Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Cobalt Sulfate Heptahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt(II) Sulfate Heptahydrate is a moderately water and acid soluble Cobalt source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogens with a metal.

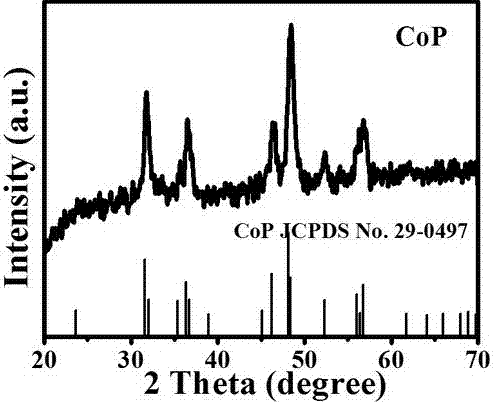

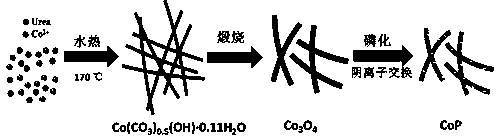

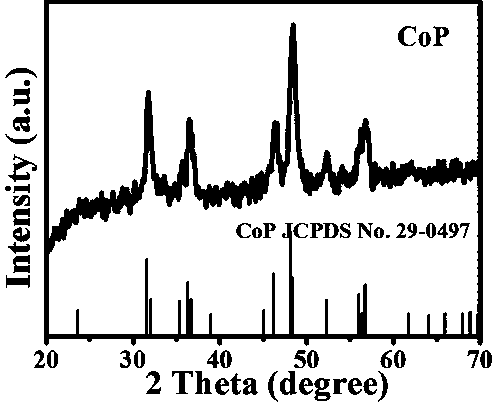

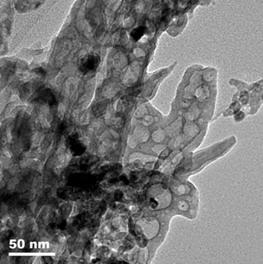

Preparation method of porous cobalt phosphide nanowire catalyst

InactiveCN107245727AImprove electrochemical activityImprove electrochemical stabilityNanotechnologyElectrode shape/formsNanowireFiltration

The invention discloses a preparation method of a porous cobalt phosphide nanowire catalyst. The method comprises the following steps that a solution is prepared by taking urea as a precipitant, taking cobalt sulfate hepathydrate as a cobalt source and taking glycerin and deionized water as solvents; the solution is added into a high pressure reactor for a hydrothermal reaction, after sufficient reaction is achieved, suction filtration and washing are conducted, vacuum drying is conducted, and then linear basic cobalt carbonate is obtained; in a tubular furnace, air burning is conducted on the linear basic cobalt carbonate at certain temperature, and cobaltosic oxide is obtained; and sodium hypophosphite serves as a phosphorus source, a cobaltosic oxide precursor and sodium hypophosphite are placed at the two ends of the same porcelain boat according to a certain proportion, the phosphorus source is placed at the upper stream of airflow, the treated porcelain boat is put into the tubular furnace for lower temperature calcination in an inert atmosphere, and preparation of the porous cobalt phosphide nanowire catalyst is achieved. The preparation method of the porous cobalt phosphide nanowire catalyst has the advantages that the production technology is simple, the cost is low, electrochemical activity and stability of the catalyst can be effectively improved, and the method is wide in application.

Owner:NANCHANG HANGKONG UNIVERSITY

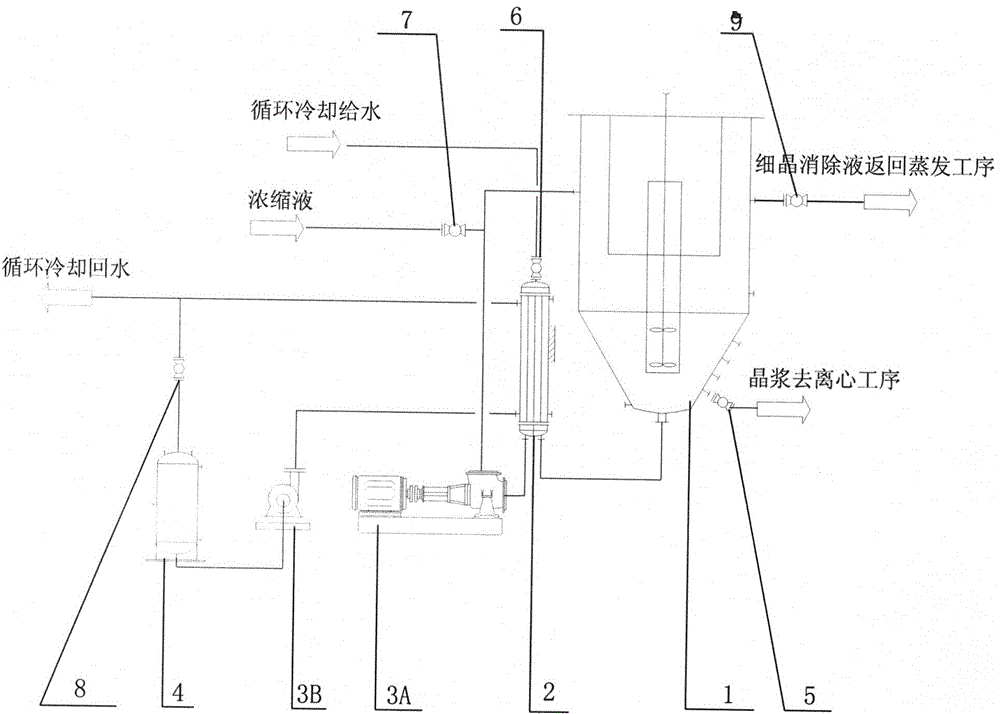

Nickel-cobalt sulfate continuous-crystallizing process

ActiveCN104192917AImprove energy savingRealize continuous productionNickel sulfatesEvaporationSlurry

The invention discloses a nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process which comprises the following steps: firstly carrying out MVR evaporation concentration on a high-purity solution produced through an extraction procedure to 30%-39%, and secondly continuously cooling and crystallizing through an improved cooling type internal-circulating continuous crystallizer; continuously discharging crystal slurry from the bottom of the crystallizer for centrifugal solid-liquid separation; and continuously drying a crystal product at low temperature to produce product crystals with large granularity and uniform size distribution, and recovering a mother solution to an evaporation process. Compared with the traditional periodic crystallization process, the nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process disclosed by the invention has the advantages of low evaporation energy consumption, fewer crystallization control process parameters, stability in operation, high automation degree, high production efficiency and the like and is easy to control, and operators are reduced.

Owner:ZHEJIANG HUAYOU COBALT

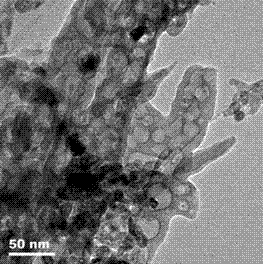

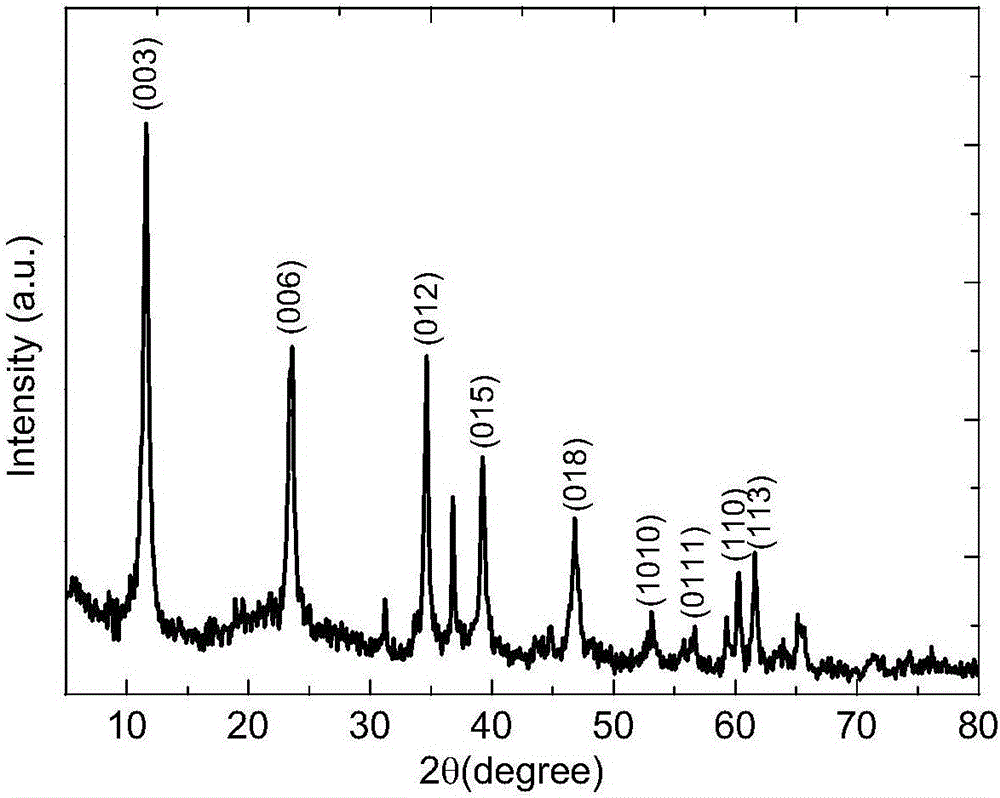

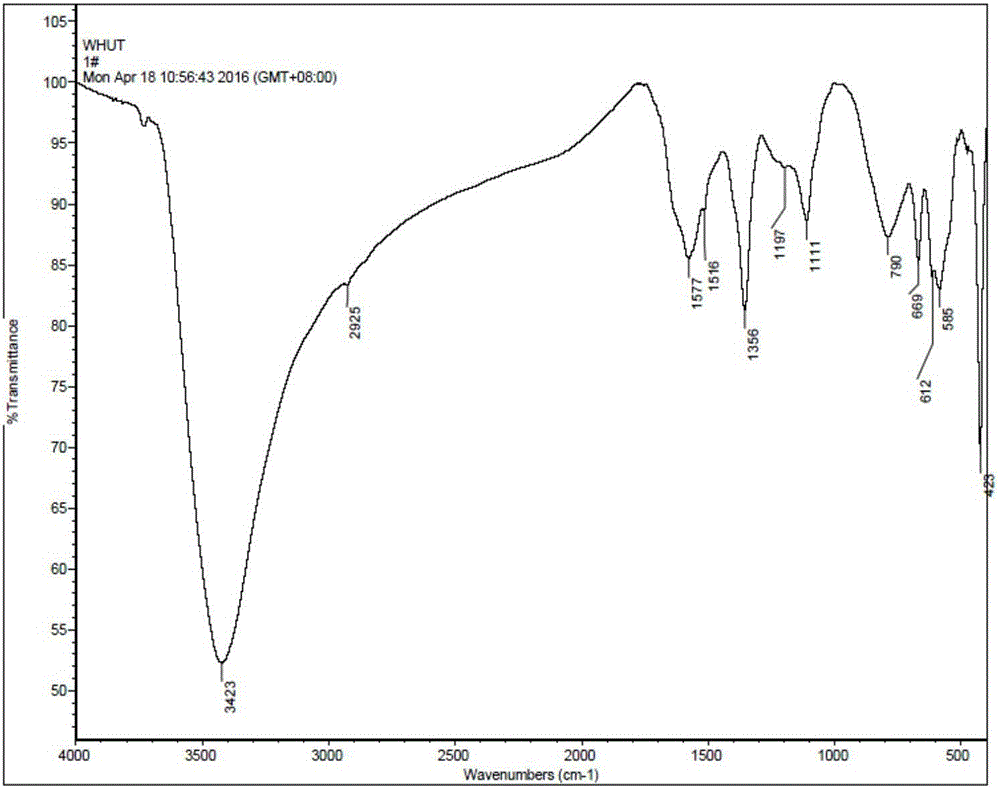

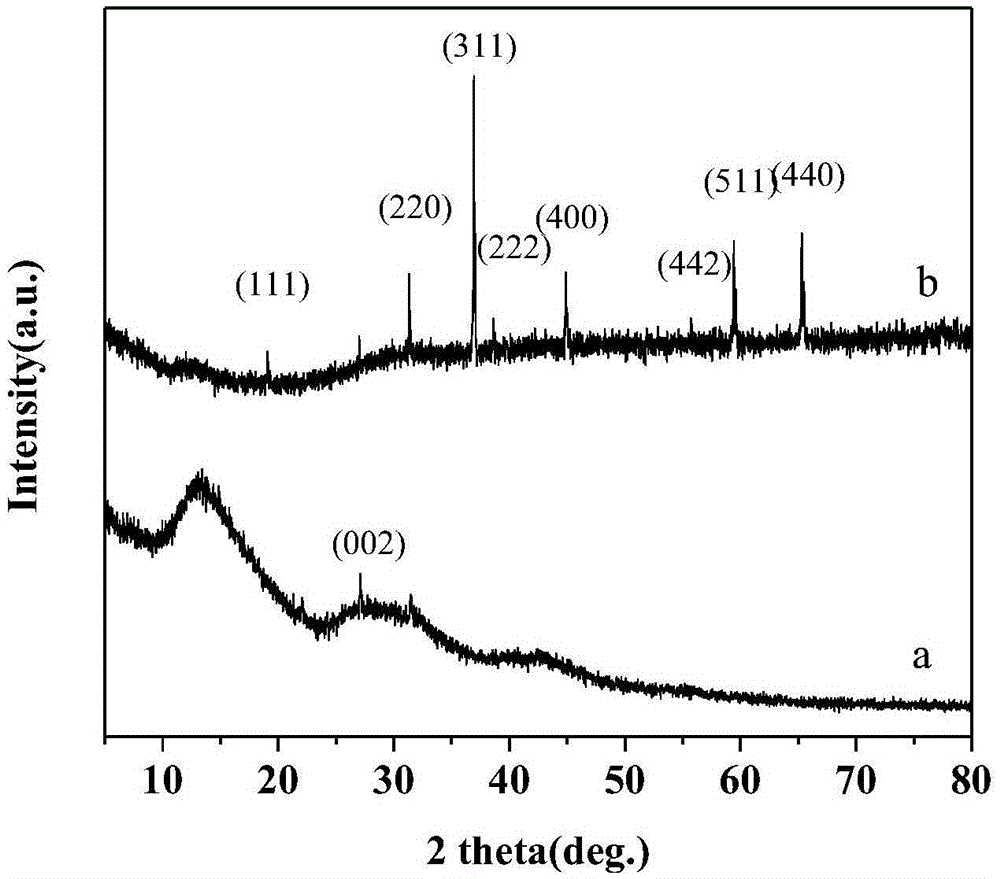

Cobalt aluminum hydrotalcite/fluorinated graphene composite material, and preparation method thereof

ActiveCN106206056AImprove electrochemical performanceImprove stabilityHybrid capacitor electrodesCobalt compoundsHigh pressureCrusher

This invention relates to a cobalt aluminum hydrotalcite / fluorinated graphene composite material, and a preparation method thereof. The composite material is prepared by the steps of: 1) preparing graphite oxide powder by a Hummers method; 2) dispersing the graphite oxide powder in deionized water; stripping by an ultrasonic cell crusher; centrifuging by a centrifuge; obtaining supernatant liquor; adding hydrofluoric acid solution in the supernatant liquor to stir and react; putting the solution into a high-pressure reactor to perform constant-temperature fluoridation; cooling to room temperature; filtering and washing till the solution is neutral, so as to obtain the fluorinated graphene; 3) dispersing the fluorinated graphene in ethanol solution; stripping by the ultrasonic cell crusher to obtain fluorinated graphene suspension; 4) adding cobalt sulfate heptahydrate, aluminum chloride hexahydrate and urea into the fluorinated graphene suspension to stir and react; putting the solution into the high-pressure reactor to perform hydrothermal reaction; then cooling to the room temperature; and obtaining the cobalt aluminum hydrotalcite / fluorinated graphene composite material after post-processing.

Owner:WUHAN UNIV OF TECH

Preparation method of Co3O4/nitrogen doped graphene composite electrode material

InactiveCN105489399AEasy to operateStable structureHybrid capacitor electrodesHybrid/EDL manufactureFiltrationNitrogen doped graphene

The invention provides a preparation method of Co3O4 / nitrogen doped graphene composite electrode material. The preparation method comprises the following steps that step 1. nitrogen doped graphene is prepared; step 2. a soluble alkaline solution is prepared; step 3. polyacrylamide (PAM), heptahydrated cobalt sulfate and nitrogen doped graphene prepared in the step 1 are ultrasonic-dispersed in deionized water so that mixed liquid A is obtained; step 4. the soluble alkaline solution prepared in the step 2 is dropped in the mixed liquid A to react, and pH=8.5-10 is obtained through adjustment so that mixed liquid B is obtained; and step 5. the mixed liquid B is transferred to a microwave reactor to perform heating reaction, and suction filtration, washing and drying are performed on the product after the end of reactor so that the Co3O4 / nitrogen doped graphene composite electrode material is obtained finally. The prepared composite material is stable in structure, and the method has advantages that the method is simple and environment-friendly, the reaction conditions are moderate, reaction is easy to control, cost is low and the technology and the process are simple and convenient.

Owner:JIANGSU UNIV

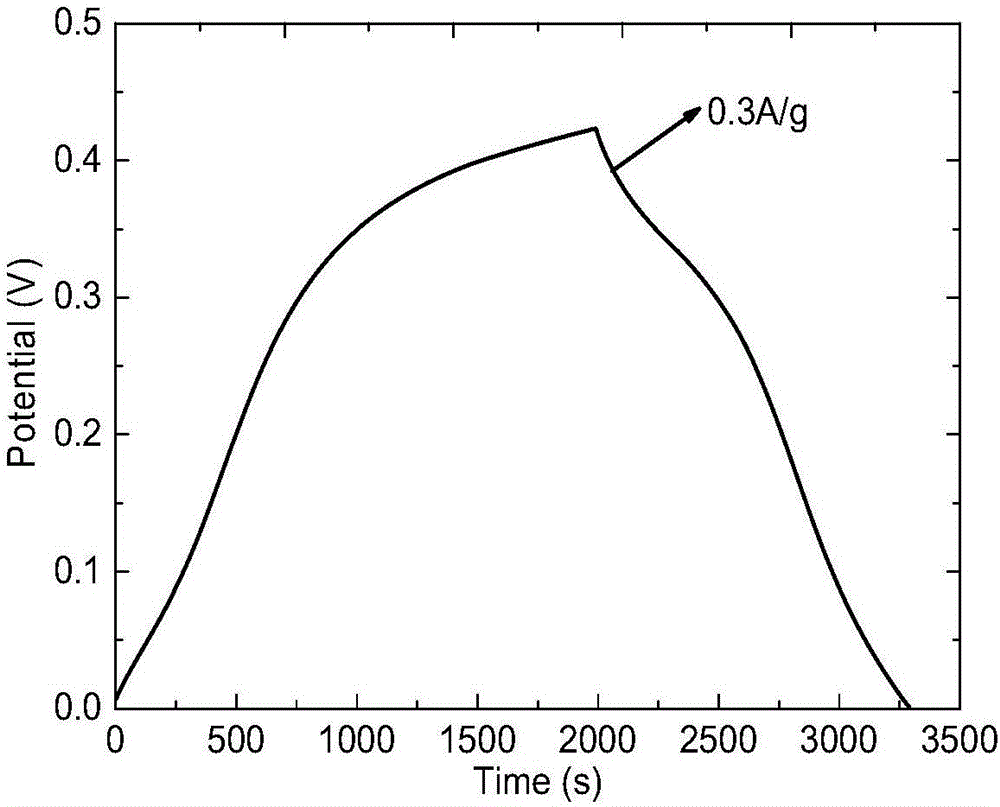

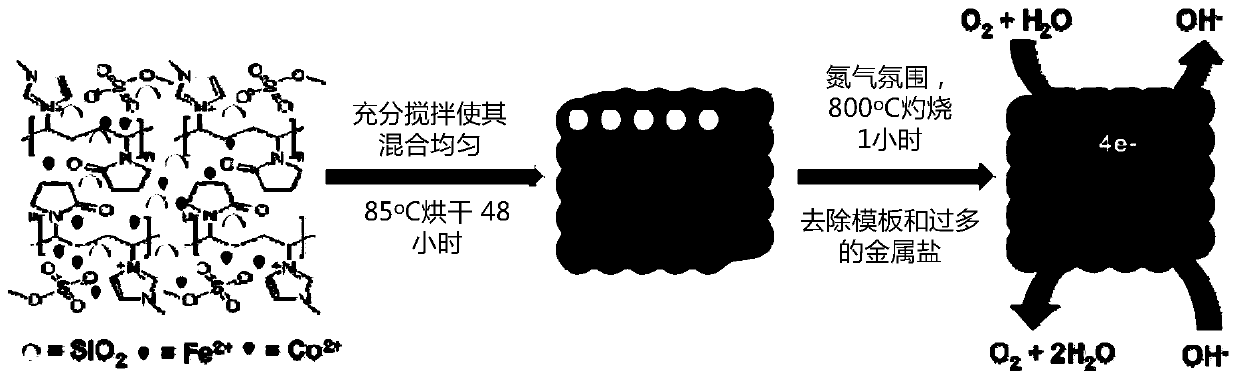

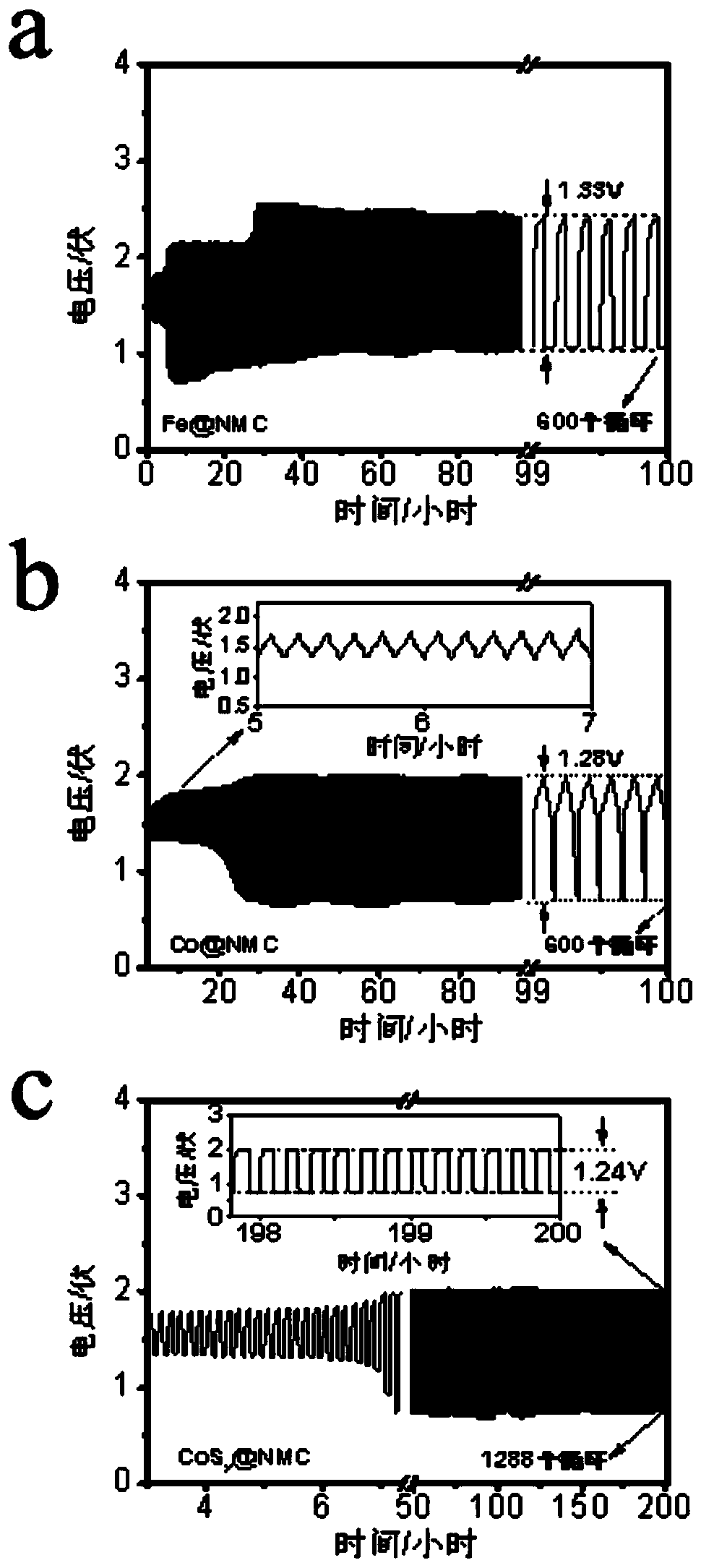

Cobaltous sulfide/ nitrogen-doped mesoporous carbon material, preparation method and application thereof

ActiveCN110504459ARich pore sizeGood repeatabilityMaterial nanotechnologyFuel and secondary cellsCarbonizationMicroparticle

The invention discloses a preparation method for a cobaltous sulfide / nitrogen-doped mesoporous carbon material (CoSx@NMC) with bifunctional activities. The preparation method adopts a one-pot methodto prepare the mesoporous carbon material with oxygen reduction and oxygen evolution reaction in one step, i.e., a high polymer containing nitrogen and sulphur elements is used as an organic precursor, ferrous sulfate and cobalt sulfate are taken as metal precursors, the organic precursor and the metal precursors are evenly mixed under the assistance of solvent, and a mixture is subjected to high-temperature carbonization under an inert atmosphere to obtain CoSx in-situ loaded nitrogen-doped mesoporous carbon material of a 2-5nm size. By use of the method, under a blending function of double metals, on one hand, cobalt aggregation can be effectively inhibited, on the other hand, nitrogen active sites with efficient catalytic oxygen reduction and cobaltous sulfide particles with oxygen evolution activities are synchronously generated on a mesoporous carbon substrate, and the mesoporous carbon material which is finally obtained can be used on a zinc air battery to realize a long-time high-stability charging and discharging cycle.

Owner:DONGHUA UNIV

Milk cow vitamine and mineral matter nutrition licking block and method for preparing the same

The present invention discloses a milch cow vitamin and mineral nutrition licking block, and its preparing method, belonging to animal nutrition field. The milch cow nutrition licking block is composed of the following components: Fe2O3, bluestone, an water sulfate manganese, cobalt sulfate heptahydrate, zinc vitriol, an water carbonate magnesium, calcium iodate, mildselenium natrium, vitamin E microcapsule embedded agent, vitamin A microcapsule embedded agent, vitamin D microcapsule embedded agent, carbamide, common salt, calcium hydrogen phosphate, gooey, bran, portland cement and loess. The formation ratio of the present invention is high, damp-absorbing and dilatability is low, usage is convenient, nutrition is comprehensive. Milch cow breeding examination indicates, by means of feeding the licking block of the present invention, the milch cow milk amount can be increased by above 10 percent, also can improve the body health of the milch cow during lactation period and non-lactation period, reduces the disease of generation paralysis as well as bone metabolism.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

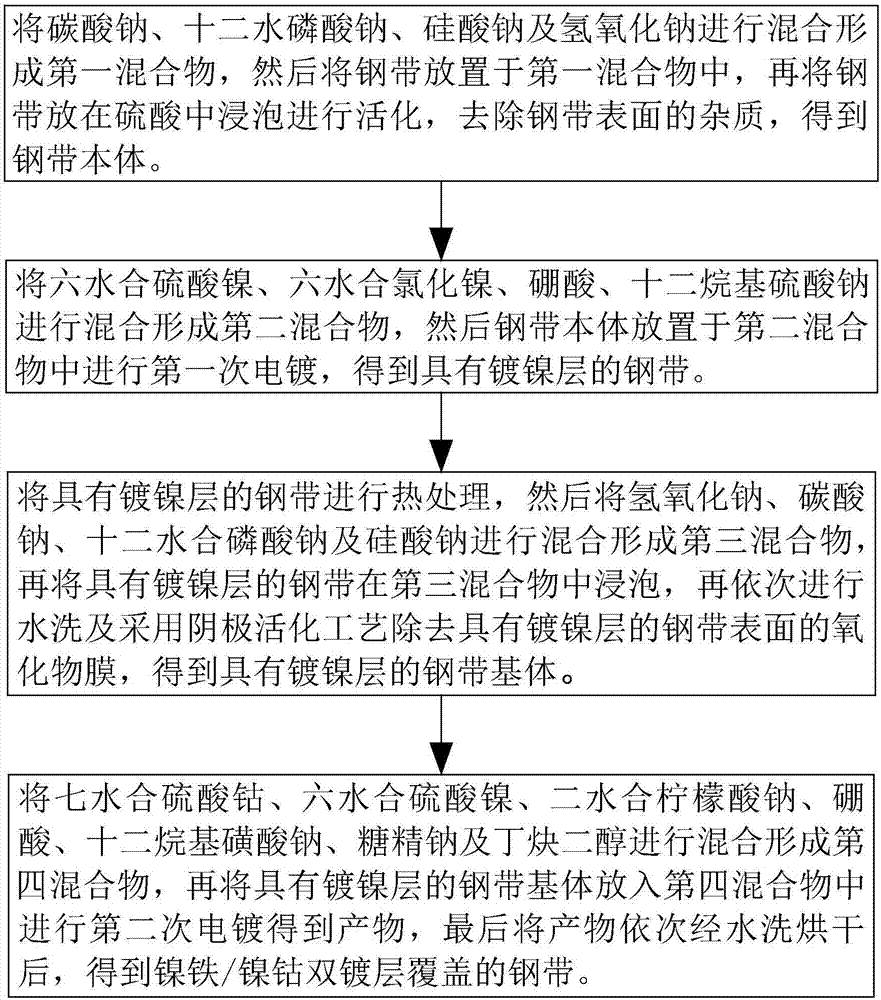

Preparation method of steel strip covered by ferronickel/nickel-cobalt double coatings

A preparation method for a steel strip covered by a nickel-iron / nickel-cobalt double coating, comprising the following steps: Step 1: mixing sodium carbonate, sodium phosphate dodecahydrate, sodium silicate and sodium hydroxide, and placing the steel strip in the first mixture , the steel strip is soaked in sulfuric acid to activate and remove impurities; step 2: nickel sulfate hexahydrate, nickel chloride hexahydrate, boric acid, and sodium lauryl sulfate are mixed, and the steel strip body is placed in the second mixture for the first electroplating; Step 3: heat-treat the steel strip with the nickel-plated layer, mix sodium hydroxide, sodium carbonate, sodium phosphate dodecahydrate and sodium silicate, soak the steel strip with the nickel-plated layer in the third mixture, wash with water and perform cathodic activation process Removing the oxide film of the steel strip with the nickel-plated layer; step 4: mixing cobalt sulfate heptahydrate, nickel sulfate hexahydrate, sodium citrate dihydrate, boric acid, sodium dodecylsulfonate, sodium saccharin and butynediol , the steel strip substrate with the nickel-plated layer is put into the fourth mixture for the second electroplating, and is successively washed and dried.

Owner:SHENZHEN ANDING NEW ENERGY TECH DEV CO LTD

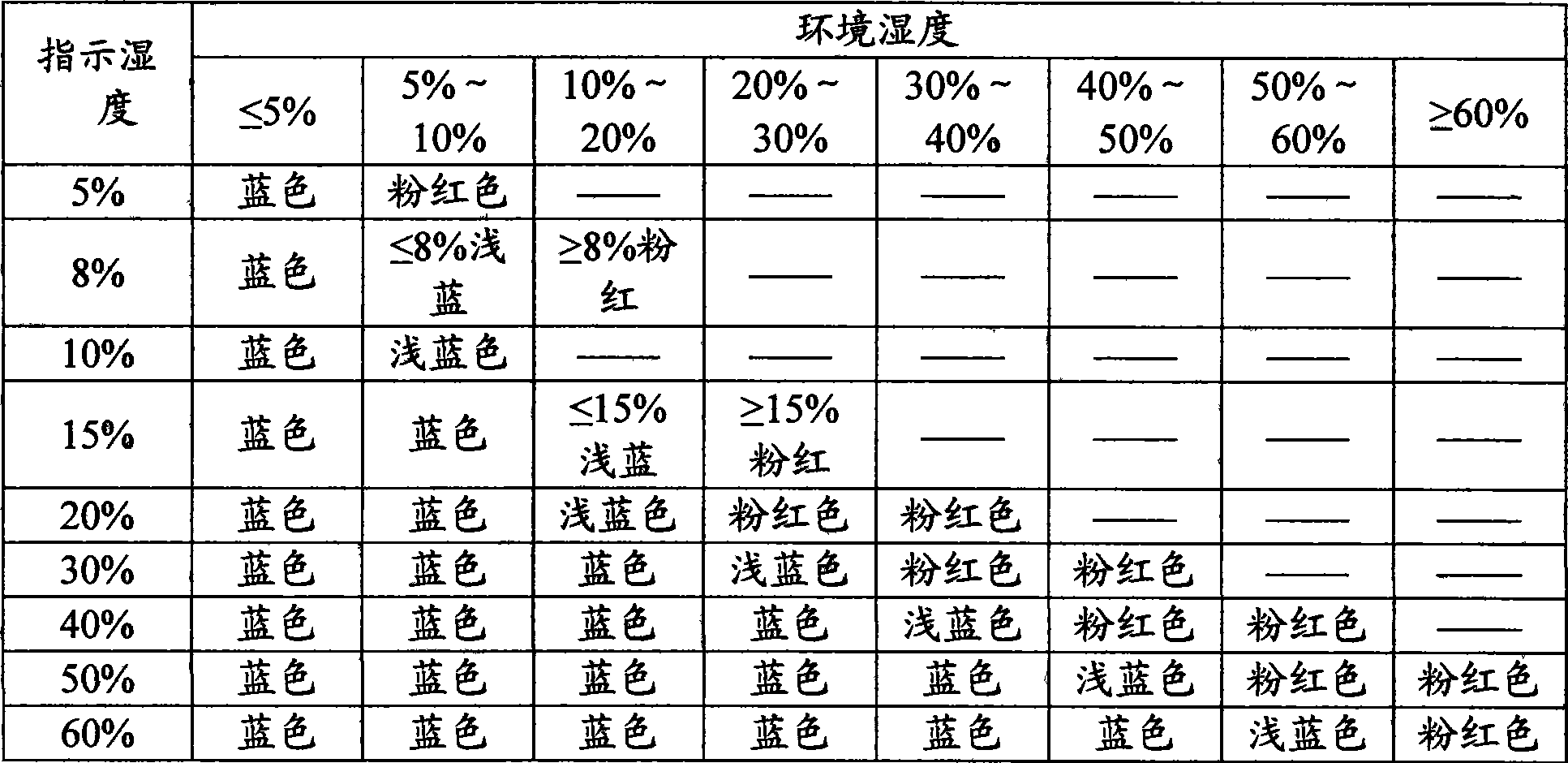

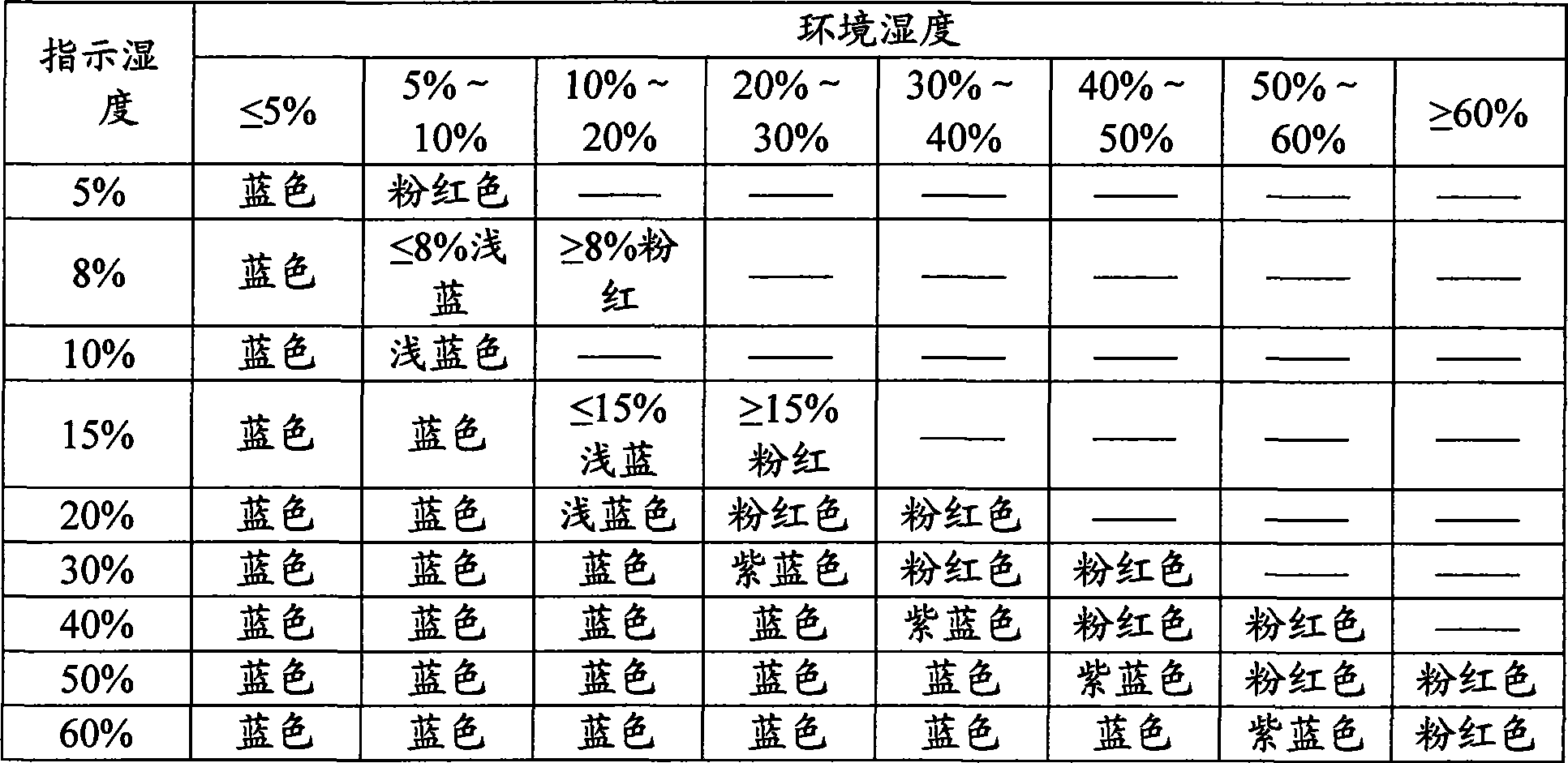

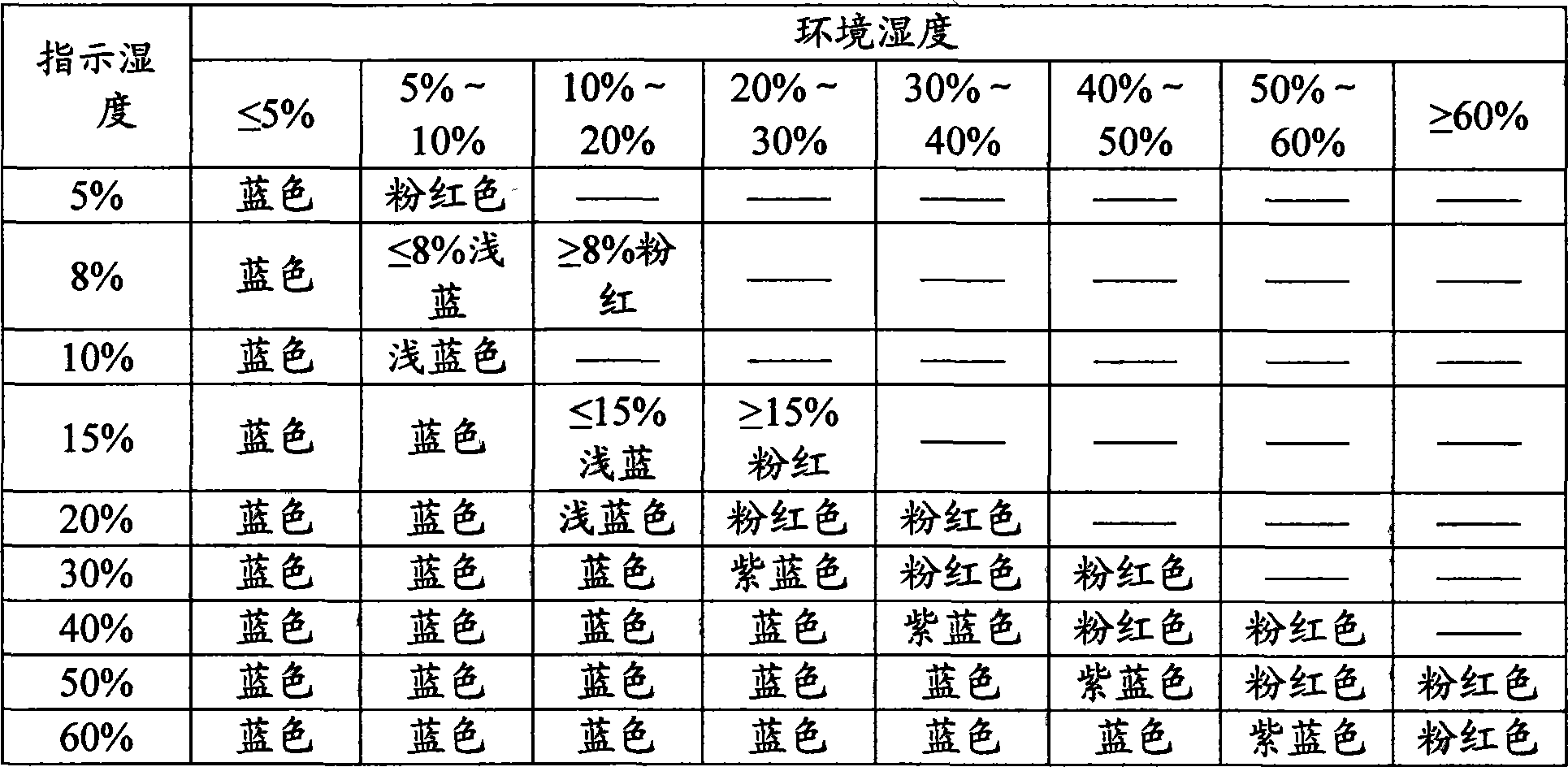

Humidity indicator and preparation method thereof

The invention provides a humidity indicator which comprises carrier and solution dipping the carrier, the solution contains the following components according to the weight percent: 30-97.5 of water, 2-40 of cobalt salt and 0.5-30 of bromine salt, wherein the cobalt salt is cobalt sulfate heptahydrate and / or cabaltous nitrate hexahydrate. The humidity indicator contains no cobalt chloride and copper salt but can show the indication effect of the common humidity indicator, is blue in the drying state and pink in the wet state and has high sensitivity. The invention also provides a preparation method of the humidity indicator.

Owner:JIANGSU SUD CHEM PERFORMANCE PACKAGING MATERIALCO

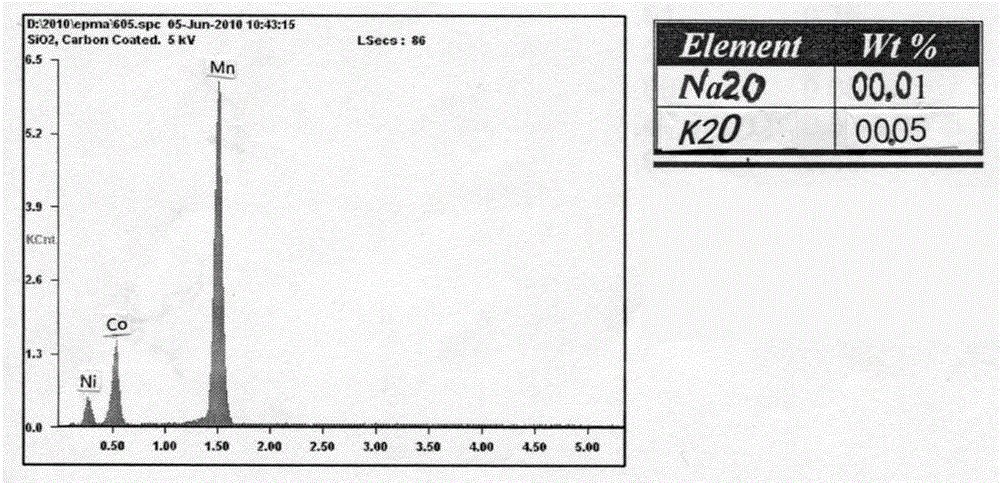

Preparation method for cobalt-manganese-nickel oxides

InactiveCN105140505AEvenly distributed ingredientsImprove uniformityCell electrodesSecondary cellsManganeseNickel sulfate hydrate

The invention discloses a preparation method for cobalt-manganese-nickel oxides. The preparation method comprises steps of separately dissolving industrial products including manganese sulfate monohydrate, cobaltous sulfate heptahydrate and nickel sulfate hexahydrate by hot water, gradually adding a NH4HCO3 solution for performing a neutralization reaction and a precipitation reaction, then continuing to add a KOH solution to react, discharging, filtering, washing by water until SO42-ions disappear, drying, roasting by a high-temperature furnace at the temperature of 820 DEG C for 2-3 hours, ball milling and smashing, stirring and washing by hot water, then filtering, washing, drying and smashing to obtain the cobalt-manganese-nickel oxides. The preparation method is simple, easy to operate, and low in production cost; and the prepared cobalt-manganese-nickel oxides are excellent in product uniformity, stability and electric property, and low in production cost, and can be used for industrial production.

Owner:GUIZHOU ACADEMY OF TESTING & ANALYSIS

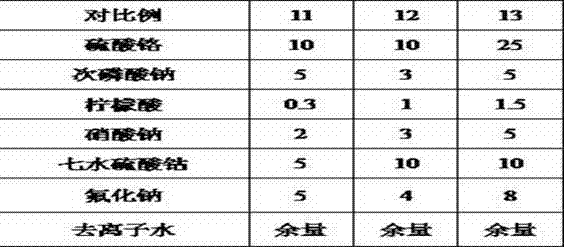

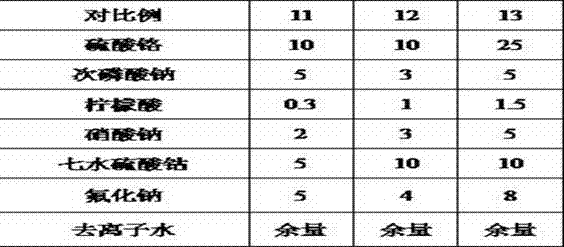

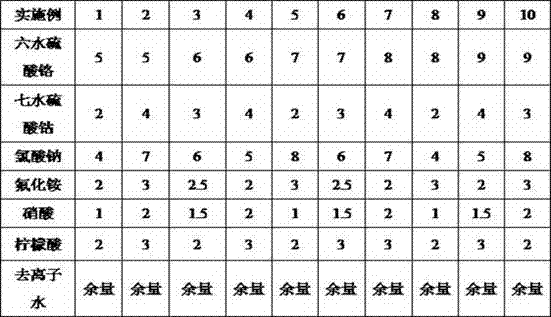

Colorful trivalent chromium passivation liquid, preparation method and use method thereof

ActiveCN104498923AQuality improvementStable passivation working fluidMetallic material coating processesSodium chlorateSalt spray test

The invention provides a colorful trivalent chromium passivation liquid. A plurality of raw materials are dissolved in deionized water to form the passivation liquid. The passivation liquid comprises the following components by a ratio: 5-9 g / L chromium sulfate hexahydrate, 2-4 g / L cobalt sulfate heptahydrate, 4-8 g / L sodium chlorate, 2-3 g / L ammonium fluoride, 1-2 g / L of nitric acid, 2-3 g / L citric acid, and the balance of water. The resulting passive film has good corrosion resistance, the time can be up to 120 hours or more in a salt spray test, the surface has no any white rust or white spots, the porosity is low, and a blocking agent does not need to be used for treating.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Environment-friendly electroplating formula with cobalt-based ternary alloy replacing hard chromium plating and preparation method thereof

The invention discloses an environment-friendly electroplating formula with cobalt-based ternary alloy replacing hard chromium plating and a preparation method thereof. The environment-friendly electroplating formula with the cobalt-based ternary alloy replacing hard chromium plating includes cobaltous sulfate heptahydrate, nickel sulfate hexahydrate, sodium tungstate dihydrate, citric acid monohydrate and sodium lauryl sulfate. By means of the environment-friendly electroplating formula with the cobalt-based ternary alloy replacing hard chromium plating and the preparation method thereof, the problem of environmental pollution caused by hexavalent chromium is solved, and the technical difficulty on the aspects of hardness and bonding force of a plating layer is overcome.

Owner:SHANGHAI YOUXIANG CHEM CO LTD

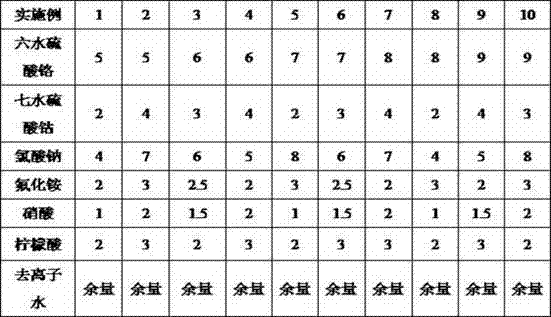

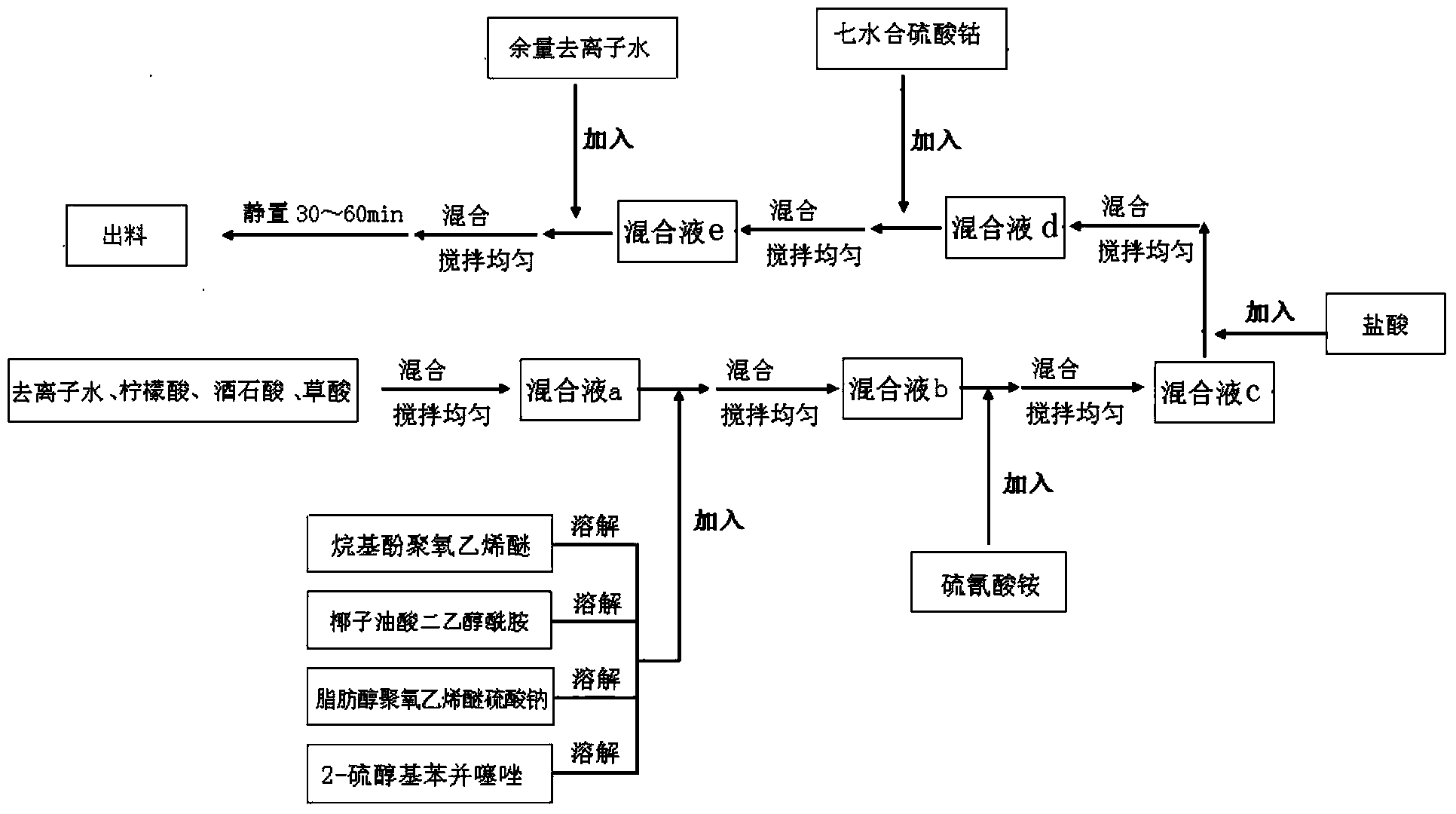

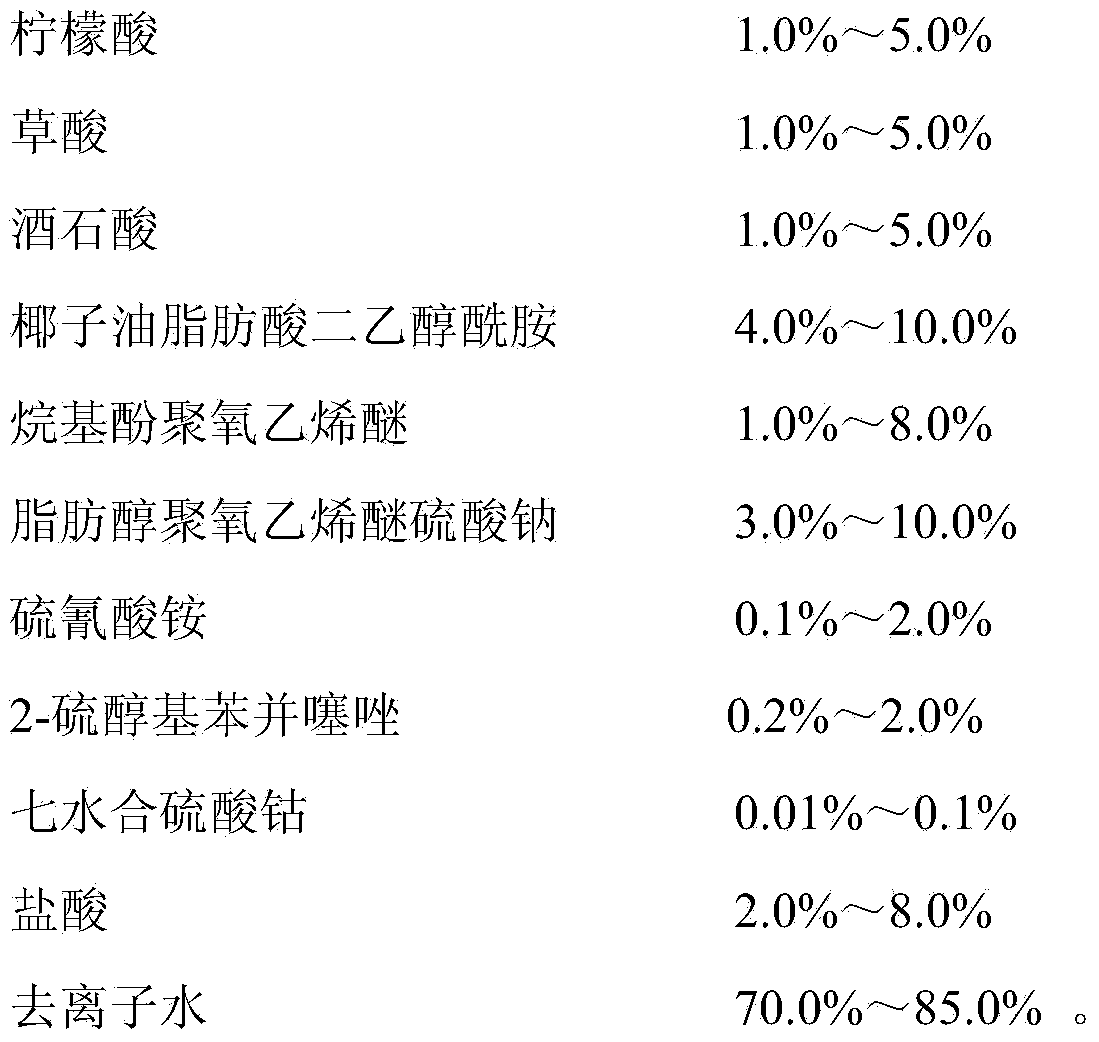

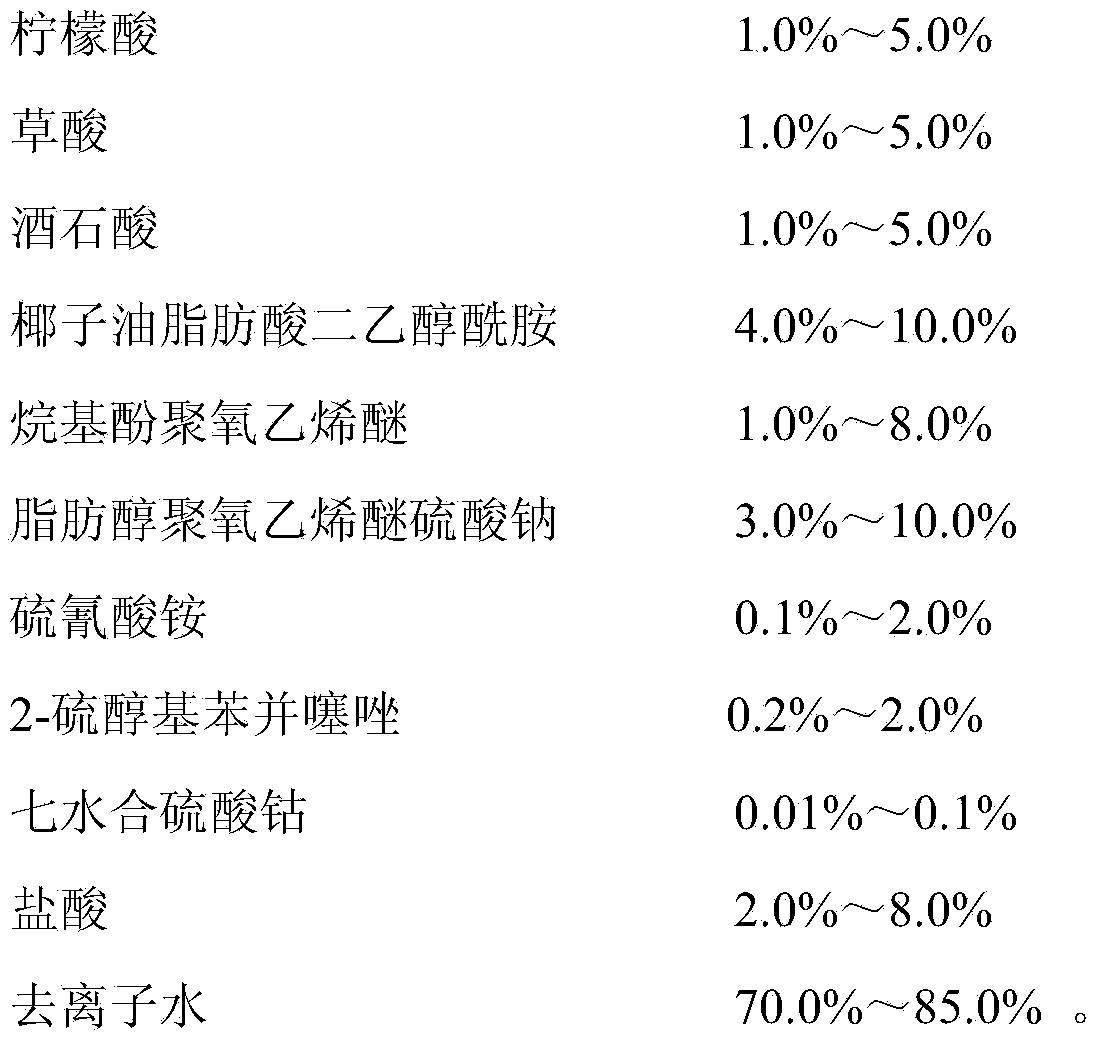

Surface treatment solution for bicycle common carbon steel and preparation method of surface treatment solution

InactiveCN103849869AImprove solubilityPlay a passivation and anti-corrosion effectMetallic material coating processesAlkylphenolCleansing Agents

The invention discloses a surface treatment solution for bicycle common carbon steel and a preparation method of the surface treatment solution, belonging to the technical field of chemical descaling. The treatment solution comprises citric acid, oxalic acid, tartaric acid, coconut fatty acid diethanol amide, alkylphenol polyoxyethylene ether, sodium fatty alcohol ether sulfate, ammonium thiocyanate, 2-thiol benzothiazole, cobaltous sulfate heptahydrate, hydrochloric acid and de-ionized water. The finished treatment solution is obtained by mixing and uniformly stirring the various components. The treatment solution, as a cleaning agent, is good in descaling effect, strong in detergency, convenient to use, environment-friendly, high in biodegradation rate, green and environmental protecting; in addition, the treatment solution is quite low in corrosion rate on equipment.

Owner:江苏省轻工业科学研究设计院有限公司

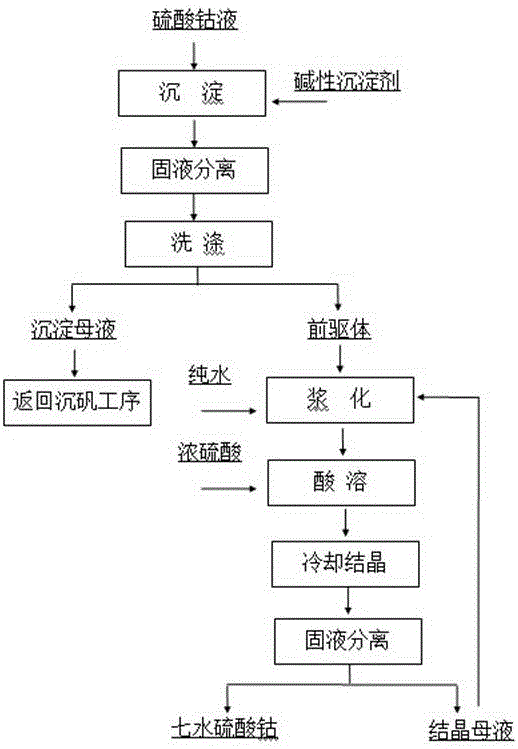

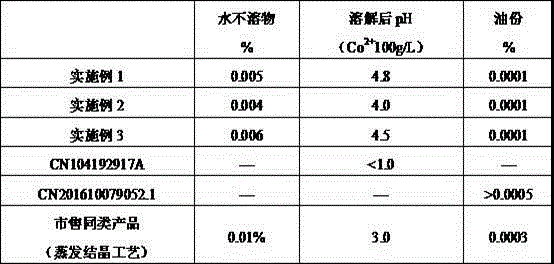

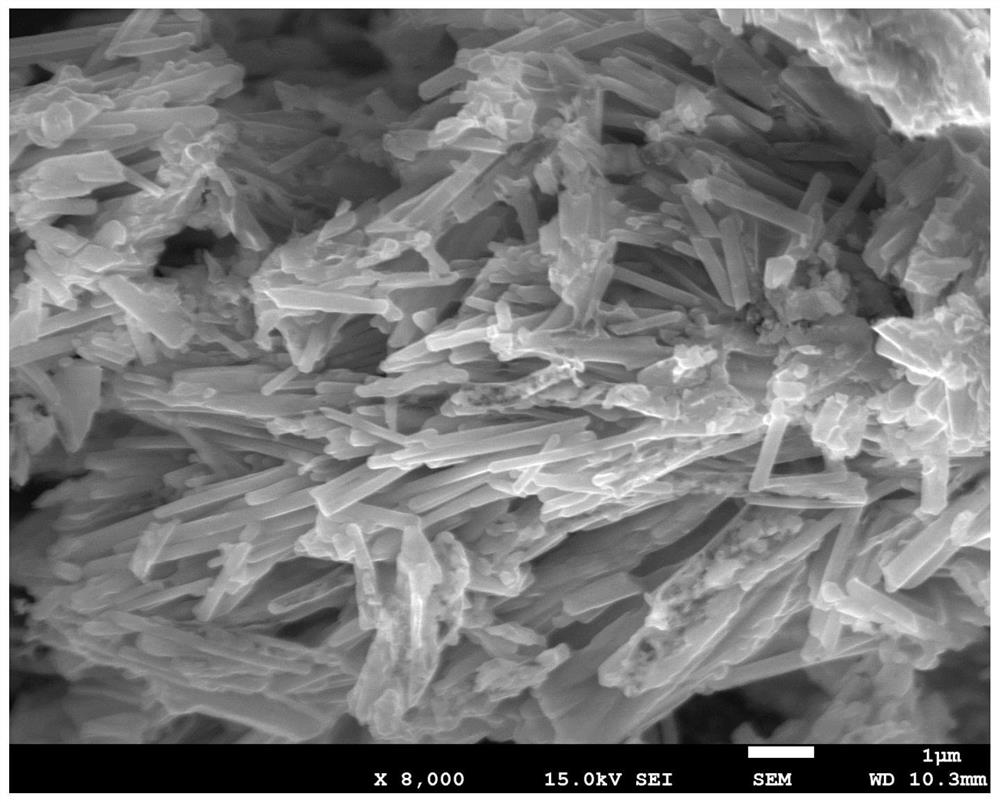

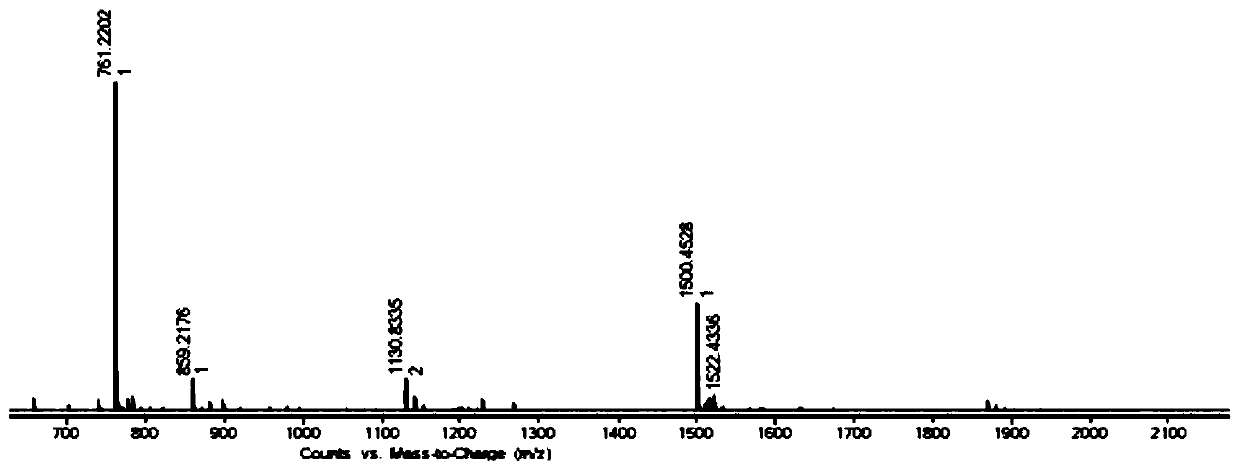

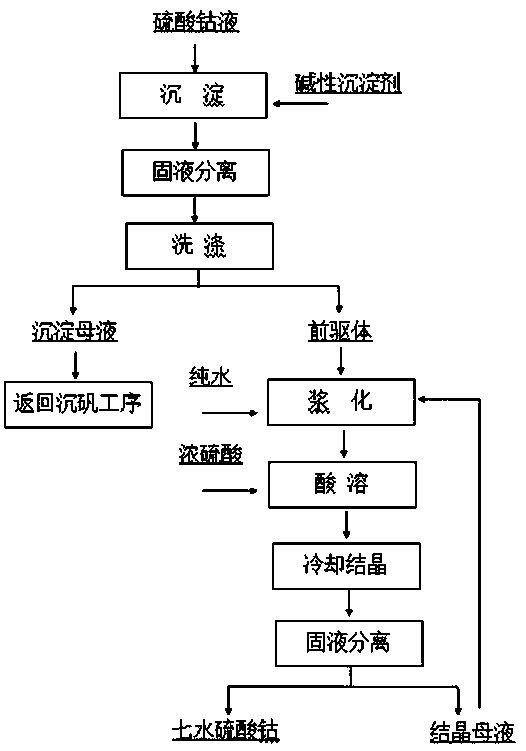

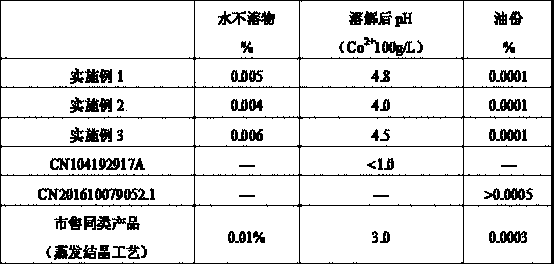

Cobalt sulfate heptahydrate production method

ActiveCN106830104AAvoid consumptionAvoid it happening againCobalt sulfatesWater insolubleAcid dissolution

The invention provides a cobalt sulfate heptahydrate production method. The method includes steps: (1) precursor preparation, to be more specific, adding an alkaline precipitator into pure cobalt sulfate solution, filtering and washing precipitates to obtain cobalt carbonate or cobalt hydroxide precursor, and returning precipitation mother liquor to a vitriol precipitation procedure in cobalt hydrometallurgy; (2) precursor acid dissolution, to be more specific, stirring and pulpifying the precursor with pure water or mother liquor in a dissolving tank, and adding concentrated sulfuric acid for acid dissolution, so that acid solution slurry is heated by reaction heat and dilution heat; (3) acid solution cooling and crystallization, to be more specific, stopping addition of concentrated sulfuric acid after dissolution is completed, cooling and crystallizing in a crystallization tank, cooling to the room temperature, subjecting crystal slurry to solid-liquid separation to obtain a cobalt sulfate heptahydrate product and crystallization mother liquor, and returning the mother liquor to the precursor pulpifying procedure. Steam consumption in evaporation and concentration in an existing cobalt sulfate evaporative crystallization production process is avoided, so that cost is sharply reduced while formation of water insoluble matters in an evaporation process is avoided. In addition, cobalt liquid precipitation and precursor dissolution equipment is simple, and investment cost is low and operations are simple as compared with those of an evaporation procedure.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

A method for efficiently removing nitrate impurities in cobalt sulfate solution

ActiveCN105905951BSuitable for large-scale industrial productionSuitable for industrial productionCobalt sulfatesFiltrationElectronic information

Owner:GUANGDONG GUANGHUA SCI TECH

Antimony cobalt sulfide-carbon composite nanorod and preparation method and application thereof

ActiveCN113735181AHigh structural porosityLarge specific surface areaMaterial nanotechnologyCell electrodesCarbon compositesCarbon coating

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Aquiculture nutrient solution for pakchoi

InactiveCN105732169ANutritional balanceReduce the presence of hazardous substancesFertilizer mixturesNutrient solutionCopper sulfate

The invention relates to an aquiculture nutrient solution for pakchoi, which belongs to the technical field of aquiculture nutrient solutions. The aquiculture nutrient solution comprises calcium nitrate, potassium nitrate, ammonium dihydrogen phosphate, magnesium sulfate, zinc sulfate, copper sulfate, EDTA ferric sodium salt, boric acid, manganese chloride, ammonium molybdate, cobalt sulfate heptahydrate, sodium selenate and sodium fluoride. The aquiculture nutrient solution enables pakchoi to grow in an aquiculture environment; pakchoi growing in the aquiculture nutrient solution environment is cleaner and nutritionally balanced; tap water is treated by using a nanometer titanium dioxide photocatalysis system, so harmful substances in the nutrient solution are greatly reduced; and directed at the nutritional components of pakchoi, a proper amount of trace elements cobalt, fluorine and selenium essential for the human body are added on the basis of a common nutrient solution, so nutritional components of pakchoi are increased. In aquiculture of pakchoi, it only needs to supplement the nutrient solution to pakchoi plants regularly, so operation is simple, convenient, time-saving and labor-saving; and an application method of the aquiculture nutrient solution is simple and easy to promote.

Owner:CHONGQING MAODE AGRI DEV CO LTD

Preparation method and application of cobalt organic macro-cyclic compound

InactiveCN111153937AHigh yieldChemically stableOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsTetrafluoroborateEnamine

The invention belongs to the technical field of supramolecular chemistry, and relates to a preparation method and application of a cobalt organic macro-cyclic compound. The preparation method is characterized in that Co<2+> in a transition metal cobalt salt is used as a node, L is used as a ligand for reaction to prepare the metal organic macro-cyclic compound, and the synthetic route is as follows: Co<2+>+L-> Co-L; wherein the ligand L is selected from DTP; the transition metal cobalt salt is selected from one of cobalt chloride hexahydrate, cobalt nitrate hexahydrate, cobalt sulfate heptahydrate, cobalt tetrafluoroborate hexahydrate or cobalt perchlorate hexahydrate. The prepared cobalt organic macro-cyclic compound is low in raw material price and high in yield. The obtained compound isstable in chemical property, can catalyze an intra-molecular dehydrogenation coupling reaction of N-phenyl enamine, realizes efficient and green dehydrogenation, and has an important realistic meaning.

Owner:DALIAN UNIV OF TECH

Chemical passivation processing method for surface of copper foil

InactiveCN107164748AImprove antioxidant capacityImprove passivation effectLiquid/solution decomposition chemical coatingCopper foilSolvent

The invention discloses a chemical passivation processing method for the surface of a copper foil. A copper foil is fed in a passivation tank where a zinc and cobalt-containing chemical plating solution taking deionized water as a basic solvent is stored for surface chemical replacement processing, and metal deposition is generated on the surface of the copper foil by using redox reaction. The zinc and cobalt-containing chemical plating solution contains 8-20g / L of sodium phosphate, 2-10g / L of glucose, 2-12g / L of zinc oxide and 2-8g / l of cobaltous sulfate heptahydrate. The chemical passivation processing method has the characteristics of capabilities of reducing energy consumption and reducing pollutant emission and better passivation effect.

Owner:江西铜博科技股份有限公司

Method for efficiently removing nitrate radical impurities in cobalt sulfate solution

ActiveCN105905951ASuitable for large-scale industrial productionSuitable for industrial productionCobalt sulfatesFiltrationImpurity

The invention provides a method for efficiently removing nitrate radical impurities in a cobalt sulfate solution. The method comprises the steps of firstly, adjusting the pH value of a crude cobalt sulfate solution to be lower than or equal to 2.5 with dilute sulphuric acid; then adding a formaldehyde solution with the concentration being 40% and the mass of nitrate radicals being 0.4-0.5 time to the cobalt sulfate solution; conducting a reaction at the temperature of 75-85 DEG C; then removing formaldehyde left by the reaction with hydrogen peroxide with the concentration being 30% and the formaldehyde amount being 1.4-1.5 times; then conducting filtration, concentration, cooling and crystallization, so that high-purity cobalt sulfate heptahydrate is obtained. The impurity removal method is easy and convenient to operate, short in production procedure, mild in technological condition and easy to control; no other impurity is generated in the reaction process except a target product, gas and water; the nitrate radical impurities can be effectively removed; the content of the nitrate radical impurities in an obtained cobalt sulfate hexahydrate product can reach 0.02% or below; the method meets the using requirements of such industries as electronic information, batteries, catalysis and analytical tests.

Owner:GUANGDONG GUANGHUA SCI TECH

Preparation method of copper-cobalt-based catalyst for preparing low-carbon alcohols from synthesis gas

ActiveCN110665510AHigh activityStable structureOrganic compound preparationHydroxy compound preparationElectrolytic agentPtru catalyst

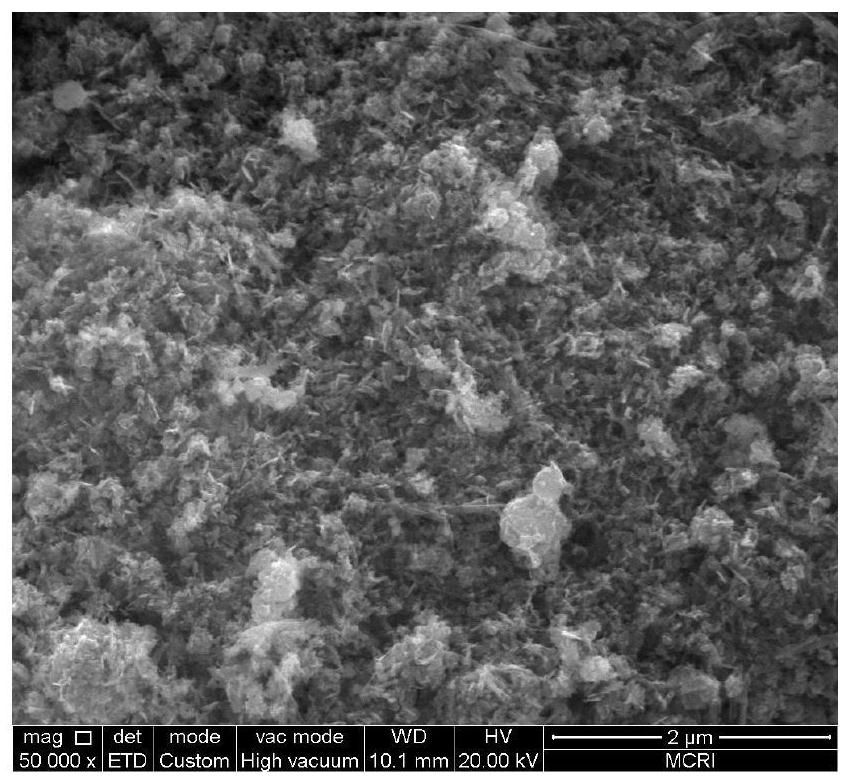

The invention discloses a preparation method of a copper-cobalt-based catalyst for preparing low-carbon alcohols from synthesis gas. The preparation method comprises the following specific steps: step1, treating carbon nanotubes in concentrated nitric acid, coating carbon paper with the treated carbon nanotubes by evaporation, and naturally airing to obtain a cathode electrode material; 2, addinganhydrous cupric sulfate, cobalt sulfate heptahydrate, sodium citrate and sodium sulfate into ionized water, uniformly stirring to obtain a solution a, adjusting the pH value, and putting the solution into a constant-temperature water bath kettle to obtain an electrolyte; 3, putting the cathode electrode material and an anode electrode material into an electrolyte, connecting the cathode electrode material and the anode electrode material by adopting a numerical control constant-current electroplating power supply, and carrying out electrolysis to obtain a copper-cobalt-based catalyst sample;and 4, washing the copper-cobalt-based catalyst sample into a container, drying, roasting, tabletting, grinding and screening to obtain the copper-cobalt-based catalyst. The prepared catalyst is loose and porous in surface, large in specific surface area, highly dispersed in active components and good in catalytic effect.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Passivation solution and preparation method thereof

InactiveCN106756929AQuality improvementStable passivation working fluidMetallic material coating processesPorositySalt spray test

The invention provides a passivation solution which is prepared by dissolving various raw materials in deionized water. The materials comprise 6-9 g / L of chromium sulfate hexahydrate, 2-4 g / L of cobalt sulfate heptahydrate, 4-8 g / L of sodium chlorate, 2-3 g / L of ammonium fluoride, 1-2 g / L of sulfuric acid, 2-3 g / L of citric acid and the balance water. According to an obtained passivation film, the corrosion resisting property is good, a salt spray test can be kept for 120 h or longer, the workpiece surface has no white rust or white spot, the porosity is low, and no sealing agent is needed for treatment.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

A kind of nickel-cobalt sulfate continuous crystallization process

ActiveCN104192917BImprove energy savingRealize continuous productionNickel sulfatesGranularitySulfate

The invention discloses a nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process which comprises the following steps: firstly carrying out MVR evaporation concentration on a high-purity solution produced through an extraction procedure to 30%-39%, and secondly continuously cooling and crystallizing through an improved cooling type internal-circulating continuous crystallizer; continuously discharging crystal slurry from the bottom of the crystallizer for centrifugal solid-liquid separation; and continuously drying a crystal product at low temperature to produce product crystals with large granularity and uniform size distribution, and recovering a mother solution to an evaporation process. Compared with the traditional periodic crystallization process, the nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process disclosed by the invention has the advantages of low evaporation energy consumption, fewer crystallization control process parameters, stability in operation, high automation degree, high production efficiency and the like and is easy to control, and operators are reduced.

Owner:ZHEJIANG HUAYOU COBALT

A kind of preparation method of porous cobalt phosphide nanowire catalyst

InactiveCN107245727BImprove electrochemical activityImprove electrochemical stabilityNanotechnologyElectrode shape/formsNanowireFiltration

The invention discloses a preparation method of a porous cobalt phosphide nanowire catalyst. The method comprises the following steps: using urea as a precipitating agent, cobalt sulfate heptahydrate as a cobalt source, and glycerol and deionized water as solvents to prepare a solution. The solution is added into a high-pressure reaction kettle for hydrothermal reaction, and after sufficient reaction, suction filtration, washing, and vacuum drying are performed to obtain linear basic cobalt carbonate. In a tube furnace, the linear basic cobalt carbonate is air-fired at a certain temperature to obtain tricobalt tetroxide. Using sodium hypophosphite as the phosphorus source, the precursor of tricobalt tetroxide and sodium hypophosphite are placed on both ends of the same porcelain boat in a certain proportion, the phosphorus source is placed in the upstream of the air flow, and placed in a tube furnace under an inert atmosphere for low-temperature calcination to achieve Preparation of Porous Cobalt Phosphide Nanowire Catalysts. The invention has the advantages of simple production process, low cost, can effectively improve the electrochemical activity and stability of the catalyst, and has wide application.

Owner:NANCHANG HANGKONG UNIVERSITY

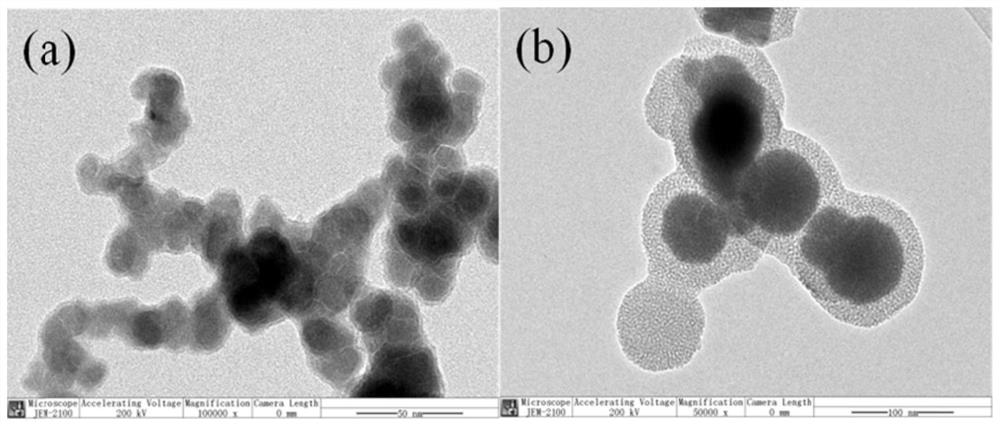

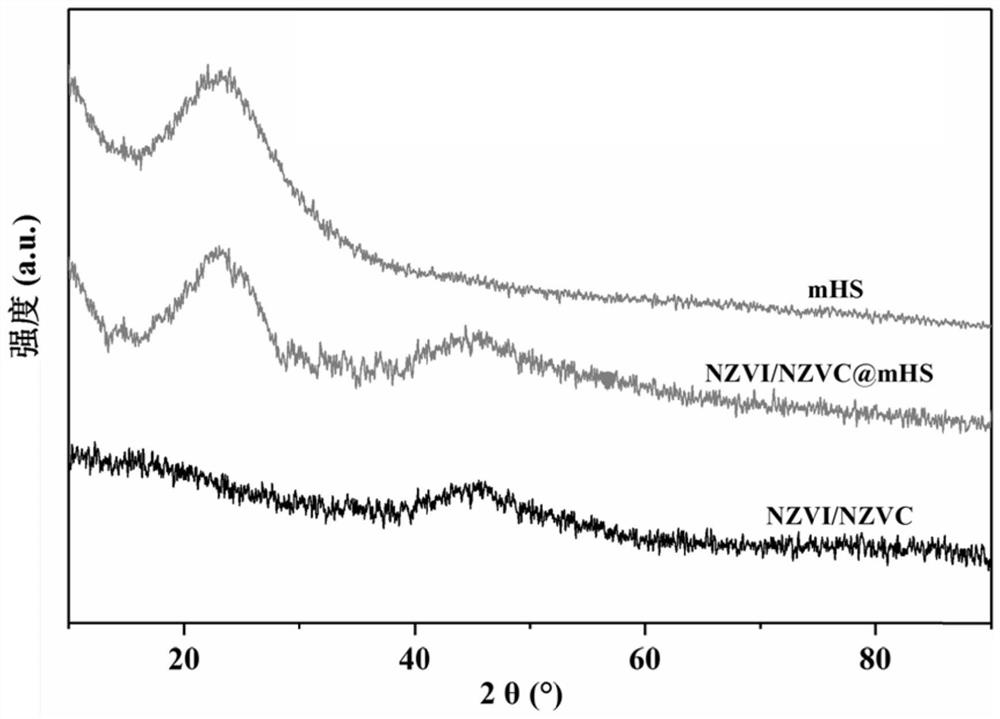

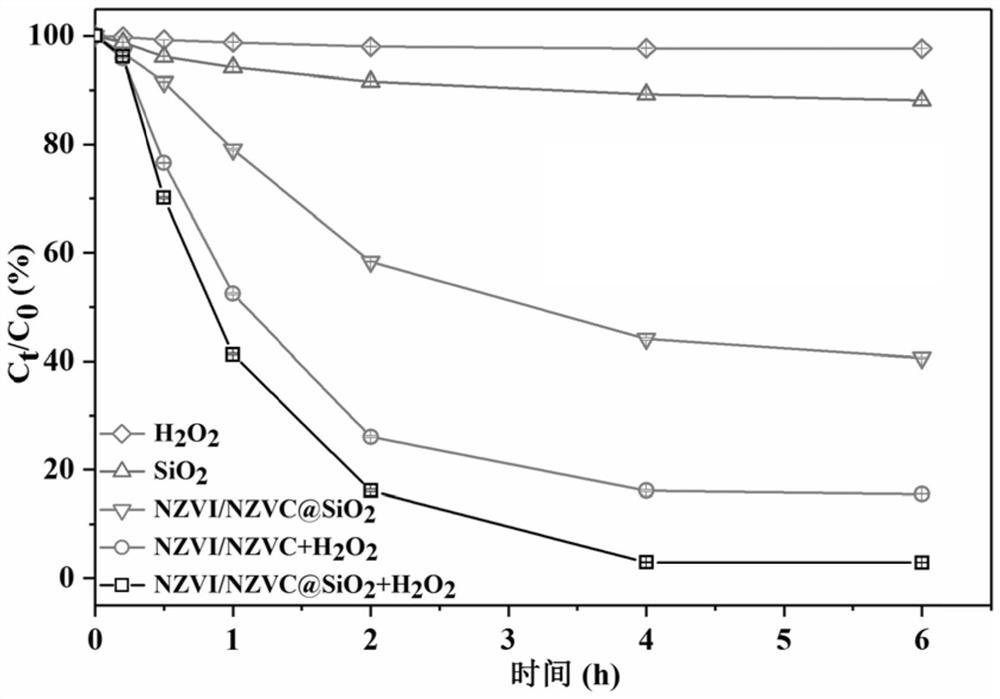

Hydrated mesoporous silica coated nano iron-cobalt bimetallic composite material and application thereof

InactiveCN112473672AThe molar ratio of iron to cobalt can be adjustedSimple preparation processWater treatment compoundsWater contaminantsIron sulfateHydration reaction

The invention discloses a preparation method of a hydrated mesoporous silica coated nano iron-cobalt bimetallic composite material. The preparation method comprises the following steps: 1, adding 0.496 g of ferric sulfate heptahydrate and 0.502 g of cobalt sulfate heptahydrate into a mixed solution of ethanol and water, and mechanically stirring until solid particles are dissolved; 2, dropwise adding a NaBH4 solution into the mixed solution at a speed of 1.5 ml / min, and continuously stirring for 30 minutes to obtain a nano zero-valent iron-cobalt bimetallic suspension; 3, continuing to add ammonia water and hexadecyl trimethyl ammonium bromide into the suspension, continuously stirring for 30 minutes, adding 1ml of tetraethyl orthosilicate, and stirring for 4 hours at a low speed (300rpm);and 4, separating a solid from a liquid by using a magnet, sequentially washing with deionized water and absolute ethyl alcohol for three times respectively, and finally drying in a drying oven for 12 hours, and obtaining a final product, namely the hydrated mesoporous silica coated nano iron-cobalt bimetallic composite material. Through the action of the hydrated mesoporous silica coated nano iron-cobalt bimetal, the problems that the nano iron-cobalt bimetal is easy to agglomerate and inactivate and Co ions are easy to leach are solved, and the dispersity and reactivity of the nano iron-cobalt bimetal are improved. The hydrated mesoporous silica coated nano iron-cobalt bimetallic composite material obtained by the method and hydrogen peroxide form a Fenton-like system which is used forremoving tetrabromobisphenol A in underground water. The method has a very strong remediation effect on the soil and underground water of the tetrabromobisphenol A contaminated site.

Owner:SHANGHAI UNIV

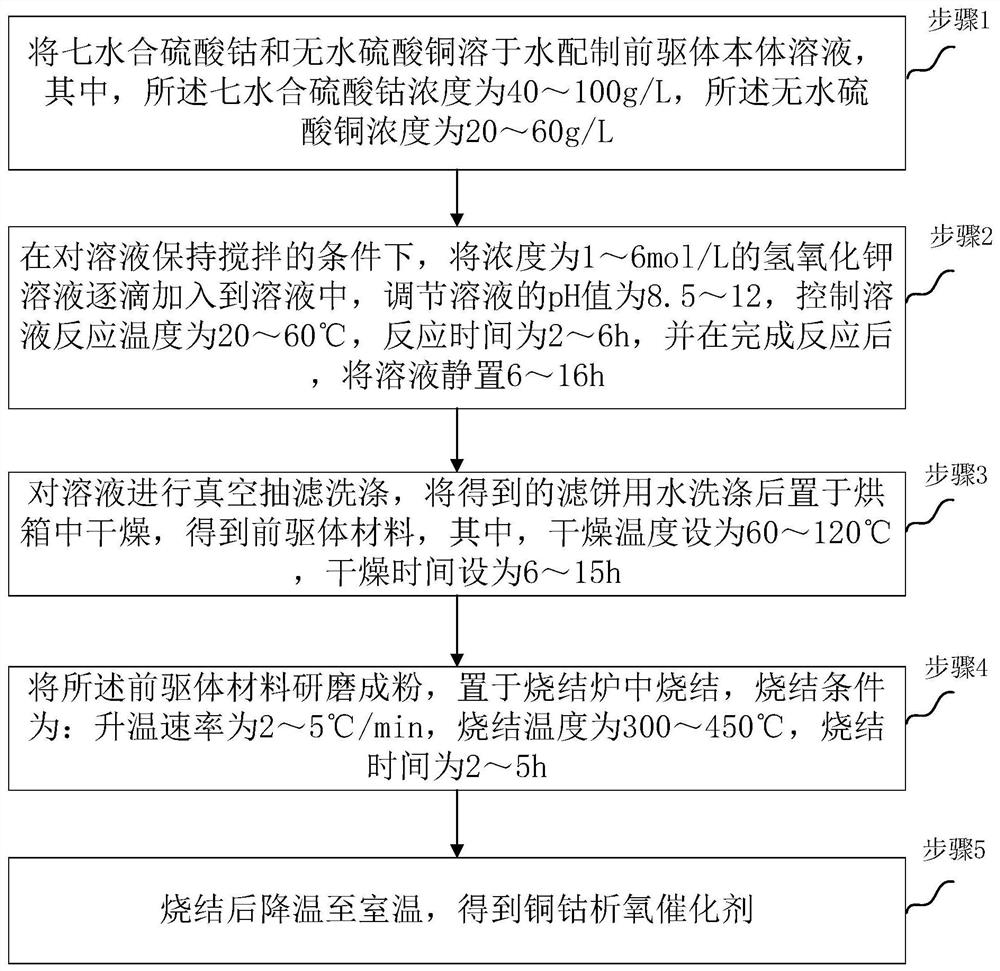

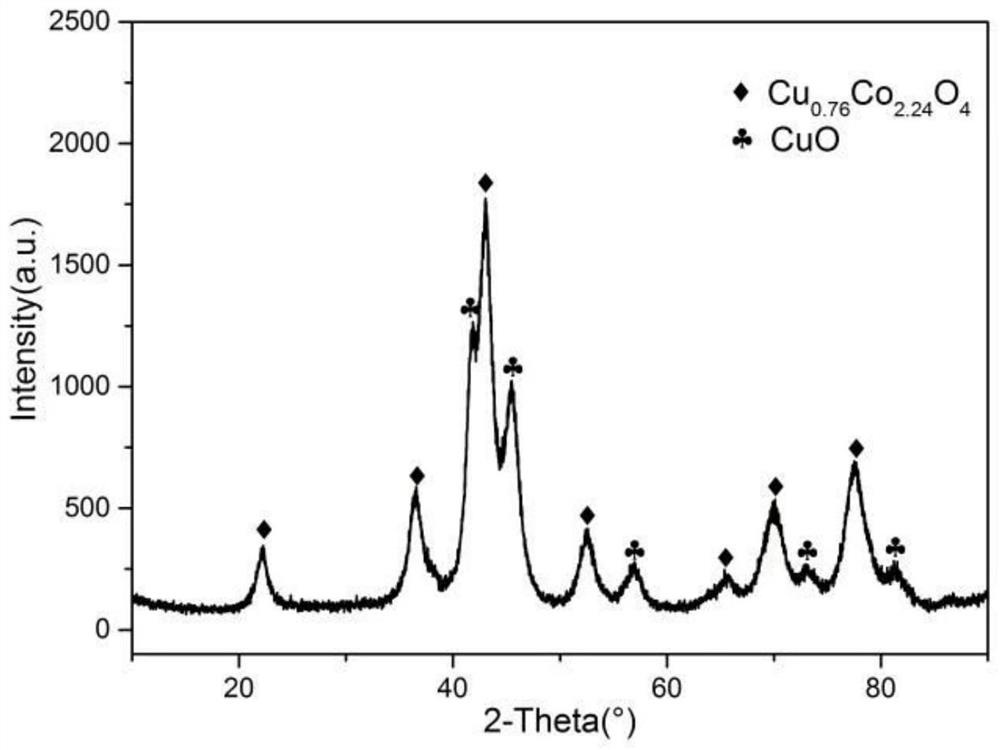

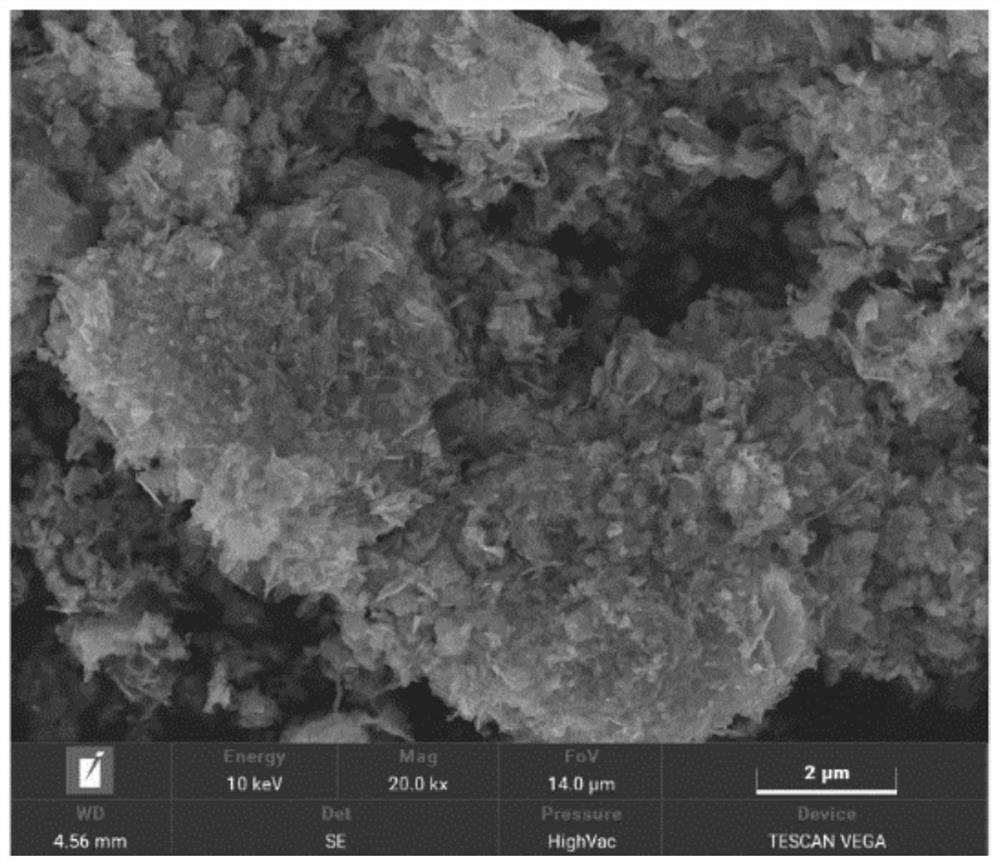

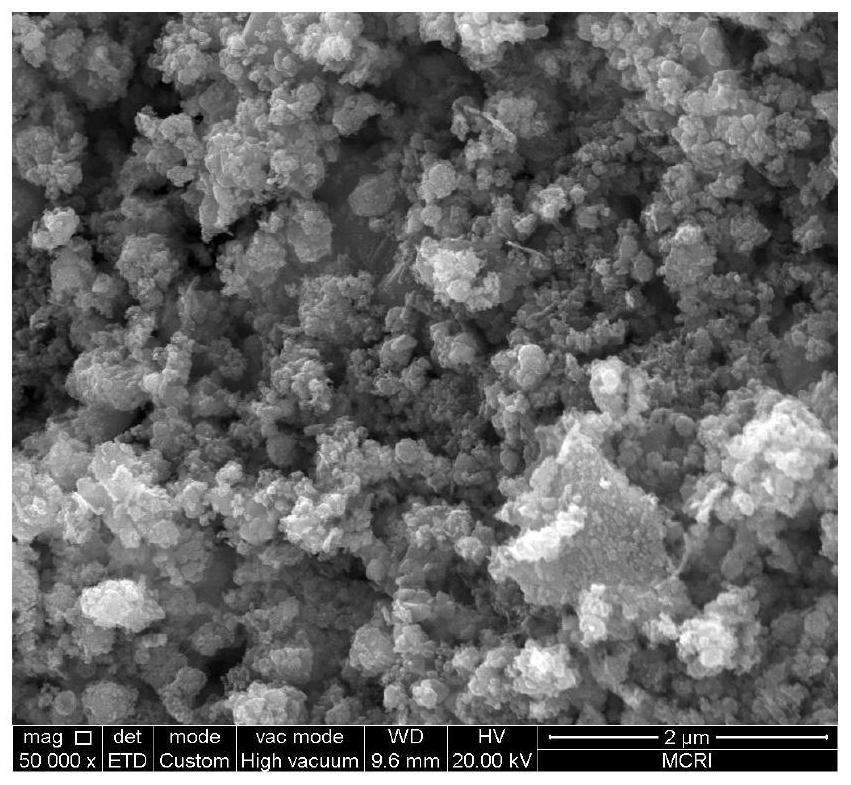

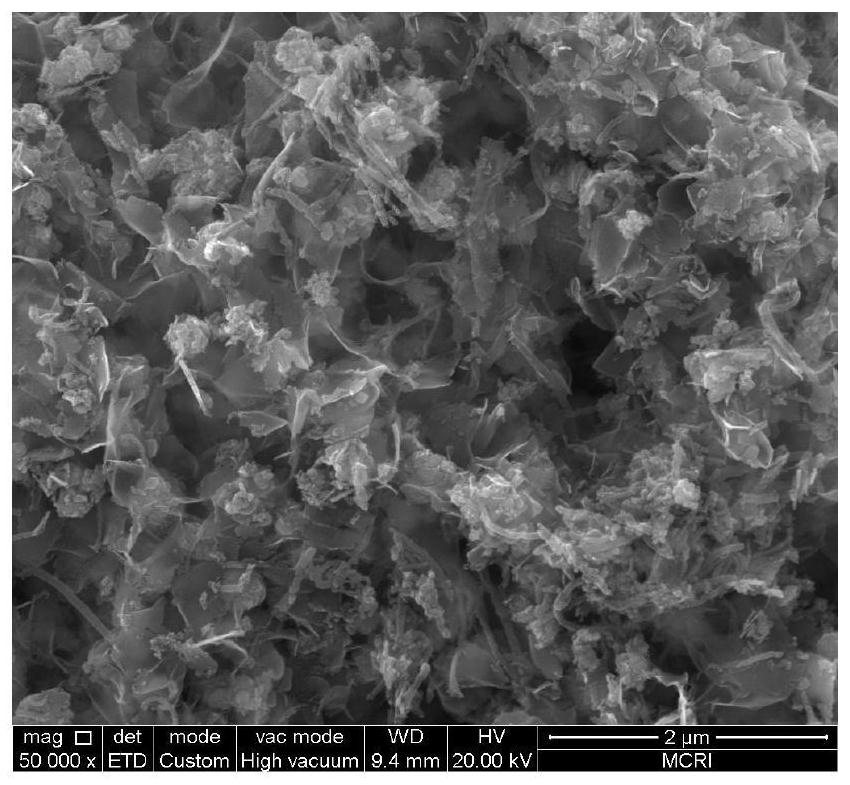

Preparation method of copper-cobalt oxygen evolution catalyst

The embodiment of the invention discloses a preparation method of a copper-cobalt oxygen evolution catalyst. The preparation method comprises the steps of: dissolving cobalt sulfate heptahydrate with the concentration of 40-100g / L and anhydrous cupric sulfate with the concentration of 20-60g / L into water to prepare a precursor body solution; dropwise adding a potassium hydroxide solution with the concentration of 1-6 mol / L into the solution while stirring the solution, adjusting the pH value of the solution to 8.5-12, controlling the reaction temperature of the solution to be 20-60 DEG C and the reaction time to be 2-6 hours, and standing the solution for 6-16 hours after the reaction is completed; vacuum-filtering and washing the solution, washing the obtained filter cake with water, and drying the filter cake in a drying oven with the drying temperature set to be 60-120 DEG C and the drying time set to be 6-15 hours to obtain a precursor material; grinding the precursor material into powder, and sintering the powder in a sintering furnace under the sintering conditions that the heating rate is 2-5 DEG C / min, the sintering temperature is 300-450 DEG C and the sintering time is 2-5 hours; and after sintering, cooling to room temperature to obtain the copper-cobalt oxygen evolution catalyst with high activity, high stability and low cost.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

Micro relay contacts, reed gold plating process

The invention discloses a gold-plating process method for contacts and reeds of miniature relays. The materials and the composition thereof are: gold trichloride of 6-14g / L in terms of gold content; anhydrous sodium nitrite 100-200g / L ; Potassium citrate 30-100g / L; Potassium chloride 30-90g / L; EDTA 5-15g / L; Cobalt sulfate heptahydrate 0.5-5g / L; The electroplating of silver nitrate 0.01-0.3g / L Put the electroplating workpiece into the solution for electroplating. Compared with the prior art, in terms of structural features of the present invention, the density is higher than that of the original cyanide gold-plated cobalt alloy gold plating, the purity of the gold coating reaches 99.99%, and the hardness is (110-120) HV, which is higher than the original cyanide gold-plated cobalt alloy gold plating The hardness of the gold layer (85-100) HV is high, which is lower than that of the original cyanide gold-plated nickel alloy (180-220) HV; in terms of technical improvement, the stability of the electrolyte and the dispersion ability are greatly improved, and the compactness of the coating layer is improved; quality; In terms of improvement, the contact resistance failure rate of its products decreased by 95%, the bonding failure rate decreased by 70%, and the consistency of coating quality increased by 80%.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

A kind of preparation method of the copper-cobalt base catalyst that is used for synthesis gas to make low-carbon alcohol

ActiveCN110665510BHigh activityStable structureOrganic compound preparationHydroxy compound preparationElectrolytic agentPtru catalyst

The invention discloses a preparation method of a copper-cobalt-based catalyst for producing low-carbon alcohols from syngas, specifically implemented according to the following steps: step 1, placing carbon nanotubes in concentrated nitric acid for treatment, and then vapor-coating them on carbon paper, Dry naturally to obtain the cathode electrode material; step 2, add anhydrous copper sulfate, cobalt sulfate heptahydrate, sodium citrate and sodium sulfate in the ionized water, stir evenly to obtain solution a, then adjust the pH value, adjust the rear In a constant temperature water bath, the electrolyte is obtained; step 3, the cathode electrode material and the anode electrode material are placed in the electrolyte, connected with a numerical control constant current electroplating power supply, and electrolyzed to obtain a copper-cobalt-based catalyst sample; step 4, The copper-cobalt-based catalyst sample is rinsed into a container, dried, roasted, pressed into tablets, ground and sieved to obtain the copper-cobalt-based catalyst. The surface of the catalyst prepared by the invention is loose and porous, the specific surface area is large, the active components are highly dispersed, and the catalytic effect is good.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Blue-white passivation solution with high corrosion resistance and application method of blue-white passivation solution

InactiveCN108239770AGuaranteed stabilityThe method of use is safe and controllableMetallic material coating processesPhosphoric acidCitrinin hydrate

The invention discloses a blue-white passivation solution with high corrosion resistance. The blue-white passivation solution comprises, by weight, 3-7 parts of chalybeate, 11-15 parts of phosphoric acid, 7-11 parts of citric acid monohydrate, 10-14 parts of zinc citrate dehydrate, 3-7 parts of cobalt sulfate heptahydrate, 0.1-1 part of a surface active agent and 35-55 parts of water. Through theformula of the blue-white passivation solution, parameters such as the passivation concentration, the PH value and time are controlled, a passivation film stable in performance and excellent in corrosion resistance can be obtained, the ROHS standard is completely met, and during galvanization surface neutral salt spray resisting testing, the time for white rust is 96 h, and the time for red rust is 240 h or above.

Owner:ZHEJIANG KANGSHENG CO LTD

A kind of method of producing cobalt sulfate heptahydrate

ActiveCN106830104BAvoid consumptionAvoid it happening againCobalt sulfatesWater insolubleAcid dissolution

The invention provides a cobalt sulfate heptahydrate production method. The method includes steps: (1) precursor preparation, to be more specific, adding an alkaline precipitator into pure cobalt sulfate solution, filtering and washing precipitates to obtain cobalt carbonate or cobalt hydroxide precursor, and returning precipitation mother liquor to a vitriol precipitation procedure in cobalt hydrometallurgy; (2) precursor acid dissolution, to be more specific, stirring and pulpifying the precursor with pure water or mother liquor in a dissolving tank, and adding concentrated sulfuric acid for acid dissolution, so that acid solution slurry is heated by reaction heat and dilution heat; (3) acid solution cooling and crystallization, to be more specific, stopping addition of concentrated sulfuric acid after dissolution is completed, cooling and crystallizing in a crystallization tank, cooling to the room temperature, subjecting crystal slurry to solid-liquid separation to obtain a cobalt sulfate heptahydrate product and crystallization mother liquor, and returning the mother liquor to the precursor pulpifying procedure. Steam consumption in evaporation and concentration in an existing cobalt sulfate evaporative crystallization production process is avoided, so that cost is sharply reduced while formation of water insoluble matters in an evaporation process is avoided. In addition, cobalt liquid precipitation and precursor dissolution equipment is simple, and investment cost is low and operations are simple as compared with those of an evaporation procedure.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

Trivalent chromium color passivation solution, preparation method and use method thereof

ActiveCN104498923BQuality improvementStable passivation working fluidMetallic material coating processesPorositySalt spray test

The invention provides a colorful trivalent chromium passivation liquid. A plurality of raw materials are dissolved in deionized water to form the passivation liquid. The passivation liquid comprises the following components by a ratio: 5-9 g / L chromium sulfate hexahydrate, 2-4 g / L cobalt sulfate heptahydrate, 4-8 g / L sodium chlorate, 2-3 g / L ammonium fluoride, 1-2 g / L of nitric acid, 2-3 g / L citric acid, and the balance of water. The resulting passive film has good corrosion resistance, the time can be up to 120 hours or more in a salt spray test, the surface has no any white rust or white spots, the porosity is low, and a blocking agent does not need to be used for treating.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com