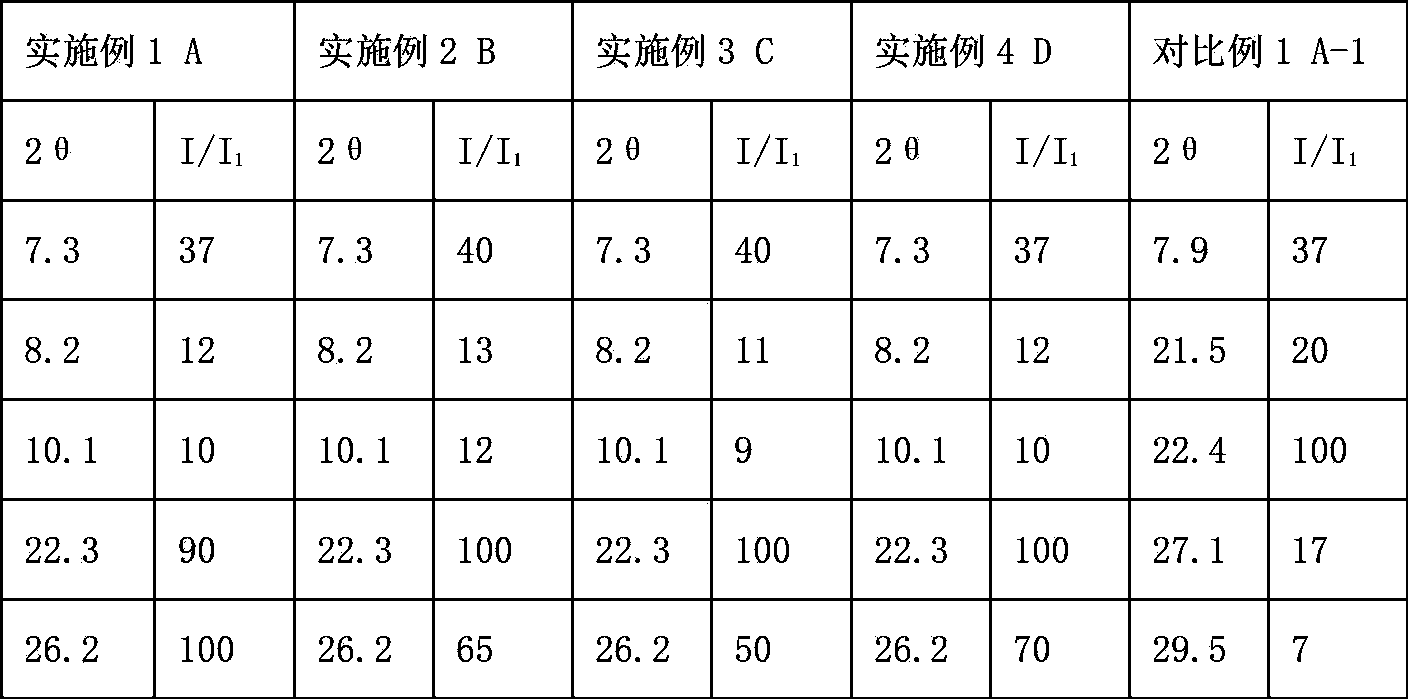

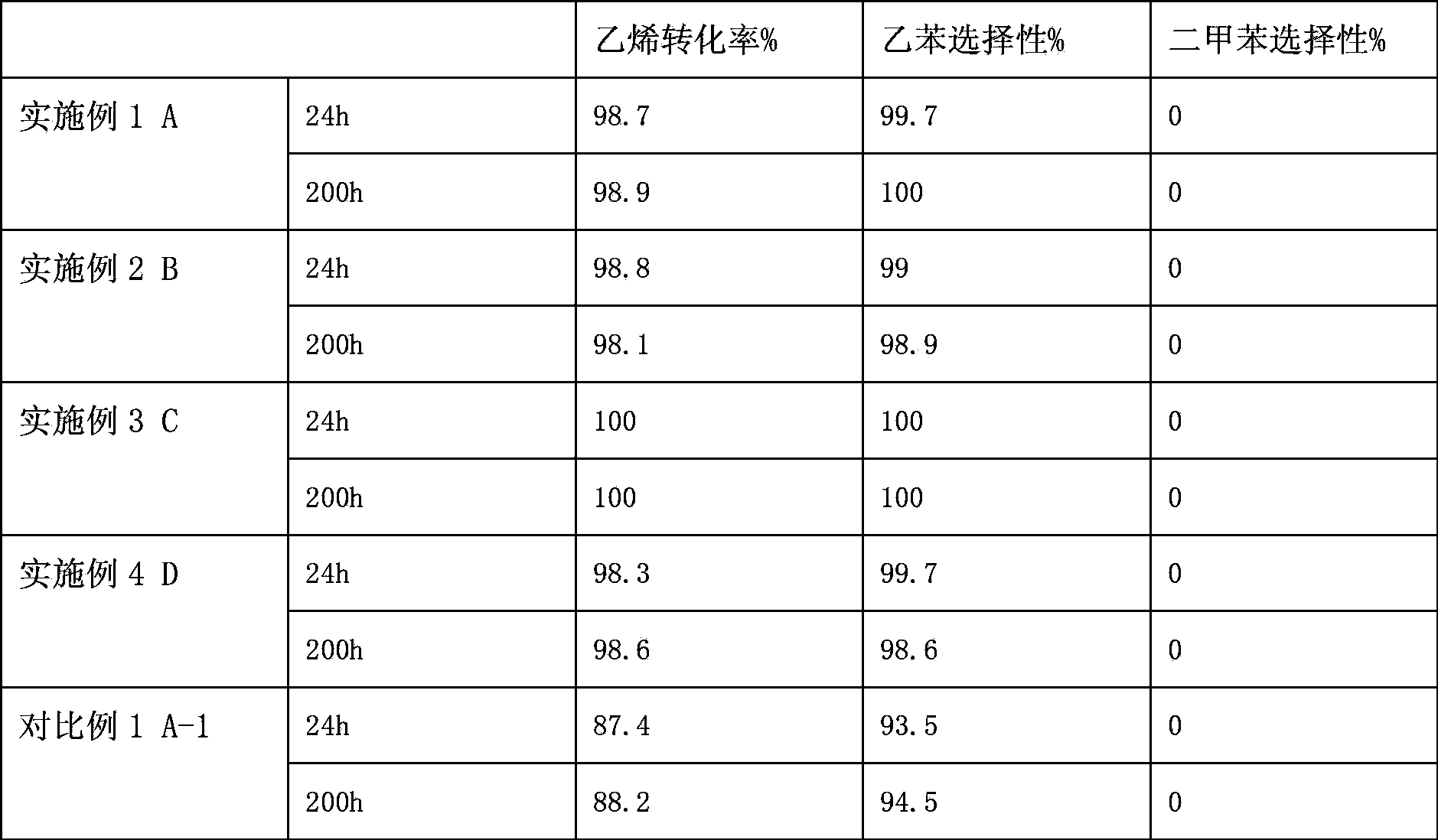

The invention relates to a catalyst for synthesizing ethylbenzene through an ethylene and benzene liquid phase method and preparation and application of catalyst. The preparation method comprises the following steps: uniformly mixing and stirring an MCM-49 molecular sieve, sodium hydroxide, water, tetraethylammonium bromide and silica sol in a gelatinizing kettle at the temperature of 20-60 DEG C, forming uniform sol-gel, and continuously stirring for 5-10 minutes; crystallizing in a crystallization kettle at the temperature of 140-150 DEG C for 48-96 hours; and filtering the obtained product, washing to pH of 10 by using distilled water, drying at the temperature of 110 DEG C for 12 hours, roasting at the temperature of 560-580 DEG C for 4 hours, performing ion exchange on the obtained MCM-49-beta molecular sieve in a ammonium nitrate solution with the concentration of 10-20 percent, drying at the temperature of 110 DEG C for 12 hours, and roasting at the temperature of 560-580 DEG C for 4 hours. According to the catalyst, the ethylene conversion rate is above 98 percent in the process of preparing the ethylbenzene through ethylene and benzene, the selectivity of the ethylbenzene is above 99 percent, and the product does not contain dimethylbenzene.

Owner:PETROCHINA CO LTD

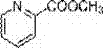

Synthesis method of methyl picolinate

InactiveCN107400898AEfficient use ofReduce pollutionElectrolysis componentsElectrolytic organic productionTetramethylammonium bromideTetrafluoroborate

The invention discloses a synthesis method of methyl picolinate. The method comprises the following steps that 2-bromopyridine, N,N-dimethylformamide or acetonitrile and tetraethylammonium chloride or tetraethylammonium bromide or tetraethylammonium iodide or tetraethylammonium tetrafluoroborate or tetrabutylammonium chloride or tetrabutylammonium bromide or tetrabutylammonium iodide are mixed into an electrolyte; carbon dioxide is introduced for 30min at normal pressure; then, electric carboxylation reaction is performed by using constant current (the carbon dioxide is continuously introduced in the electrolysis process until the electrolysis is completed); then, the methyl picolinate is obtained through esterification and post treatment. A reaction system is simple; the control is easy; in addition, rich Cl resources and CO2 are used as one of raw materials; the raw materials are cheap and can be easily obtained; the cost is low; a novel path is developed for the study on challenging organic matters of green synthetic heterocyclic ring carboxylic acid derivatives and the like.

Owner:LIAOCHENG UNIV

Synthetic method of isonicotinic acid

InactiveCN107354477AEfficient use ofEfficient synthesisElectrolysis componentsElectrolytic organic productionChemical industryTetramethylammonium bromide

The invention discloses a synthetic method of isonicotinic acid. The method comprises the following steps: mixing 4-bromopyridine with N, N-dimethylformamide or acetonitrile and tetraethylammonium chloride or tetraethylammonium bromide or tetraethylammonium iodide or tetraethylammonium tetrafluoroborate or tetrabutylammonium chloride or tetrabutylammonium bromide or tetrabutylammonium iodide to form an electrolyte; introducing carbon dioxide at normal pressure for 30 minutes; and carrying out electrolysis at a constant current, keeping introducing the carbon dioxide during the electrolysis process until the electrolysis is ended, and obtaining the isonicotinic acid after carrying out post-treatments. According to the synthetic method of the isonicotinic acid, the reaction system is simple and easy to control, the rich C1 resource, namely the carbon dioxide is used as one of the raw materials, is cheap and easy to obtain, is low in cost and does not pollute the environment, and therefore a new way is developed for the study of the green isonicotinic acid, an extremely good application prospect of the synthetic method is displayed in the medicine industry, the food industry, the chemical industry and the electronic industry, and the synthetic method of the isonicotinic acid is a process route with high industrial synthetic value.

Owner:LIAOCHENG UNIV

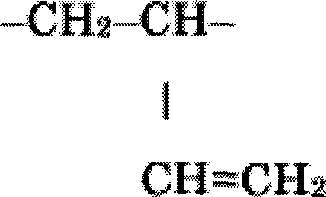

Process for brominating butadiene polymers

Butadiene polymers are brominated using tetraethylammonium tribromide as the brominating agent. The bromination is performed in a solvent for the starting polymer and for the tetraethylammonium bromide that is formed as a reaction byproduct. The process proceeds easily under mild conditions. In some cases, a solution of the brominated polymer and the tetraethylammonium monobromide is produced; this solution separates into a layer that contains the brominated polymer and another layer that contains most or all of the tetraethylammonium monobromide salt. In other cases, the brominated polymer precipitates from the reaction mixture and is separated from the tetraethylammonium monobromide salt in that manner. This process therefore permits the tetraethylammonium monobromide reaction by-product to be separated easily from the brominated product, and allows aqueous washing steps to be reduced or eliminated.

Owner:DOW GLOBAL TECH LLC

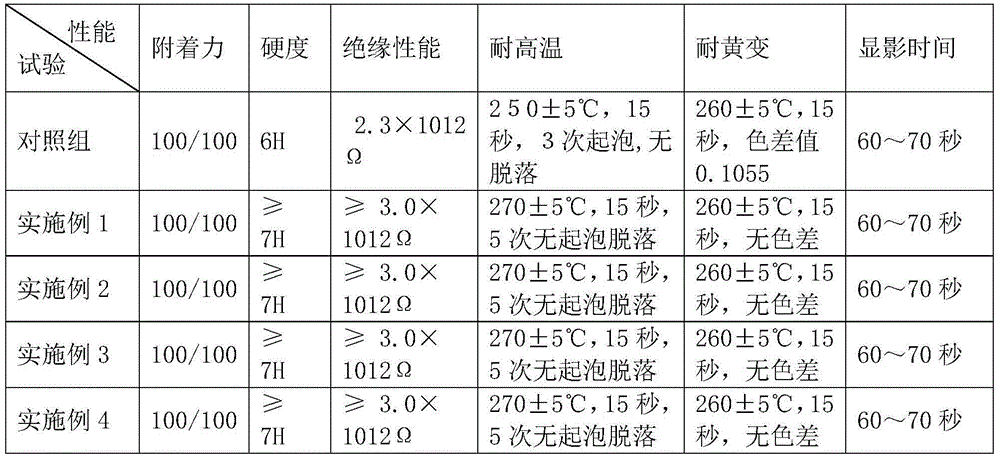

Method for preparing photosensitive resin for solder mask ink

ActiveCN103554418AModerate viscosityShort reaction timeInksPhotosensitive materials for photomechanical apparatusPolyesterEpoxy

The invention discloses a method for preparing photosensitive resin for solder mask ink. The method comprises the following steps: (1) carrying out a ring-opening reaction by taking acrylic acid and o-cresol formaldehyde epoxy resin as raw materials, and adding a polymerization inhibitor hydroquinone and a catalyst tetraethylammonium bromide into the reaction process, thus obtaining a prepolymer A; (2) performing chain extension by using a small molecular weight polyurethane prepolymer of which a polyether or polyester opposite terminal group is an NCO group, thus obtaining a prepolymer B; and (3) enabling the prepolymer A and the prepolymer B to react, and adding tetramethylbenzene and a catalyst dibutyl tin dialurate into the reaction process. Compared with the prior art, the method has the advantages that the production period is short, and the obtained photosensitive resin has the advantages of high-temperature resistance, yellowing resistance, high adhesive force and good insulating performance.

Owner:ZHUHAI CHANGXIAN CHEM TECH

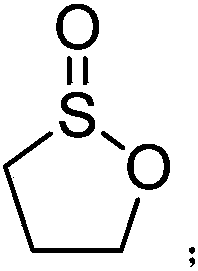

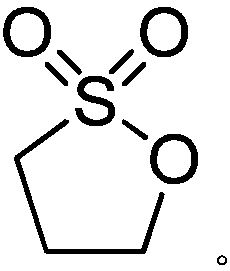

Preparation method of 1,3-propane sultone

ActiveCN108164502AMeet the protection requirementsHigh yieldOrganic chemistryTetramethylammonium bromideDichloropropane

The invention discloses a preparation method of 1,3-propane sultone. The preparation method of the 1,3-propane sultone comprises the following steps of (1) under the existence of tetraethylammonium bromide, reacting 1,3-dichloropropane and sulfur dioxide in acetonitrile under the action of a constant current so as to obtain 1,3- propane sulfincacid lactone; (2) carrying out oxidation reaction on the prepared 1,3-propane sulfincacid lactone and an oxidizing agent in an organic solvent to obtain the 1,3-propane sultone. The preparation method of the 1,3-propane sultone provided by the inventionhas the advantages of higher yield, high purity, cheap and easy-to-get raw materials, mild reaction conditions, simple preparation process and the like.

Owner:SUZHOU HUAYI NEW ENERGY TECH CO LTD

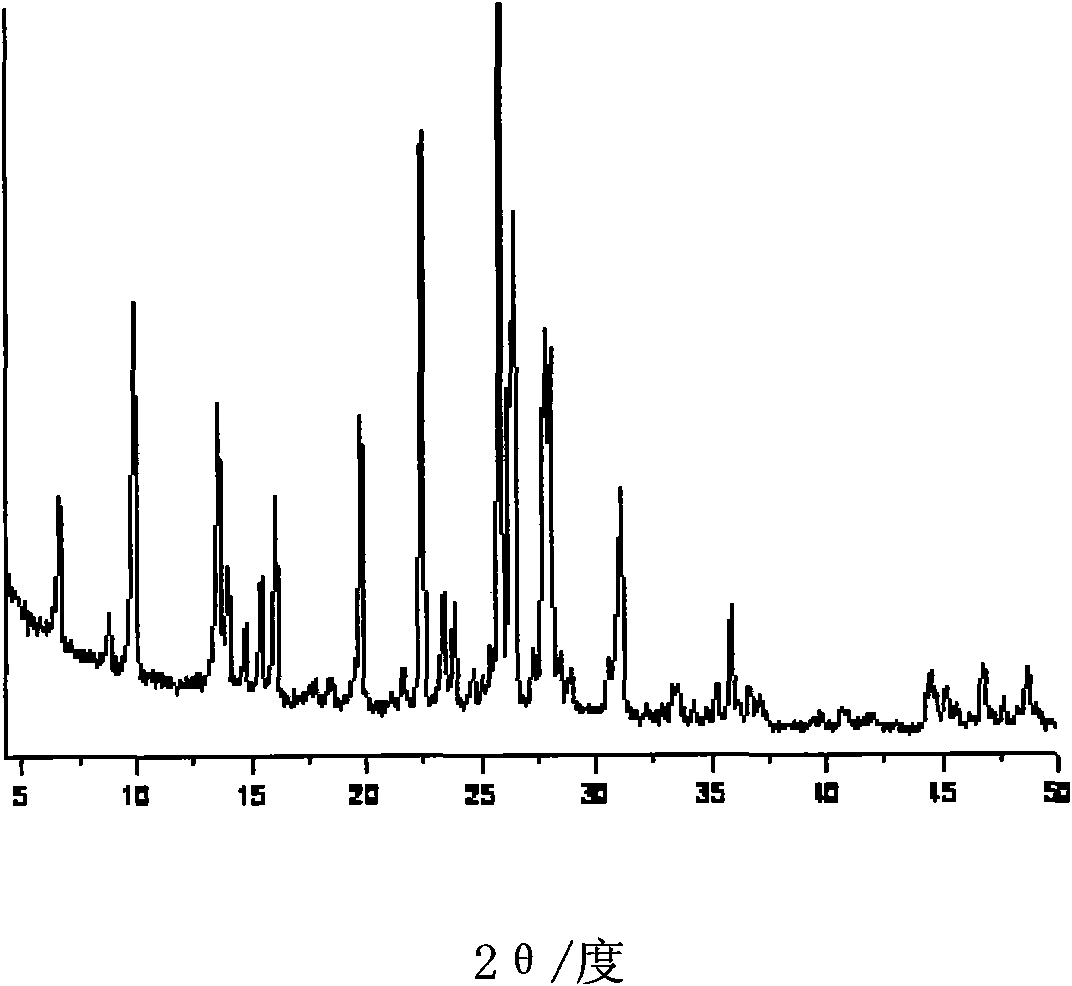

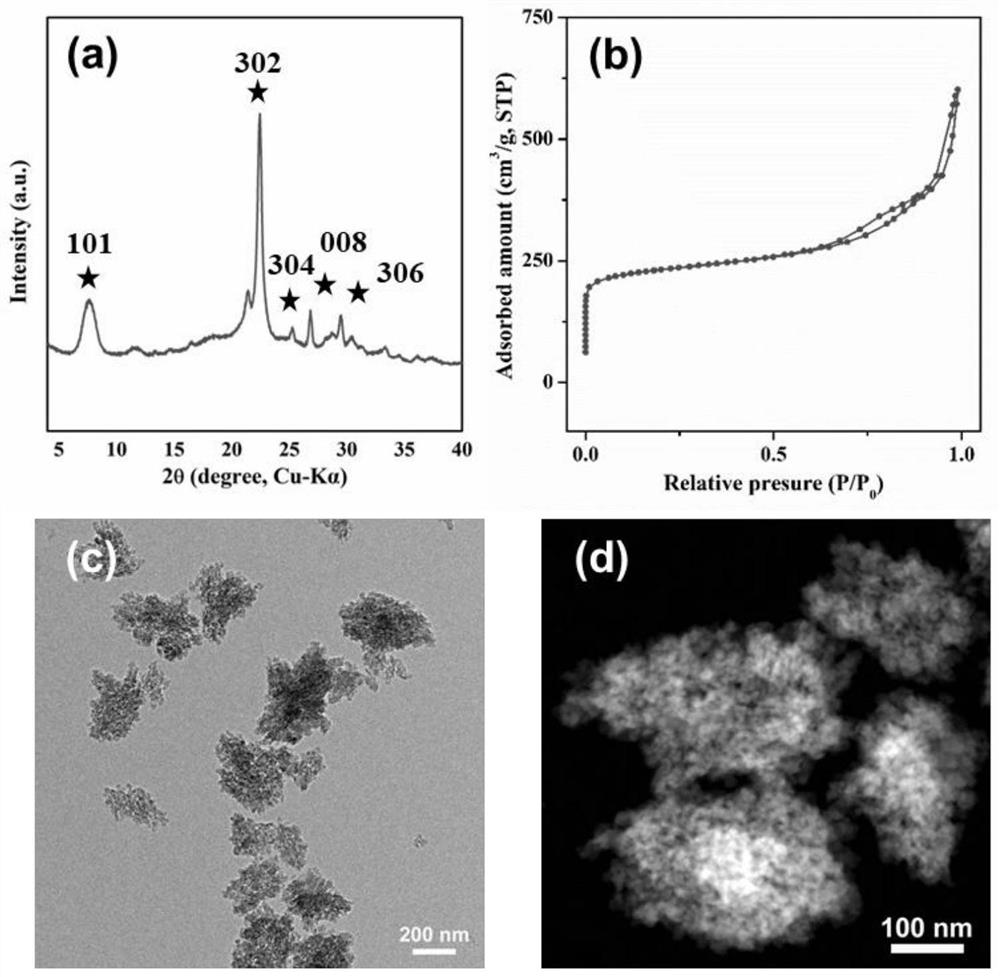

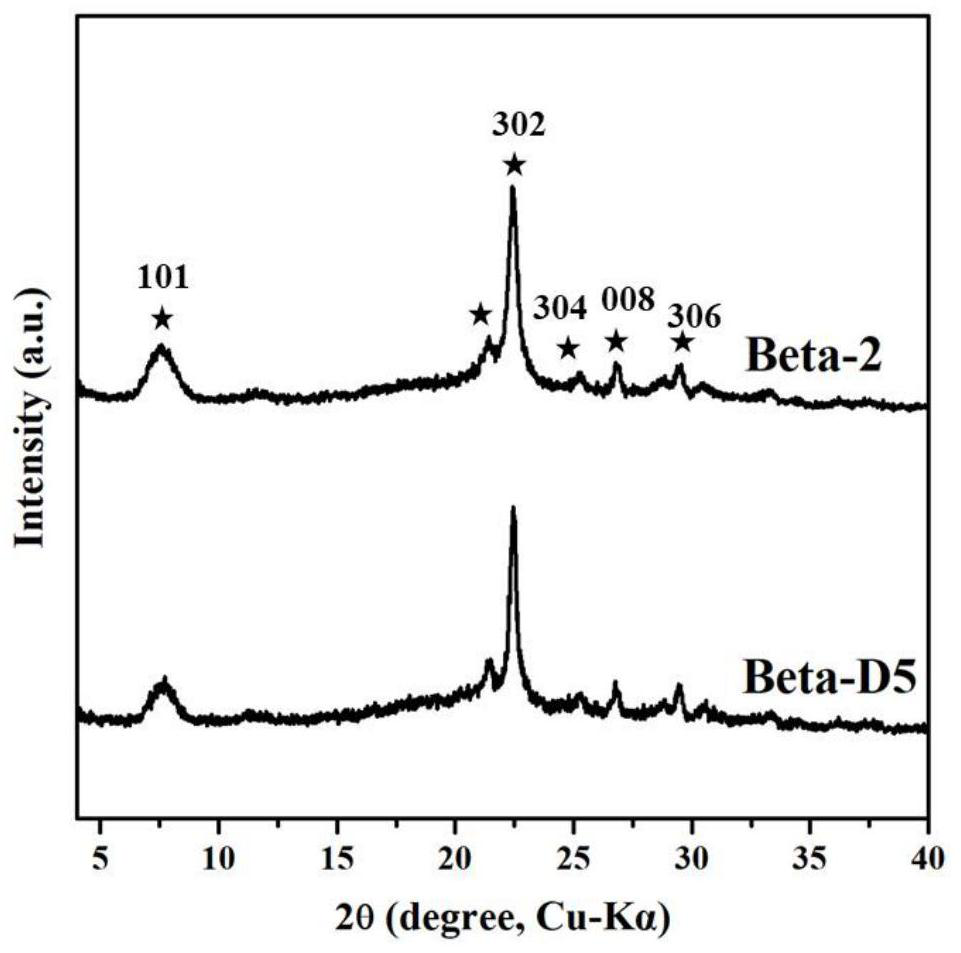

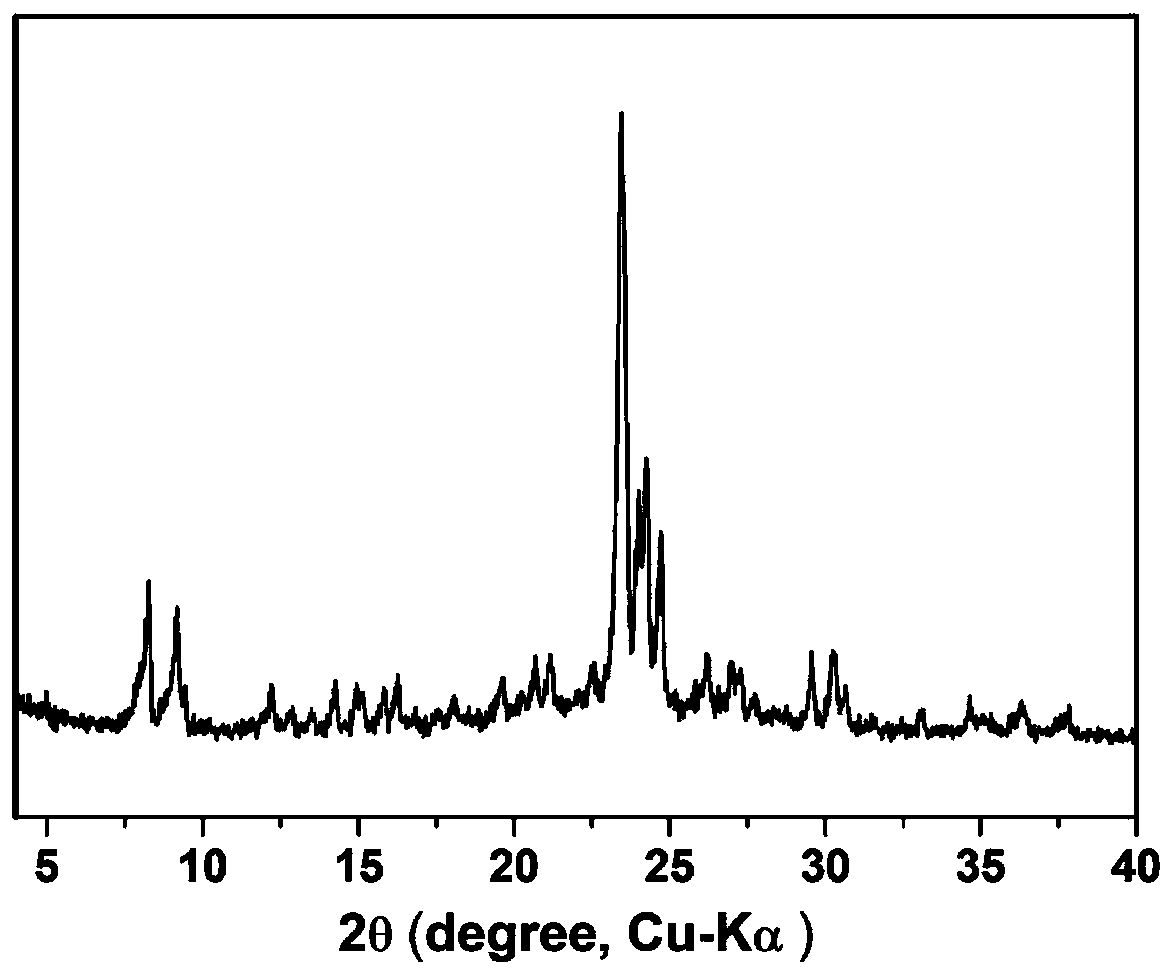

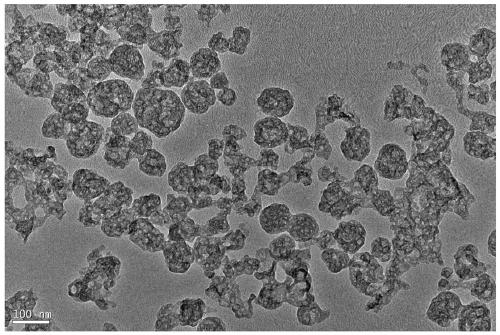

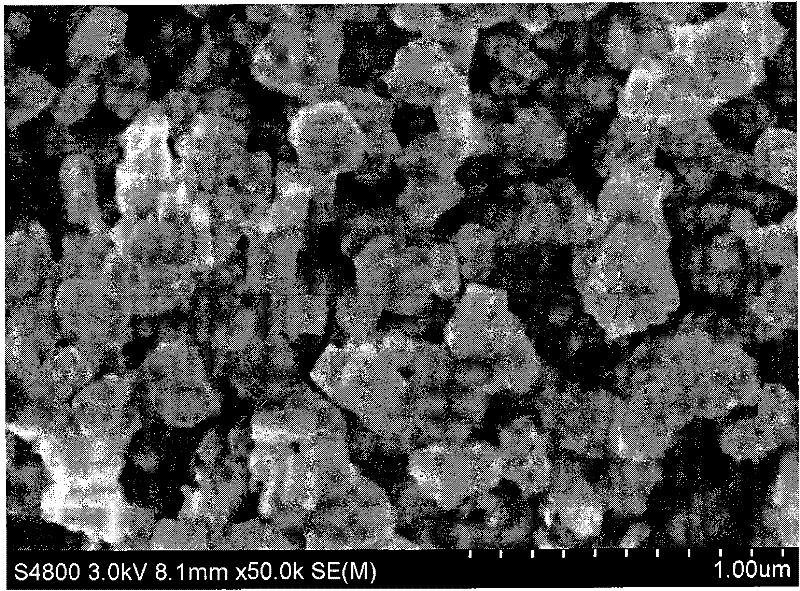

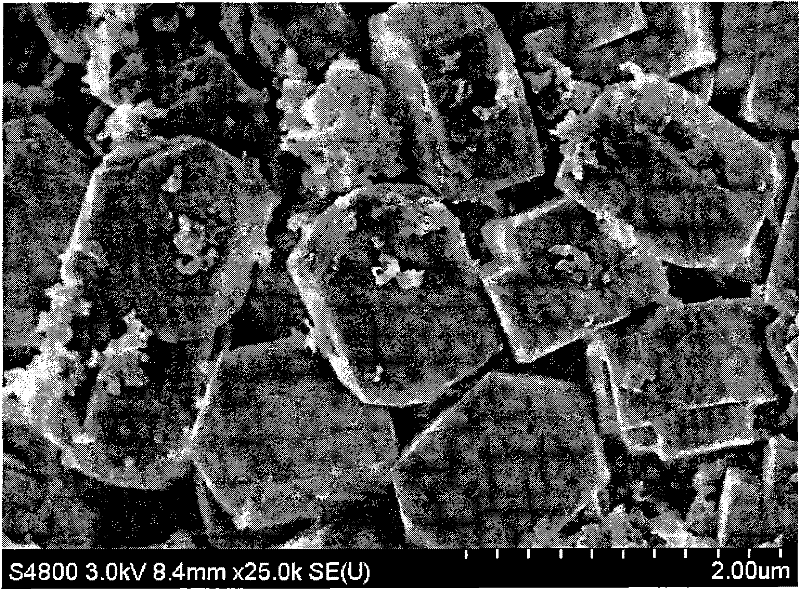

Preparation method of nano hierarchical pore Beta molecular sieve

ActiveCN112624142APromote migrationGood dispersionMaterial nanotechnologyMolecular sieve catalystsMolecular sieveTetramethylammonium bromide

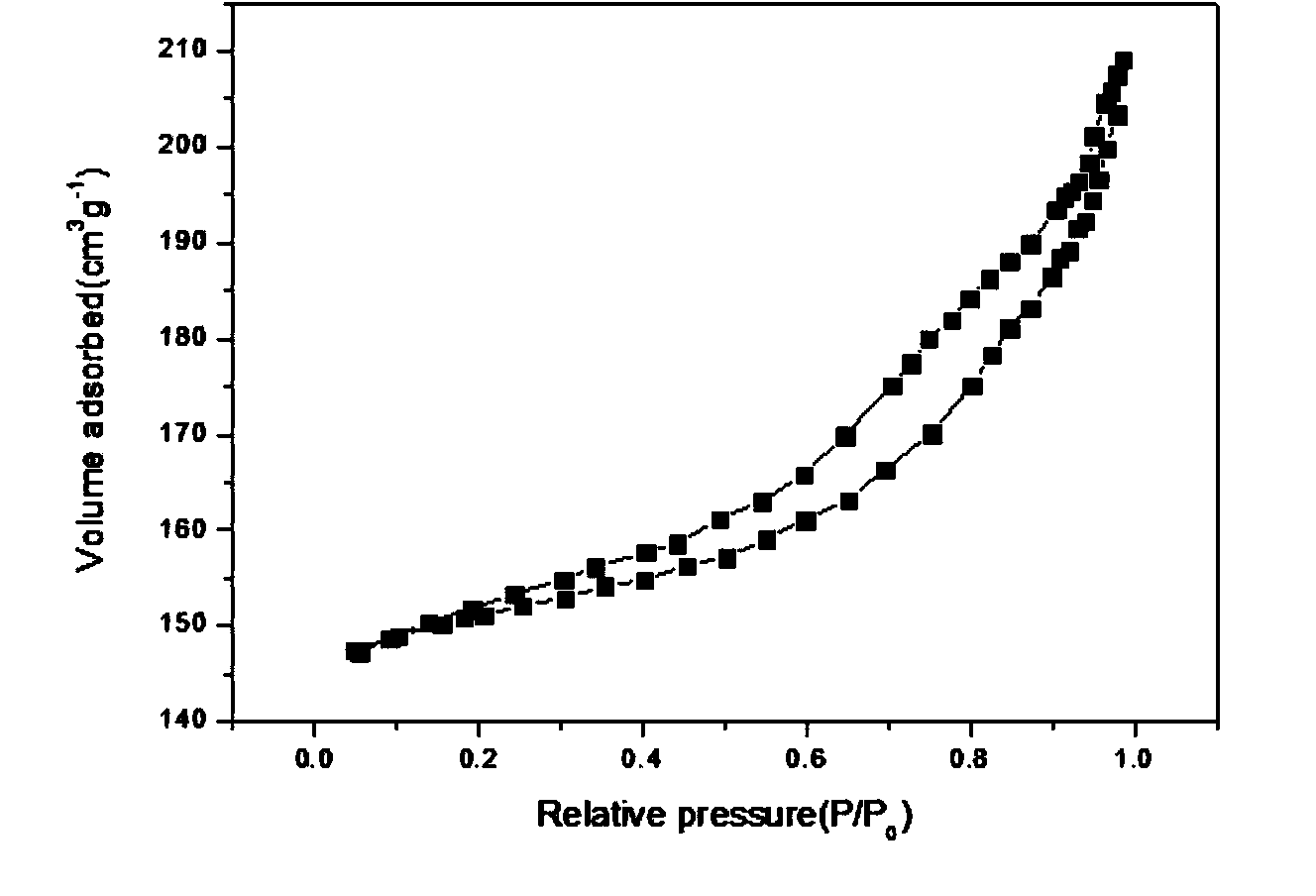

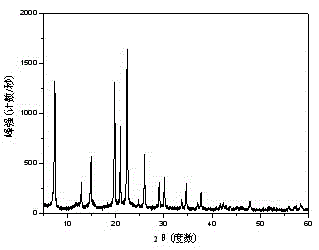

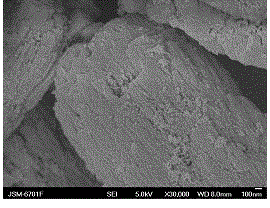

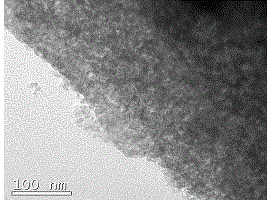

The invention provides a preparation method of a nano hierarchical pore Beta molecular sieve, and belongs to the technical field of preparation of Beta molecular sieves. Compared with an existing steam-assisted xerogel conversion method for preparing the Beta molecular sieve, the method has the advantages that the process of obtaining xerogel through evaporation of synthetic gel is avoided, a solid-phase reaction mixture obtained after raw materials such as tetraethylammonium bromide and solid silica gel are subjected to ball milling is directly used for steam-assisted conversion, the synthesis steps are simplified, and the synthesis cost is reduced; meanwhile, due to the existence of the steam, the migration and dispersion of the solid-phase raw material are promoted, so that the nano hierarchical pore Beta molecular sieve with relatively small and dispersed nano particles and rich intracrystalline mesopores is prepared.

Owner:JILIN UNIV +1

Method for directly preparing meso-porous molecular sieves by hydrothermal process in system using meso-porous silica as silicon source precursor without meso-porous template

InactiveCN109721078AHigh crystallinityIncreased mesopore volumePentasil aluminosilicate zeolitePorous substrateTetramethylammonium bromide

A method for directly preparing meso-porous molecular sieves in situ by a hydrothermal process in a system using meso-porous silica as a silicon source precursor without a meso-porous template belongsto the technical field of preparation of molecular sieves. Molecular sieve crystals are formed and grown on a meso-porous substrate with tetrapropylammonium hydroxide, tetraethylammonium hydroxide, tetrapropylammonium bromide and tetraethylammonium bromide as a micro-porous template and the meso-porous silica as the silicon source to synthesize the meso-porous molecular sieves having a good crystallization degree, a high micro-pore specific surface area, a large external specific surface area and a large micro-pore volume. The ZSM-5 and Beta molecular sieves synthesized in the invention havea large meso-porous volume, greatly improve the mass transfer rate in the field of molecular sieve catalysis, and have a broad industrial prospect.

Owner:JILIN UNIV

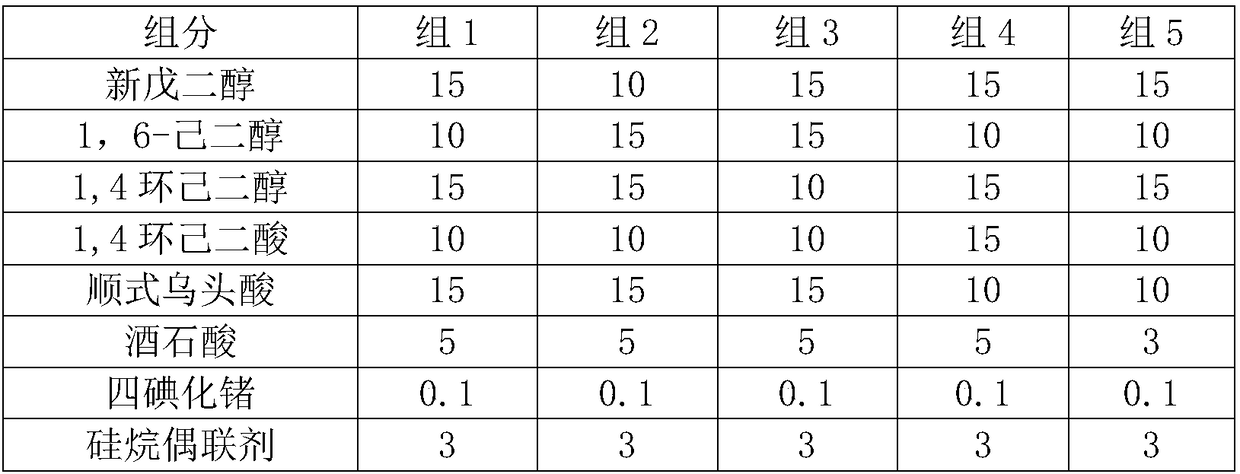

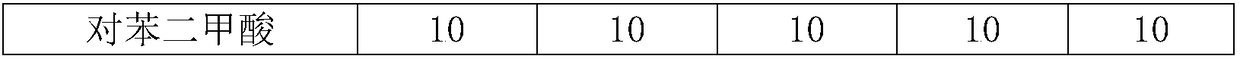

Processing method of powder paint for coating composite material

InactiveCN108484893ASmooth appearanceHigh glossPowdery paintsPolyester coatingsTetramethylammonium bromideTrimethylolpropane

The invention belongs to the field of chemical materials, and particularly relates to a processing method of powder paint for coating a composite material. The preparation method of polyester resin comprises the following steps: heating a reaction kettle to 85 to 95 DEG C, and adding neopentyl glycol, 1,6-hexanediol, 1,4-cyclohexanediol, 1,4-cyclohexanedioic acid, cis-aconitic acid, tartaric acid,germanium tetraiodide and trimethylolpropane; heating to 230 DEG C, and reacting until an acid value reaches 10 to 15 mg KOH / g; and adding a silane coupling agent and terephthalic acid, heating to 280 DEG C, then adding tri(2,4-di-tert-butylphenyl)phosphite ester and tetraethylammonium bromide, uniformly stirring, and cooling, thus obtaining the polyester resin. The powder paint is prepared by adopting polyester resin as a raw material and prepared from 280 parts of polyester resin, 200 to 220 parts of TGIC, 5 parts of Resiflow PV88, 3 parts of benzoin, 155 parts of titanium dioxide and 155 parts of ultrafine barium. The powder paint provided by the invention is smooth in appearance, good in glossiness, excellent in weather resistance and mechanical performance and low in curing temperature.

Owner:黄山市向荣新材料有限公司

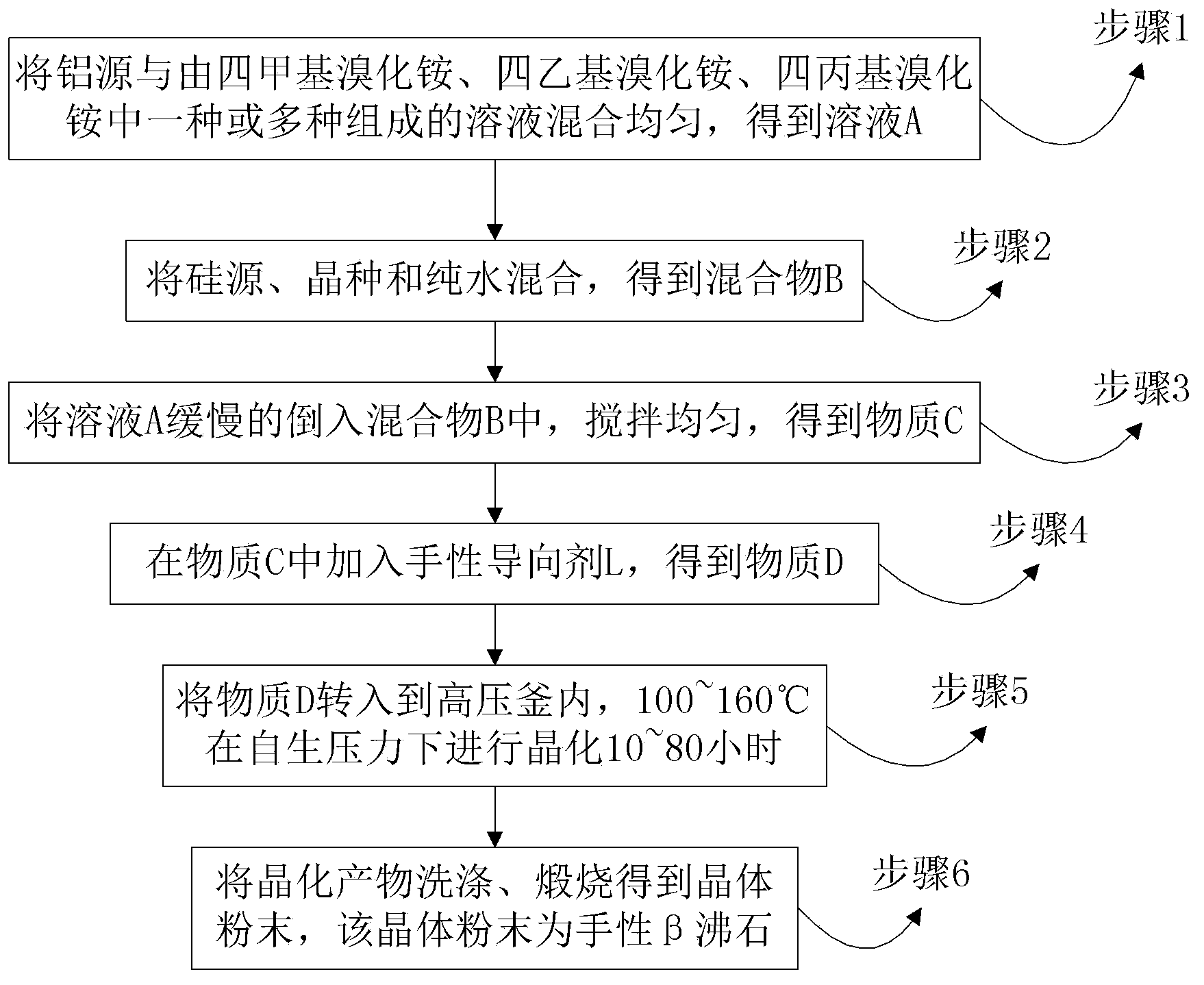

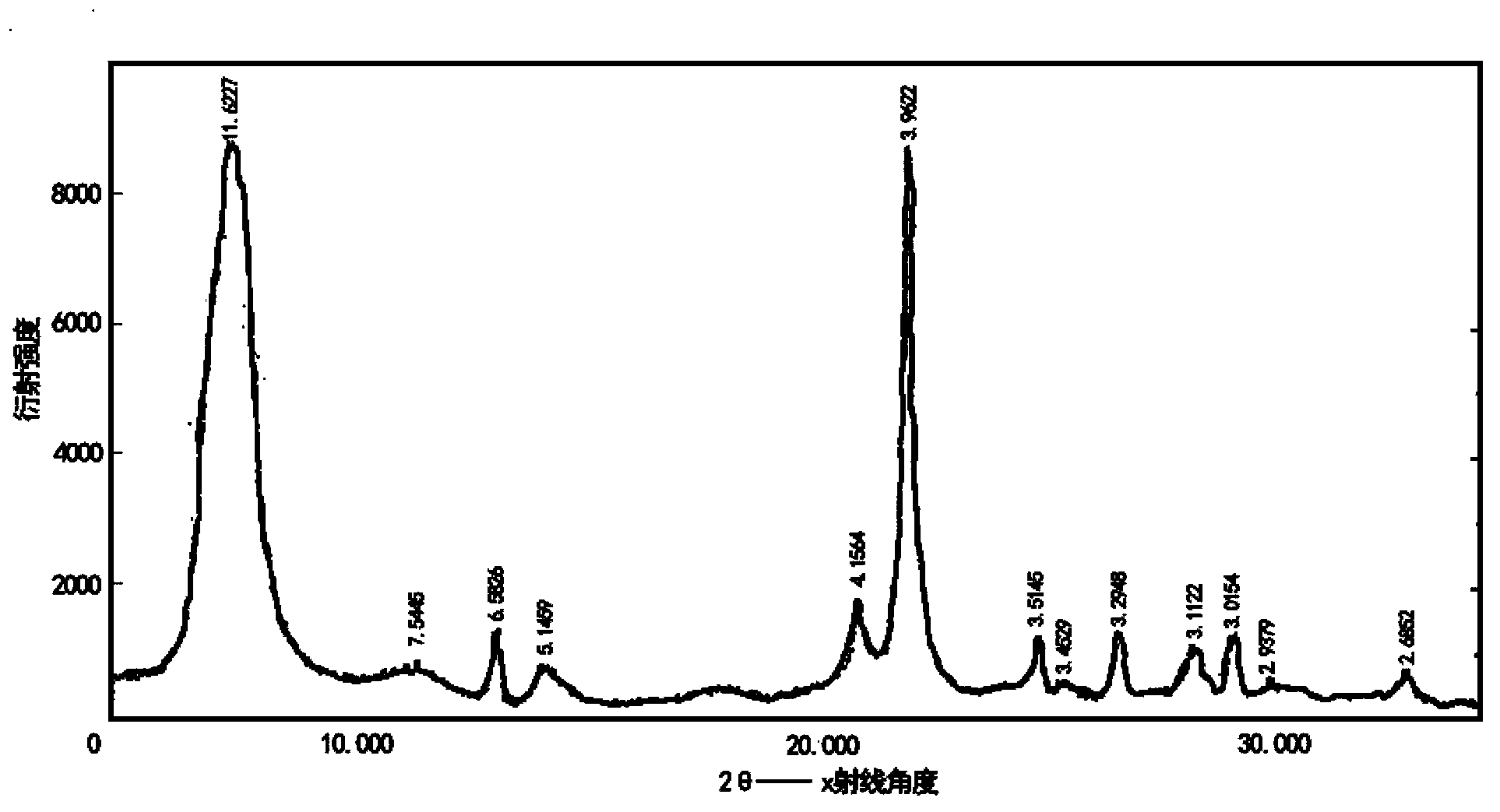

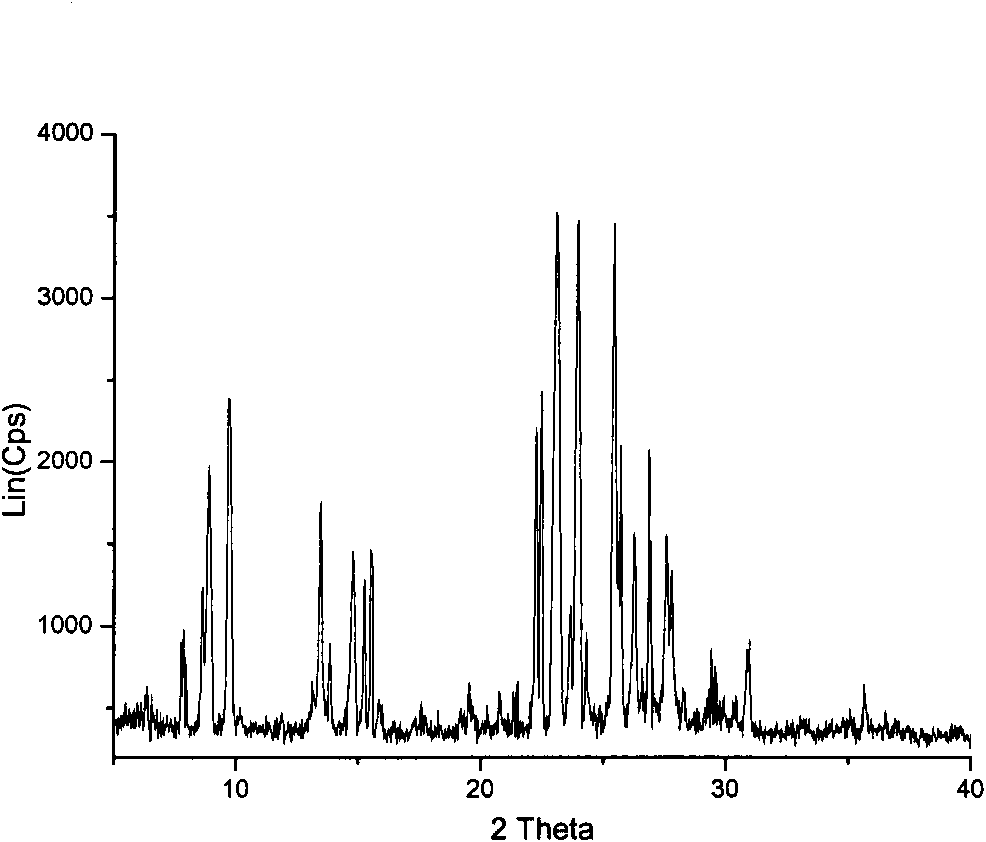

Preparation method for chiral beta zeolite

The invention provides a preparation method for chiral beta zeolite. The method comprises: uniformly mixing an aluminium source and a mixed solution composed of tetramethylammonium bromide, tetraethylammonium bromide and tetrapropylammonium bromide according to a certain ratio, so as to obtain a solution A; mixing a silicon source, proper amount of a crystal seed and pure water according to a certain ratio, so as to obtain a solution B; slowly pouring the solution A into the solution B and stirring uniformly, so as to obtain a material C; adding a chiral guiding agent into the material C, so as to obtain a material D; transferring the material D into a high-pressure kettle, and performing crystallization under an automatically-generated pressure; and washing the crystallized product, and calcining to obtain the chiral beta zeolite. The obtained chiral beta zeolite obtained by employing the preparation method can be used as a chiral stationary phase of liquid chromatogram for chiral resolution, makes up the disadvantages of chiral resolution technology, has important meaning on fields such as life science, medicinal chemistry, material chemistry and the like, and possesses great business value.

Owner:天津海赛纳米材料有限公司

Preparation method of nano-porous copper cooling fin

The invention relates to a preparation method of a nano-porous copper cooling fin and belongs to the field of metal materials. The requirements for cooling of cooling fins are higher and higher along with increasingly powerful functions of a computer, an existing alloy cooling fin meets the computer cooling requirement difficultly, and a pure copper cooling fin has the defects of being too large in weight and high in machining difficulty and also has the problem that the limitation of a CPU to the weight of the cooling fin is prone to being exceeded. The preparation method of the nano-porous copper cooling fin comprises the steps that copper nitrate serves as raw materials and react with succinic acid, tetraethylammonium bromide and hydrazine hydrate to prepare nano-copper powder, a graphite structure carbon nitride prepared from melamine serving as an opening agent and a copper fiber serving as a reinforcing agent are mixed with the nano-copper powder, extrusion forming is conducted in a cooling fin mould, and a green body is prepared and subjected to high-temperature sintering forming; then the surface of porous copper is ground through abrasive paper for metallograph until the surface of the porous copper is smooth and free of scratches, and after polishing is conducted, the nano-porous copper cooling fin is prepared.

Owner:袁春华

Preparation method of non-binder ZSM-5/zeolite beta coexisting molecular sieve catalyst

ActiveCN102039171AHigh activityHigh strengthMolecular sieve catalystsCatalyst activation/preparationEthylenediamineTetramethylammonium bromide

The invention relates to a preparation method of a non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst. In the invention, the problems that when a hydrothermal synthesis method is adopted to prepare the existing ZSM-5 / zeolite beta coexisting molecular sieve, the preparation process is complicated, the cost is higher, the ZSM-5 / zeolite beta coexisting molecular sieve catalyst with the binder has lower activity, the non-binder ZSM-5 / zeolite beta coexisting molecular sieve has lower strength and the mechanical mixture of ZSM-5 with the binder and zeolite beta has lower activity, are mainly solved. The technical scheme in the invention comprises the following steps: mixing ZSM-5 / zeolite beta coexisting molecular sieve, alkaline substance, aluminum compound and silicon oxide, forming, drying, placing the dried mixture in template agent vapor containing at least one of ammonia water, ethylenediamine, triethylamine, n-butylamine, hexanediamine, tetrapropylammonium bromide or tetrapropylammonium hydroxide, and tetraethylammonium hydroxide or tetraethylammonium bromide to perform crystallization treatment at 100-200 DEG C for 10-300 hours and obtain the non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst, wherein the weight contents of ZSM-5 / Magadiite coexisting molecular sieve, alkaline substance, aluminum compound and silicon oxide calculated according to the weight of the formed and roasted catalyst are 10-80%, 0.1-10%, 0.5-20%, and 20-80% respectively. The problems can be better solved and the prepared non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst can be used in the naphtha catalytic cracking reaction for preparing propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

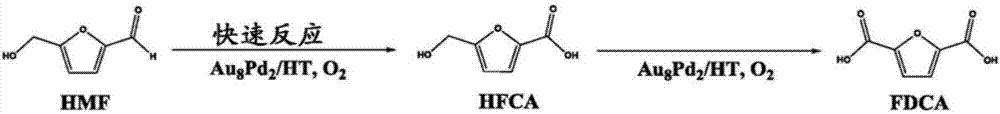

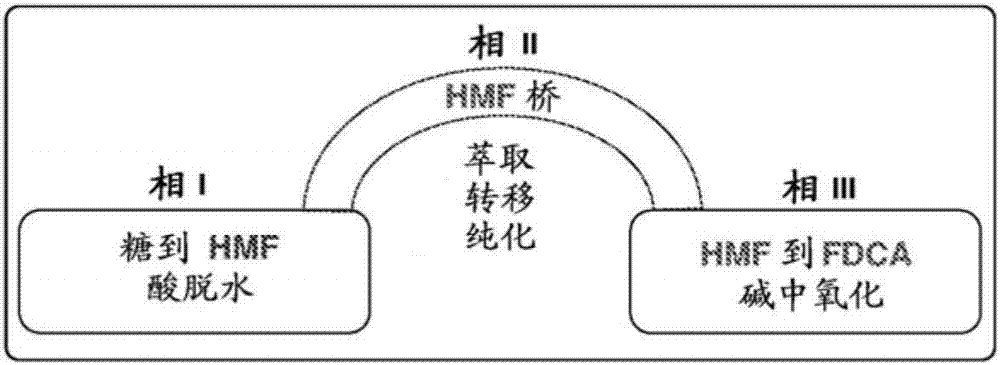

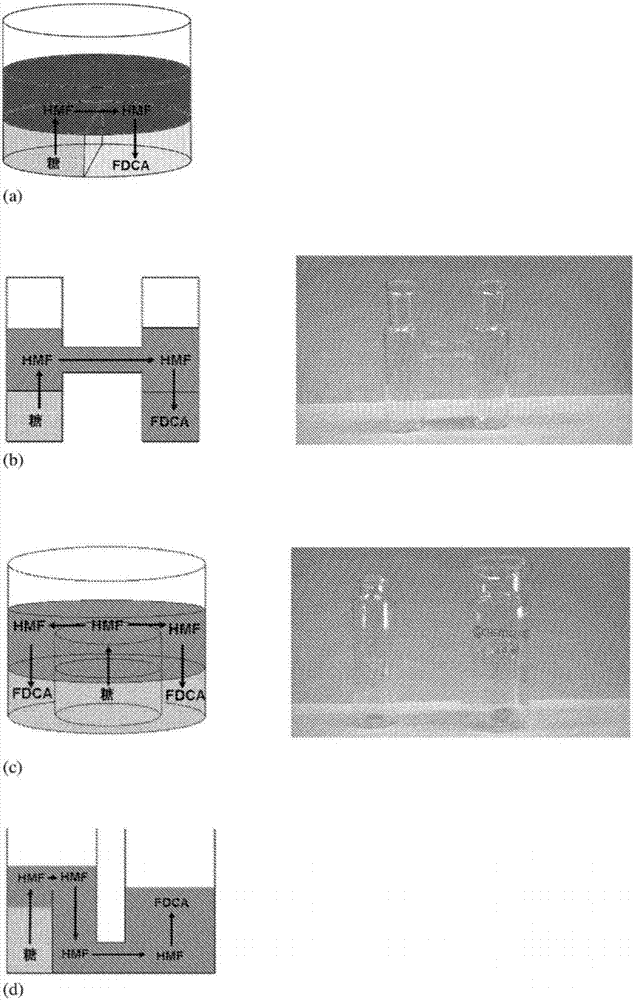

Triphasic system for direct conversion of sugars to furandicarboxylic acid

InactiveCN107001306AShort reaction timeOrganic chemistryChemical/physical/physico-chemical processesTetramethylammonium bromideFuran

There is provided a one-pot process for the conversion of sugars to furancarboxylic acids, such as 2,5-furancarboxylic acid (FDCA), in a triphasic system (e.g. water or tetraethylammonium bromide (TEAB)-methyl isobutyl ketone (MIBK)-water). In this reaction setup, sugars are first converted to 5-hydroxymethylfurfural (HMF) in a first phase. Then HMF is then extracted into a second phase and transferred to a third phase of water. In the third phase HMF is converted to the furancarboxylic acid. The overall acid yields obtainable are between about 78% and 50% for conversion from fructose and glucose, respectively. The invention further relates to an apparatus for the triphasic reaction. The apparatus comprises two chambers which allow for the chemically separated reaction of the sugars and the intermediate of the sugars to form the final product in one process. The process according to the invention may be useful for industrial fabrication.

Owner:AGENCY FOR SCI TECH & RES

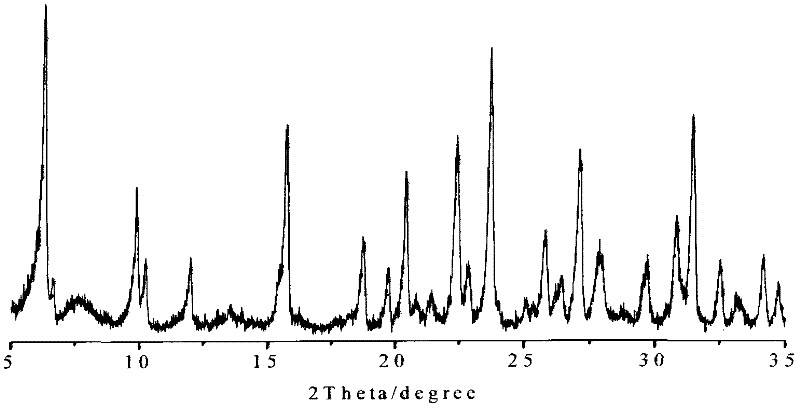

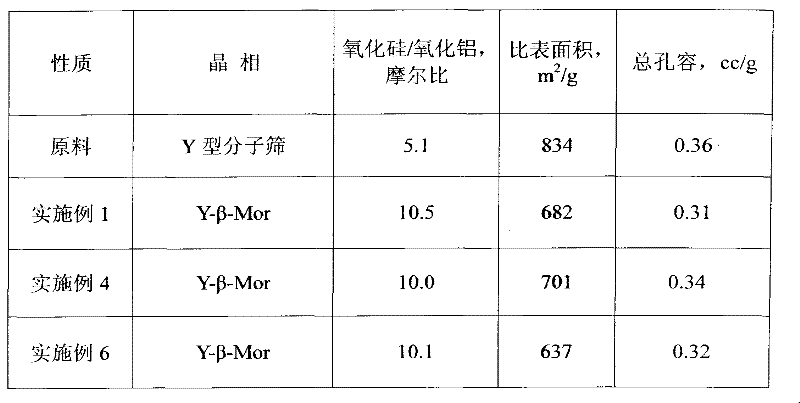

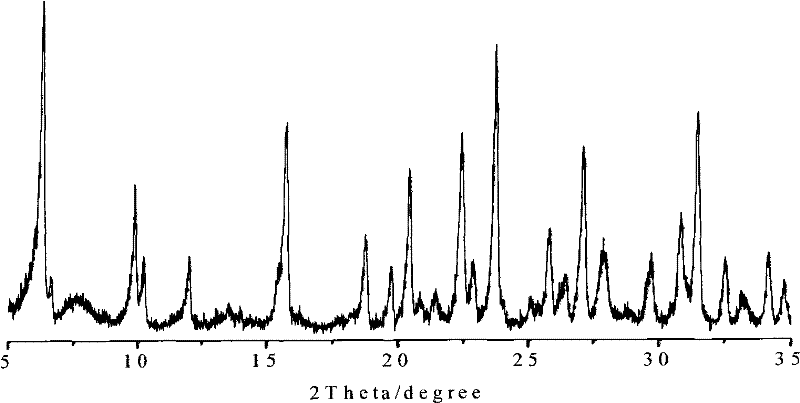

Three-crystal phase composite molecular sieve and preparation method thereof

The invention discloses a three-crystal phase composite molecular sieve and a preparation method thereof. The composite molecular sieve is provided with a Y-type molecular sieve crystal phase, a Beta zeolite crystal phase and a Mor zeolite crystal phase. The preparation method for the three-crystal phase composite molecular sieve includes the following steps: Y-type molecular sieve powder is added into solution containing sodium hydroxide and tetraethylammonium bromide, ammonia water is selectively added, a silicon source is added, a reaction mixture gel system is obtained after uniform stirring, the molar ratio of the mixture of the reaction mixture gel system is (1.18 to 1.24) Na2O:(8.5 to 13.0) SiO2:Al2O3:(2.75 to 3.10) TEABr:(1.0 to 4.0) NH4OH:(170 to 220) H2O, the reaction mixture is crystallized under a hermetic condition and at the temperature of 130 DEG C to 150 DEG C for 4 to 7 days, and thereby the Y-Beta-Mor composite molecular sieve is obtained. The composite molecular sieve provided by the invention is a new product, and can be used in a variety of catalytic processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method of high silica ZSM-5 zeolite

InactiveCN101898767BReduce dosageShape is easy to controlPentasil aluminosilicate zeoliteTetramethylammonium bromideAdhesive

The invention discloses a synthetic method of high-silica ZSM-5 zeolite, the method comprises the steps of adopting water glass as a silica source, adopting aluminum salts of aluminum sulfate, aluminum nitrate, aluminum chloride and the like, as well as organic aluminum compounds of sodium metaaluminate, isopropanol and the like as aluminum sources, using sulfuric acid or hydrochloric acid to regulate alkalinity, adding an organic template, simultaneously adding a guide adhesive, carrying out high-temperature crystallization at 120-200 DEG C, and then synthesizing the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100; and the molar ratio of raw materials is as follows: SiO2 / Al2O3 is equal to 100-infinity, Na2O / SiO2 is equal to 0.05-0.20, and H2O / SiO2 is equal to 10-100. The organic template comprises tetrapropylammonium bromide, tetrapropylammonium hydroxide, tetraethylammonium bromide, tetraethylammonium hydroxide, n-butylamine, ethylamine, hexamethylene diamine and any other organic matters which can synthesize the ZSM-5 zeolite or the mixture thereof, wherein the using amount of the organic template is that R / SiO2 is equal to 0.005-0.50; and the amount of silicon dioxide in the guide adhesive is 0-5% of the total weight of the silicon dioxide in a synthetic system. The synthetic method can synthesize the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100 and has the advantages of cheap raw materials, a small using amount of the organic template, and capability of realizing the control of product appearance and particle size by changing the relative using amount of the template and the guide adhesive.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com