Method for directly preparing meso-porous molecular sieves by hydrothermal process in system using meso-porous silica as silicon source precursor without meso-porous template

A technology of mesoporous silica and mesoporous template, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, borocarbonane silicone crystalline aluminum silicate zeolite, etc. It can reduce the problem of lowering and consume a lot of energy, and achieve the effect of large mesopore volume, high crystallinity, and avoiding the reduction of the degree of crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

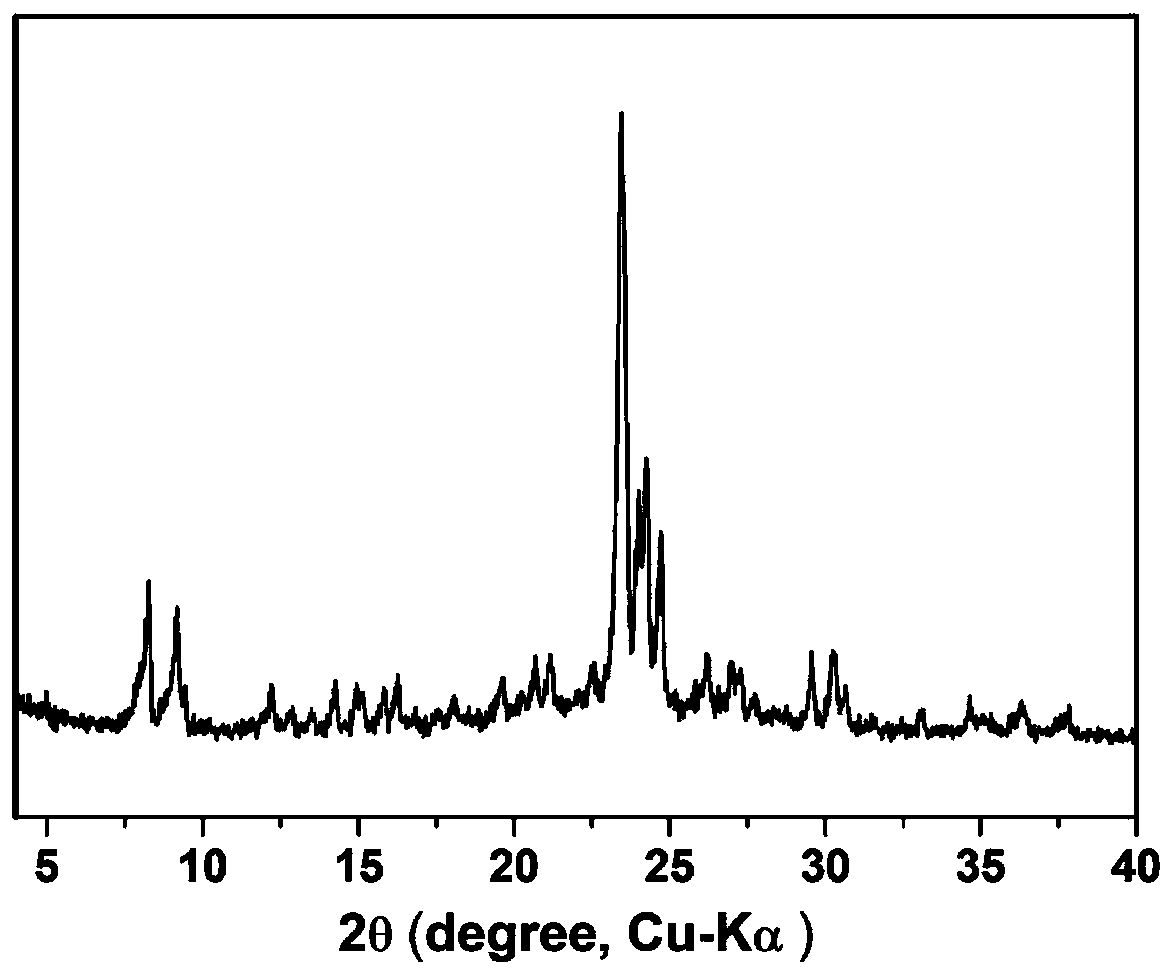

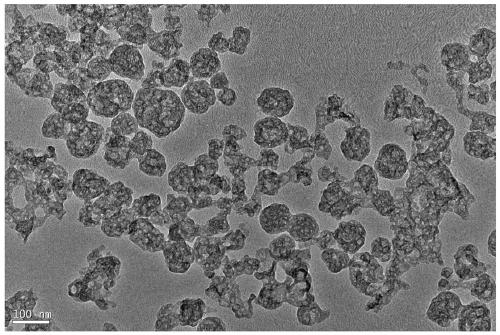

Embodiment 1

[0031] Disperse 0.813g tetrapropylammonium hydroxide aqueous solution (the mass fraction of tetrapropylammonium hydroxide solute is 25%), 0.931g tetrapropylammonium bromide is dispersed in 4.79g deionized water, and stir uniformly for 1 hour at room temperature to reach the system Uniform; then 0.031g sodium metaaluminate (of which Al 2 O 3 =41wt%) add the above solution, stir for 30min until the dispersion is uniform, add 0.6g of mesoporous silica balls (the diameter of the mesoporous silica beads is 80-200nm), stir for 2h until the system is uniform, and fill it with In a stainless steel reaction kettle lined with polytetrafluoroethylene, crystallize in an oven at 170°C for 72 hours. After the crystallization reaction is completed, the crystallization reaction product is obtained, which is then washed with deionized water to neutrality and dried in the air at 50°C. Porous ZSM-5 molecular sieve raw powder; the obtained mesoporous ZSM-5 molecular sieve raw powder is calcined in ...

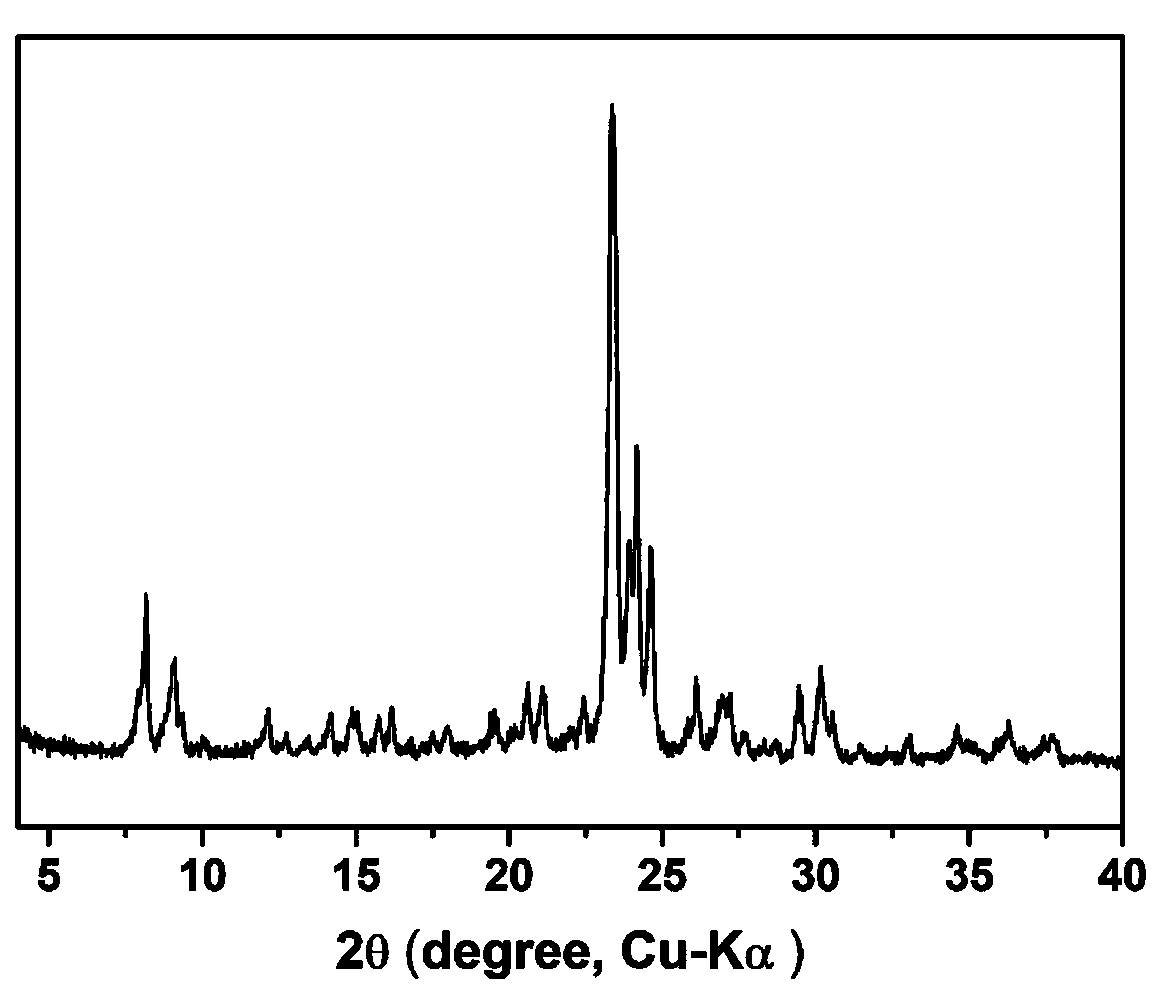

Embodiment 2

[0035] Disperse 1.22g tetrapropylammonium hydroxide aqueous solution (the mass fraction of tetrapropylammonium hydroxide solute is 25%), 0.798g tetrapropylammonium bromide is dispersed in 4.49g deionized water, and stir uniformly at room temperature for 1 hour to reach the system Uniform; then 0.031g sodium metaaluminate (of which Al 2 O 3 =41wt%) add the above solution, stir for 30min until the dispersion is uniform, add 0.6g of mesoporous silica balls, stir for 2h until the system is uniform, put it into a stainless steel reactor with PTFE lining to 170℃ oven After the crystallization reaction is completed for 72 hours, the crystallization reaction product is obtained, and then washed with deionized water to neutrality, and dried in the air at 50°C to obtain the original mesoporous ZSM-5 molecular sieve powder; the obtained mesoporous ZSM- 5. The original molecular sieve powder is calcined in the air at 500℃ for 8 hours to obtain ZSM-5 molecular sieve; the molar ratio of the e...

Embodiment 3

[0039] Disperse 0.407g tetrapropylammonium hydroxide aqueous solution (the mass fraction of tetrapropylammonium hydroxide solute is 25%), 1.064g tetrapropylammonium bromide is dispersed in 5.10g deionized water, and stir uniformly for 1 hour at room temperature to reach the system Uniform; then 0.031g sodium metaaluminate (of which Al 2 O 3 =41wt%) add the above solution, stir for 30min until the dispersion is uniform, add 0.6g of mesoporous silica balls, stir for 2h until the system is uniform, put it into a stainless steel reactor with PTFE lining to 170℃ oven After the crystallization reaction is completed for 72 hours, the crystallization reaction product is obtained, and then washed with deionized water to neutrality, and dried in the air at 50°C to obtain the original mesoporous ZSM-5 molecular sieve powder; the obtained mesoporous ZSM- 5. The original molecular sieve powder is calcined in the air at 500℃ for 8 hours to obtain ZSM-5 molecular sieve; the molar ratio of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com