Method for preparing mordenite/ Zeolite Socony Mobil (ZSM)-5 composite molecular sieve

A technology of ZSM-5 and composite molecular sieve, which is applied in the direction of mercerized crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of high conversion rate of C4 hydrocarbons, low Catalytic activity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 0.42g of solid sodium hydroxide, 1.5g of tetraethylammonium bromide (TEABr, 99%, analytically pure), and 15g of deionized water evenly, add 0.4g of ZSM-5 seed crystals, and oscillate ultrasonically for 30 minutes to disperse the crystal seeds evenly . After that, 5.0 g of kaolin microspheres and 2.0 g of white carbon black were added, and stirred for 20 min to form a uniform gel. The gel was transferred to a polytetrafluoroethylene self-pressurized reactor, sealed and aged at room temperature for 30 hours, and then moved into an oven for crystallization at 150°C for 48 hours. After the reaction, the solid product was isolated, washed with deionized water until neutral, dried overnight at 120°C, and calcined at 550°C to obtain a sodium-type mordenite / ZSM-5 composite molecular sieve product.

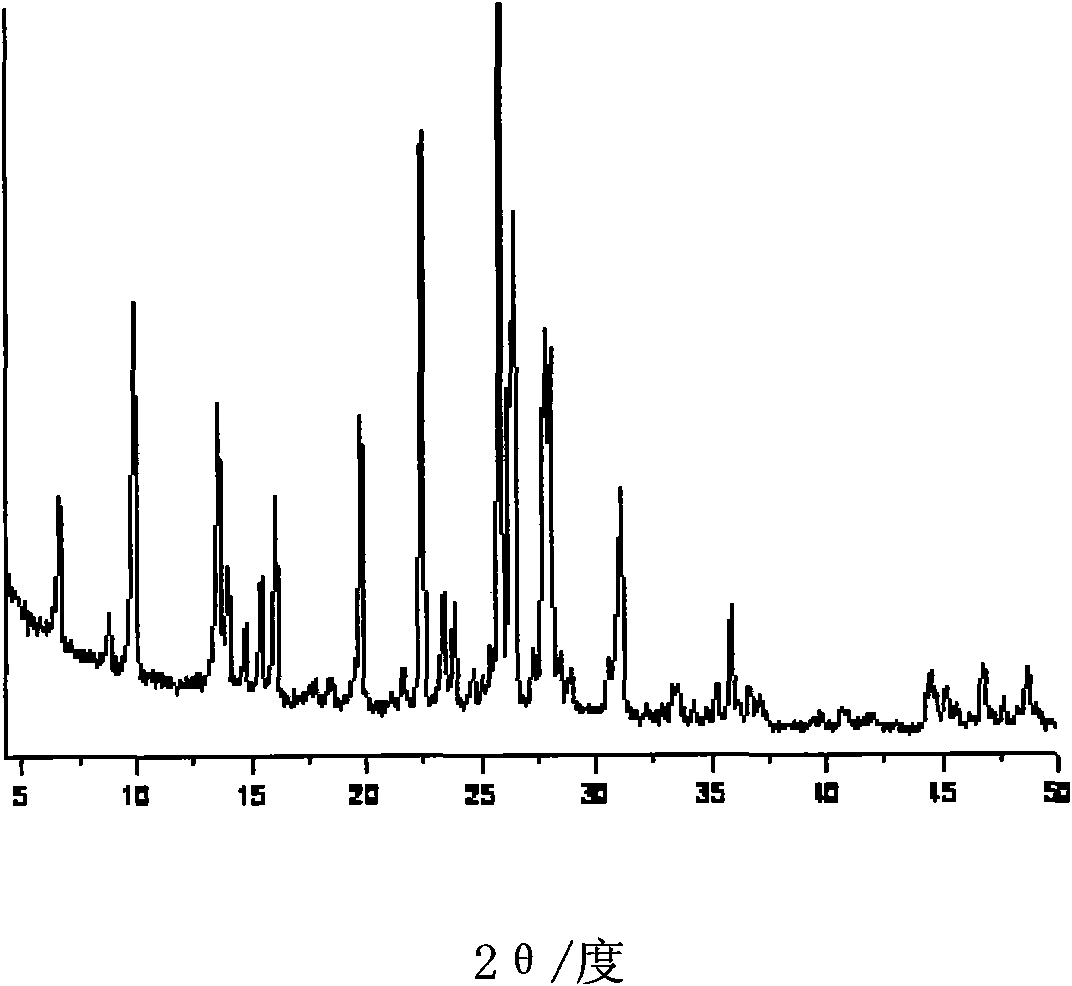

[0025] The molar ratio of raw materials in the reaction system is: SiO 2 / Al 2 o 3 =30,Na 2 O / SiO 2 =0.1, TEA+ / SiO 2 =0.15,H 2 O / SiO 2 =17. Comparing the XRD diffracti...

Embodiment 2

[0027] Mix 0.30 g of solid sodium hydroxide, 1.5 g of tetraethylammonium bromide (TEABr, 99%, analytically pure), and 15 g of deionized water evenly, add 0.4 g of ZSM-5 seed crystals, and oscillate ultrasonically for 30 minutes to disperse the crystal seeds evenly . After that, 5.0 g of kaolin microspheres and 2.0 g of white carbon black were added, and stirred for 20 min to form a uniform gel. The gel was transferred to a polytetrafluoroethylene self-pressurized reactor, sealed and aged at room temperature for 30 hours, and then moved into an oven for crystallization at 150°C for 48 hours. After the reaction, the solid product was isolated, washed with deionized water until neutral, dried overnight at 120°C, and calcined at 550°C to obtain a sodium-type mordenite / ZSM-5 composite molecular sieve product.

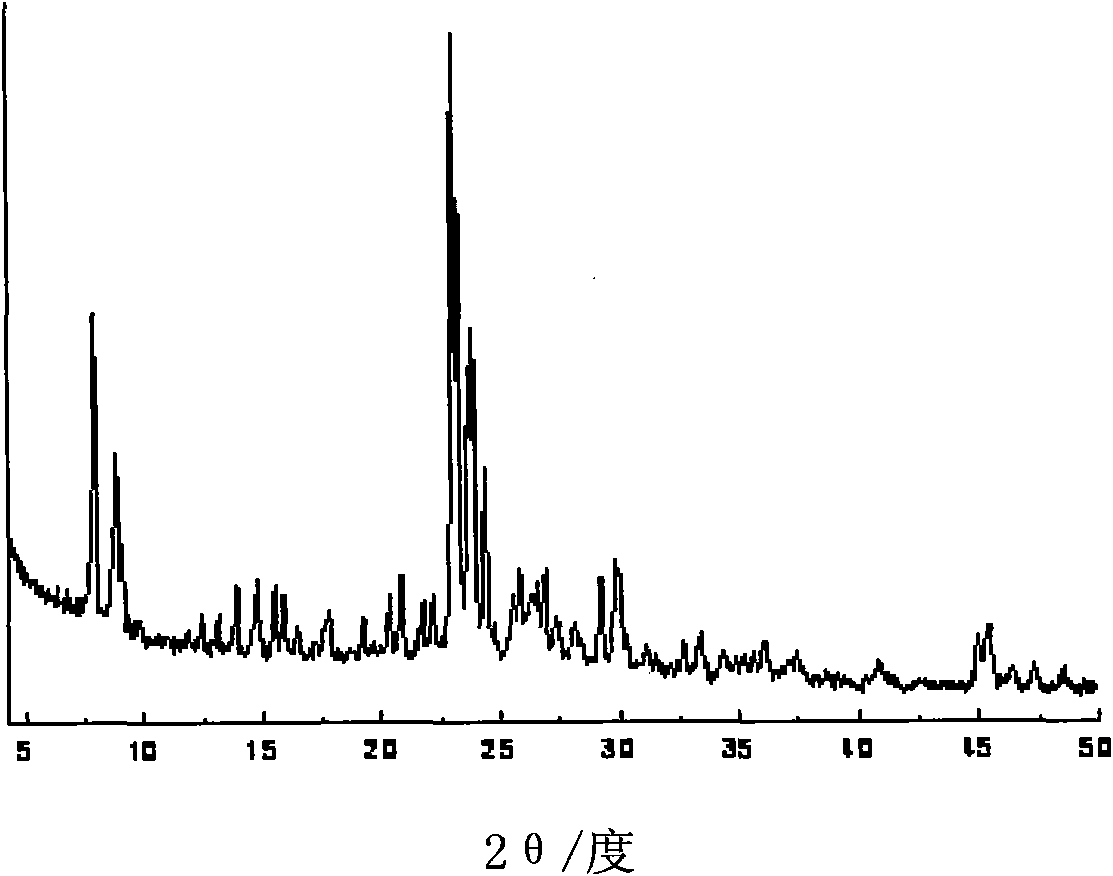

[0028] The molar ratio of raw materials in the reaction system is: SiO 2 / Al 2 o 3 =30,Na 2 O / SiO 2 =0.075, TEA+ / SiO 2 =0.15,H 2 O / SiO 2 =17. Comparing the XRD dif...

Embodiment 3

[0030] Mix 0.42 g of solid sodium hydroxide, 1.5 g of tetraethylammonium bromide (TEABr, 99%, analytically pure), and 15 g of deionized water evenly, add 0.4 g of mordenite seed crystals, and oscillate ultrasonically for 30 minutes to disperse the crystal seeds evenly. After that, 5.0 g of kaolin microspheres and 2.0 g of white carbon black were added, and stirred for 20 min to form a uniform gel. The gel was transferred to a polytetrafluoroethylene self-pressurized reactor, sealed and aged at room temperature for 30 hours, and then moved into an oven for crystallization at 150°C for 48 hours. After the reaction, the solid product was isolated, washed with deionized water until neutral, dried overnight at 120°C, and calcined at 550°C to obtain a sodium-type mordenite / ZSM-5 composite molecular sieve product.

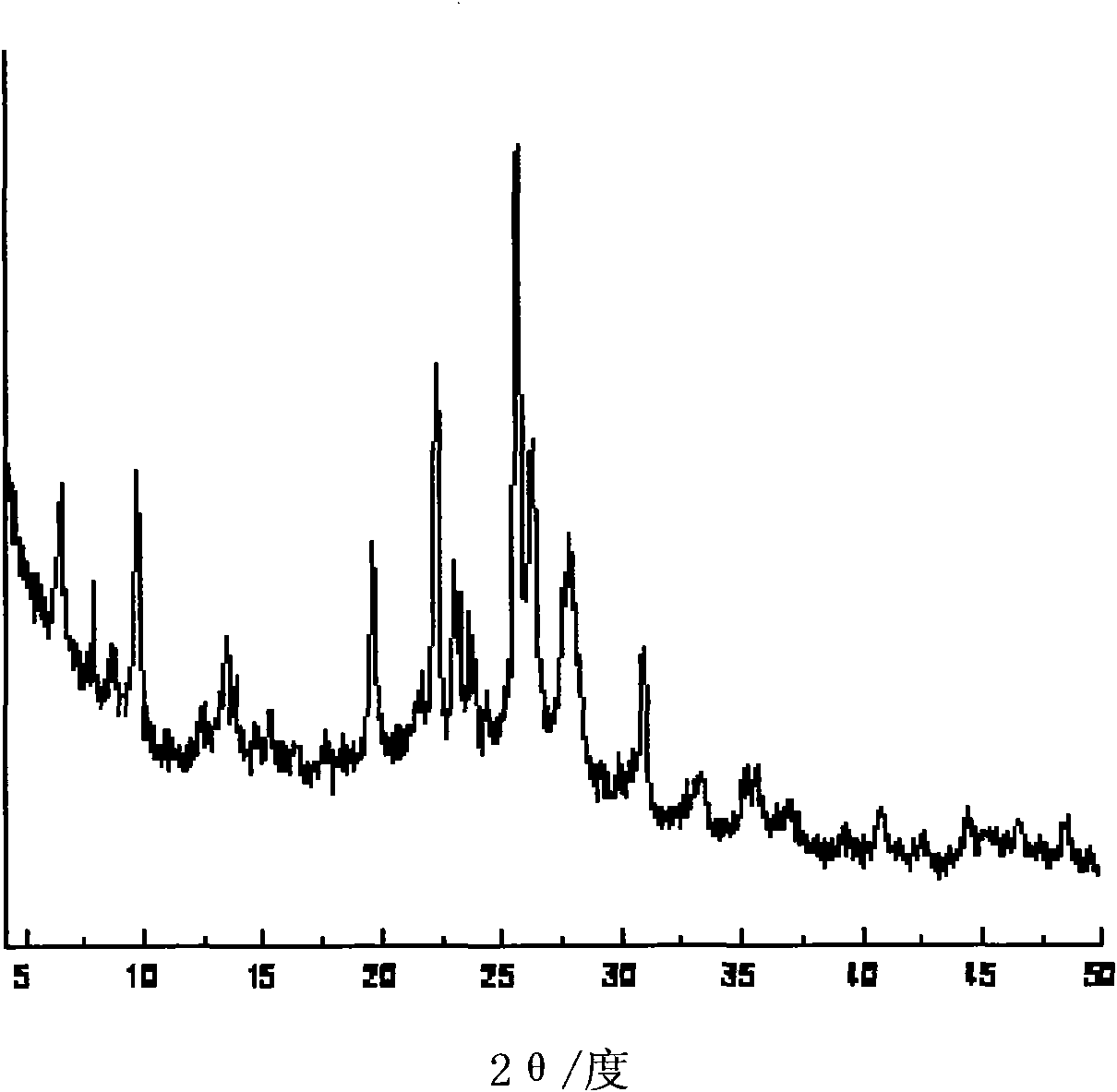

[0031] The molar ratio of raw materials in the reaction system is: SiO 2 / Al 2 o 3 =30,Na 2 O / SiO 2 =0.1, TEA+ / SiO 2 =0.15,H 2 O / SiO 2 =17. Comparing the XRD diffr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com