Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "International level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

International or Systemic Level. The international or systemic level of analysis argues that all foreign policy can be understood without even looking at the internal characteristics of nations or individuals.

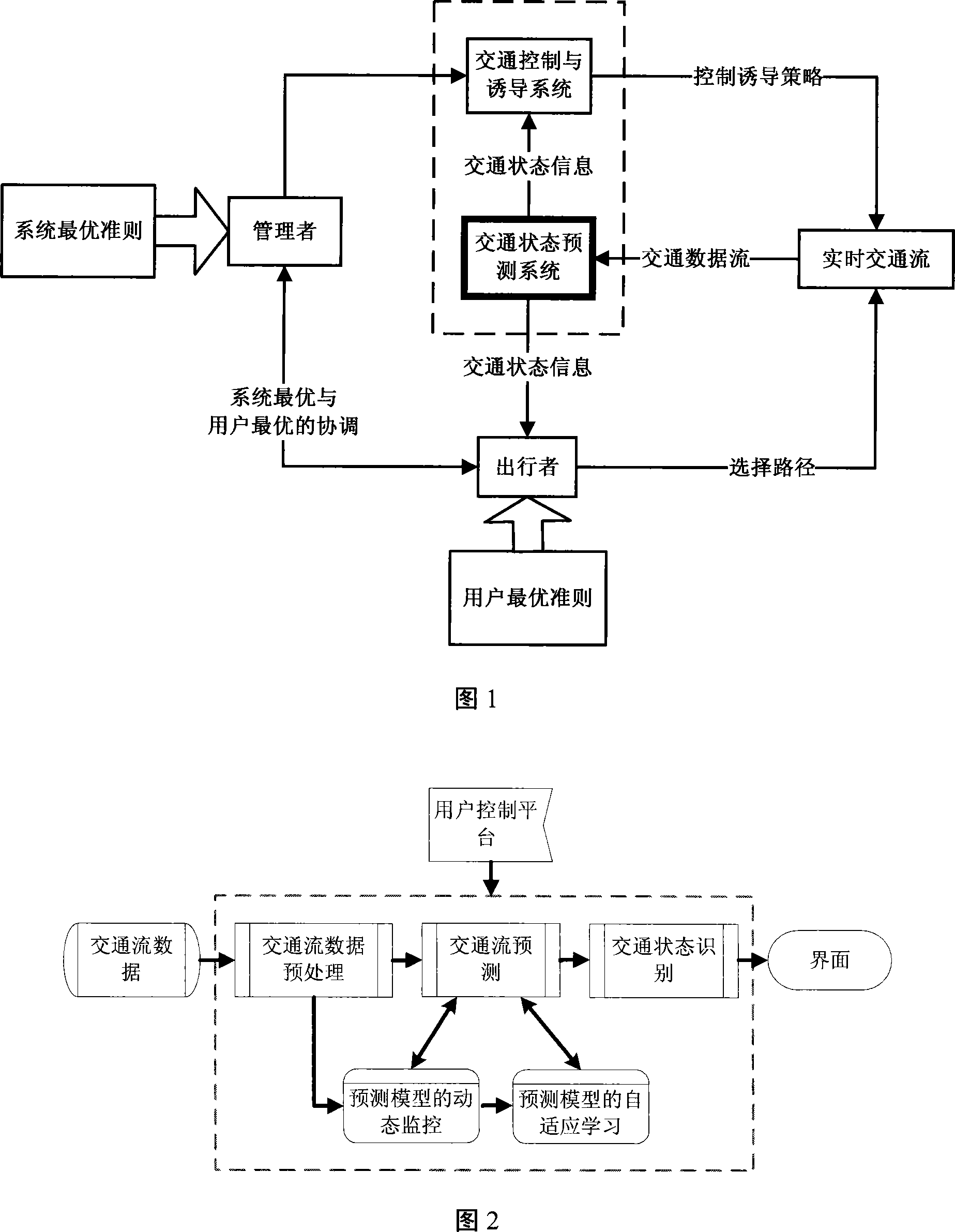

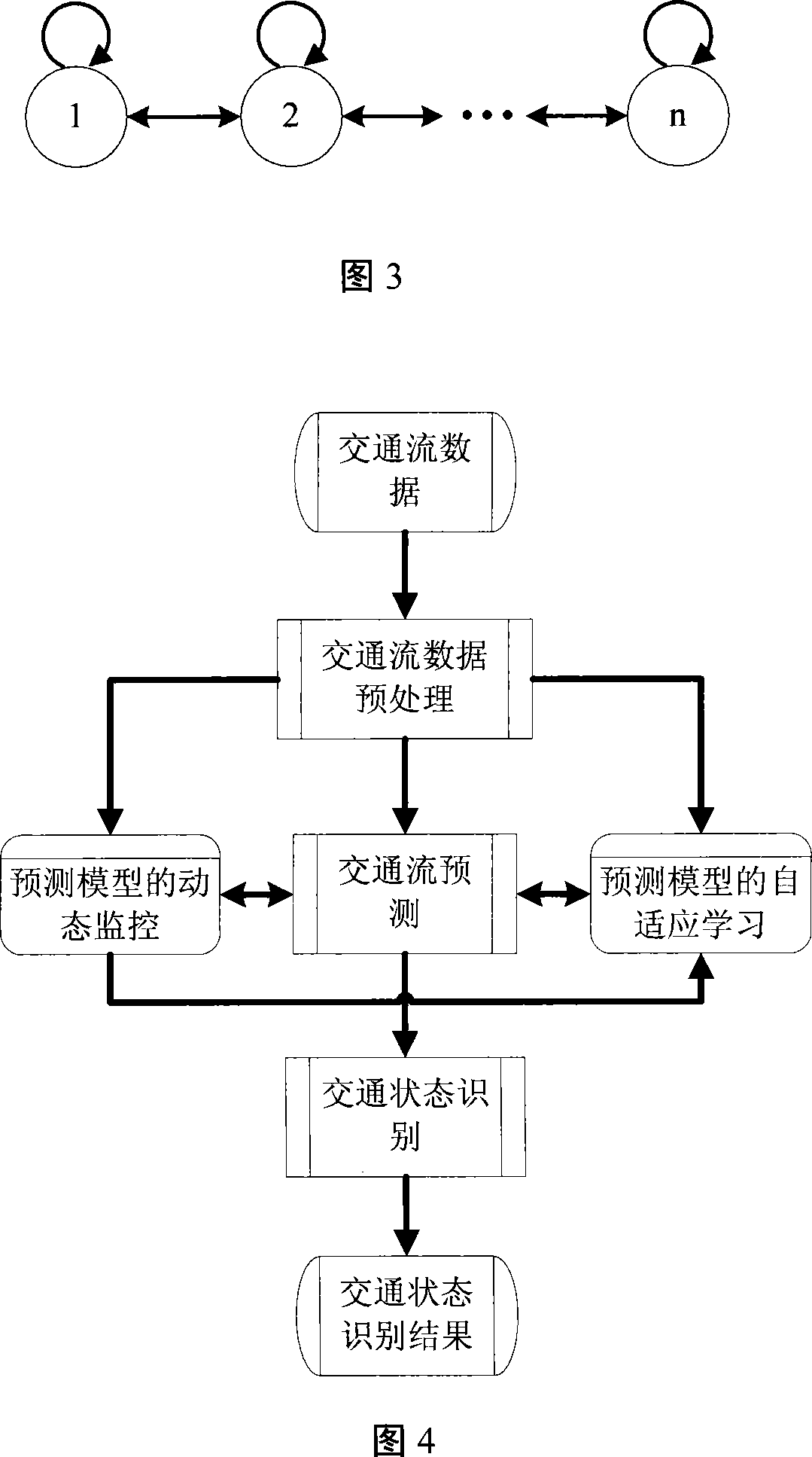

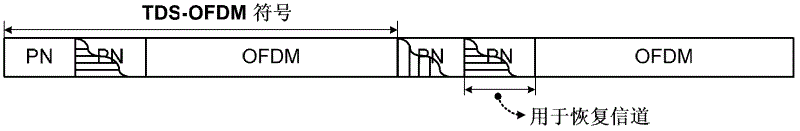

A city traffic dynamic prediction system and method with real time and continuous feature

InactiveCN101188002AMeet real-time requirementsMeet the needs of traffic conditionsForecastingData streamActive monitoring

Owner:PEKING UNIV

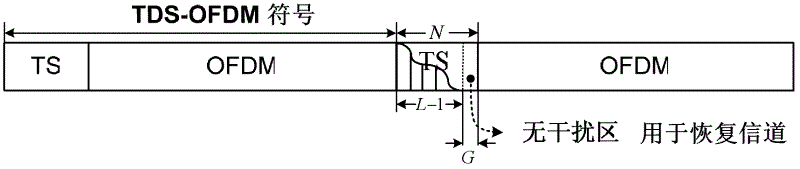

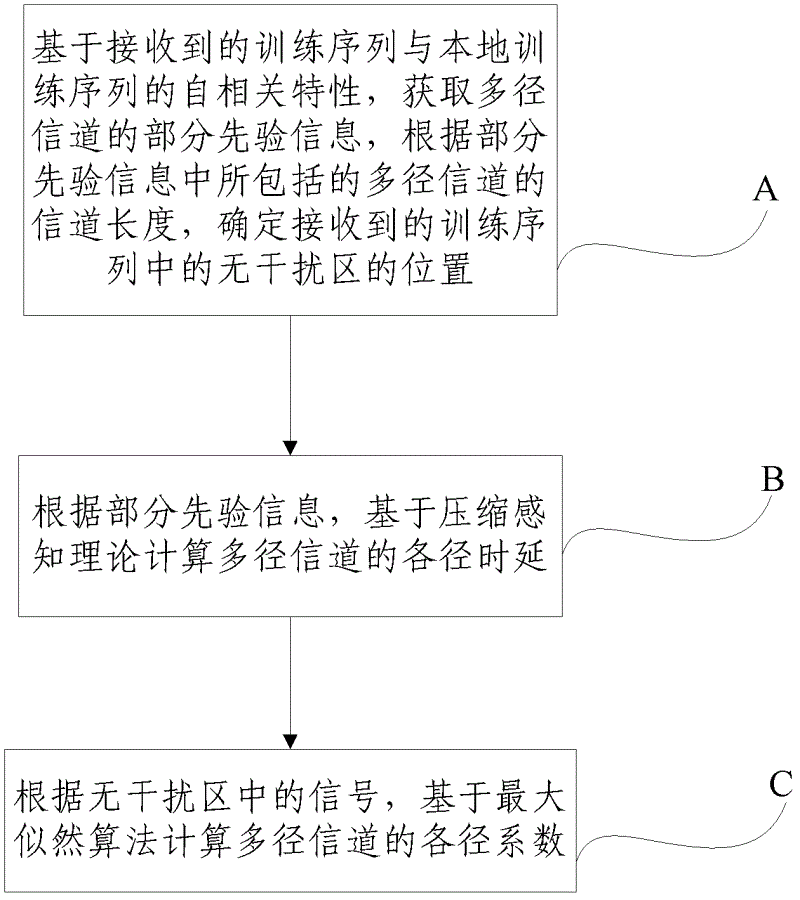

Transmission method of time domain synchronous-orthogonal frequency division multiplexing (TDS-OFDM) based on theory of compressive sensing

InactiveCN102624658ABaseband system detailsMulti-frequency code systemsFrequency spectrumDynamic channel

The invention discloses a transmission method of time domain synchronous-orthogonal frequency division multiplexing (TDS-OFDM) based on a theory of compressive sensing and relates to the field of wireless communication. The method comprises the following steps: on the basis of self-correlation properties of a received training sequence and a local training sequence, obtaining parts of prior information of multi-path channels, and confirming a position of a non-interference area in the received training sequence according to the channel length of the multi-path channels included in parts of the prior information; according to parts of the prior information and on the basis of the theory of compressive sensing, calculating time delay of each path of the multi-path channels; and according to signals in the non-interference area and on the basis of a maximum likelihood algorithm, calculating coefficient of each path of the multi-path channels. According to the transmission method of the TDS-OFDM based on the theory of the compressive sensing, two technical problems that the TDS-OFDM is difficult to support high order modulation of 256 quadrature amplitude modulation (QAM) and the performance deterioration in dynamic channels is obvious are solved, and a strong theoretical and technical support is provided so that digital terrestrial multimedia broadcasting (DTMB) can catch up with and surpass the advanced international levels in key performance indicators of spectral efficiency, high-speed motion and receiving and the like.

Owner:TSINGHUA UNIV +1

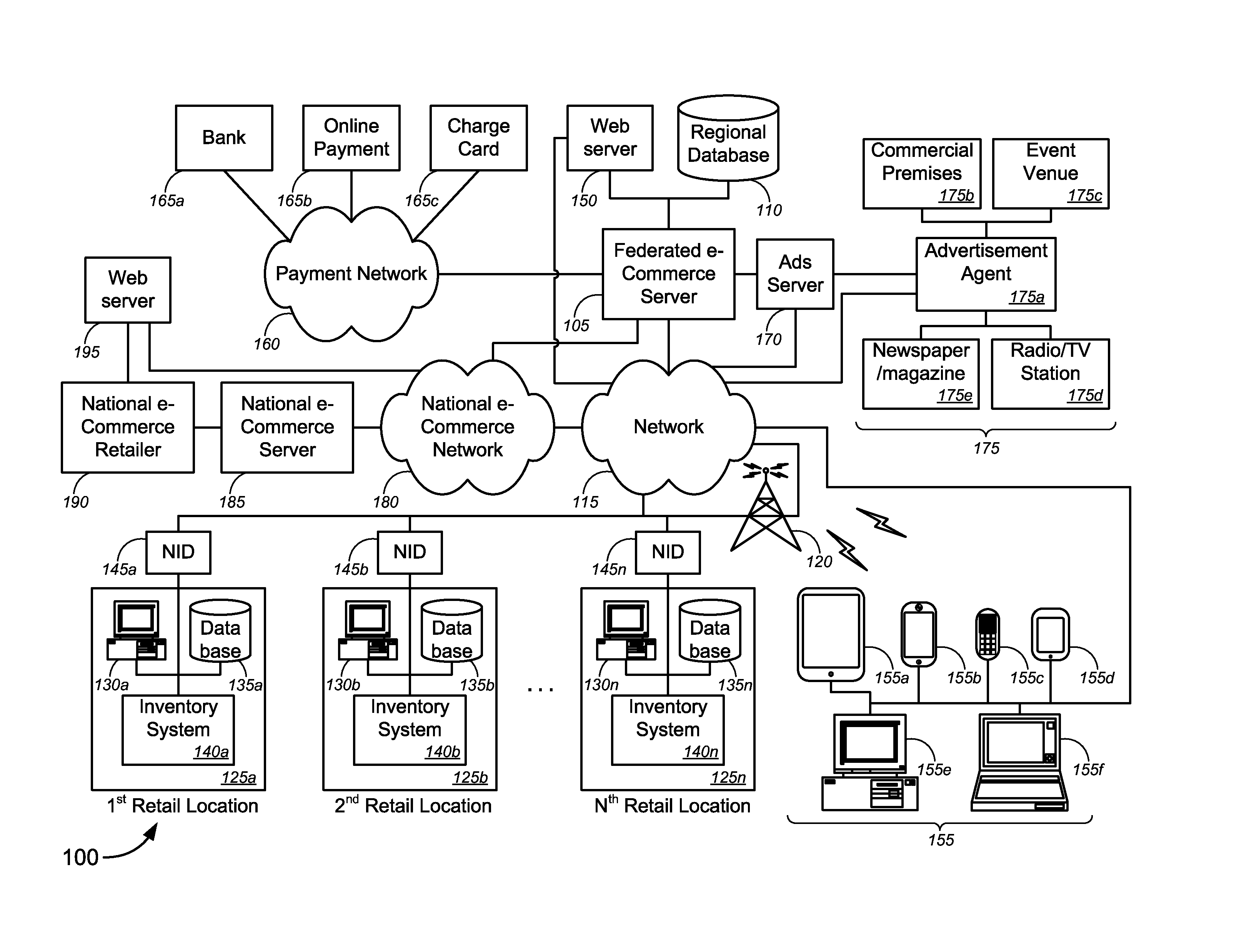

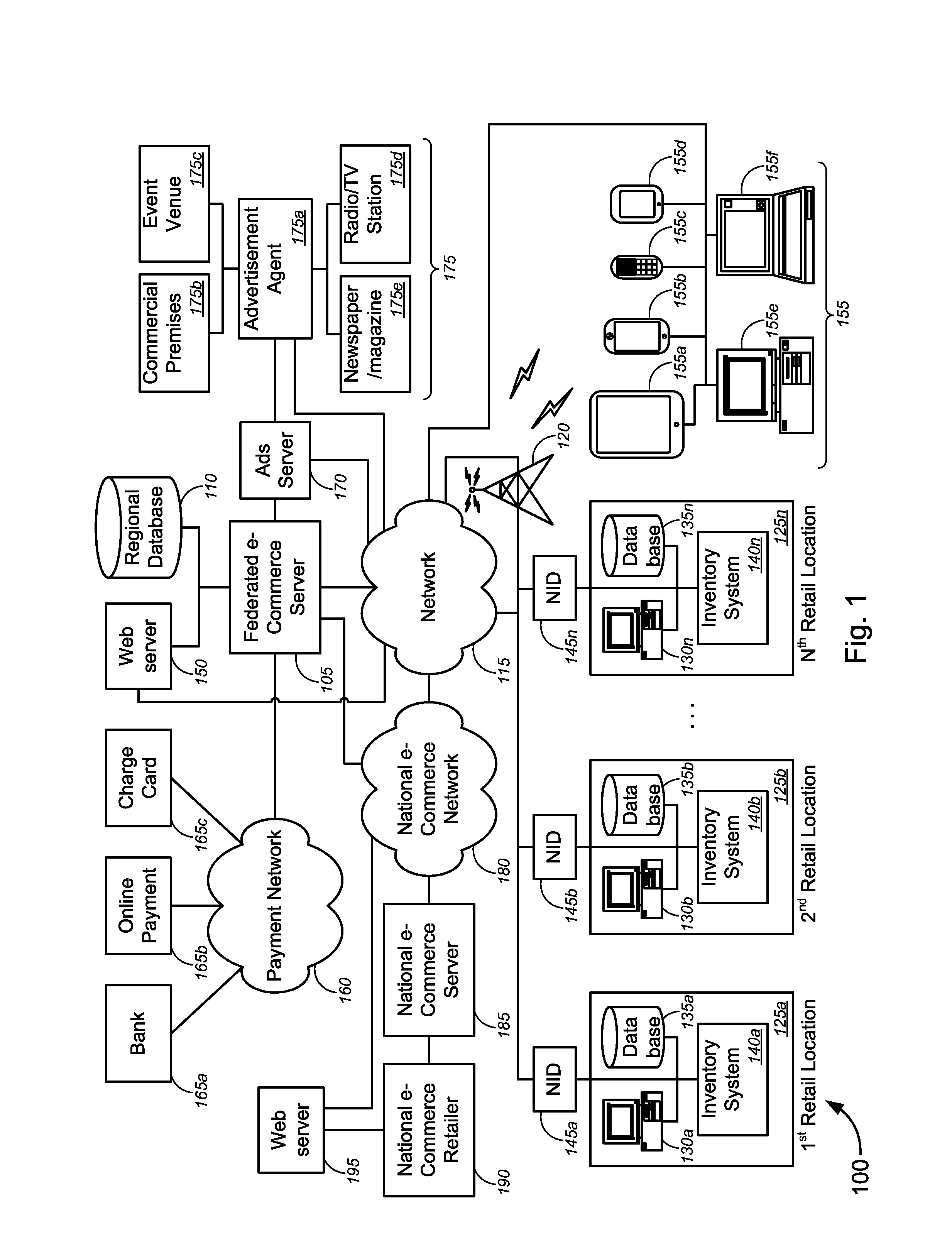

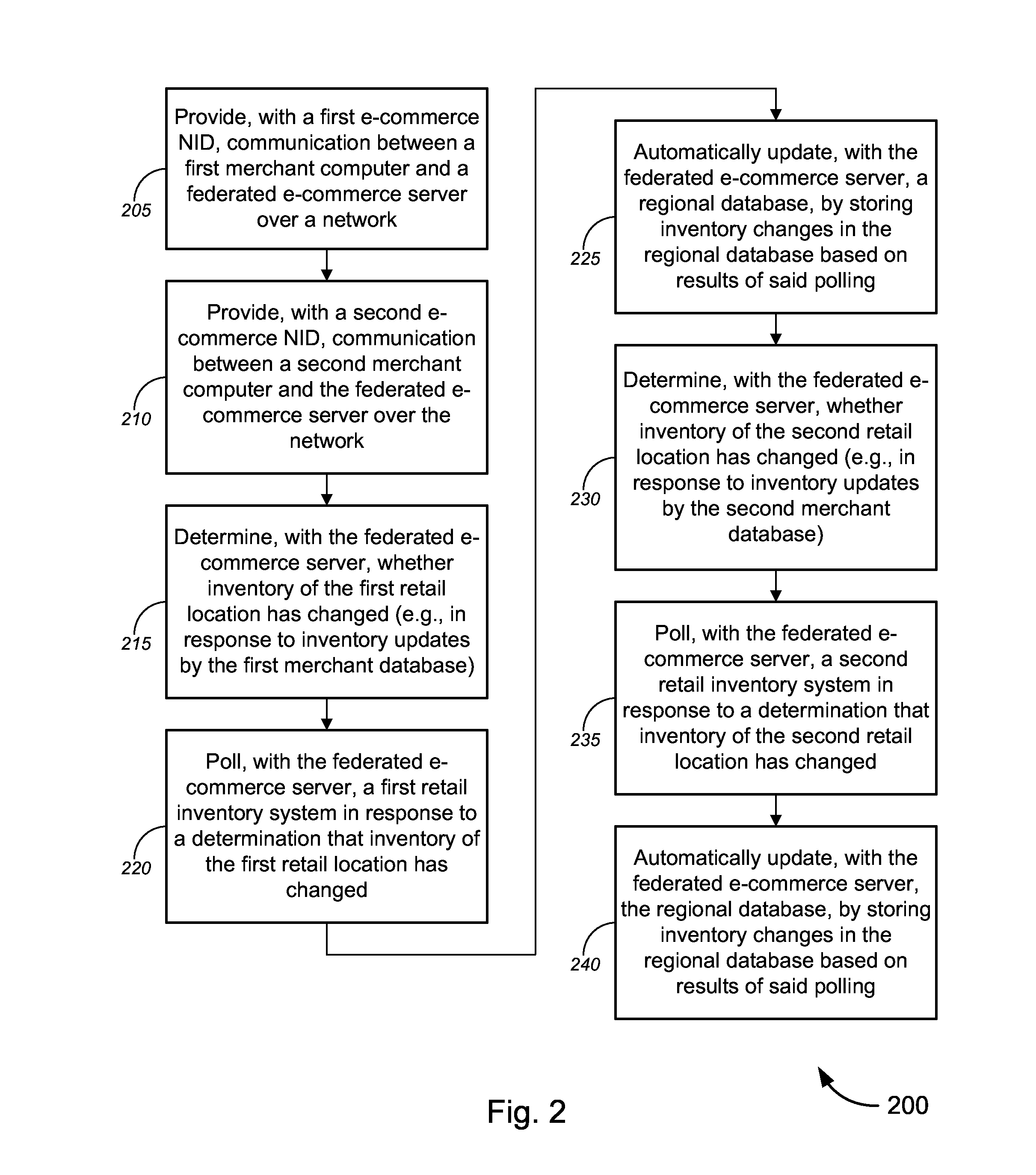

Federated E-Commerce System and Method

Novel tools and techniques are provided for providing and operating a federated e-commerce network. In some embodiments, a standard database is provided for local providers, stores, or retailers to automatically reflect their supply levels and price in order to facilitate providing a national-level or international-level type e-commerce experience for the local providers, stores, or retailers. A website might be established or maintained that provides local retailers with control over sale of items, while allowing customers to search and purchase items listed in a consolidated inventory list compiling inventory information from databases associated with two or more local retailers in the federated e-commerce network. Customers may also be provided with options to create, modify, or delete wish lists, hate lists, and / or gift lists. Ads may automatically be generated based on one or more of viewing or buying patterns, the wish lists, the hate lists, or gift lists associated with each customer.

Owner:CENTURYLINK INTPROP

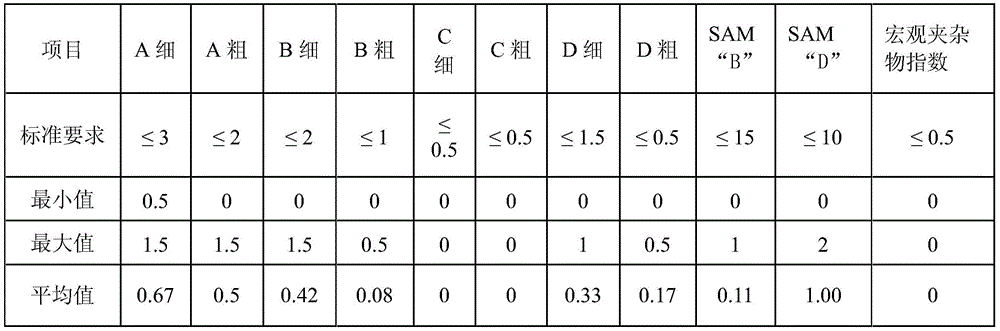

Steel smelting process used for automobile hub bearing

ActiveCN105463150AReduce contentReduce non-metallic inclusion contentManufacturing convertersProcess efficiency improvementSmelting processSlide plate

The invention belongs to the field of metallurgy, and relates to a steel smelting process, in particular to a steel smelting process used for an automobile hub bearing. The steel smelting process comprises the steps that 1, high-quality molten iron and scrap steel are added into a converter, tapping is conducted through a sliding plate, remaining steel operation is adopted, and deoxidizing is conducted on molten steel through different numbers of Al cakes according to the C content at the end; 2, aluminum is used in advance in the refining process, white slag is controlled to be kept for more than 30 min, and maintaining of deoxidization and the liquidity of the slag is reinforced in the whole refining process; 3, enough vacuum deairing time is ensured in the RH process, and the soft blowing time is ensured; and 4, double slag is adopted for covering a continuous casting tundish, so that impurities in the molten steel are adsorbed, and meanwhile secondary oxidation is prevented. According to the steel smelting process used for the automobile hub bearing, the purity of the molten steel is improved to the greatest extent, the oxygen content of a produced bearing steel for a hub reaches 5.2 ppm, the titanium content of the molten steel is 10 ppm, rating of non-metallic impurities reaches the best international level, the fatigue life of the bearing steel for the hub is prolonged, sequence continuous casting of the molten steel is achieved, and the production cost is reduced.

Owner:ZENITH STEEL GROUP CORP

Steel pipe-straightening roller for casting high chromium iron or high chrome steel

A new type casting chromium iron or casting chromium iron tube rectifier roll is used for steel tube straightener, with main element of the direct roll with C: 1.8-2.8%,Si:<=1.0%,Mn:<=1.0%,P:<=0.04%,S:<=0.04%, Cr:12-22%,Ni:0.5-3.0%,Mo:0.8-3.0%,V:0-1.0%,Cu:0-1.0%, the rest with Fe. Rated in weight of the components should be C: 0.7-1.2%,Si:<=1.0%,Mn:<=1.0%,P:<=0.04%,S:<=0.04%; Cr:8.0-12%,Ni:0.5-2.0%,Mo:0.8-3.0%,V:0-1.0%, with the rest being Fe. Due to even inside and outside of the cast iron steel tube roll, it has higher performance in wearing resistance and toughness, with doubled durability. Due to reduced material, it greatly reduces production cost. Its performance surpasses the international level with life span of it over two times of the national made ones.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

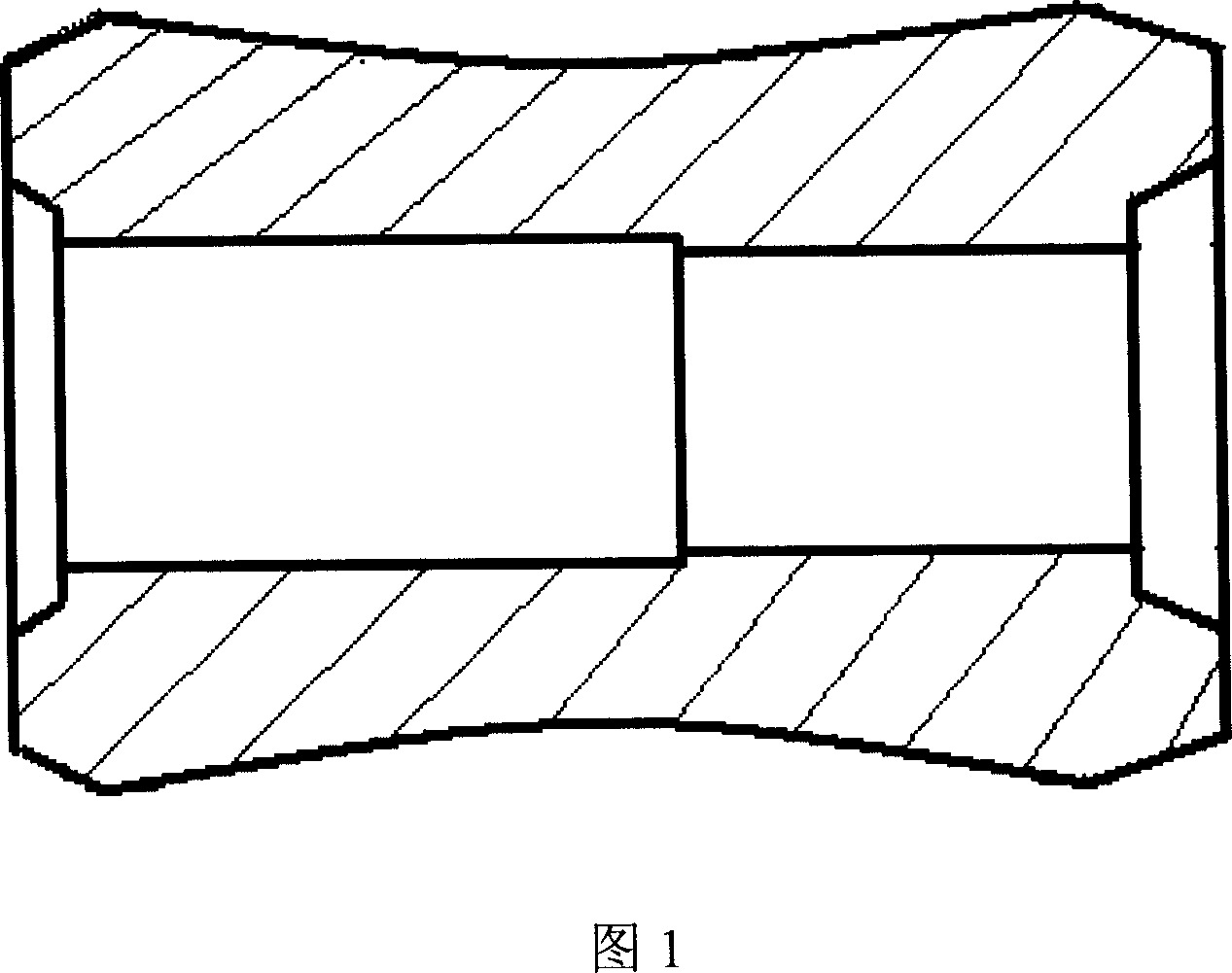

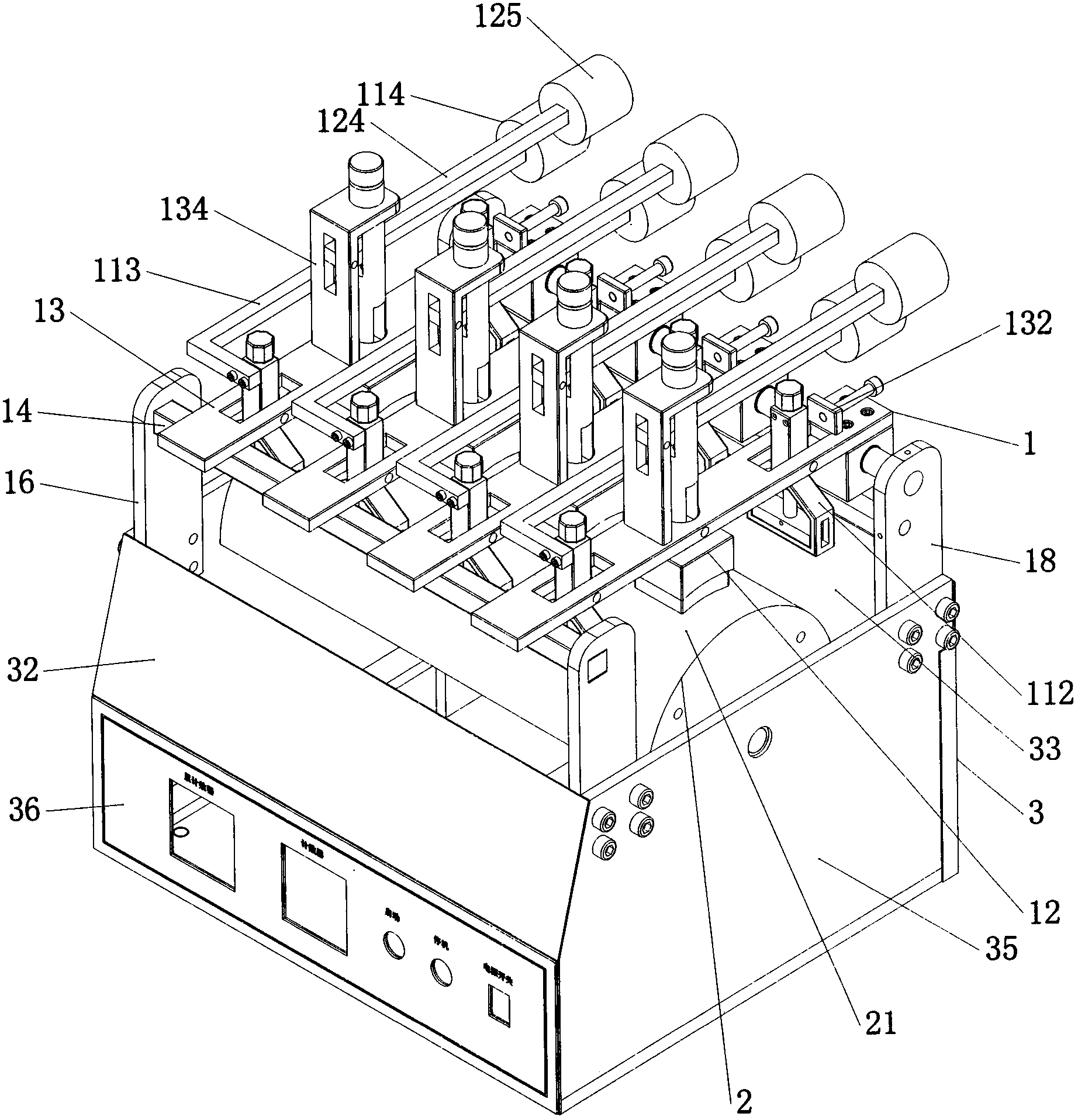

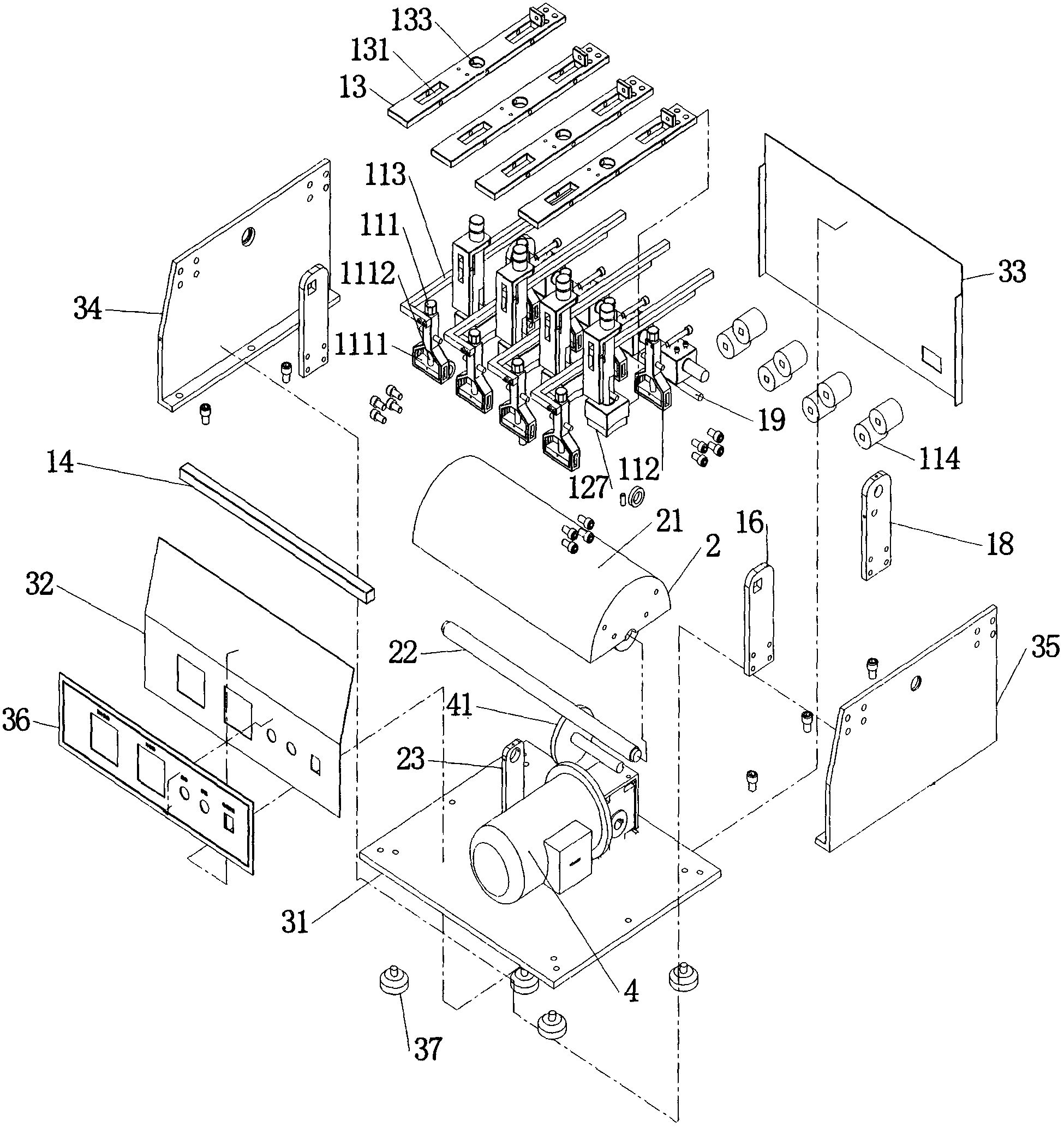

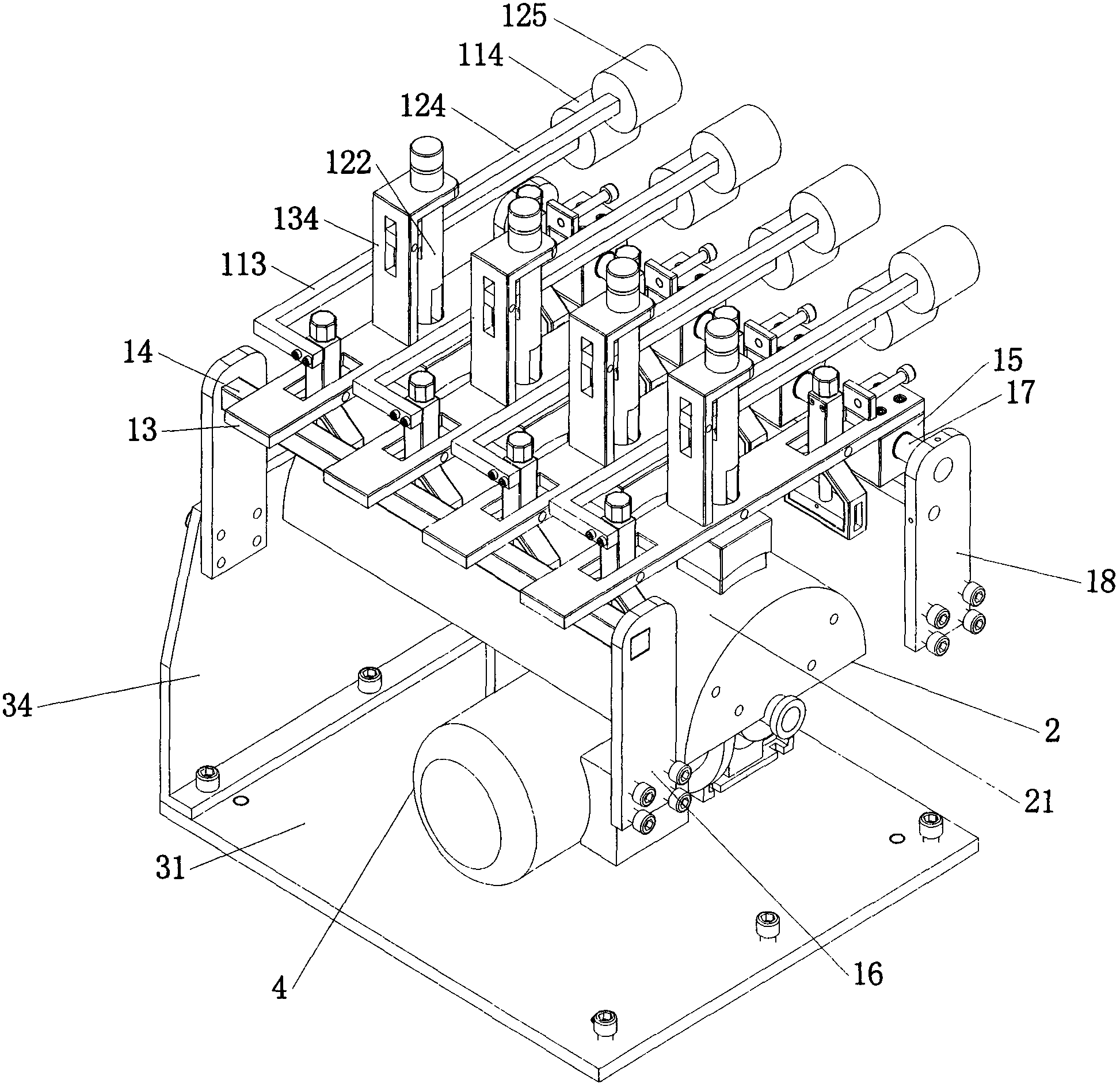

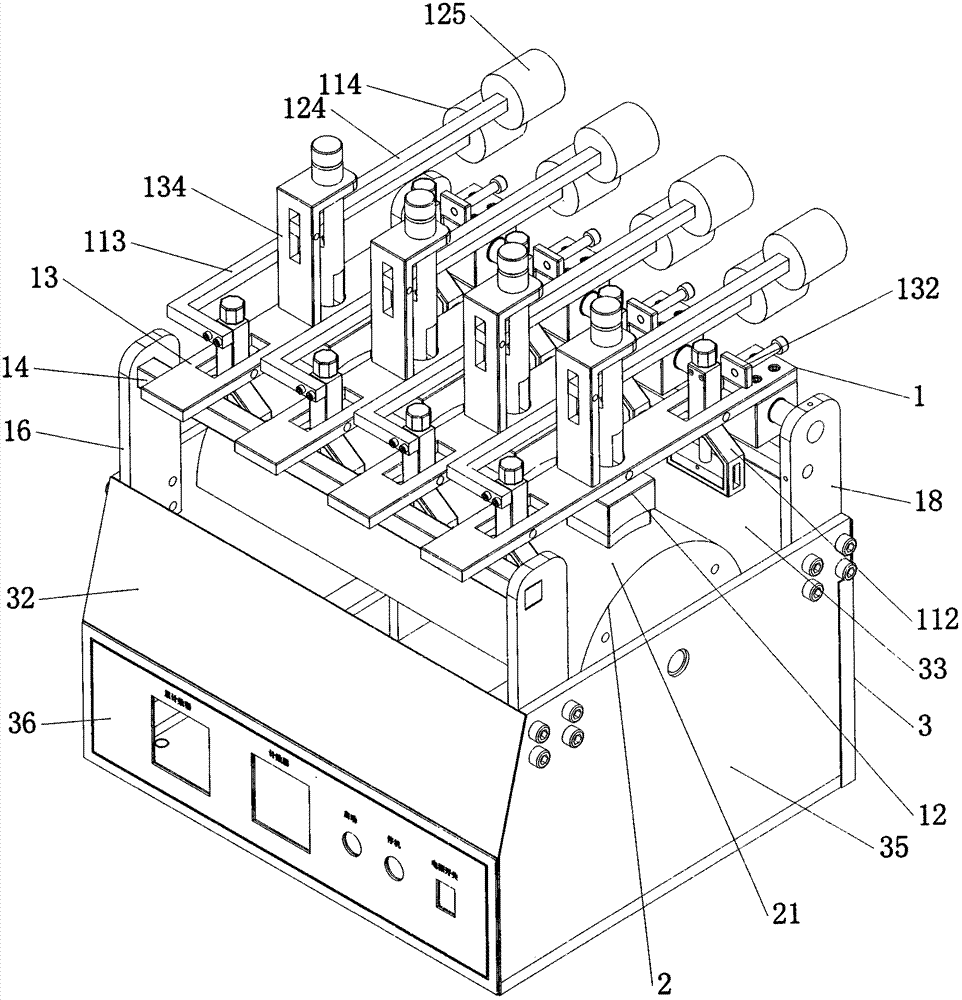

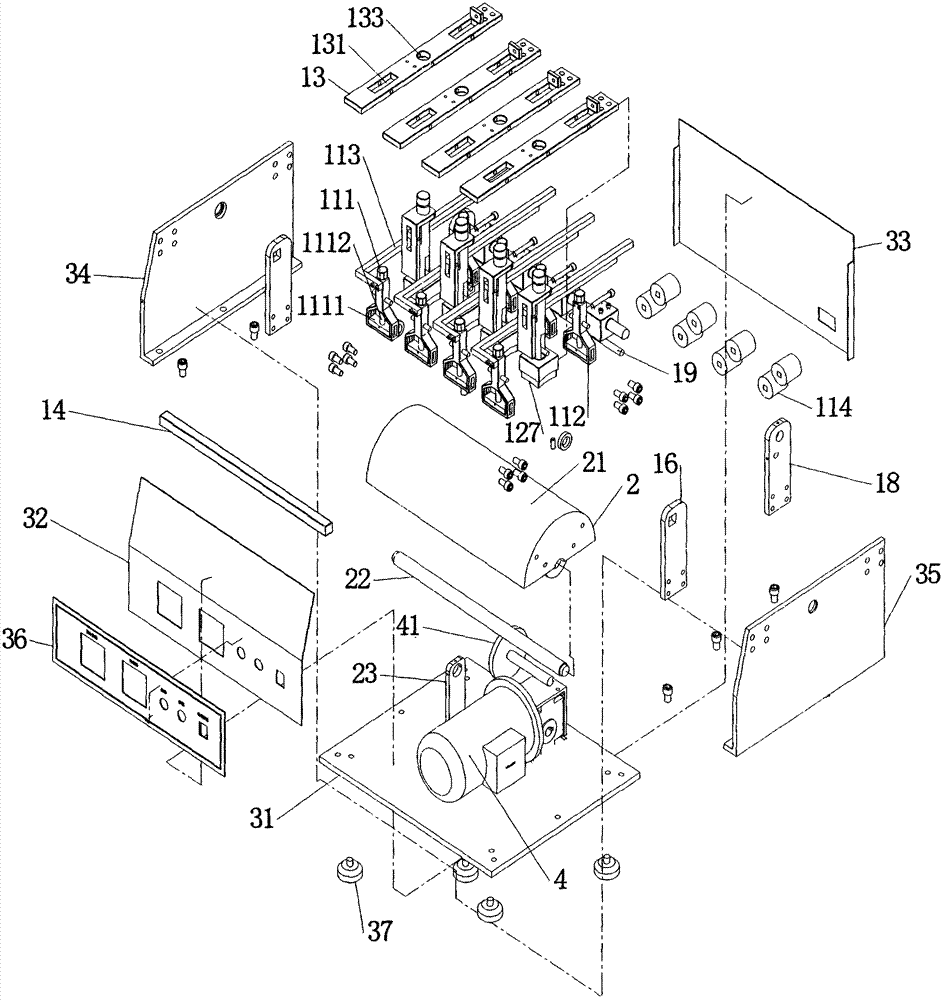

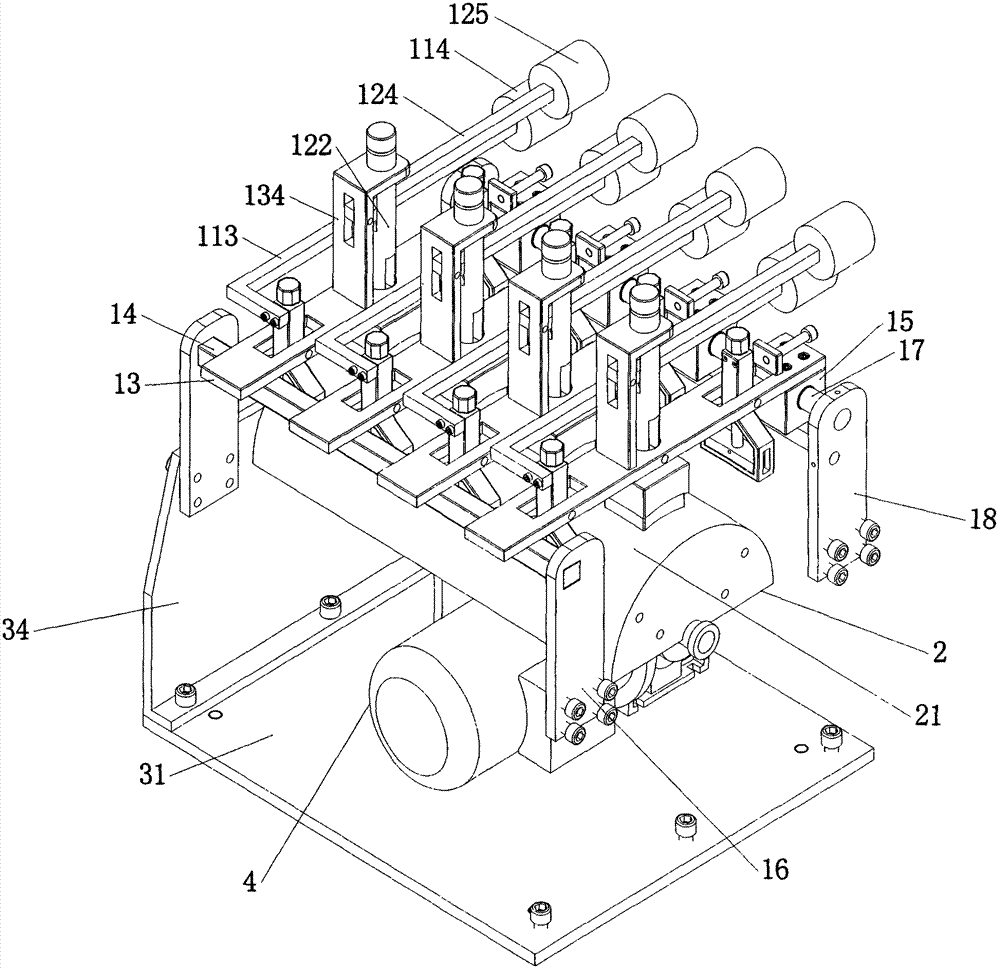

Friction tester

ActiveCN102706764AImprove accuracyImprove efficiencyInvestigating abrasion/wear resistanceBuilding materialInternational level

The invention discloses a friction tester which comprises a sample bearing platform on which the sample can be arranged, a friction platform on which the friction medium can be arranged and a power device. The power device is used for driving the friction platform to do reciprocating motion relative to the sample bearing platform; the sample bearing platform comprises at least one group of clamping components and compressing components; the clamping components are used for fixing the sample; and the compressing components match with each group of clamping components and used for keeping the sample to contact the friction medium. With the structure, the friction tester has the advantages of simple structure, low noise, low pollution, low energy consumption, simple and smooth production process, high technology content and high productivity. All the quality indexes of the product reach the international level of the industry of decorative building materials.

Owner:TST INSTR FUJIAN

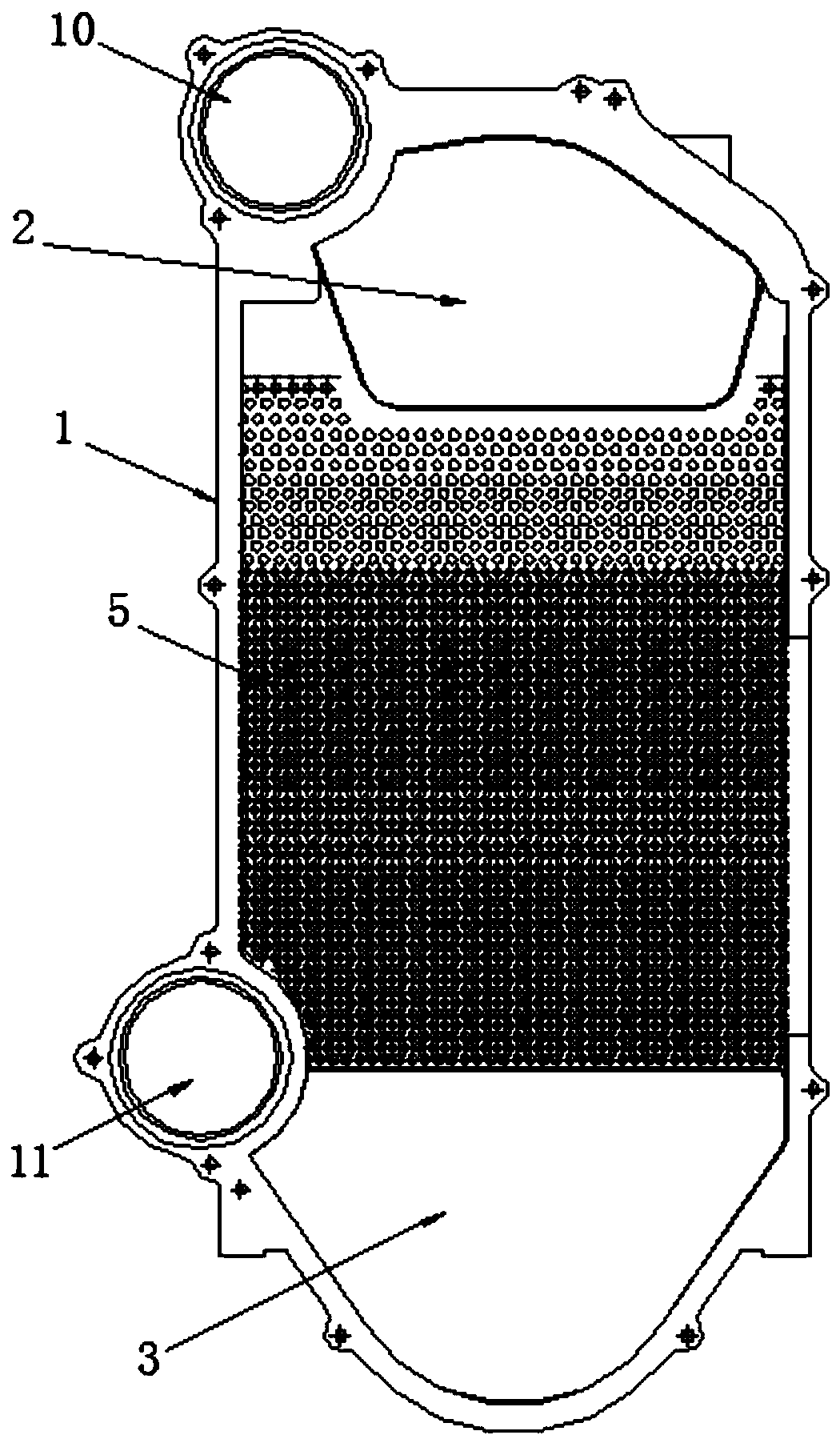

Scale production method for high-content astaxanthin haematococcus pluvialis

InactiveCN106906142AFull flowFull exchange compensationUnicellular algaeMutant preparationGreen cellStress conditions

The invention discloses a scale production method for high-content astaxanthin haematococcus pluvialis. The scale production method includes algae species culture, species bottle culture, closed tubular photobioreactor culture, indoor pond photobioreactor culture and outdoor pond reactor astaxanthin accumulation culture. Algae species rapidly grow and breed under an optimized growth condition in a laboratory and are accumulated to reach a certain cell concentration and then inoculated to a closed tubular photobioreactor by a sterile tube for secondary enlarged culture, the algae species are inoculated to an indoor pond photobioreactor for tertiary growth culture to reach the highest algae cell quantity after haematococcus pluvialis grows to a certain density, cultured haematococcus pluvialis green cells are transferred into the outdoor pond photobioreactor and accumulate a large quantity of astaxanthin under stressed conditions, and the scale production process of the haematococcus pluvialis is finally finished. Compared with the prior art, the scale production method has the advantage that the astaxanthin content exceeds international level reported at present and reaches 7.2% or more.

Owner:烟台布鲁拜尔生物制药有限公司

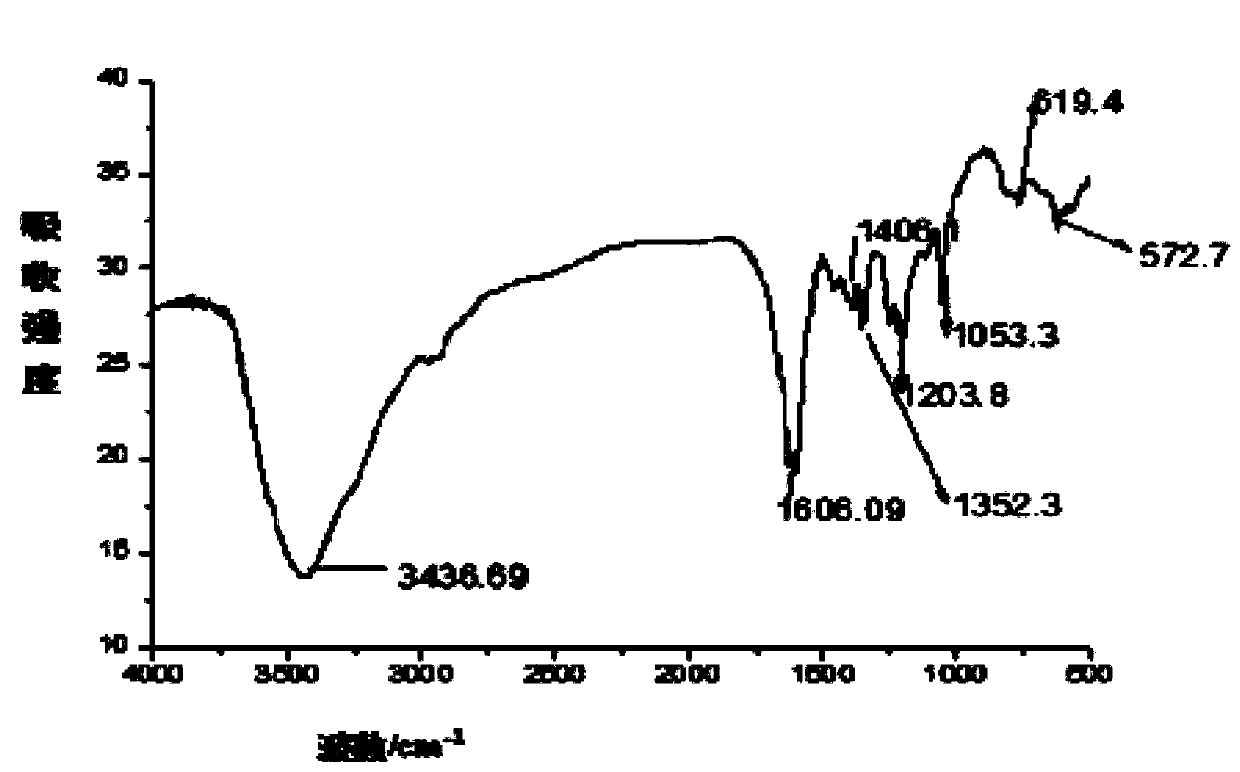

Super absorbent resin with high absorbent velocity and preparation method

Provided are a super absorbent resin with a high absorbent velocity and a preparation method. A polymer and monomer aqueous solution composed of, by weight, 2-10 wt% of PVA, 18-26 wt% of PAAS and 3-9 wt% of AMPS is heated and dissolved. Copolymer gel is synthesized through electron beam radiation crosslinking and grafting. The copolymer gel is then subjected to swelling and immersion cleaning by an immersion cleaning liquid, and then subjected to extraction freezing and freeze-drying to obtain a super absorbent resin. The pH value, normal saline absorbent amount and centrifugal preservation amount of the super absorbent resin have reached international level, and the super absorbent resin is remarkably superior to famous super absorbent resin products (P is less than 0.01) at home and abroad especially in the absorbent amount and the absorbent velocity of triple-distilled water and is in international advanced level. The super absorbent resin has advantages of simple technology, good biocompatibility and safe usage. The super absorbent resin can be widely used in a plurality of fields of medical and health supplies such as uracratia mattresses, infant diapers, woman sanitary napkins and the like, water retention and moisture preservation of agriculture and forestry and the like. The super absorbent resin has great application and development values.

Owner:SUZHOU UNIV

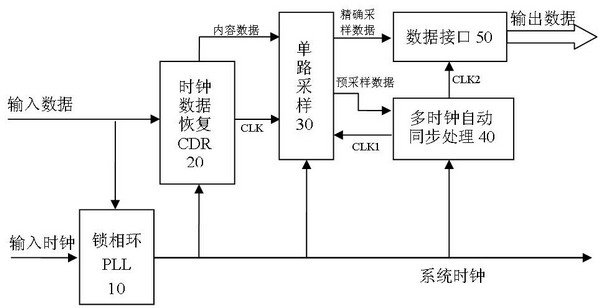

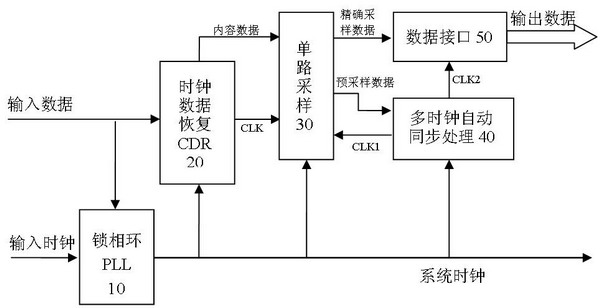

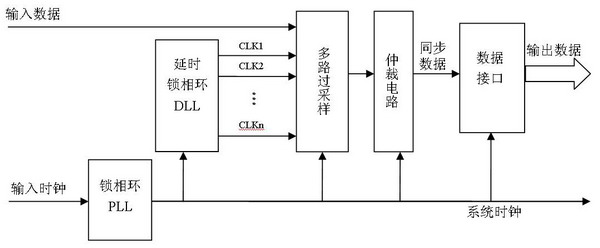

Framework of high speed and low power consumption serial communication data receiving interface

InactiveCN101950278AImprove efficiencyLower layout (FloorPlan)Energy efficient ICTEnergy efficient computingSignal onOversampling

The invention relates to a framework of a high speed and low power consumption serial communication data receiving interface, which discards the arrangement of a multi-channel oversampling and arbitration circuit. Through utilizing the technology of combining single-channel sampling asynchronization and multiple-clock automatic synchronization, an original clock frequency signal CLK is extracted from input data, and content data are pre-sampled; and after the pre-sampling data and a system clock are synchronized, a clock CLK1 is fed back and adjusted to a single-channel sampling module so that a result of precisely sampling the content data is completely synchronous to a target clock CLK2, thereby realizing the combination of clock domain asynchronization and synchronization and improving the efficiency. Under the condition of the similar realization area of an ASIC (Application Specific Integrated Circuit), the power consumption of realizing a physical layer (PHY) is reduced by more than 70% and exceeds the international level achieved by the traditional realization framework, thereby reducing the interference of a high speed signal on other circuits inside an ASIC chip, lowering the requirements for the layout and the wiring of a module inside the chip, reducing the energy consumption and also lowering the production cost.

Owner:昆山芯视讯电子科技有限公司

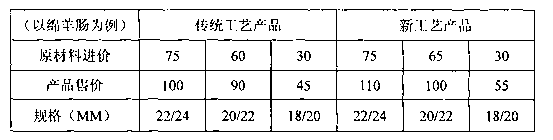

Production process of milky-white casing

InactiveCN103262880AQuality is not affectedImprove qualitySausage casingsReduction treatmentRoom temperature

The invention belongs to the field of a production method of a casing and particularly relates to a production process of a milky-white casing. The invention aims to provide the production process of the milky-white casing so as to enable the quality of casing products of China to be greatly improved and reach an international level and the economic value of exported casing products to be improved. In order to realize the technical scheme, the production process comprises the specific steps of: 1, washing a semi-finished product casing by clean water; 2, treating the semi-finished product casing at a room temperature by using an oxidization solution; 3, putting the casing subjected to oxidization treatment into a reducing solution and fishing out when the color of the casting is consistent; washing the casing to be neutral by using the clean water; and 4, putting the casing subjected to reduction treatment into the oxidization solution again to be treated and slightly agitating for 15min; and then taking out the casing and washing the casing to be neutral by using the water to obtain a finished product. The production process disclosed by the invention has the advantages that the casing produced by adopting the production method is milky white, pure in glossiness, glossy and transparent, smooth in hand feeling, fresh in smell, good in elasticity and great in tension; the utilization rate of raw materials is greatly improved; and the economic values are greatly improved on the aspect of export for earning foreign exchange.

Owner:如皋市天源肠衣有限公司

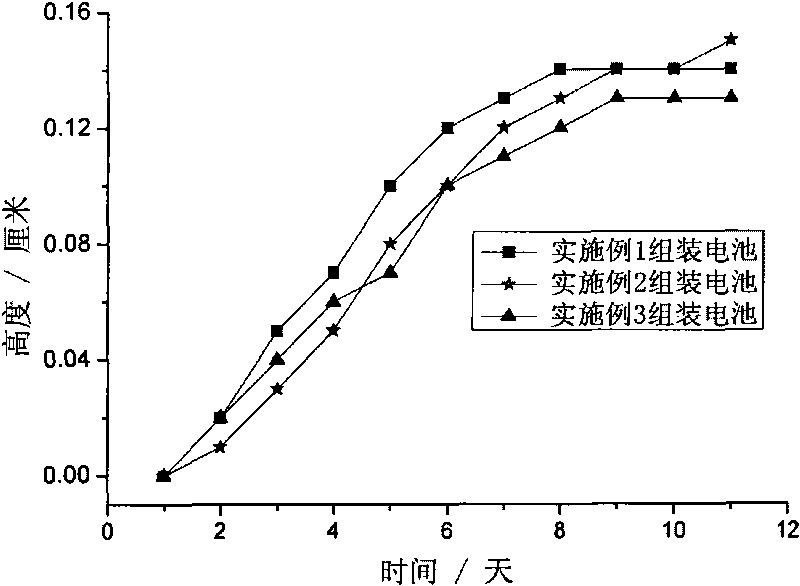

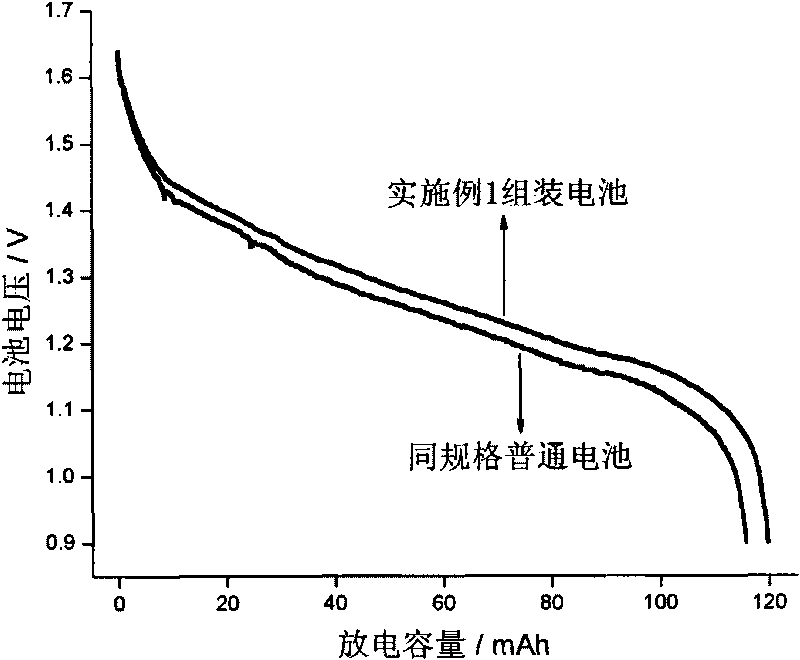

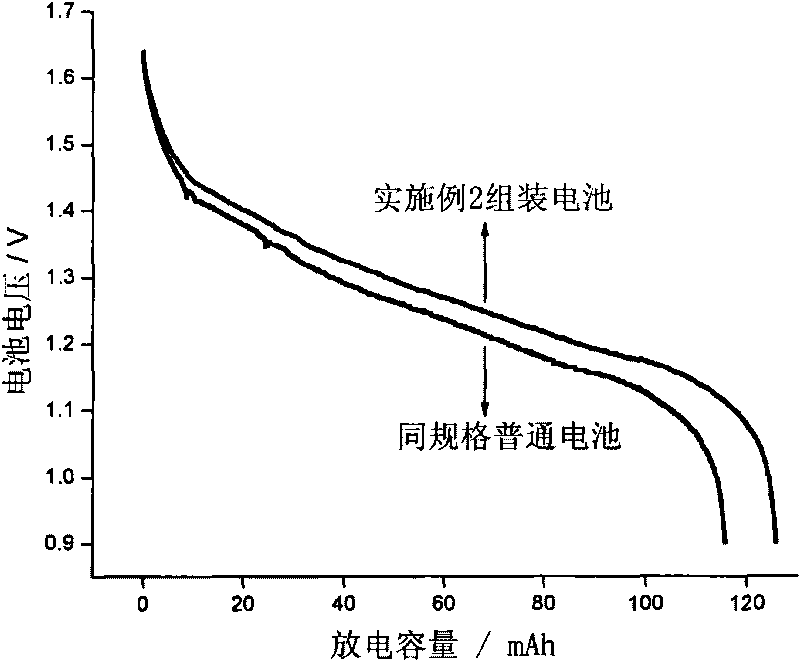

Alkaline zinc cell complex additive, preparation method thereof and application thereof

InactiveCN101702430APromote environmental protectionReduce manufacturing costPrimary cell electrodesCell component detailsCapacitanceIndium

The invention provides an alkaline zinc cell complex additive, a preparation method thereof and application thereof. The method comprises the step of mixing polyethylene glycol with iminazole to obtain a complex additive for preparing negative electrode liquid and negative electrode zinc cream of the alkaline zinc cell, wherein the negative electrode cover or the current collector of the alkaline zinc cell does not need electroplating or to be replaced with noble metal such as plated indium, and the like; zinc powder does not need to add heavy metal or harmful metal such as mercury, indium, lead and cadmium, and the like; the zinc cream does not need to add rare noble metal compound such as indium oxide, indium hydroxide, lean compound, mercury and compound thereof, and the like, and materials which pollute the environment; the negative electrode liquid does not need to add organic additive with high price; the obtained cell can completely meet the requirement of cell international level in the field of air expansion; and the discharging capacitance is improved at less extent, compared with a common cell. Therefore, the alkaline zinc cell made from the alkaline zinc cell complex additive is environmentally friendly, and has low cost and large market potential.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Cultivation method for mulberry chromosome doubling

InactiveCN105993933AHigh rate of polyploid inductionGraftingPlant genotype modificationShootShoot apex

A cultivation method for mulberry chromosome doubling includes the following steps that firstly, stem tips of grafting seedlings of a target parent in the current year are subjected to continuous five-day instilling treatment by means of colchicines with the concentration gradient from 0.4% to 0.1%, wherein the grafting seedlings are 20-30 cm high; secondly, during treatment, kraft bags or envelopes are adopted for moisture retention and shading; thirdly, shoots germinating below treated portions are cleaned in time after treatment; fourthly, in the next year, abnormal leaves and branches are subjected to single-bud separation and grafting. The method has the advantage of being high in polyploidy induction rate. Experiments prove that the polyploidy induction rate can reach 32-56% by grafting individuals through the cultivation method for mulberry chromosome doubling, and the average polyploidy induction rate reaches 47% and is much higher than the domestic and international level.

Owner:NORTHWEST A & F UNIV

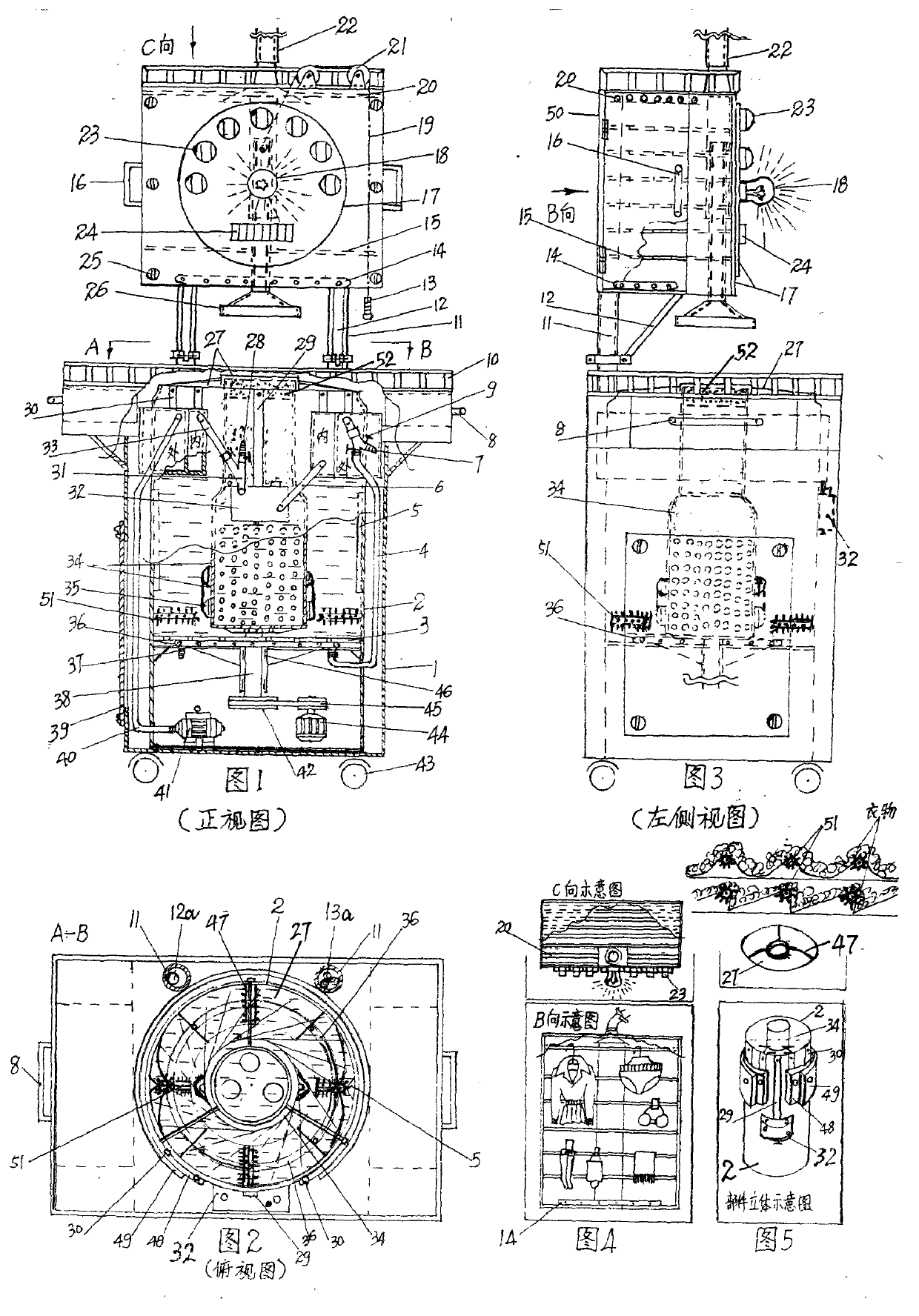

High control sleeve barrel serial washing rotating squirt rubbing imitation fireless hot wind double-drying washing machine

The invention relates to the field of washing machines of household appliances in the light industry. China has brought in an impeller type washing machine and a roller type washing machine from Japan and Germany since more than thirty years ago. But the impeller type washing machine and the roller type washing machine still have some defects and are far away from the target of ideal laundry of consumers. The creativity of a high control sleeve barrel serial washing rotating squirt rubbing imitation fireless hot wind double-drying washing machine is to try to make an ideal washing machine which is coveted and desirable for millions of households for a long time. Therefore, the inventor utilizes a unique design tip which is distinctive, advanced in consciousness, and free from impeller and roller factors. For instance, a switchboard is controlled in a high-post mode, boiling is imitated through fireless heating, space is used skillfully to achieve double baking, double drying is achieved though fireless hot wind, sterilization capacity is better than that of solar energy, an inner sleeve barrel and an outer sleeve barrel are utilized to achieve serial washing, a rotating squirt penetrates to wash a deep layer, a four-pronged approach is achieved, three-dimensional static and dynamic washing is carried out, and all-directions washing and rinsing are most clean and effort-saving. Through the eight laundry revolution unique skills, the cleaning rate can reach 100%, the wear rate (the clothes damage rate) can nearly reach zero, the vibration noise decibel reaches the lowest frequency, and water and electric energy can be efficiently saved by about 30%. Washing indicators are enabled to catch up with the international level through efforts. The machine is luxury and magnificent in appearance, and comprehensive and innovative in structure and function.

Owner:周耀培

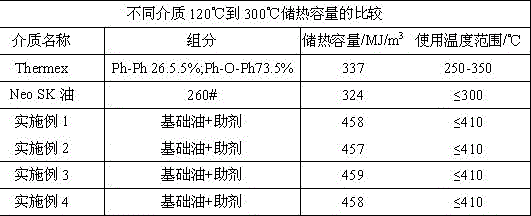

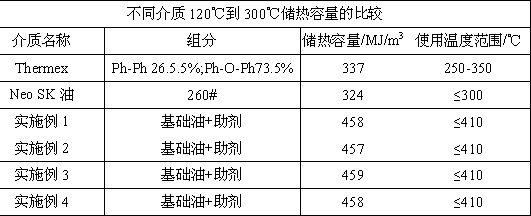

Preparation method of environmentally-friendly and durable totally-synthesized thermal conduction liquid

ActiveCN106010462AImprove thermal stabilityFast heat conductionHeat-exchange elementsBase oilThermal stability

The invention belongs to the field of chemical engineering, and relates to a preparation method of an environmentally-friendly and durable totally-synthesized thermal conduction liquid. The method comprises a step of base oil synthesis and a step of base oil and assistant mixing, and the base oil is (3-alkyl-1-methyl-imidazolium)hexafluorophosphate. The thermal conduction liquid synthesized through the method has the characteristics of good thermal stability, good thermal conductivity, and realization of recycling. The quality of the above product is in a leading international level, and the product can provide a high-quality green and environmentally-friendly long-life thermal conduction liquid for production of domestic thermal conduction oil, and greatly promotes the thermal conduction industry to develop toward the environment compatibility and renewability.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

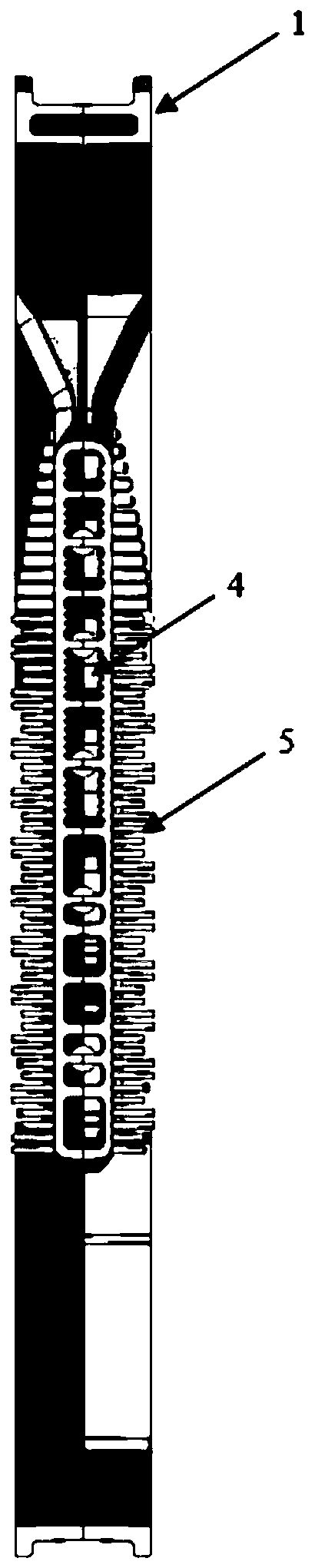

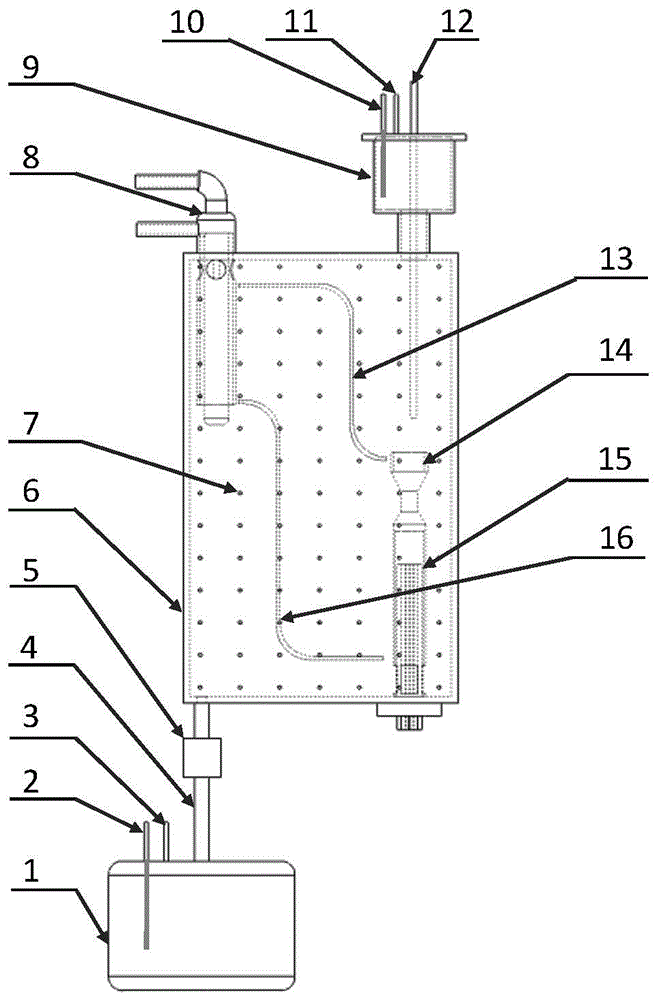

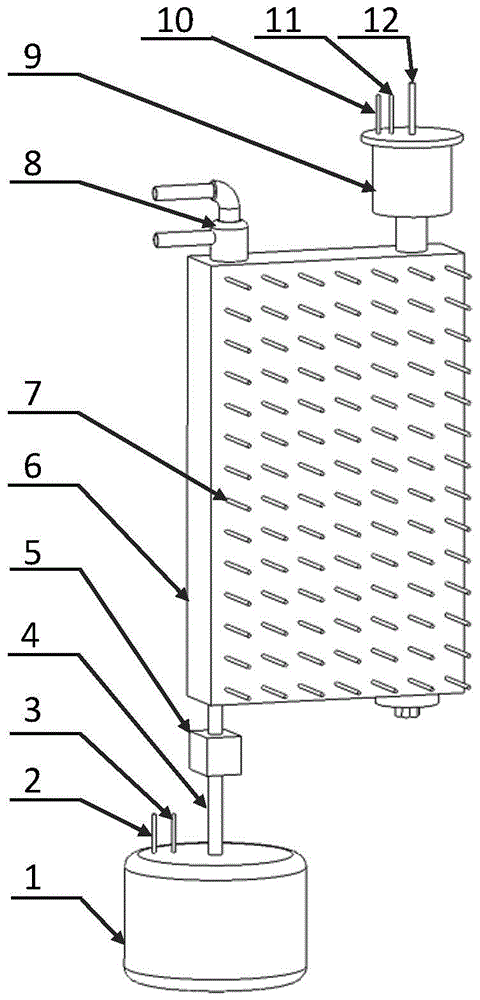

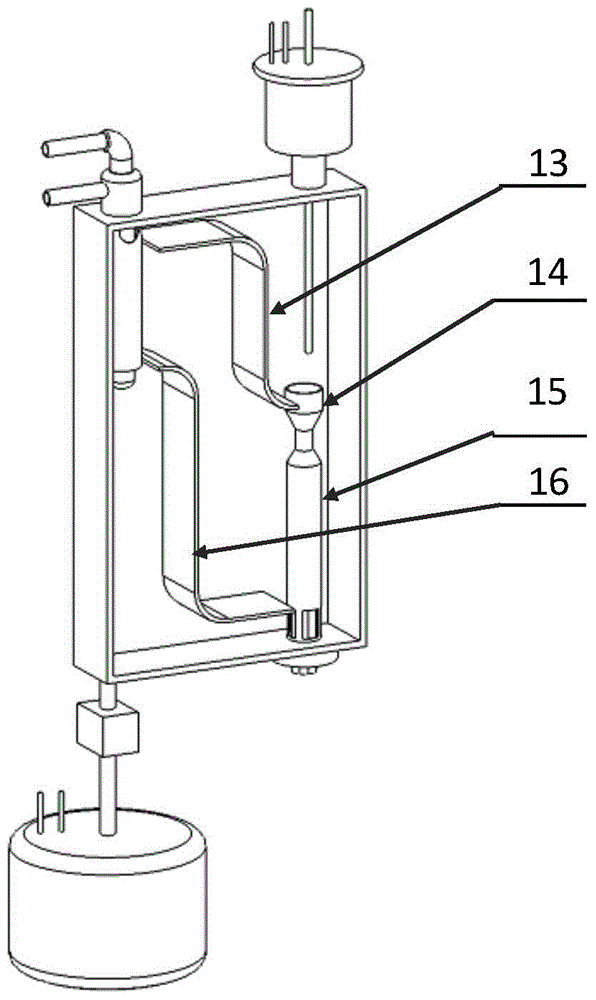

Sliced natural circulation device for heavy liquid metal

ActiveCN104200853AFull flow fieldOverall temperatureNuclear energy generationNuclear monitoringTechnology researchEngineering

The invention discloses a sliced natural circulation device for heavy liquid metal. A device body adopts the rectangular sliced structural design and mainly comprises a rectangular loop main body, a heat exchanger, a heating assembly, a flowmeter and an inserting thermocouple. At the international level, the research on a natural circulation experiment of the heavy liquid metal is mainly performed in an experiment platform formed by round tubes; the device disclosed by the invention adopts the rectangular sliced square box design and a reactor core body structure of a reactor is simplified, so that complex flow filed information which are more abundant than a round tube type natural circulation loop and similar to operating conditions of a real reactor is acquired while the development cost of an experimental verification platform is reduced; qualitative simulation and confirmatory research for a heavy liquid metal flow field inside the reactor can be realized; the device can be applied to the field of technology research and development and basic scientific research of the nuke industry as well as verification of analysis software and simulation software of a thermal hydraulic system, and has important research and engineering values.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Water-repellent, oil-repellent, wash and wear clothing lining finishing production technology for purified cotton woven fabric

The invention relates to a production technology for managing the pure cotton woven fabric to the clothes lining with water resisting, oil resisting, and wash-and-use effect, which is mainly used to produce pure cotton clothes lining. The technology applies delay baking process, at the same time, screens the catalyst matching crosslinking agent, and applies the softening agent which can increase tearing strength in the working solution; thereby, the product maintains high strength of fabric, and achieves the wash-and-use effect and durable water resistance and oil resistance; and the product has reached the advanced international level.

Owner:上海王港华纶印染有限公司

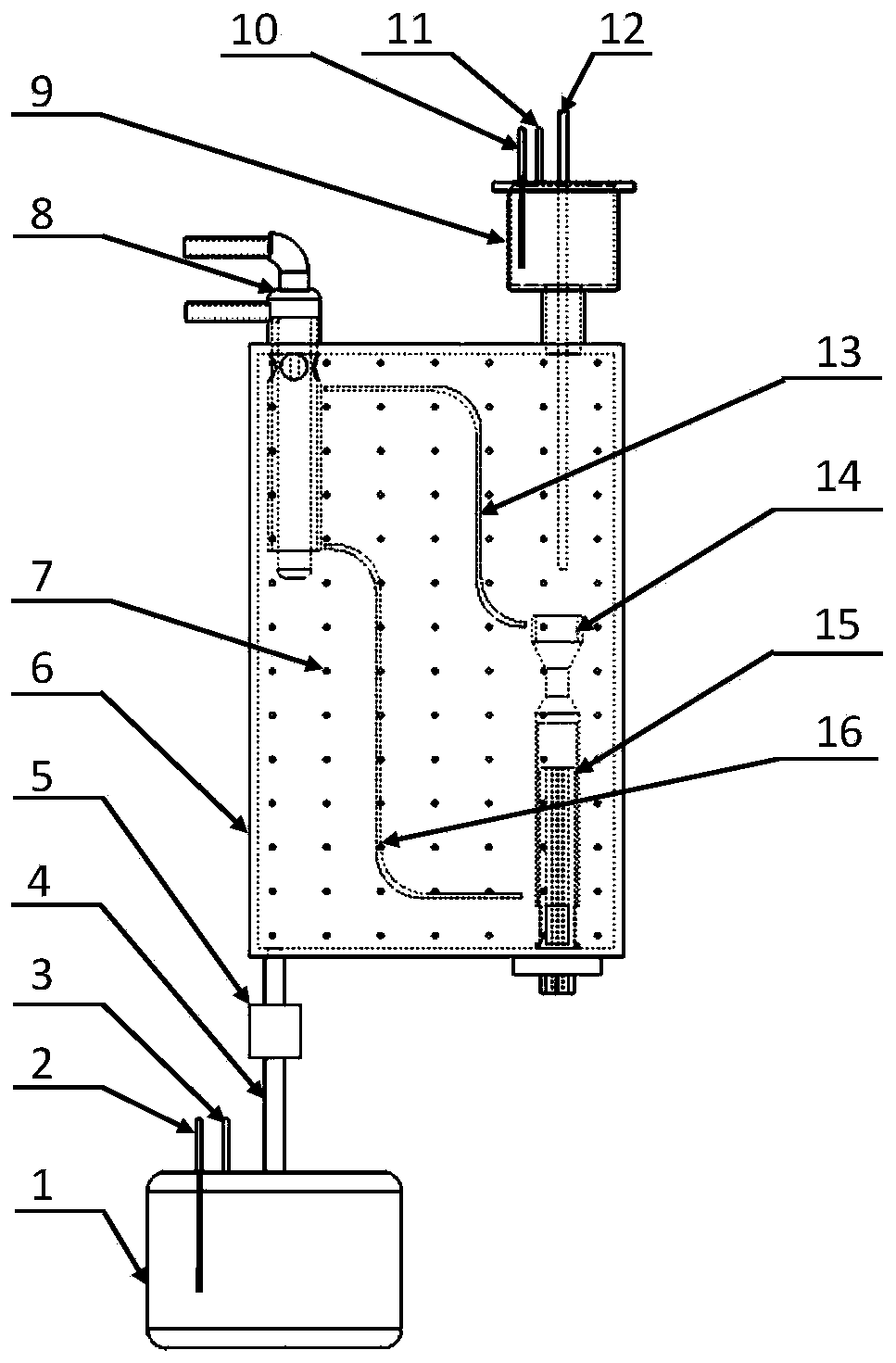

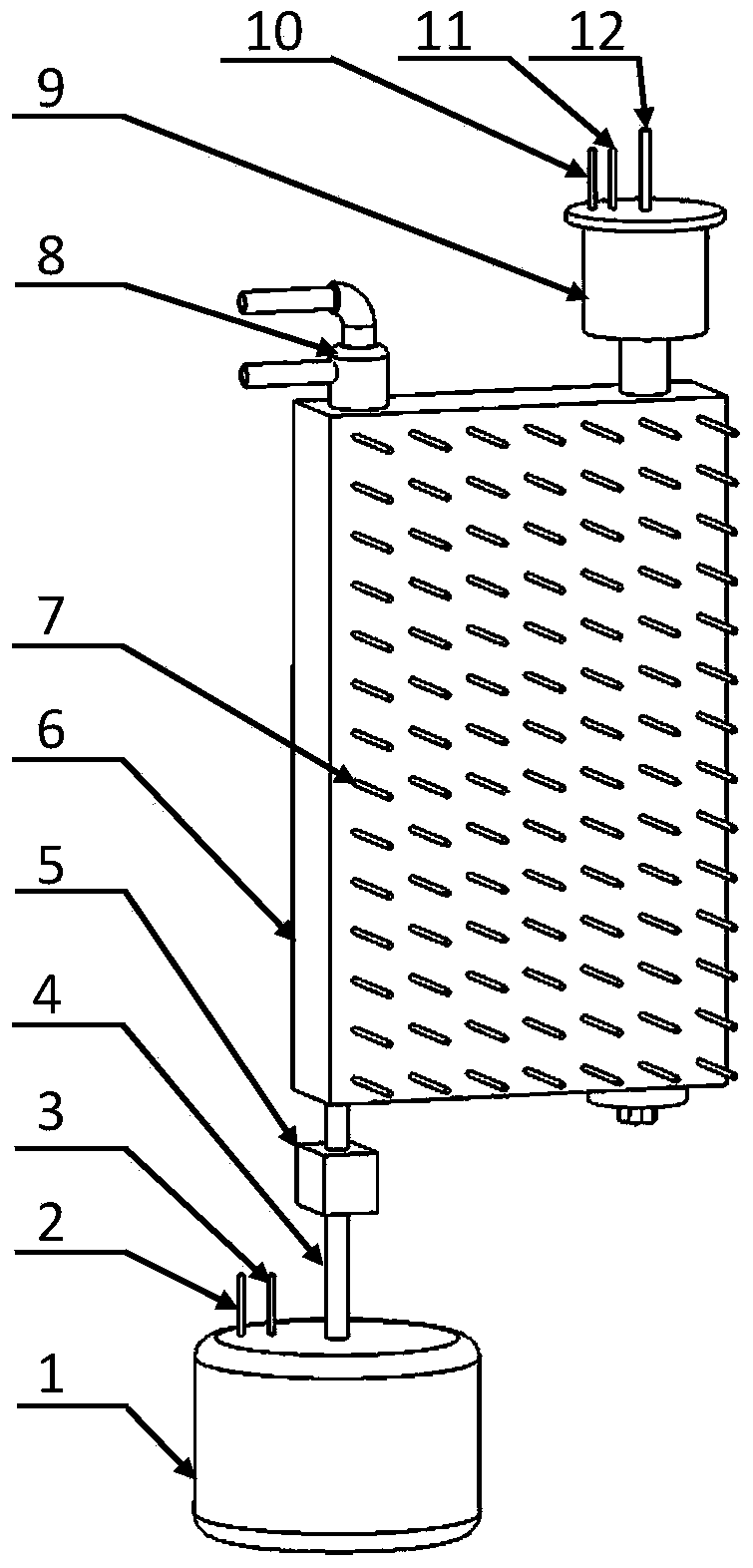

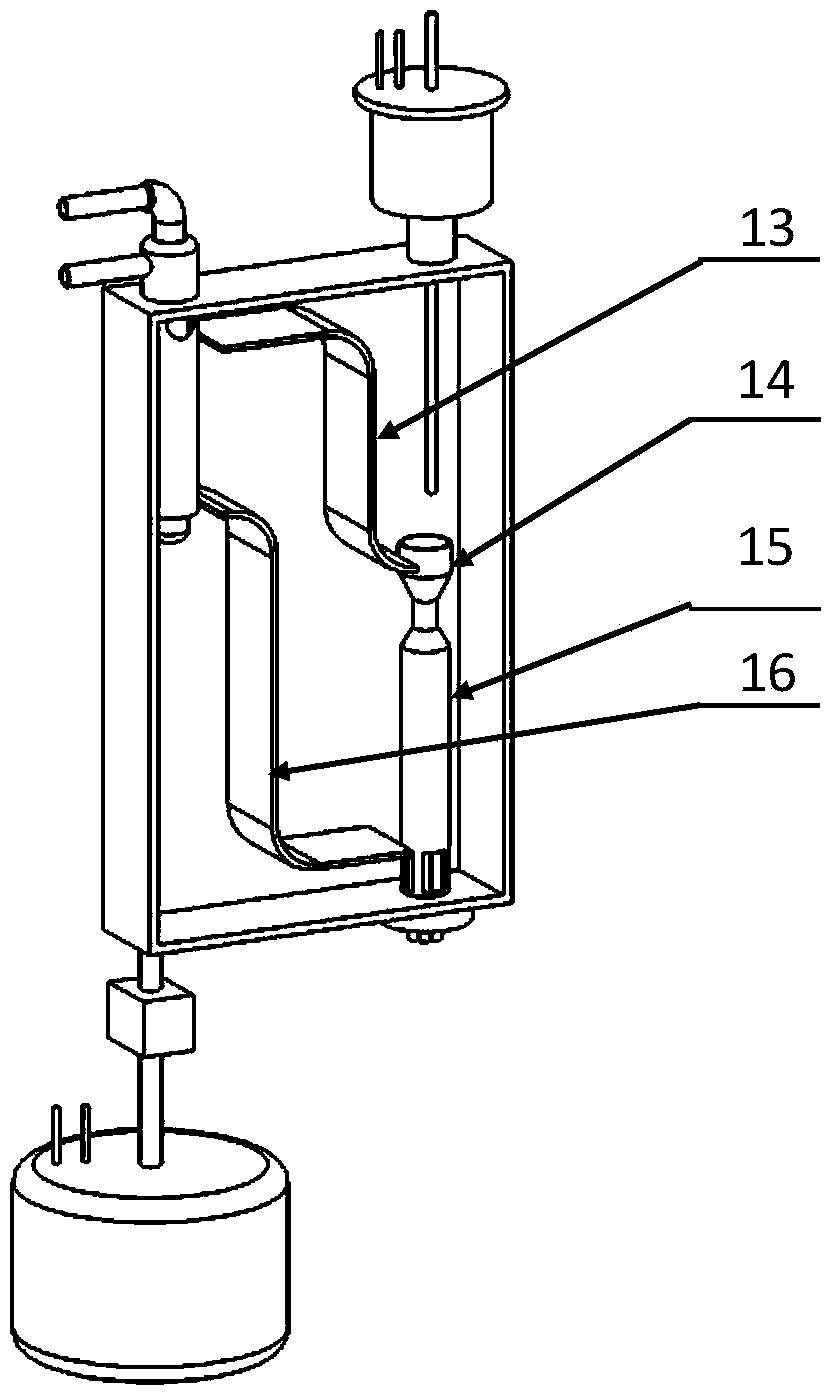

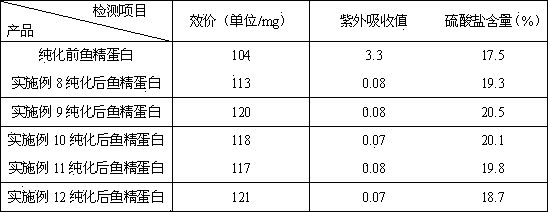

Purification technology of protamine

ActiveCN103509098ARealize online continuous monitoringImprove collection efficiencyPeptide preparation methodsAnimals/human peptidesSilica gelProtein purification

The invention relates to the pharmaceutical field, particularly relates to the field of protein purification, more particularly relates to a purification technology of protamine, and aims to solve the problem of low purity of the protamine in the prior art. According to the purification technology of the protamine, by a reverse silica gel filler chromatography separation mode and ratio control of water phase and an organic phase in an eluant, non-functional impurity proteins in the protamine can be removed by one-step chromatography, the product quality is improved, reaches an international level, and meets relevant provisions of United States pharmacopeia (USP) and British pharmacopoeia (BP), and the product safety is improved.

Owner:XUZHOU WANBANG JINQIAO PHARMA +1

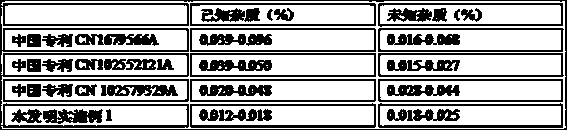

Milrinone compound and pharmaceutical composition containing milrinone compound

ActiveCN104173343AAvoid adsorptionGuaranteed sterilization effectOrganic active ingredientsPharmaceutical delivery mechanismMilrinonePh regulation

The invention discloses a milrinone compound and a pharmaceutical composition containing the milrinone compound. According to the invention, lactic acid is adopted for helping solubilization and regulating the pH value, so that hyperchloremia which is possibly caused by extremely high Cl- concentration brought by pH regulation by adopting hydrochloric acid is avoided. In addition, the milrinone compound and the pharmaceutical composition are reasonable in prescription, high in quality standard, low in impurity content and high in bioavailability, has unique advantages in safety, effectiveness and quality stability, and also has an international level and more outstanding advantages.

Owner:朗天药业(湖北)有限公司

A kind of preparation method of environment-friendly and durable fully synthetic heat transfer fluid

ActiveCN106010462BImprove thermal stabilityFast heat conductionHeat-exchange elementsHeat conductingThermal stability

The invention belongs to the field of chemical engineering, and relates to a preparation method of an environmentally-friendly and durable totally-synthesized thermal conduction liquid. The method comprises a step of base oil synthesis and a step of base oil and assistant mixing, and the base oil is (3-alkyl-1-methyl-imidazolium)hexafluorophosphate. The thermal conduction liquid synthesized through the method has the characteristics of good thermal stability, good thermal conductivity, and realization of recycling. The quality of the above product is in a leading international level, and the product can provide a high-quality green and environmentally-friendly long-life thermal conduction liquid for production of domestic thermal conduction oil, and greatly promotes the thermal conduction industry to develop toward the environment compatibility and renewability.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

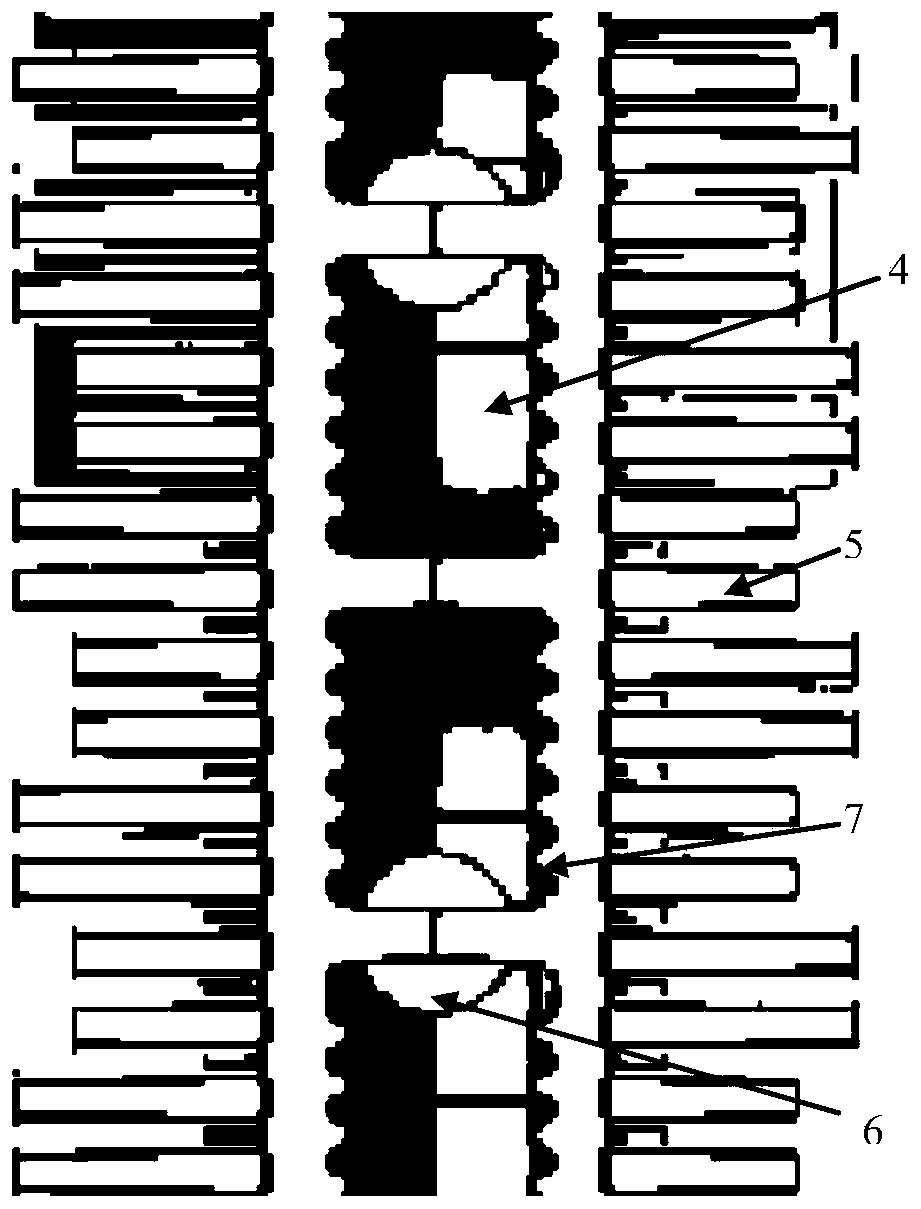

Condensing type gas-fired boiler heat exchanger, alloy for heat exchanger and boiler

PendingCN110260515AImprove heat exchange efficiencyEfficient latent heatFluid heatersStationary conduit assembliesCombustion chamberAlloy

The invention discloses a condensing type gas-fired boiler heat exchanger. The condensing type gas-fired boiler heat exchanger comprises a heat exchanger body, wherein a combustion chamber and a smoke exhausting chamber which communicate with each other are formed in the heat exchanger body; condensing water channels which are integrated with the heat exchanger body is arranged between the combustion chamber and the smoke exhausting chamber; heat dissipating bumps are integrally arranged or fixed on the outer surfaces of the condensing water channels; and the closer to the combustion chamber, the more arrangement density of the condensing water channels increases. According to the condensing type gas-fired boiler heat exchanger, the heat dissipating bumps are arranged on the outer surface of the heat exchanger, so that the heat exchanging area is increased, and the condensing effect of the heat exchanger to smoke is improved. The invention also discloses alloy for the heat exchanger. The alloy comprises the following components in percentage by mass: 8-11% of silicon, 0.2-0.45% of magnesium, not greater than 0.2% of iron, 0.02-0.14% of titanium, 0.01-0.03% of strontium, and the balance aluminum. The mechanical performance of manufactured condensing heat exchanger entity reaches international level; the tensile strength and the yield strength of the condensing heat exchanger are equal to those of an imported heat exchanger; and the ductility and the impact resistance are beyond those of the imported heat exchanger.

Owner:程银萍

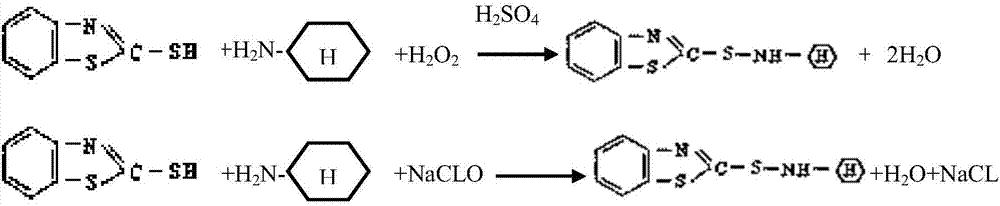

Method for using rubber accelerator M to synthesize sulfonamide accelerator CBS by solvent purification method

InactiveCN107445918AReduce chemical oxygen demand CODcrReduce generationOrganic chemistryPurification methodsReaction temperature

The invention discloses a method for using a rubber accelerator M to synthesize an sulfonamide accelerator CBS by a solvent purification method. The method comprises the following steps of: by adopting the rubber accelerator M and cyclohexylamine as materials, adopting hydrogen peroxide and sodium hypochlorite as oxidants, adopting sulfuric acid as a catalyst, reacting to synthesize the accelerator CBS, wherein the optimum production process conditions include: (1) the molar ratio between all the materials and the oxidants is as follows: n(M):n(cyclohexylamine) is equal to 1:2.2; n(M):n(20% hydrogen peroxide):n(15% sodium hypochlorite) is equal to 1:0.6:0.65-0.75; (2) the reaction temperature is 35-40 DEG C; and (3) the reaction time is 2.0-2.5 hours. The method disclosed by the invention has the advantages that the technical problem in using the rubber accelerator M to synthesize the sulfonamide accelerator CBS by the solvent purification method is comprehensively solved, the product quality index is higher than international level, the consumption index reaches lower industrial level, and the problem of treatment of waste water, solid wastes and odor pollutants is solved.

Owner:QINGDAO AUX CHEM

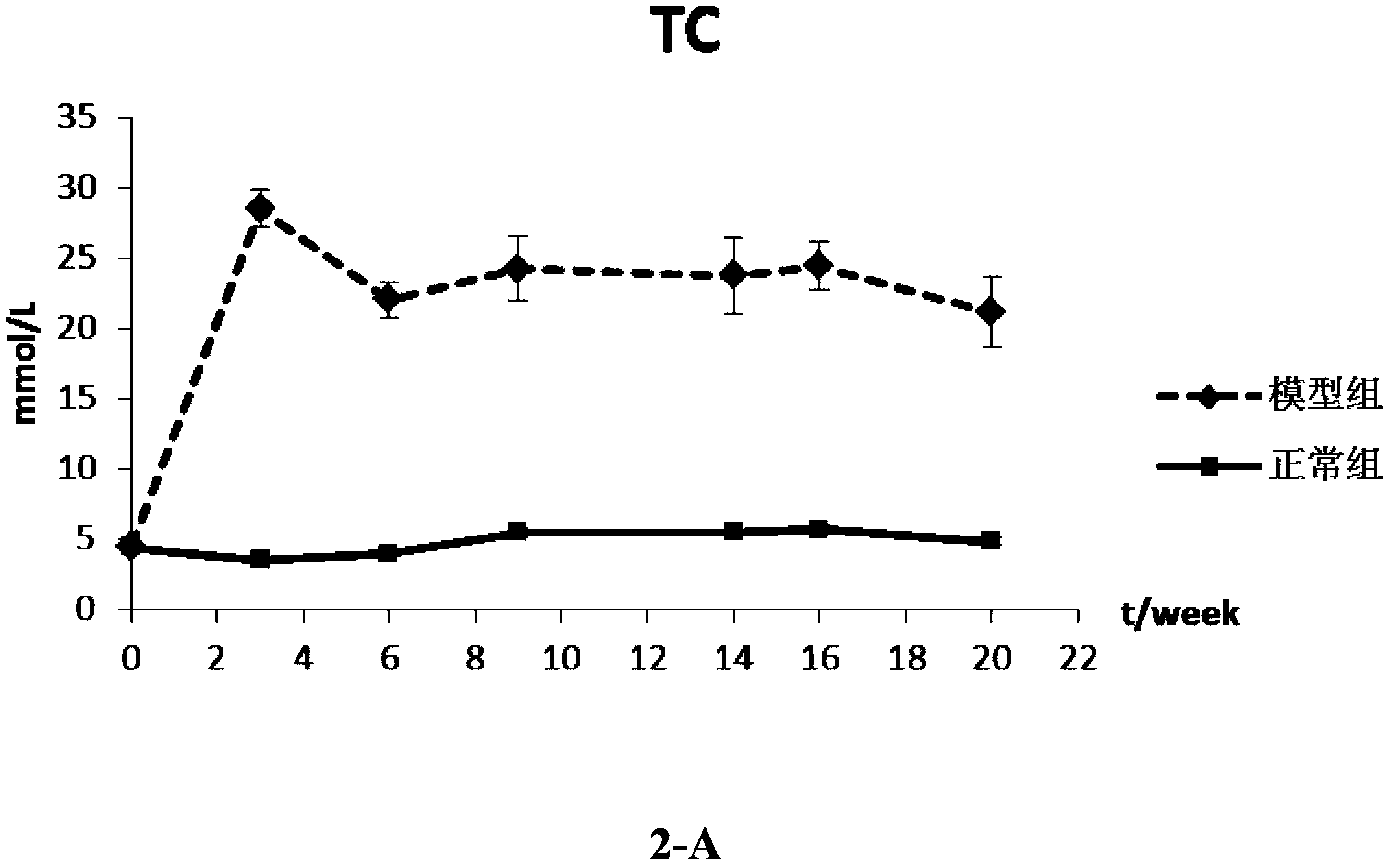

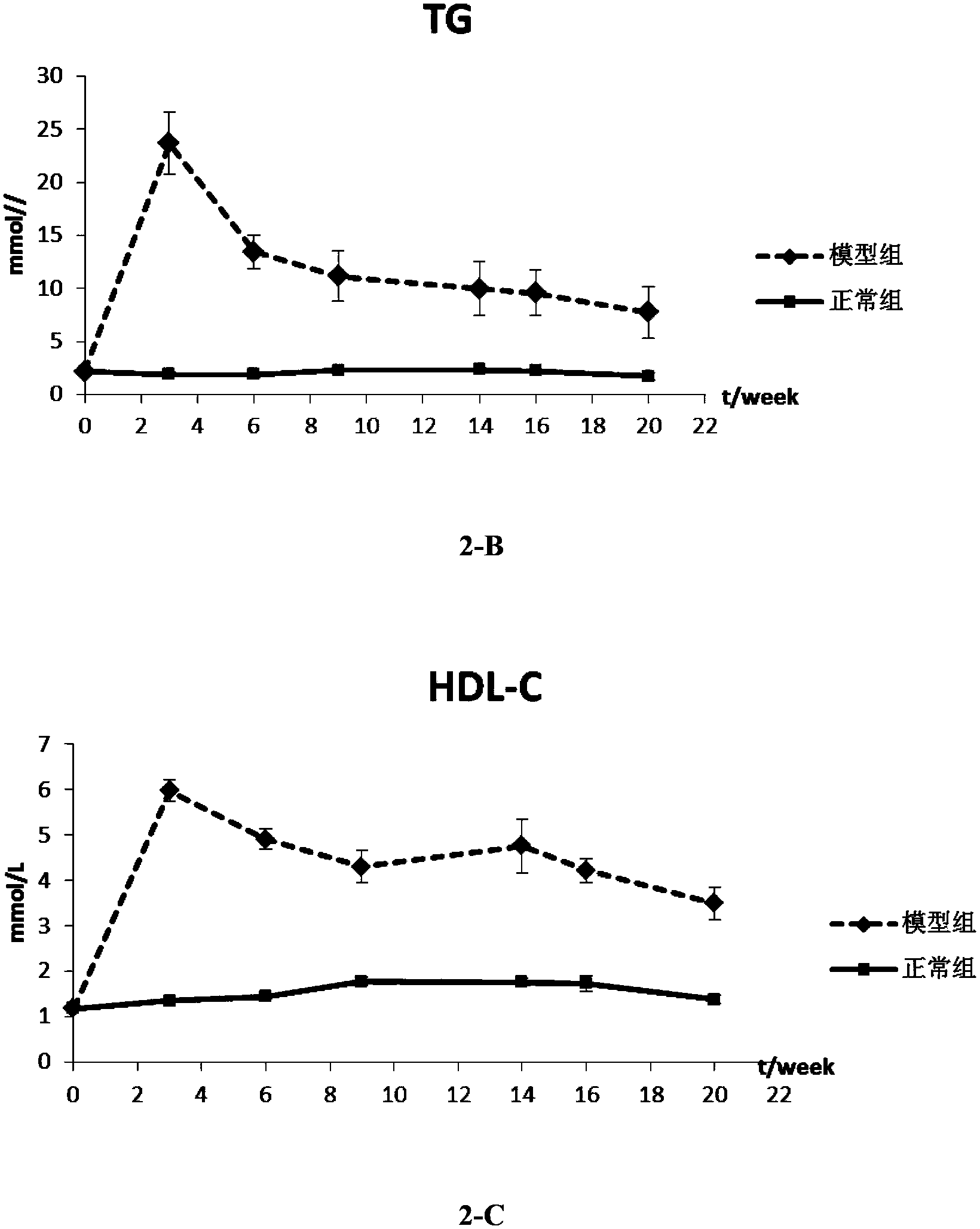

Fast manufacturing technology for establishing golden hamster atherosclerotic model

InactiveCN104095144AShorten the research processReduce feeding costsAnimal feeding stuffAccessory food factorsManufacturing technologyGolden hamster

The invention discloses a fast simple low-cost manufacturing technology for establishing an atherosclerotic model. The atherosclerotic model is established by feeding high fat diet with unique formula to Syria golden hamster for 5 months, the modeling time is 5 months shorter than the time for forming atherosclerotic plaque on the same species on an international level. The technical scheme provided by the invention can rapidly establish a blood lipid dynamic graph and ultrasound imaging characteristics of the atherosclerotic model and blood vessel arteriosclerosis model characteristics, and is conducive to shortening the research process of atherosclerotic experimental model and innovative drug preclinical evaluation, and provides the reference standard for the model manufacturing technique.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

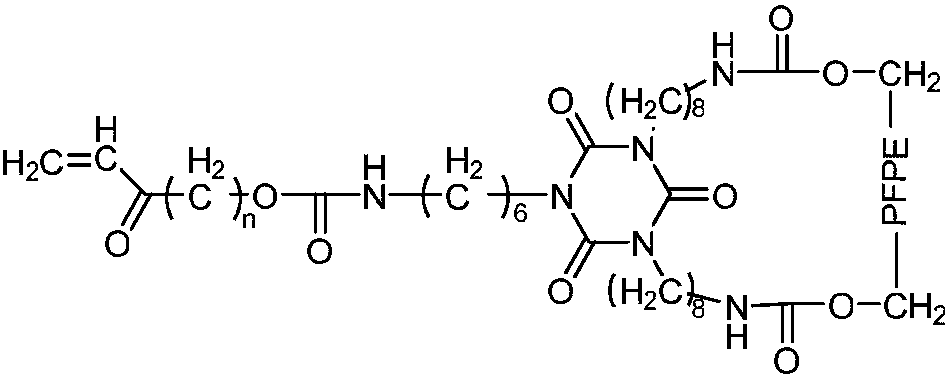

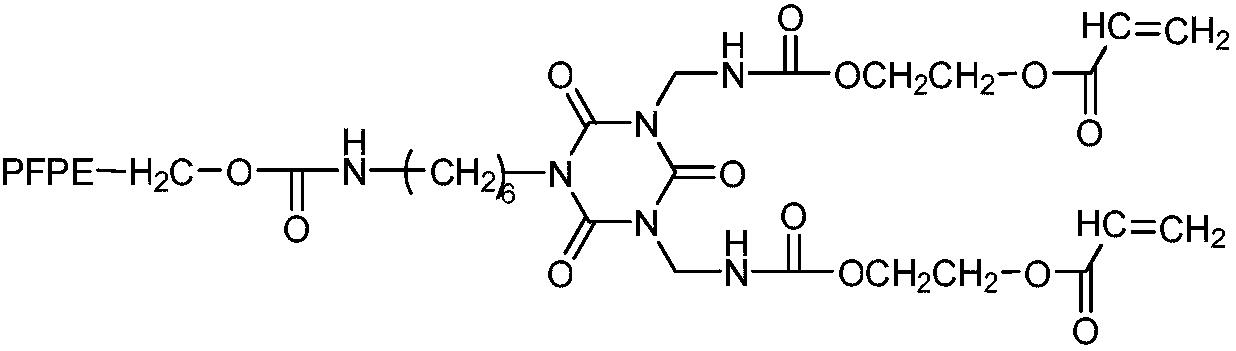

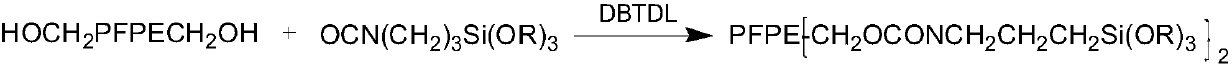

Compound with anti-pollution effect and preparation method of compound

ActiveCN109517132APlay the role of anti-pollutionEffective attachmentAntifouling/underwater paintsPaints with biocidesSteel woolOrganic chemistry

The invention relates to a compound with an anti-pollution effect. The compound is PFPE(CH2OCONCH2CH2CH2Si(OR)3)2, wherein the PFPE is -(CF2O)x-(CF2CF2O)y-, and R is methyl or ethyl. According to thecompound disclosed by the invention, by virtue of tests, the contact angle of the compound to water reaches 114 degrees after film formation on a glass slide; and the compound has a contact angle of 72 degrees to n-hexadecane, and belongs to waterproof and oil-repellent materials. Meanwhile, the film-formed glass slide can be rubbed by steel wool under a load of 1kg for 10000 times without obviously reducing the waterproof and oil-repellent properties, so the glass slide has excellent rub resistance. By testing the dynamic friction coefficient, the dynamic friction coefficient reaches 0.03, the smoothness reaches an international level, and the compound also has wide application prospects in the field of other high-end optical device.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Preparation method of adhesive-free medium and high density plant fiber board

The invention relates to a preparation method of an adhesive-free medium and high density plant fiber board, and belongs to the technical field of composite materials. According to the preparation method, soybean meal and cassava residues are used as raw materials, and an adhesive is not added; soybean isolate protein and starch, which are rich in the soybean meal and the cassava residues, are utilized, and sugar and colloidal substances are released under the action of high temperature and are crossly linked to obtain an adhesive for connecting plant fibers; then the plant fibers are hotly pressed to prepare a medium and high density board which nearly comprises all plant fibers, and hydrogen bonding between the fibers is improved; furthermore, the quality of a medium and high density plant fiber functional material is improved; the adhesive-free medium and high density plant fiber board can be completely degraded, and toxic substances including formaldehyde and the like are not released in a utilization process; the adhesive-free medium and high density plant fiber board has the advantages of simple raw material components, wide source, low price, no toxin and no harms; the plantfiber board has a good machining property and has very good stiffness, flexibility, toughness, tensile force and waterproof performance; the rigidity, bonding strength and toughness reach the advanced international level of like products.

Owner:张静

Friction tester

ActiveCN102706764BImprove accuracyImprove efficiencyInvestigating abrasion/wear resistanceLow noiseReciprocating motion

The invention discloses a friction tester which comprises a sample bearing platform on which the sample can be arranged, a friction platform on which the friction medium can be arranged and a power device. The power device is used for driving the friction platform to do reciprocating motion relative to the sample bearing platform; the sample bearing platform comprises at least one group of clamping components and compressing components; the clamping components are used for fixing the sample; and the compressing components match with each group of clamping components and used for keeping the sample to contact the friction medium. With the structure, the friction tester has the advantages of simple structure, low noise, low pollution, low energy consumption, simple and smooth production process, high technology content and high productivity. All the quality indexes of the product reach the international level of the industry of decorative building materials.

Owner:TST INSTR FUJIAN

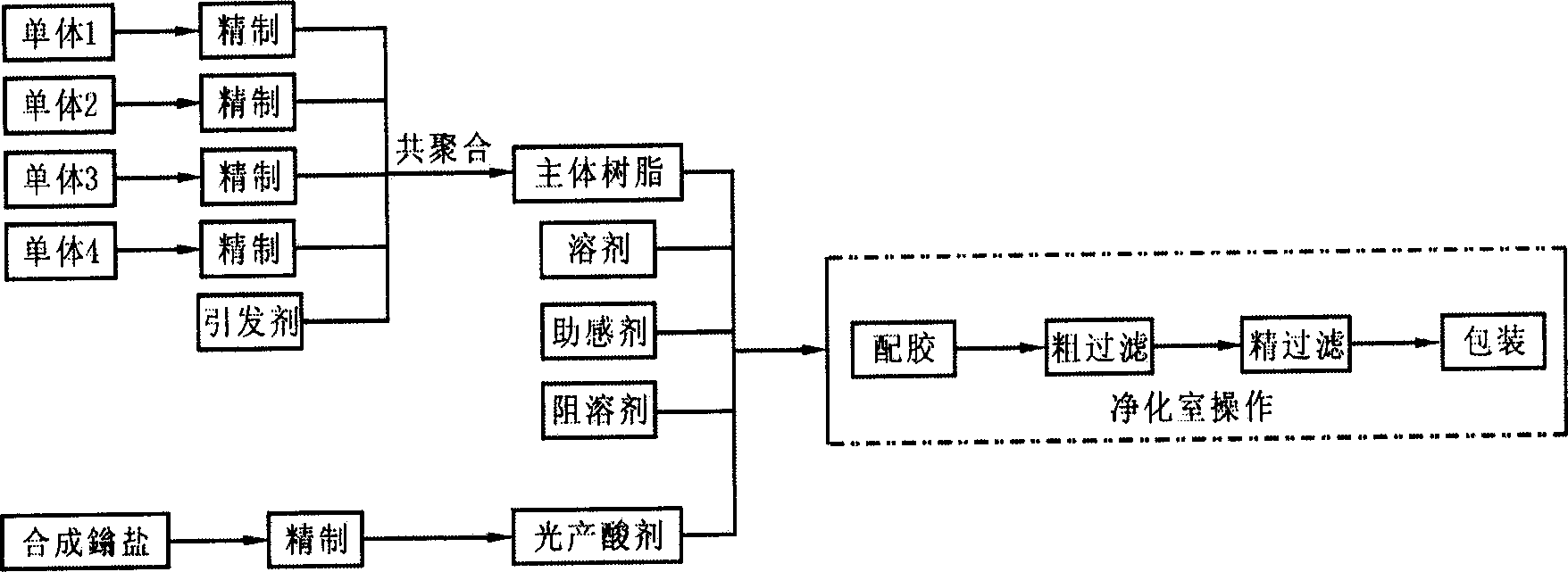

A electron beam chemical amplitude positive resist and method for making same and photoetching technology

InactiveCN1547078APhotomechanical exposure apparatusMicrolithography exposure apparatusLithography processImage resolution

The invention is a kind of electron beam chemical amplifies positive slushing compound and the manufacturing method, and the etching process. The invention uses P (MMA-TBMA-MAA-IBMA) as the primary resin, the slushing compound belongs to the positive one with high resolution performance, or positive glue. The invention provides the synthesis of the primary resin, the synthesis of optical acid generating agent dibenzio-triflumidatemethyl petroleum sulfonate, the prescription and manufacturing method of the slughing compound. The resolution is 0.13ª–m, the sensitivity is 5-10ª–C / cm2 (50kV), reaches or approaches the international level.

Owner:WUXI RES & DESIGN INST OF CHEM IND

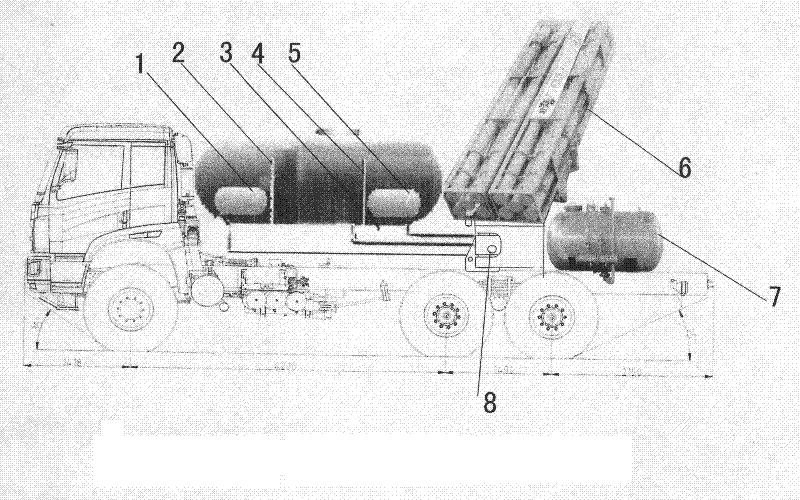

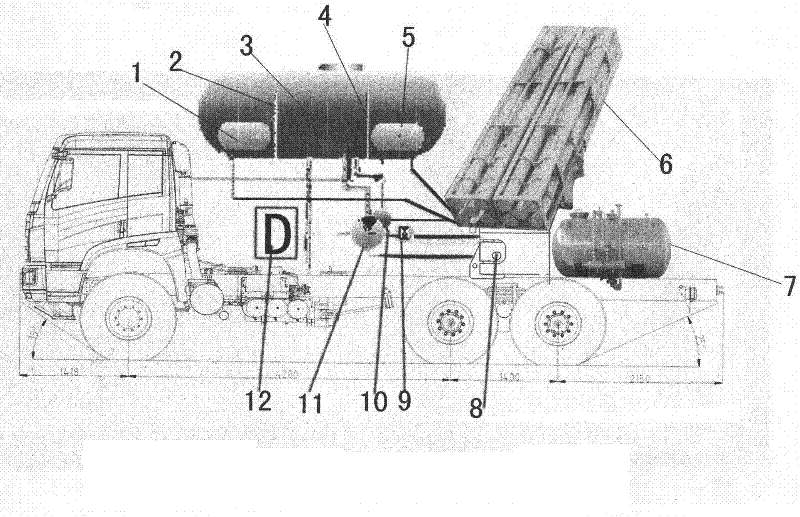

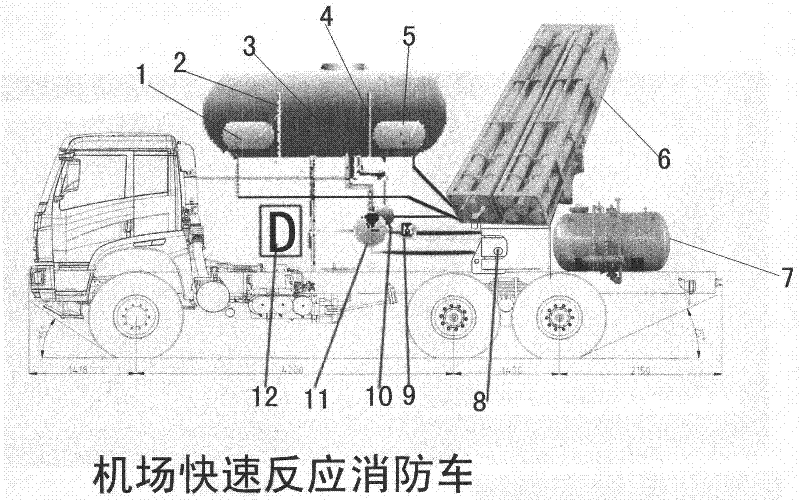

Airport quick-response fire engine

InactiveCN102233163AMeeting Fire RequirementsEfficient fire extinguishing effectFire rescueJet flowIntellectual property

The invention discloses an airport quick-response fire engine, wherein a highly compressed air cylinder is used as an injection source directly; water foam / dry powder and the like are matched respectively for injection with a jet flow of up to 10 Mpa; with 500-kw power and a 6*6 chassis, the unit power reaches an international level of up to 25 kw / T; a multiple launch rocket system piston retrothrust water cannon is adopted, which greatly reduces the recoil force, and improves the injection capability; the performance of the invention is superior to that of foreign products with the same kind; the invention is a product with Chinese independent intellectual property rights, is firstly witnessed domestically, and is completely manufactured in China.

Owner:李仁 +1

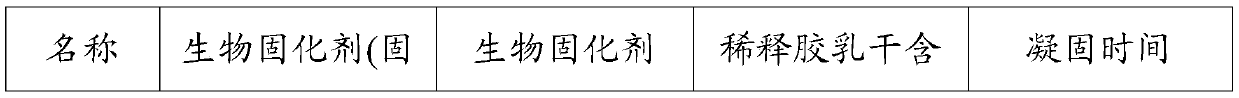

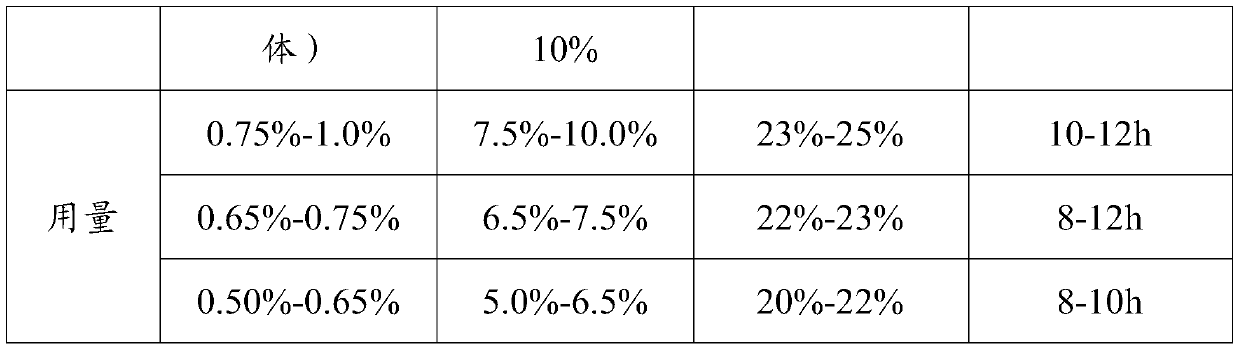

Natural rubber with high PO and PRI and preparation method of natural rubber

The invention relates to a natural rubber with high PO and PRI and a preparation method of the natural rubber, and belongs to the technical field of natural rubber production. The natural rubber is prepared from the following raw materials: natural rubber, a biological preservative, a heat resistant oxidizing agent and a biological curing agent. According to the natural rubber and the preparationmethod, a wet mixing method is adopted to prepare the natural rubber, and the natural rubber with high PO and PRI is obtained; quality parameters of the PO and PRI of the natural rubber are improved by directly adding the preservative, a biomass active agent and a curing agent to natural latex, and therefore, the technical standard of the natural rubber surpasses the international level; and the method is simple and convenient in process, the conditions are easy to control, and the processing and production process of the high-performance natural rubber can be optimized.

Owner:青岛金瑞纳橡胶科技有限公司

Protein misfolding-based establishing method of cell model for antioxidant drug screening

ActiveCN108823170AEffectively assess roles and effectsStable genetic traitsMicrobiological testing/measurementFluorescence/phosphorescenceDiseaseCritical illness

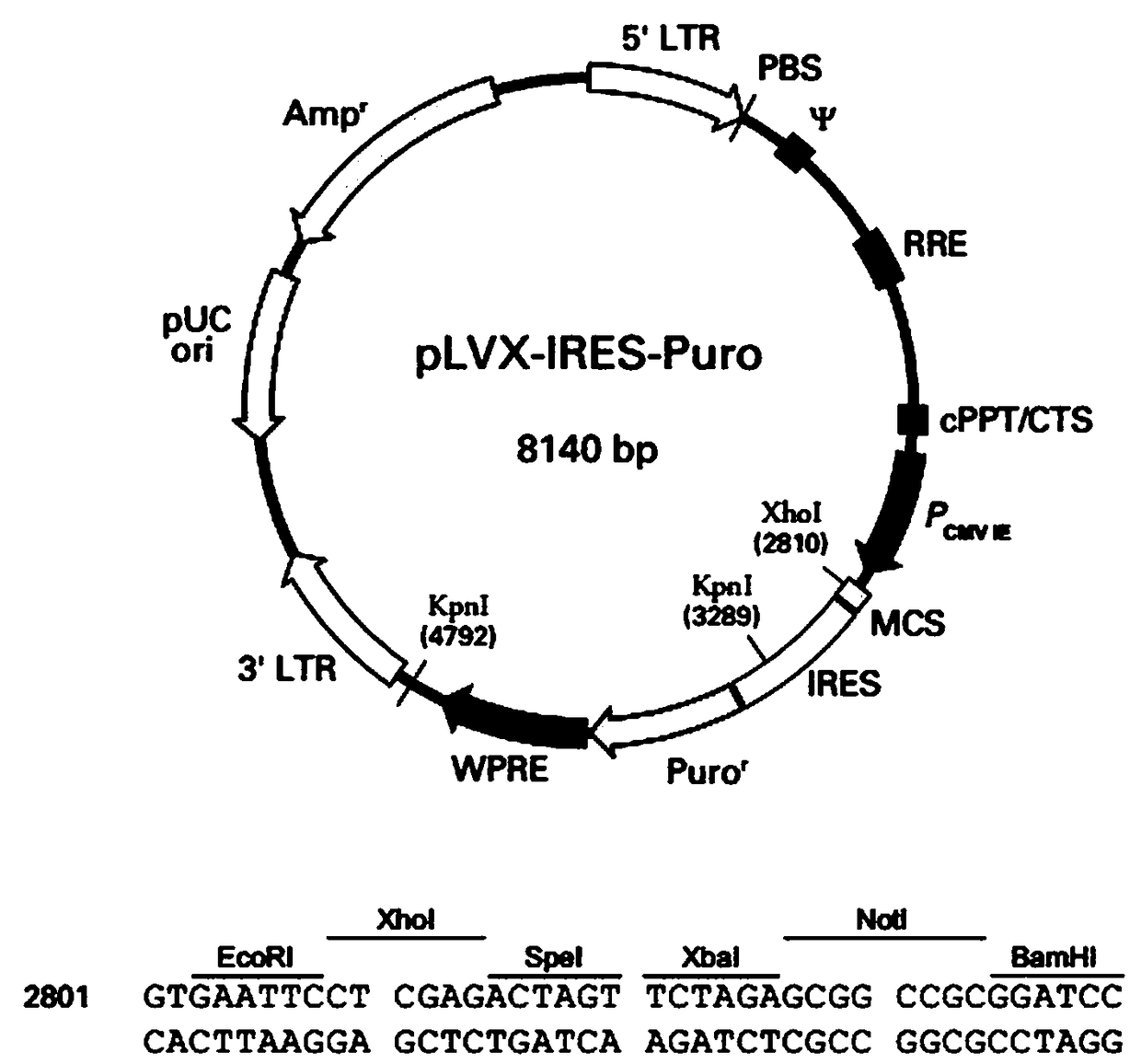

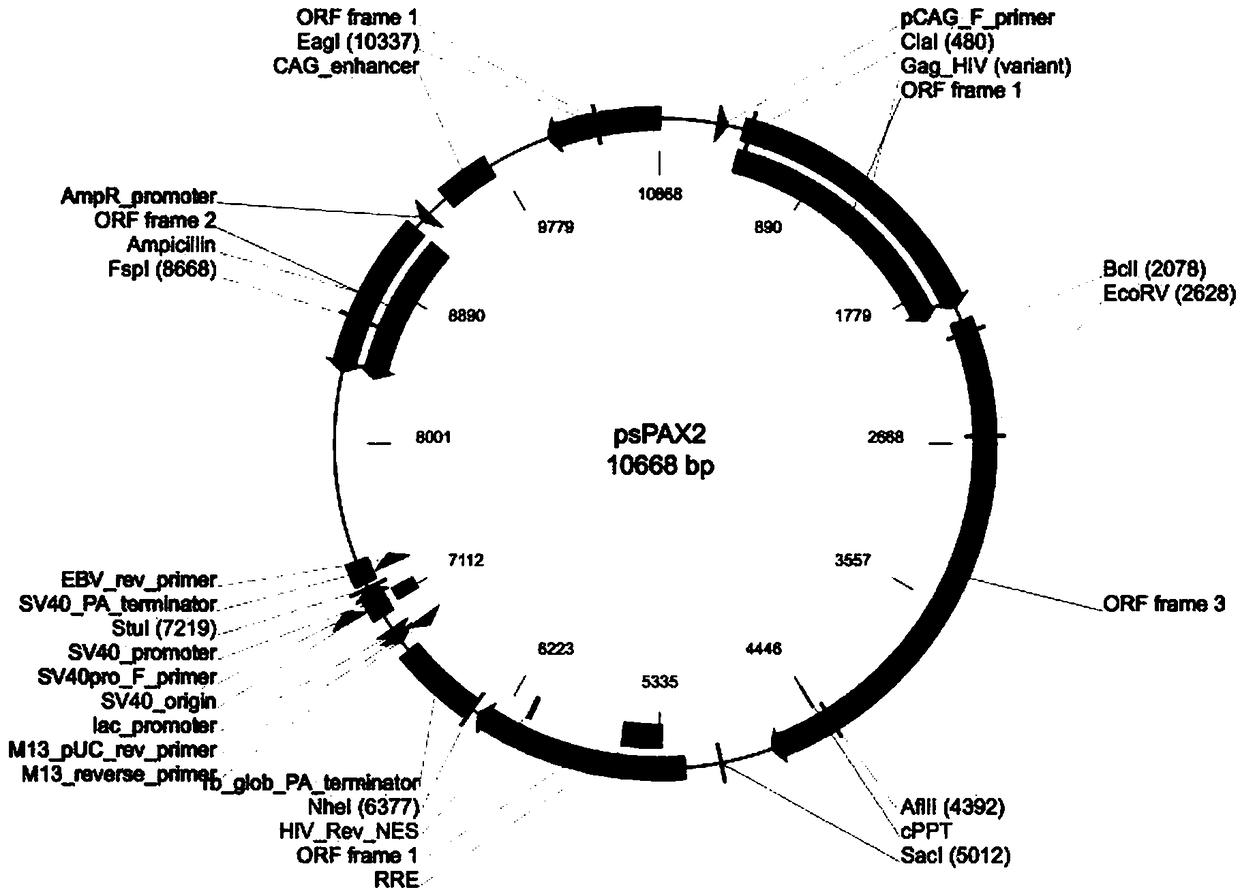

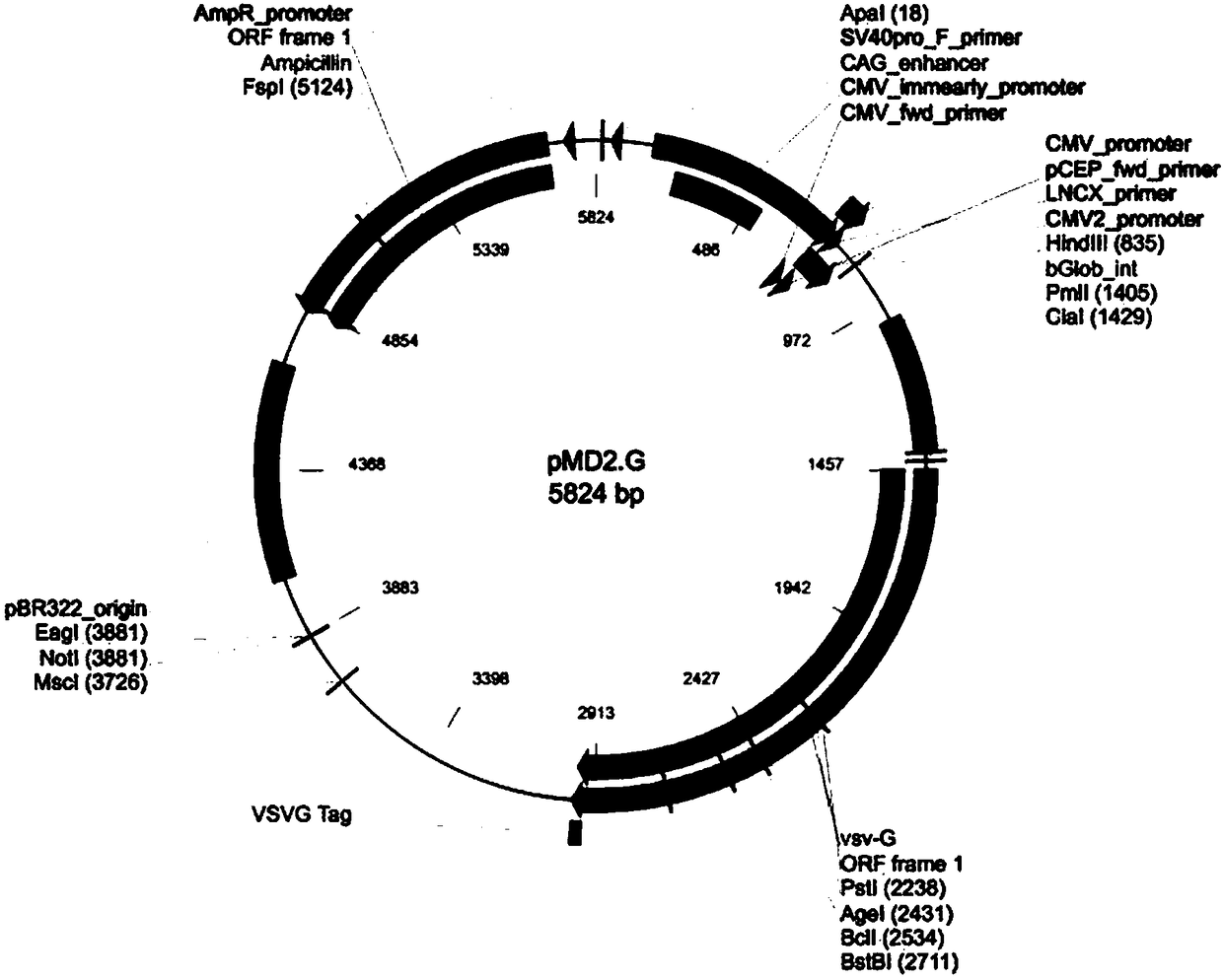

The invention belongs to the field of cytobiology, and provides a protein misfolding-based establishing method of a cell model for antioxidant drug screening aiming at the defect that real-time quantitative establishment on protein misfolding cannot be carried out in living cells at present. The protein misfolding-based establishing method comprises the following steps: establishing fluorescent protein labeled wild and mutant reporter gene COMP (Cartilage Iligomeric Matrix Protein) gene lentiviral vector, packaging virus in human embryo kidney 293T cells, transducing HeLa cells, and screeningpuromycin, thus obtaining the cell model for stably expressing COMP cells. A drug screening cell model which is in international level and independent innovation is established, not only key parameters can be provided for a protein misfolding drug screening industrialization study in the further, but also correlated scientific basis is provided for a sustainable study on serious illness; the cellmodel has the characteristics of high chromosome integration degree, high fluorescence strength, stable inheritable character and antioxidant drug sensitiveness, and is an ideal model for studying protein misfolding drug screening.

Owner:SHANXI UNIV

A slice type liquid heavy metal natural circulation device

ActiveCN104200853BRich experimental dataNuclear energy generationNuclear monitoringTechnology researchLiquid metal

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com