Three-crystal phase composite molecular sieve and preparation method thereof

A composite molecular sieve, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

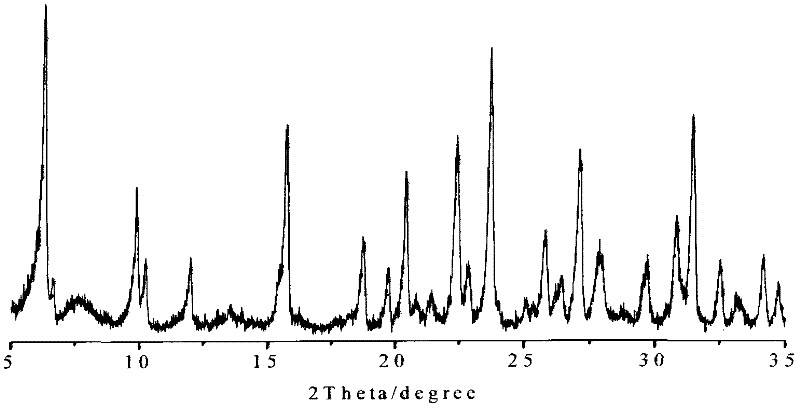

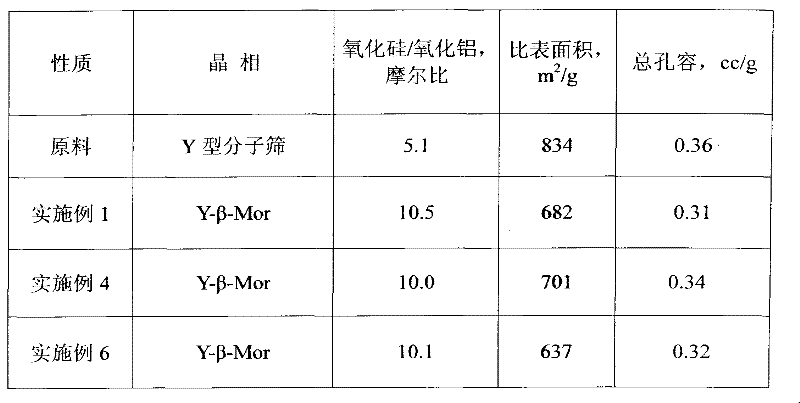

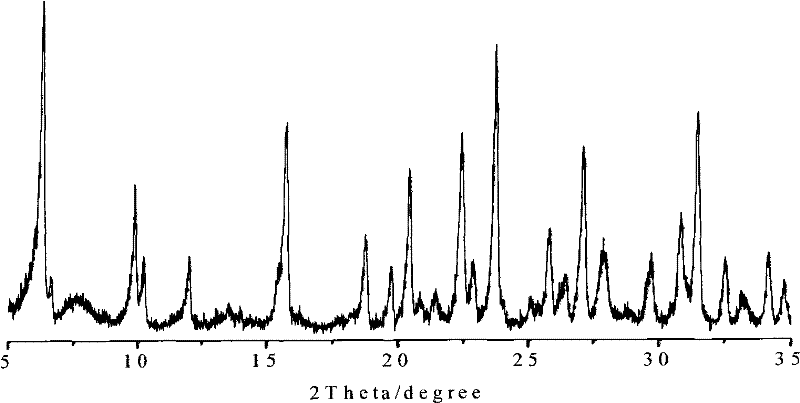

Embodiment 1

[0022] Take by weighing 0.60g sodium hydroxide and 10.0g tetraethylammonium bromide and dissolve in 36.0ml deionized water, then add 7.5g Y-type molecular sieves (molar ratio of silicon to aluminum is 5.1) while stirring, add 4.0ml ammoniacal liquor after stirring evenly In the mixture, after stirring evenly, add 20.0ml of silica sol, stir evenly, and transfer to a closed stainless steel reaction kettle. Ratio of each component of the mixture: 1.20Na 2 O: 12.3SiO 2 :Al 2 o 3 : 2.90TEABr : 3.6NH 4 OH: 204H 2 O. Crystallize at 140°C for 5.0 days to obtain a composite molecular sieve product, which is a Y-β-Mor triple crystal phase composite molecular sieve after analysis.

Embodiment 2

[0024] Take by weighing 0.58g sodium hydroxide and 10.0g tetraethylammonium bromide and be dissolved in 34.0ml deionized water, then add 7.5gY type molecular sieve (silicon-aluminum molar ratio is 5.1) while stirring, add 4.0ml ammoniacal liquor after stirring evenly In the mixture, after stirring evenly, add 20.0ml of silica sol, stir evenly, and transfer it into a closed stainless steel reaction kettle. The ratio of each component of the mixture: 1.19Na 2 O: 12.3SiO 2 :Al 2 o 3 : 2.90TEABr : 3.6NH 4 OH: 197H 2 O. Crystallize at 140°C for 4.5 days to obtain a composite molecular sieve product, which is a Y-β-Mor triple crystal phase composite molecular sieve after analysis.

Embodiment 3

[0026] Take by weighing 0.64g sodium hydroxide and 10.0g tetraethylammonium bromide and be dissolved in 40.0ml deionized water, then add 7.5gY type molecular sieve (silicon-aluminum molar ratio is 5.1) while stirring, add 4.0ml ammoniacal liquor after stirring evenly In the mixture, after stirring evenly, add 16.0ml of silica sol, stir evenly, and transfer it into a closed stainless steel reaction kettle. The ratio of each component of the mixture: 1.22Na 2 O: 10.9SiO 2 :Al 2 o 3 : 2.90TEABr : 3.6NH 4 OH: 204H 2 O. Crystallized at 140° C. for 4 days to obtain a composite molecular sieve product, which was analyzed as a Y-β-Mor three-phase composite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com