Natural rubber with high PO and PRI and preparation method of natural rubber

A technology of natural rubber and natural latex, applied in the field of natural rubber production, can solve the problems of non-rubber components and physical and chemical changes of rubber molecular chains, and achieve the effects of optimizing the processing and production process, the process is simple, and the conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of natural rubber with high PO, PRI, comprising:

[0028] Step 1: the preparation of biological antistaling agent: take nano titanium dioxide 3kg in proportion, ethylparaben 5kg, chitosan 39kg, lysozyme 50kg, sodium metabisulfite (sodium pyrosulfite) 3Kg, get antistaling agent after mixing;

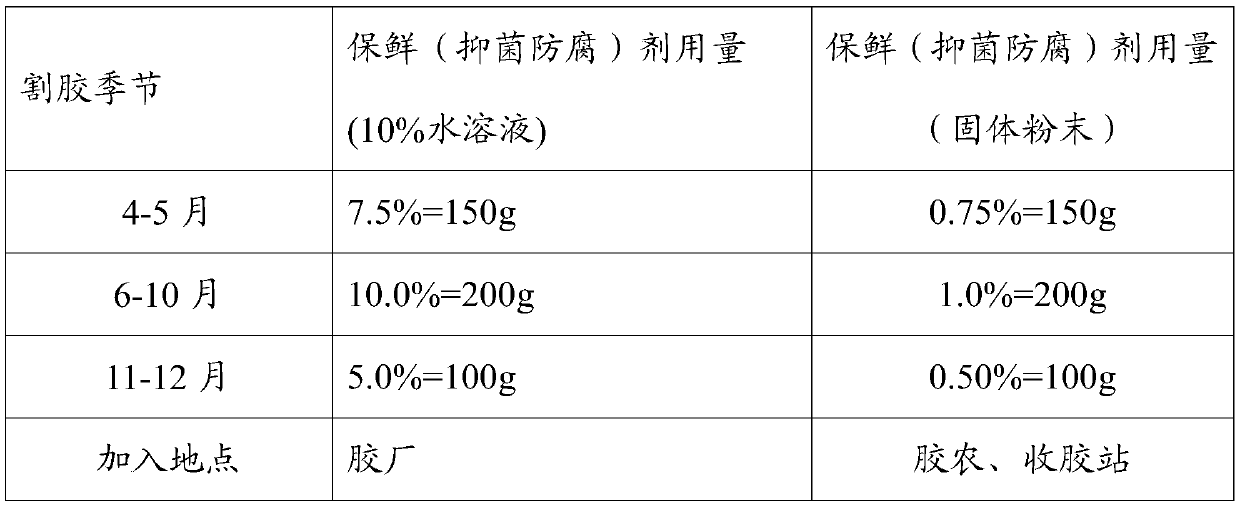

[0029] The time from rubber tapping to rubber harvesting is about 4-5 hours. You can put preservative in the rubber harvesting barrel in advance. The general size of the rubber barrel is 20-25 kg. According to the need, you can put about 100-200g of preservative when tapping the rubber ( The seasons are different, see Table 1), when putting latex in rubber barrel, stir, make antistaling agent fully, evenly in latex.

[0030] Step 2: Preparation of heat-resistant oxidant: Weigh the biomass active agent in proportion, add water and grind it with a high-speed refiner for 8-12 minutes to prepare a 14.3% concentration of the biomass active agent aging-resistant slur...

Embodiment 2

[0057] A preparation method of natural rubber with high PO, PRI, comprising:

[0058] Step 1: the preparation of biological antistaling agent: take by weighing nano-titanium dioxide 3kg, ethylparaben 5kg, chitosan 39kg, lysozyme 50kg, sodium metabisulfite (sodium pyrosulfite) 3Kg, add 900kg deionized water, stir into slurry.

[0059] The time from rubber tapping to rubber harvesting is about 4-5 hours. You can put preservative in the rubber harvesting barrel in advance. The general size of the rubber barrel is 20-25 kg. According to the need, you can put about 100-200g of preservative when tapping the rubber ( The seasons are different, see Table 1), when putting latex in rubber barrel, stir, make antistaling agent fully, evenly in latex.

[0060] Step 2: Preparation of heat-resistant oxidant: Weigh the biomass active agent in proportion, add water and grind it with a high-speed refiner for 8-12 minutes to prepare a 14.3% concentration of the biomass active agent aging-resist...

Embodiment 3

[0070] The preparation of the step 2 heat-resistant oxidant is modified to take 2656.25Kg of natural rubber with a dry content of natural rubber milk of 32%, weigh 1048.95Kg of the heat-resistant oxidation bioactive agent slurry prepared with a concentration of 14.3%, and pour the bioactive agent Put it into natural rubber latex and stir it mechanically at high speed for 10-20 minutes, and then solidify. All the other steps are the same as in Example 1.

[0071] The performance test was carried out on the natural rubber prepared in the above embodiment, and the test data was passed according to GB / T8018-2008, and the results are shown in Table 5.

[0072] table 5

[0073]

[0074]

[0075] It can be seen from the above Tables 3-5 that the natural rubber prepared by the present application has a relatively high initial value of plasticity PO and plasticity retention rate, and its other properties are also higher than international standards.

[0076] In summary, this ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com