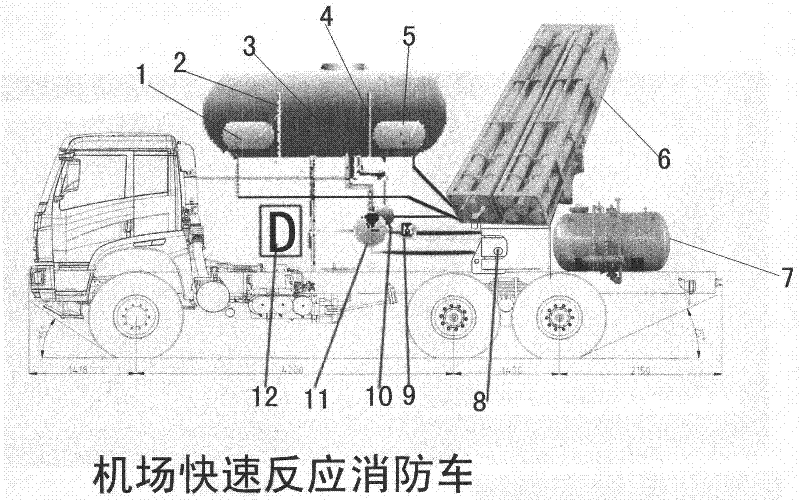

Airport quick-response fire engine

A quick-response, fire-fighting truck technology, applied in the field of patented fire-fighting equipment, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

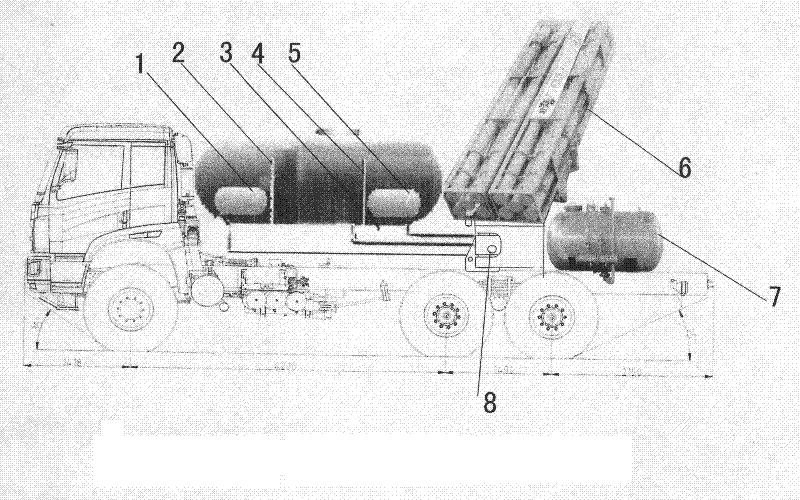

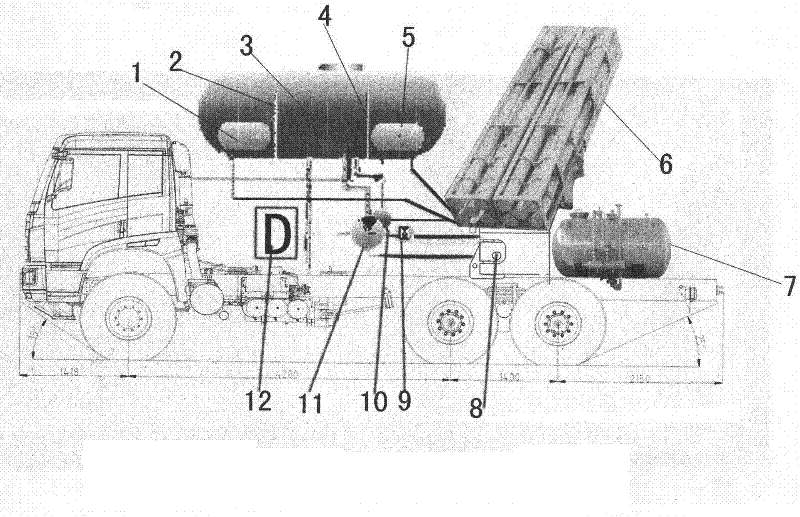

Image

Examples

Embodiment approach

[0005] Implementation scheme: the afterbody of the multi-barrel rocket launcher type piston reverse thrust water cannon (6) is a high-compression gas cylinder, and the air pressure of part 1-2Mpa is sent to the water tank (3) by a three-stage decompression regulator (9), so that the water is Under the pressure of 2Mpa, according to the instructions of the automatic system, the water is delivered to the matched pipeline water tank under positive pressure. The soft composite material foam boxes (1) and (5) deliver the foam agent along the pipeline to the gun bore of the command under water pressure, and spray the dry powder from the dry powder tank with the high-pressure airflow. The dry powder is blown out by 1-2Mpa air pressure and sent to the gun bore assigned according to the command, and the high-pressure airflow is sprayed out. The turret (8) is a hydraulic cylinder that rotates 360° and 45° to complete the adjustment of the pitch angle.

[0006] This patent uses a disposa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com