Production process of milky-white casing

A production process, milky white technology, applied in the production process of milky white casings, can solve the problems of miscellaneous colors, small elasticity, and affecting the economic value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

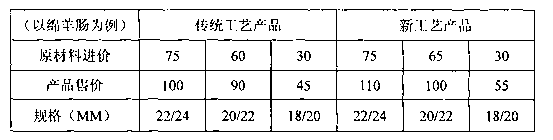

Image

Examples

Embodiment Construction

[0006] Casings are rich in protein. Generally, the feces in casings are mostly yellow, which is caused by natural pigments such as grasses. If feces touch the intestines, the casings will form varying yellows, because natural pigments have an effect on protein. Very strong affinity, the general pigment is mostly insoluble in water, so it is difficult to wash away with water; on the other hand, the pigment in the casing

[0007] The divalent iron ions in the protein-reduced myoglobin molecule are oxidized to ferric ions, which become metmyoglobin, and the color turns brown. If the oxidation continues, it becomes oxyporphyrin, which is green or yellow. And produce odor, Kazakhstan.

[0008] When bleaching, it is necessary to add an activator such as fatty alcohol microorganisms. The activator can react with the H2O2 transformed by the oxygen-containing bleaching agent during the washing process to generate peroxidized fatty acid, and then perform bleaching, and the peroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com