Super absorbent resin with high absorbent velocity and preparation method

A super absorbent resin and high liquid absorption technology, applied in the field of functional polymer materials, can solve the problems of sensitization, liquid absorption ability, low liquid absorption rate, stimulation effect, etc., and achieves excellent biocompatibility, safe use, The effect of huge application and development value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

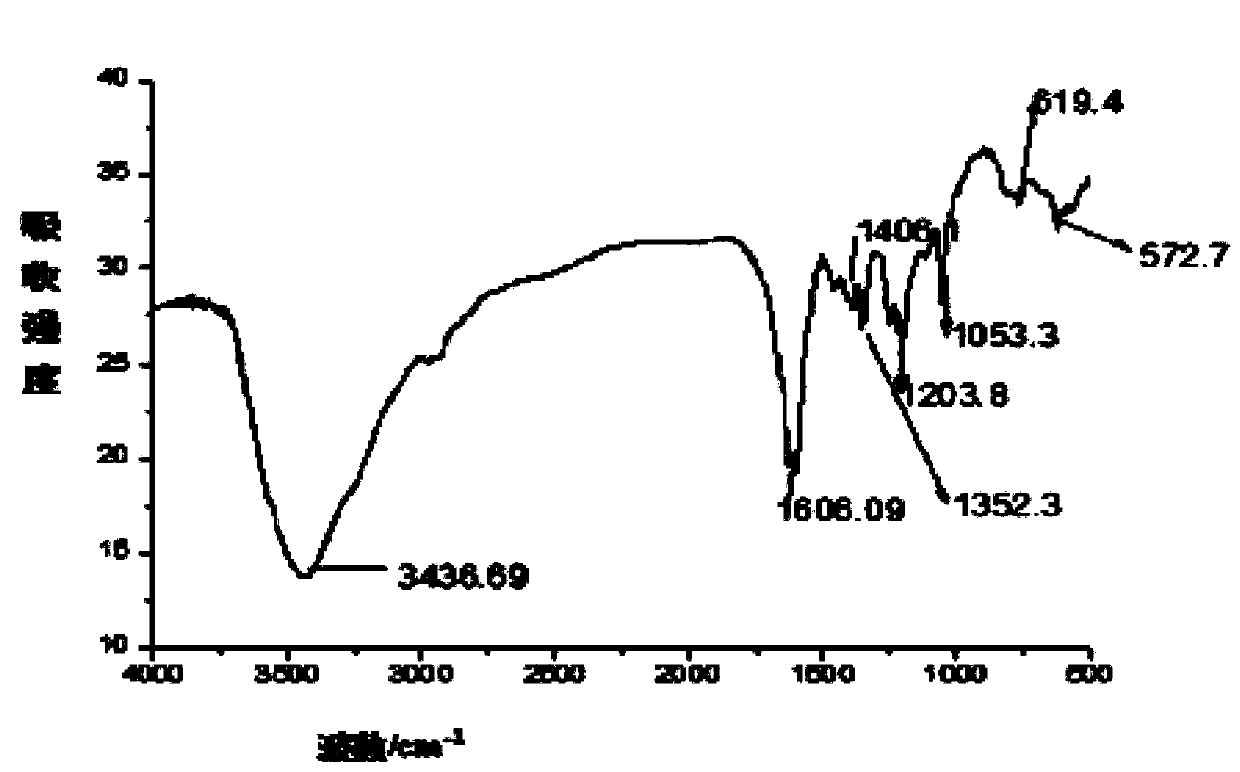

Image

Examples

Embodiment 1

[0031] Preparation of PVA / PAAS / AMPS Radiation Copolymer:

[0032] (1) PVA is chemically pure, with a degree of polymerization of 1700 and a degree of saponification of 98%; PAAS is analytically pure, with a molecular weight of 5×10 3 ; AMPS is chemically pure with a molecular weight of 207.25.

[0033] Ingredients: PVA 6wt%, PAAS 18wt%, AMPS 6wt%, triple distilled water 70wt%.

[0034] Mix the above mixture solution evenly, place in a high-pressure steam pot, heat and dissolve at 110°C for 2 hours, and prepare a uniform and transparent solution.

[0035] (2) Quantitatively pour the homogeneous solution into a smooth disc-shaped mold, which is made of aluminum alloy, its size is determined according to the width of the electron beam irradiation, and the thickness of the solution is 1 mm.

[0036] (3) The solution in the mold should be irradiated by an electron accelerator device, and the irradiation conditions: the energy is 0.8MeV, the current is 2mA, and the total absorbed ...

Embodiment 2

[0042] Preparation of PVA / PAAS / AMPS Radiation Copolymer:

[0043] (1) PVA is chemically pure, with a degree of polymerization of 2400 and a degree of saponification of 99%; PAAS is analytically pure, with a molecular weight of 2×10 3 ; AMPS is chemically pure with a molecular weight of 207.25.

[0044] Ingredients: PVA 10wt%, PAAS 22wt%, AMPS 3wt%, triple distilled water 65wt%.

[0045] Mix the above mixture solution evenly, place in a high-pressure steam pot, heat and dissolve at 120°C for 1 hour, and prepare a uniform and transparent solution.

[0046] (2) Quantitatively pour the homogeneous solution into a smooth disc-shaped mold, which is made of aluminum alloy, its size is determined according to the width of the electron beam irradiation, and the thickness of the solution is 15mm.

[0047] (3) The solution in the mold should be irradiated by an electron accelerator device, and the irradiation conditions: the energy is 2.45MeV, the current is 14mA, and the total absorbed ...

Embodiment 3

[0053] Preparation of PVA / PAAS / AMPS Radiation Copolymer:

[0054] (1) PVA is chemically pure, the degree of polymerization is 1700, and the degree of saponification is 99%; PAAS is analytically pure, with a molecular weight of 3×10 3 ; AMPS is chemically pure with a molecular weight of 207.25.

[0055] Ingredients: PVA 2wt%, PAAS 26wt%, AMPS 9wt%, triple distilled water 63wt%.

[0056] Mix the above mixture solution evenly, place it in a high-pressure steam pot, heat and dissolve at 120°C for 2 hours, and prepare a uniform and transparent solution.

[0057] (2) Quantitatively pour the homogeneous solution into a smooth disc-shaped mold, which is made of aluminum alloy, its size is determined according to the width of the electron beam irradiation, and the thickness of the solution is 8mm.

[0058] (3) The solution in the mold should be irradiated by an electron accelerator device, and the irradiation conditions: the energy is 1.5MeV, the current is 9mA, and the total absorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com