Processing method of powder paint for coating composite material

A technology of polyester resin and nitrogen protection, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of high curing temperature, high functionality, and poor weather resistance of powder coatings, and achieve weather resistance and mechanical properties Excellent, low curing temperature, smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: preparation and performance of polyester resin

[0019] 1. Preparation of polyester resin

[0020] Preparation method: raise the temperature of the reactor to 95°C, under the protection of nitrogen, add neopentyl glycol, 1,6-hexanediol, 1,4 cyclohexanediol, 1,4 cyclohexanedioic acid, cis-urethane Head acid, tartaric acid, germanium tetraiodide, and 1 part of trimethylolpropane, continue to heat up to 230°C under nitrogen protection, and keep warm for reaction until the system is clear and free of particles, and the acid value reaches 10-15mgKOH / g . Add silane coupling agent and terephthalic acid, raise the temperature to 280°C, continue to react under nitrogen protection until the acid value reaches 30-35mgKOH / g, then add tris(2,4-di-tert-butylphenyl)phosphorous acid 0.5 part of ester and 0.5 part of tetraethylammonium bromide, stir evenly, cool down to obtain polyester resin.

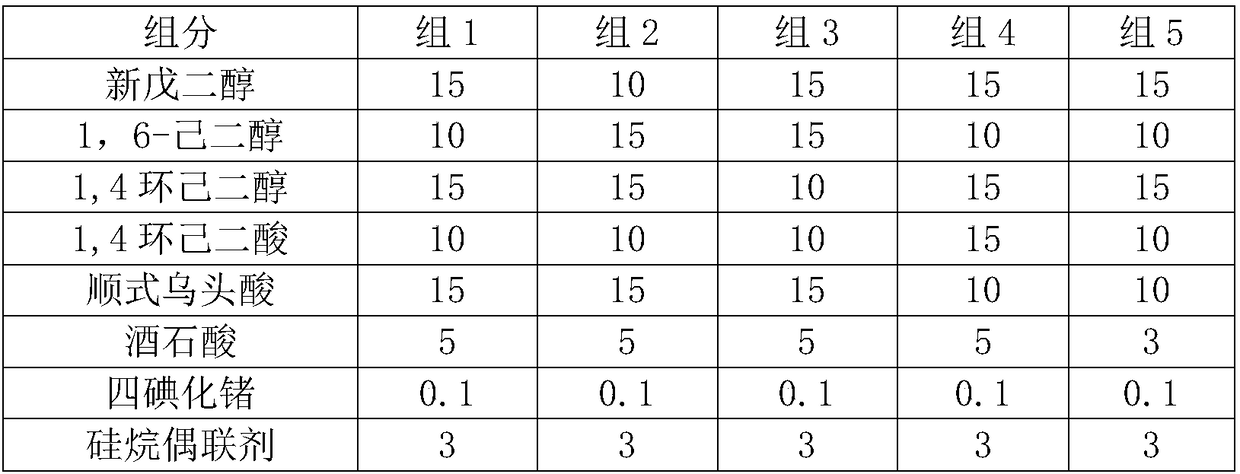

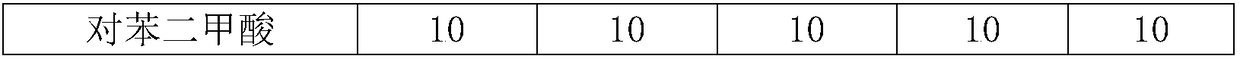

[0021] In each group, the weight of each group actually added is shown in T...

Embodiment 2

[0031] Embodiment 2: preparation and performance of powder coating

[0032] 1. Powder coating preparation:

[0033] The polyester resin prepared in Group 1 in Example 1 was selected.

[0034] In parts by weight, powder coating formula: 280 parts of polyester resin, 200-230 parts of TGIC, 5 parts of Resiflow PV88 (leveling agent), 3 parts of benzoin, 155 parts of titanium dioxide, and 155 parts of ultrafine barium (filler). The components in the above formula are mixed, extruded, pulverized and sieved to obtain the powder coating. The curing time is 15min.

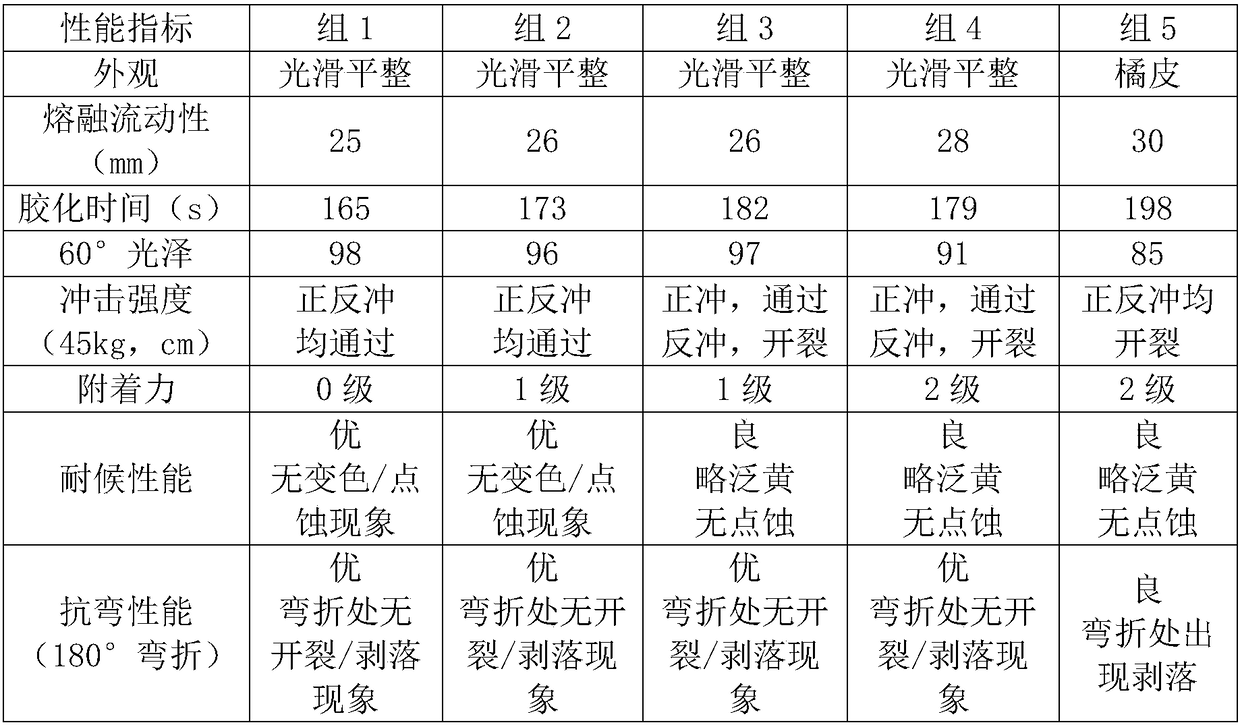

[0035] The actual parameters of each group are shown in Table 3.

[0036] Table 3 Parameter conditions in each group

[0037] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com