A kind of preparation method of environment-friendly and durable fully synthetic heat transfer fluid

A heat transfer fluid, durable technology, applied in the chemical industry, can solve the problems of stopped flow, easy carbon deposition in equipment, initial condensation, etc., and achieve the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

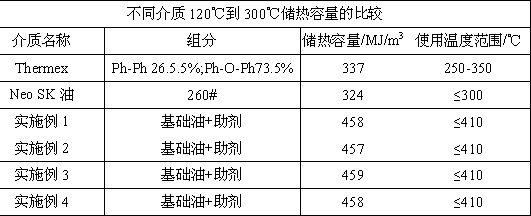

Examples

Embodiment 1

[0032] Embodiment 1. This embodiment provides an environmentally friendly and durable fully synthetic heat transfer fluid and a preparation method thereof. The heat transfer fluid includes the following substances in terms of weight fractions: Base oil: 90 parts of (3-alkyl-1-methyl-imidazole) hexafluorophosphate, 0.5 parts of high-temperature antioxidant, 0.1 part of pour point depressant, composite coke inhibitor 0.01 part, antirust agent 0.1 part.

[0033] Among them, the preparation steps of (3-alkyl-1-methyl-imidazole) hexafluorophosphate are as follows: add equimolar N-methylimidazole and chlorinated alkanes into a 500mL standard reflux device, and install a Sheng You CaCl 2 The drying tube was connected to the atmosphere, refluxed for 48 hours, and the reflux temperature was 75°C. After the reaction, the flask containing the white product was cooled in a desiccator and left overnight. There was a large amount of white product in the flask and a small amount of light ye...

Embodiment 2

[0034] Embodiment 2. This embodiment provides an environmentally friendly and durable fully synthetic heat transfer fluid and a preparation method thereof. The heat transfer fluid includes the following substances in terms of weight fraction: Base oil: 99 parts of (3-alkyl-1-methyl-imidazole) hexafluorophosphate, 1 part of high-temperature antioxidant, 0.2 part of pour point depressant, composite coke inhibitor 0.1 part, antirust agent 1 part.

[0035] Among them, the preparation steps of (3-alkyl-1-methyl-imidazole) hexafluorophosphate are as follows: add equimolar N-methylimidazole and chlorinated alkanes into a 500mL standard reflux device, and install a Sheng You CaCl 2 The drying tube was connected to the atmosphere, refluxed for 45 hours, and the reflux temperature was 71°C. After the reaction, the flask containing the white product was cooled in a desiccator, and left for 12 hours. There was a large amount of white product in the flask, and a small amount of light yellow...

Embodiment 3

[0036] Embodiment 3, this embodiment provides an environmentally friendly and durable fully synthetic heat transfer fluid and a preparation method thereof. The heat transfer fluid includes the following substances in terms of weight fractions: base oil: 92 parts of (3-alkyl-1-methyl-imidazole) hexafluorophosphate, 0.6 parts of high-temperature antioxidant, 0.15 parts of pour point depressant, composite coke inhibitor 0.18 parts, antirust agent 0.8 parts.

[0037] Among them, the preparation steps of (3-alkyl-1-methyl-imidazole) hexafluorophosphate are as follows: add equimolar N-methylimidazole and chlorinated alkanes into a 500mL standard reflux device, and install a Sheng You CaCl 2 The drying tube was connected to the atmosphere, refluxed for 46 hours, and the reflux temperature was 73°C. After the reaction, the flask containing the white product was cooled in a desiccator, and left for 11 hours. There was a large amount of white product in the flask, and a small amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com