Y/ZSM-12 composite molecular sieve and preparation method thereof

A ZSM-12, composite molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve problems such as failure to synthesize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

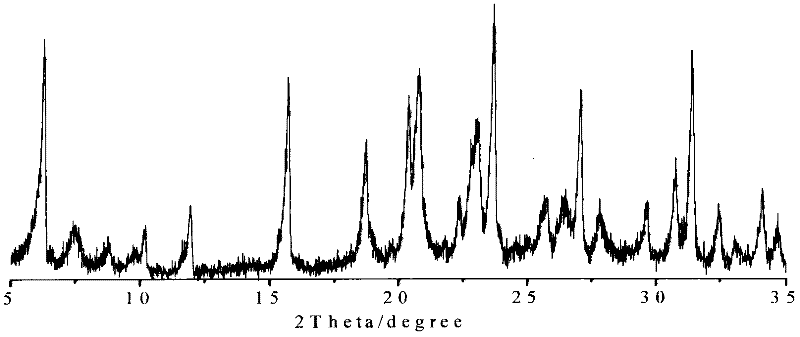

Embodiment 1

[0018] Weigh 0.65g of sodium hydroxide and 10.4g of TEABr and dissolve them in 37.0ml of deionized water, then add 10.0g of Y-type molecular sieves while stirring, stir for half an hour, then add 20.0ml of silica sol, stir for 2 hours, then move to a closed stainless steel reaction kettle . Crystallize at 138° C. for 5 days to obtain a molecular sieve product, which is a Y / ZSM-12 composite crystal phase molecular sieve through analysis.

[0019] Synthetic material ratio: 1.18Na 2 O: 10.5SiO 2 :2.25TEABr:Al 2 o 3 : 144H 2 O.

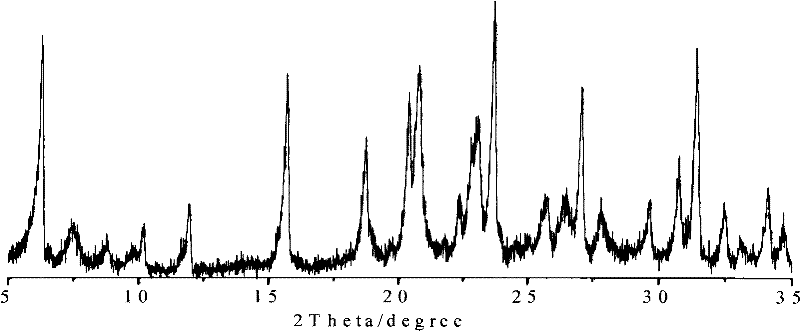

Embodiment 2

[0021] Weigh 0.65g of sodium hydroxide and 10.4g of TEABr and dissolve them in 37.0ml of deionized water, then add 10.0g of Y-type molecular sieves while stirring, stir for half an hour, then add 20.0ml of silica sol, stir for 2 hours, then move to a closed stainless steel reaction kettle . After crystallization at 139°C for 4.5 days, a molecular sieve product was obtained, and analysis showed that the molecular sieve product was a Y / ZSM-12 composite crystal phase molecular sieve.

[0022] Synthetic material ratio: 1.18Na 2 O: 10.5SiO 2 :2.25TEABr:Al 2 o 3 : 144H 2 O.

Embodiment 3

[0024] Weigh 0.65g of sodium hydroxide and 10.2g of TEABr and dissolve them in 37.0ml of deionized water, then add 10.0g of Y-type molecular sieves while stirring, stir for half an hour, then add 20.0ml of silica sol, stir for 2 hours, then move to a closed stainless steel reaction kettle . After crystallization at 140°C for 4.5 days, a molecular sieve product was obtained, and analysis showed that the molecular sieve product was a Y / ZSM-12 composite crystal phase molecular sieve.

[0025] Synthetic material ratio: 1.18Na 2 O: 10.5SiO 2 :2.21TEABr:Al 2 o 3 : 144H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com