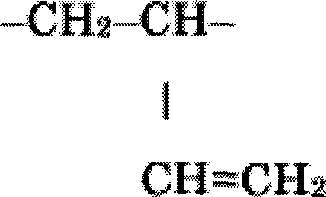

Process for brominating butadiene polymers

A technology of brominated butadiene and polymer, which is applied in the field of random or graft copolymers and blocks, can solve the problems of cost and other problems, and achieve the effect of simple recycling and simplified product recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A styrene-butadiene-styrene triblock rubber with a molecular weight of 86,000 having 46 wt% of styrene units and 54 wt% of butadiene units (of which 83% is in the form of 1,2-isomer units) was Bromide. The starting material contained 9.5 mmol of double bonds per gram. A solution of 13.0 g of the triblock rubber in 130 g of dichloromethane (DCM) was heated to reflux while adding bromine (20.7 g, 0.130 mol) and tetraethylammonium bromide (32.7 g, 0.156 mol) during 10 minutes. ) in 63 g of DCM. The resulting mixture was heated to reflux with mechanical stirring (250 rpm) for 2 hours, at which point stirring was stopped and the reaction mixture was allowed to separate into layers. The upper layer is orange and constitutes 75% by mass of the reaction mixture. The lower layer is pale yellow. The lower layer is viscous and contains brominated rubber. Partially brominated rubber was separated from part of the lower layer by casting a film and allowing the solvent to evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com