Preparation method of nano hierarchical pore Beta molecular sieve

A molecular sieve, multi-level pore technology, applied in molecular sieve catalyst, nanotechnology, nanotechnology and other directions, can solve problems such as ineffective utilization, and achieve the effect of simplifying synthesis steps and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of nanometer hierarchical porous Beta molecular sieve, comprises the following steps:

[0041] (1) Silicon source, aluminum source, inorganic base, templating agent, Beta crystal seed and water are carried out ball milling and mixing, obtain solid-phase reaction mixture; The consumption of described silicon source, aluminum source and inorganic base is represented by SiO 2 、Al 2 o 3 and Na 2 O content meter, the SiO 2 、Al 2 o 3 、Na 2 O, the molar ratio of template agent and water is 1: (0.0083~0.05): (0.113~0.168): (0.28~0.40): (1.5~3);

[0042] (2) The solid-phase reaction mixture and water are separated and placed in a reaction kettle, and a steam-assisted crystallization reaction is performed to obtain a molecular sieve precursor; the temperature of the steam-assisted crystallization reaction is 140°C, and the time is 24-72h ;

[0043] (3) Calcining the molecular sieve precursor to obtain a nano-hierarchical...

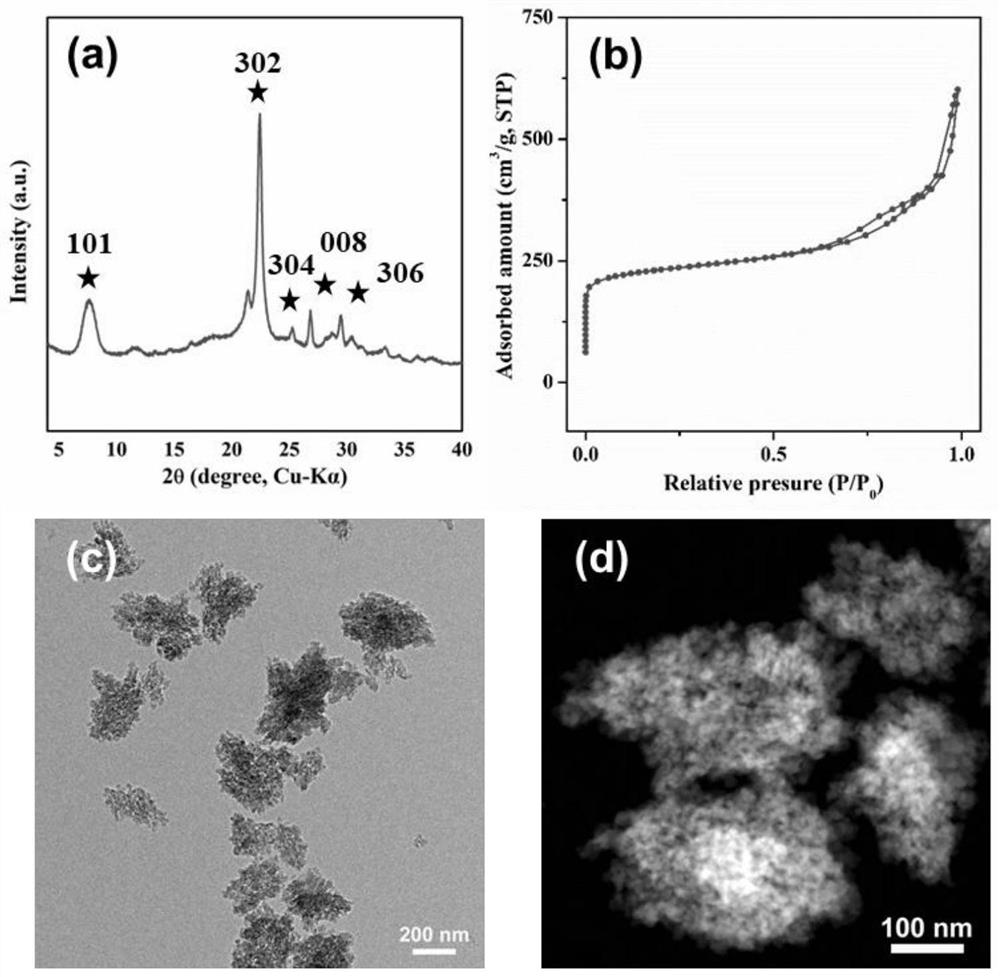

Embodiment 1

[0060] Weigh 0.5g of solid silica gel, 0.495g of tetraethylammonium bromide, 0.068g of sodium hydroxide, 0.052g of sodium aluminate, 0.05g of seed crystals and 0.45g of deionized water as solid-phase raw materials, and add them to ball mills for 5 hours Finally, the solid-phase reaction mixture was obtained; 0.5g of the solid-phase reaction mixture was weighed and packed into a 5mL polytetrafluoroethylene liner, and then embedded in a 50mL reactor with 1g of deionized water at the bottom, at 140°C Steam assisted crystallization for 72 hours. After the crystallization was completed, the product was centrifugally washed with deionized water until neutral, then dried at 60°C for 12 hours, and finally calcined at 550°C under air conditions for 6 hours to obtain a Beta molecular sieve, which was designated as sample Beta -1.

[0061] The solid silica gel is purchased from Qingdao Ocean Chemical Co., Ltd., and the molar ratio of each raw material in the solid-phase reaction mixture ...

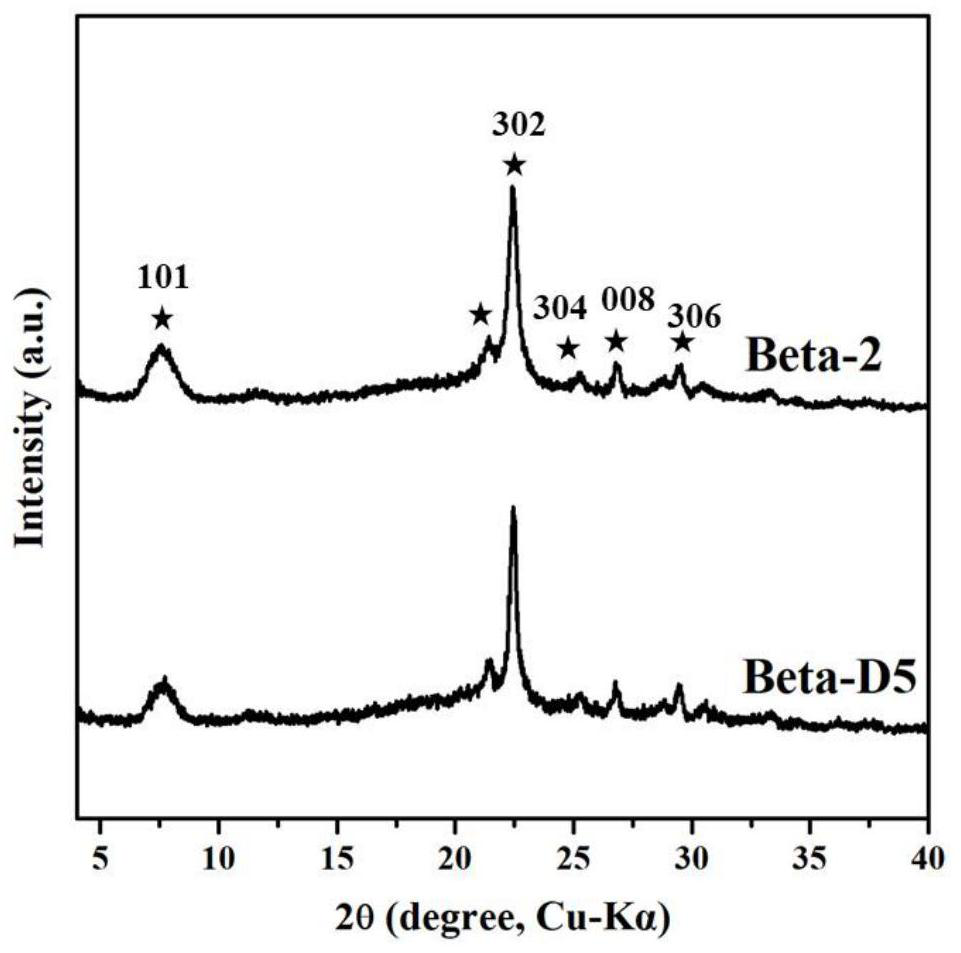

Embodiment 2

[0063] Weigh 0.5g of solid silica gel, 0.495g of tetraethylammonium bromide, 0.068g of sodium hydroxide, 0.052g of sodium aluminate, 0.05g of seed crystals and 0.225g of deionized water as solid-phase raw materials, and add them to ball mills for 5 hours Finally, the solid-phase reaction mixture was obtained; 0.5g of the solid-phase reaction mixture was weighed and packed into a 5mL polytetrafluoroethylene liner, and then embedded in a 50mL reactor with 2g of deionized water at the bottom, at 140°C Steam assisted crystallization for 72 hours. After the crystallization was completed, the product was centrifugally washed with deionized water until neutral, then dried at 60°C for 12 hours, and finally calcined at 550°C under air conditions for 6 hours to obtain a Beta molecular sieve, which was designated as sample Beta -2.

[0064] The solid silica gel is purchased from Qingdao Ocean Chemical Co., Ltd., and the molar ratio of each raw material in the solid-phase reaction mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com