Synthesis method for Silicalite-1

A synthetic method, uniform mixing technology, applied in chemical instruments and methods, molecular sieves and base exchange compounds, silica, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] At a stirring speed of 400r / min, after mixing ethyl orthosilicate, tetraethylammonium hydroxide, sodium hydroxide, sodium fluoride and deionized water evenly, the molar ratio of the mixture obtained is OH - : SiO 2 :R:F:H 2 O=0.5:1:0.2:0.8:15, then the resulting mixture was transferred to a closed pressure vessel.

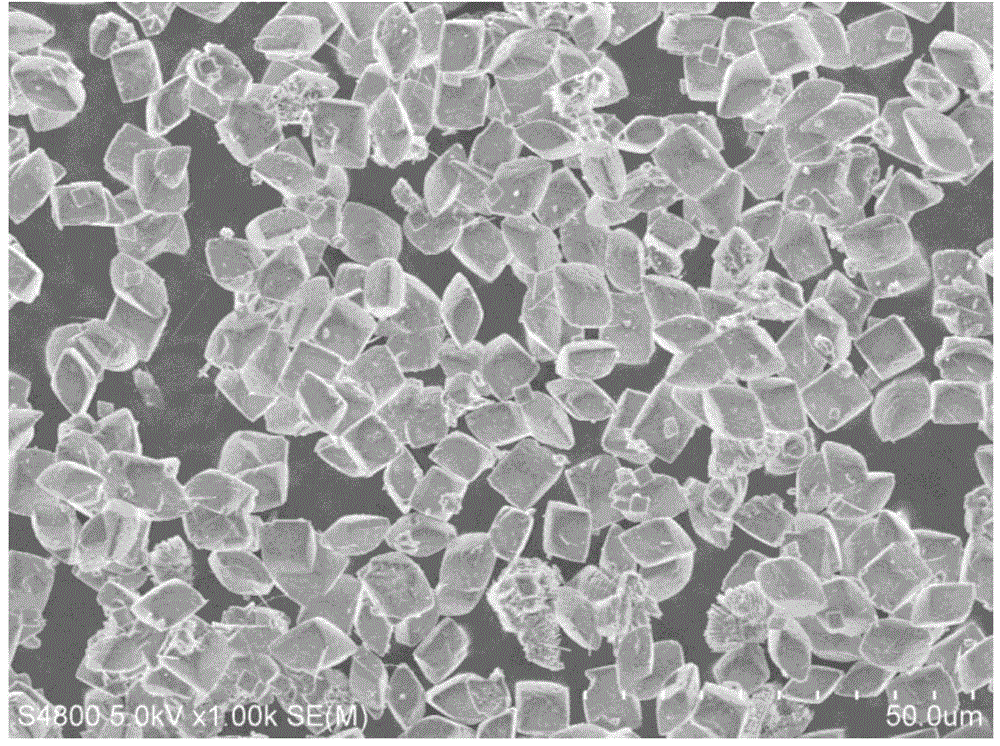

[0048] Under the stirring condition of 400r / min, the temperature of the crystallization system was raised to 150°C, and the temperature was kept at autogenous pressure for 6 days to obtain a mixture of crystallized products; the mixture was filtered and washed with water for several times; at a temperature of 110°C Dry for 6 hours, and grind the dried mixture evenly to obtain the raw powder of unroasted Silicalite-1 molecular sieve; finally, roast the raw powder of Silicalite-1 molecular sieve at a temperature of 550 °C for 4 hours to obtain Silicalite-1 molecular sieve powder. 1 molecular sieve, the crystal phase diagram of its X-ray diffraction (XRD) is ...

Embodiment 2

[0050] At a stirring speed of 400r / min, after mixing white carbon black, tetraethylammonium chloride, sodium hydroxide, sodium chloride and deionized water evenly, the molar ratio of the mixture obtained is OH - : SiO 2 :R:F:H 2 O=1.5:1:0.3:2:30, then the resulting mixture was transferred to a closed pressure vessel.

[0051] Under the condition of stirring at 300r / min, the temperature of the crystallization system was raised to 135°C, and the temperature was kept at autogenous pressure for 12 days to obtain a mixture of crystallized products; the mixture was filtered and washed with water several times; at a temperature of 130°C Dry for 4 hours, and grind the dried mixture evenly to obtain the raw powder of unroasted Silicalite-1 molecular sieve; finally, roast the raw powder of Silicalite-1 molecular sieve at a temperature of 550 °C for 6 hours to obtain Silicalite-1 molecular sieve powder. 1 molecular sieve, the crystal phase diagram of its X-ray diffraction (XRD) and fi...

Embodiment 3

[0053] At a stirring speed of 400r / min, after mixing the silica sol, tetraethylammonium bromide, sodium hydroxide and deionized water evenly, the molar ratio of the mixture obtained is OH - : SiO 2 :R:F:H 2 O=3:1:0.35:3:50, then the resulting mixture was transferred to a closed pressure vessel.

[0054] Under the stirring condition of 200r / min, the temperature of the crystallization system was raised to 180°C, and the temperature was kept at autogenous pressure for 5 days to obtain a mixture of crystallized products; the mixture was filtered and washed with water for several times; at a temperature of 150°C Dry for 2 hours, and grind the dried mixture evenly to obtain the raw powder of unroasted Silicalite-1 molecular sieve; finally, roast the raw powder of Silicalite-1 molecular sieve at a temperature of 650 °C for 8 hours to obtain Silicalite-1 molecular sieve powder. 1 molecular sieve, the crystal phase diagram of its X-ray diffraction (XRD) and figure 1 Similar (to prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com