Catalyst composition and terpolymer synthesis method

A compound and composition technology, applied in the field of catalyst composition and terpolymer synthesis, can solve the problem of low glass transition temperature and achieve good thermodynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

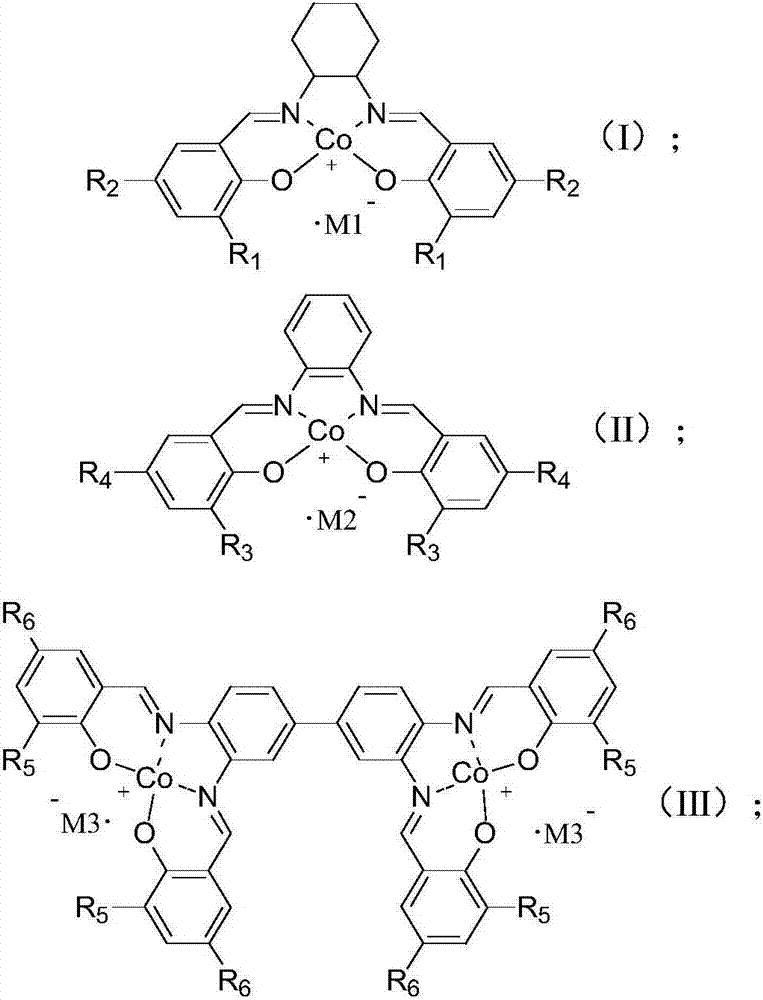

[0049] The invention provides a kind of synthetic method of terpolymer, comprises the following steps:

[0050] In the presence of the catalyst composition described in the above technical solution, the propylene oxide, carbon dioxide and lactide are polymerized to obtain a terpolymer.

[0051] In the synthesis method provided by the invention, propylene oxide, carbon dioxide and lactide are directly polymerized in the presence of the catalyst composition. The specific process includes: first adding the catalyst composition, propylene oxide and lactide into the autoclave, then feeding carbon dioxide into the autoclave, and then polymerizing the reactants in the autoclave at a certain temperature reaction. In the present invention, the molar ratio of propylene oxide to lactide is preferably 1: (0.05-0.25), and may be 1:0.05, 1:0.06, 1:0.07, 1:0.08, 1:0.09, 1:0.1, 1:0.11, 1:0.12, 1:0.13, 1:0.14, 1:0.15, 1:0.16, 1:0.17, 1:0.18, 1:0.19, 1:0.2, 1:0.21, 1:0.19 0.22, 1:0.23, 1:0.2...

Embodiment 1

[0057] 2.18g of propylene oxide, 0.82g of lactide, 0.029g of catalyst I, 0.023g of catalyst IV and 0.022g of PPNCl were mixed and added into the autoclave that had undergone high-temperature water and oxygen removal, and high-purity carbon dioxide gas was introduced into it, and Press down to 2MPa, control the temperature and stir at 60°C, and react for 2h;

[0058] After the reaction, place the reaction kettle in ice water to cool down rapidly, then slowly release the residual gas until the pressure drops to atmospheric pressure, dissolve the obtained reaction product with 15mL of dichloromethane, slowly drop the obtained solution into 200mL of ethanol, stir After 15 minutes, stand still for 30 minutes; dissolve the precipitated polymer in dichloromethane again, settle in ethanol, repeat 3 times, and vacuum-dry the precipitate obtained by the precipitation to obtain a reaction product.

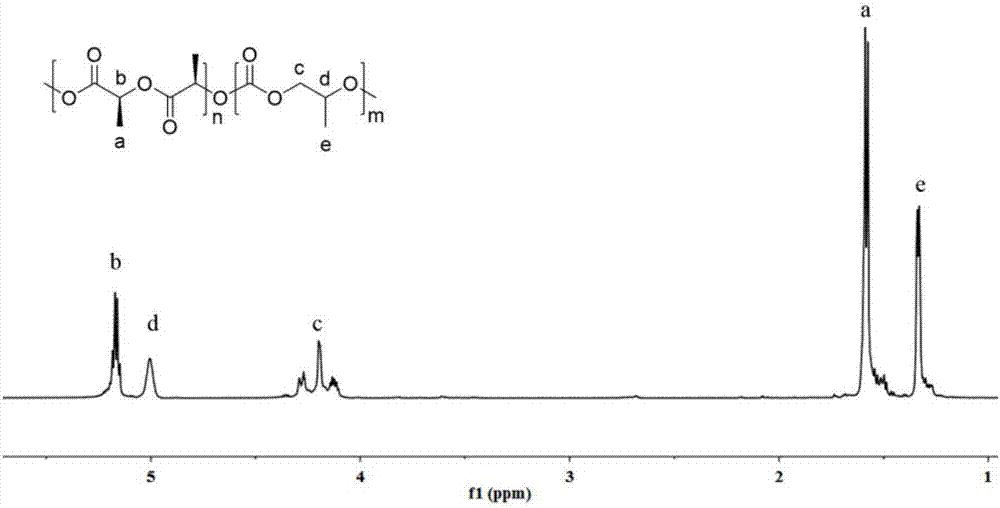

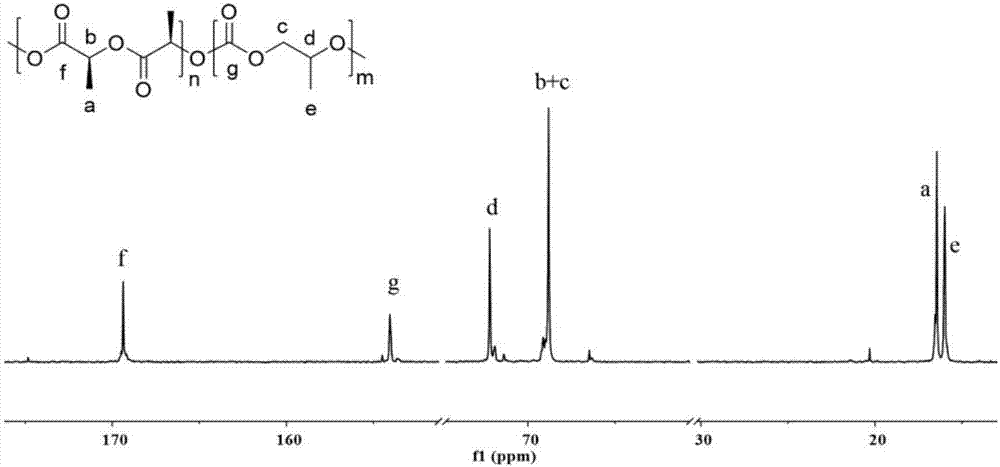

[0059] The resulting polymer was 1 H-NMR and 13 C-NMR analysis shows that the product o...

Embodiment 2

[0063] Mix 2.18g of propylene oxide, 0.82g of lactide, 0.028g of catalyst II, 0.023g of catalyst V and 0.022g of PPNCl into a high-pressure reactor that has undergone high-temperature dehydration and oxygen removal, and introduce high-purity carbon dioxide gas into it, and add Press down to 2MPa, control the temperature and stir at 60°C, and react for 2h;

[0064] After the reaction, place the reaction kettle in ice water to cool down rapidly, then slowly release the residual gas until the pressure drops to atmospheric pressure, dissolve the obtained reaction product with 15mL of dichloromethane, slowly drop the obtained solution into 200mL of ethanol, stir After 15 minutes, stand still for 30 minutes; dissolve the precipitated polymer in dichloromethane again, settle in ethanol, repeat 3 times, and vacuum-dry the precipitate obtained by the precipitation to obtain a reaction product.

[0065] The resulting polymer is 1 H-NMR and 13 C-NMR analysis shows that the product obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com